Professional Documents

Culture Documents

Specifications of Carbon Dioxide Gas

Uploaded by

gnkameshOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Specifications of Carbon Dioxide Gas

Uploaded by

gnkameshCopyright:

Available Formats

NUCLEAR POWER CORPORATION OF INDIA LIMITED

(A Government of India Enterprise)

TECHNICAL SPECIFICATION ON CARBON DIOXIDE AND Page No. 1 of 9

OXYGEN GAS CYLINDERS FOR ANNULUS GAS SYSTEM Revision No. 2

SPECIFICATION : PC-E-654 / Rev. 2

1.0 SCOPE

This Specification covers supply, inspection and testing of Carbon dioxide (CO2) and

Oxygen (O2) gas for Indian PHWRs.

2.0 CONTENTS

The requirements of this specification are presented under the following sections:-

Content Section

Scope 1.0

Contents 2.0

Applicable Specifications 3.0

General Function and Description 4.0

Requirements 5.0

Composition for Gases 6.0

Inspection & Testing 7.0

Shipment 8.0

History Docket Requirement 9.0

Data to be furnished by Bidder Annexure-1

Sample QAP Annexure-2

3.0 APPLICABLE SPECIFICATIONS

ISBT - International Society of Beverage Technologists.

IS -307 - Specification for Carbon-dioxide. (For cylinder sampling

size)

IS -3224 - Valve fittings for compressed gas cylinders excluding

L.P.G. cylinders.

IS -5844 Recommendations for Hydrostatic Stretch Testing of

Compressed Gas Cylinders

IS -7285 - Specification for Seamless Steel Cylinders for Permanent

and High Pressure Liquefiable Gases.

IS –8198 - Code of practice for steel cylinders for compressed gases

(Part –3) (high pressure liquefiable gases).

4.0 GENERAL FUNCTION AND DESCRIPTION

34000 / PC-E-654 August, 2017

NUCLEAR POWER CORPORATION OF INDIA LIMITED

(A Government of India Enterprise)

TECHNICAL SPECIFICATION ON CARBON DIOXIDE AND Page No. 2 of 9

OXYGEN GAS CYLINDERS FOR ANNULUS GAS SYSTEM Revision No. 2

The CO2 and O2 gas cylinders are used in Annulus Gas System for make-up in closed

loop and for supply of the gases in purge mode operation of the system.

5.0 REQUIREMENTS

Supplier shall have following technical prequalification criteria:

(a) Supplier shall have its own purification plant for CO2 meeting minimum food

grade standard as per ISBT.

(b) Raw CO2 gas source for gas purification plant shall not be from Ethylene oxide

plants.

(c) Supplier shall have online gas testing facility / laboratory along with valid

calibration report/certificate for their instruments to meet requirements of Table-2.

(d) Supplier shall have facility for cylinder cleaning and conditioning.

6.0 COMPOSITION FOR GASES

The Carbon dioxide (CO2) and Oxygen (O2) gases are to be supplied in cylinders

provided by NPCIL. The cylinder capacity of the CO2 is about 30 kg and Oxygen

cylinder capacity is about 7 m3. The cylinder pressure for Carbon dioxide (CO2) gas

should be about 70 kgf/cm2 and 140 kgf/cm2 for Oxygen gas. The required quality of

CO2 and O2 is specified in Table-1(a) and Table-1(b). The verification of these

components shall be as per clause no. 7.0 of this report.

Table: 1 (a): Requirements for CO2 gas

S. Parameter Limits*

No.

1. Purity 99.9 % v/v min

2. Moisture 20 ppm v/v max.

3. Oxygen (O2) 200 ppm v/v max.

4. Carbon Monoxide 10 ppm v/v max.

5. Hydrogen(H2) 10 ppm v/v max.

6. Argon 5 ppm v/v max.

7. Nitrogen (N2) 120 ppm v/v max.

8. Ammonia 2.5 ppm v/v max.

9. Nitric Oxide & Nitrogen 2.5 ppm v/v max. (each)

Dioxide

10. Non-volatile Residue 10 ppm w/w max.

11. Non-volatile Organic Residue 5 ppm w/w max.

12. Total Volatile Hydrocarbons 50 ppm v/v max. Including 20

(as Methane) ppm v/v max. as total non-

methane hydrocarbons

13. Acetaldehyde 0.2 ppm v/v max.

14. Aromatic Hydrocarbon Content 20 ppb v/v max.

34000 / PC-E-654 August, 2017

NUCLEAR POWER CORPORATION OF INDIA LIMITED

(A Government of India Enterprise)

TECHNICAL SPECIFICATION ON CARBON DIOXIDE AND Page No. 3 of 9

OXYGEN GAS CYLINDERS FOR ANNULUS GAS SYSTEM Revision No. 2

S. Parameter Limits*

No.

15. Total Sulfur Content* (as S; 7 ppm v/v max.

Total sulfur-containing

impurities including sulfur

dioxide)

16. Sulfur Dioxide 1 ppm v/v max.

17. Phosphine 0.3 ppm v/v max.

18. Vinyl Chloride 0.1 ppm v/v max.

19. Odor of Solid CO2 (Snow) No foreign odor

20. Appearance in Water No color or turbidity

21. Odor & Taste in Water No foreign odor or taste

• Note:

a. Cumulative content of the impurities shall not exceed 100 ppm.

b. None of the other impurity limit (not mentioned in this table) mentioned in

ISBT standard shall be exceeded.

Table: 1 (b): Requirements for O2 gas

Parameter Limits#

Purity (Percentage by Volume) 99.999 (min.)

# Vendor certificate to be provided.

7.0 INSPECTION & TESTING

The CO2 shall meet the requirement of ISBT standard for purity of CO2 as minimum

of 99.9%. Vendor shall submit annual test report for its CO2 gas sample analysis

carried out at ISBT approved test laboratory. The test report shall contain test results

for all the parameters mentioned in Table-1(a) and shall meet the specified limits. Any

other impurity as per ISBT [other than mentioned in table-1(a)] shall meet the limits

mentioned in ISBT. The test report ( of ISBT approved laboratory) provided by

vendor shall not be older than One year.

The manufacturer should have online instruments/ laboratory with valid calibration

report/certificatefor checking purity of CO2 gas as well as method for analyzing

impurities as a minimum mentioned in Table-2. Accuracy of the

instrument/measurement method shall be that specified gas quality is complied.

Random selection of the cylinders (by NPCIL QA as per Table-2 of IS-307:1966) and

One sample from its source bulk tank/container shall be carried out for contents as per

Table-2. NPCIL QA engineer will witness the test.

34000 / PC-E-654 August, 2017

NUCLEAR POWER CORPORATION OF INDIA LIMITED

(A Government of India Enterprise)

TECHNICAL SPECIFICATION ON CARBON DIOXIDE AND Page No. 4 of 9

OXYGEN GAS CYLINDERS FOR ANNULUS GAS SYSTEM Revision No. 2

Table-2

List of Parameters to be tested/checked at Vendor`s location

Sl. No. Parameter Limits

1. CO2 Purity ≥99.9 % v/v

2. Moisture 20 ppm v/v max.

3. Nitric Oxide & Nitrogen 2.5 ppm v/v max. (each)

Dioxide

4. Ammonia 2.5 ppm v/v max.

5. Total Volatile Hydrocarbons (as 50 ppm v/v max. Including

Methane) 20 ppm v/v max. as total

non-methane hydrocarbons

6. Aromatic Hydrocarbon 20 ppb v/v max.

Content

7. Non-volatile Residue 10 ppm w/w max.

8. Non-volatile Organic Residue 5 ppm w/w max.

9. Acetaldehyde 0.2 ppm v/v max.

10. Total Sulfur Content (as 7 ppm v/v max.

S;Total sulfur-containing

impurities including

sulfur dioxide)

11. Carbon Monoxide 10 ppm v/v max.

Oxygen gas cylinders shall be checked for its purity at NABL (National Accreditation

Board for Testing and Calibration Laboratory) on sample basis (random selection of

the cylinders for testing by NPCIL QA as per Table-2 of IS-307:1966). O2 gas

certificate provided by Oxygen gas supplier shall be verified against NABL certified

Lab test report by NPCIL for Oxygen purity.

In case bulk gas tank is meeting gas specification and cylinder gas sample quality is

not found to meet specification requirement, all 100% cylinders shall be tested for the

contents as per Table-2 for CO2 and for purity at NABL lab in case for O2. Cylinders

having deviation with respect ro specification shall be rejected.

In case Vendor is required to do the Hydro test/ any valve repair for the cylinders, it

shall be reported to NPCIL before the test/repair. All such cylinders shall be

conditioned. Hydro test shall be carried out only by De-Mineralized (DM) water (with

pH correction to 8-9 is to be done by addition of NaOH). Vendor shall submit

34000 / PC-E-654 August, 2017

NUCLEAR POWER CORPORATION OF INDIA LIMITED

(A Government of India Enterprise)

TECHNICAL SPECIFICATION ON CARBON DIOXIDE AND Page No. 5 of 9

OXYGEN GAS CYLINDERS FOR ANNULUS GAS SYSTEM Revision No. 2

cylinder conditioning procedure for NPCIL approval prior to cylinder conditioning.

After conditioning of cylinders, all cylinders shall be tested for the contents as per

Table-2 for CO2.

8.0 SHIPMENT

The contractor shall be responsible for ensuring that cylinders and shut off valves are

suitably packed for shipment so as they do not suffer deterioration, damage during

transport and storage in a tropical climate. Each shipment shall be labeled to indicate

type and quantity of cylinders and purchase order number. Contractor shall dispatch

equipment only after issue of shipment release by the purchaser or his authorized

representative.

9.0 HISTORY DOCKET REQUIREMENT

As part of the station quality assurance records requirement, a history docket shall be

prepared for each cylinder and submitted to the purchaser at the time of inspection

and delivery of the cylinder. This docket shall consist of the following quality

assurance records/ documents.

a) Test report of chemical composition of gas content as per item 7.0.

b) Test report of ISBT approved Laboratory..

c) Copy of NABL Lab certificate..

d) Any other information which is required to be submitted.

34000 / PC-E-654 August, 2017

NUCLEAR POWER CORPORATION OF INDIA LIMITED

(A Government of India Enterprise)

TECHNICAL SPECIFICATION ON CARBON DIOXIDE AND Page No. 6 of 9

OXYGEN GAS CYLINDERS FOR ANNULUS GAS SYSTEM Revision No. 2

Annexure-1

Data to be Furnished by the Bidder

Sr No. Parameter CO2 O2

2

1. Cylinder pressure kg/cm

2. Gas cylinder cleaning facility details to be

submitted with procedure

3. Name of NABL certified laboratory for N.A.

verification and copy of its valid certification

from NABL.

4. Name and address of ISBT approved N.A.

laboratory from where the sample analysis is

done by Vendor.

5. Measurement method Online/Lab (indicate

component –wise) for table-2.

6. Cylinder conditioning procedure ( In case of

Hydro test/ Valve repair being done in the

cylinder.

7. Past 3 Sample test results from ISBT approved

Laboratory.

8. Source of CO2 and O2 gas.

9. Chemical composition of gas (All the

parameters mentioned in Table-1(a) and

Table-1(b).

`Bidders Pre-qualification Criteria`

Sr. Specification Compliance

No. by the

Bidder

1. Bidder shall have own purification plant for CO2 YES/NO

2. Bidder shall have online gas testing facility/Laboratory along YES/NO

with calibration facility for their Instruments.

3. Bidder shall have facility for cylinder cleaning and YES/NO

preconditioning.

4. Bidder shall submit cleaning and preconditioning procedure of YES/NO

Carbon Dioxide cylinder so that no foreign material/

moisture/contamination is left in the cylinder and required purity

requirement of CO2 gas is met.

5. Bidder shall mention measurement method for on-line and YES/NO

laboratory testing for all the mentioned components.

6. Bidder shall submit test report indicating chemical composition YES/NO

34000 / PC-E-654 August, 2017

NUCLEAR POWER CORPORATION OF INDIA LIMITED

(A Government of India Enterprise)

TECHNICAL SPECIFICATION ON CARBON DIOXIDE AND Page No. 7 of 9

OXYGEN GAS CYLINDERS FOR ANNULUS GAS SYSTEM Revision No. 2

of gas for the listed parameters along with name of

Nationally/Internationally accredited laboratory for independent

verification.

7. Supplier must disclose the original manufacturing source of YES/NO

Carbon Dioxide. However the source should not be from

Petrochemical, especially not from Ethylene Oxide plant based

industry.

8. Bidder shall submit detail of Carbon Dioxide purification process YES/NO

in a block diagram indication various chemicals used in the

purification process coming in direct contact with Gas.

NOTE:

1) Bidder must completely fill this “ Pre-qualification Criteria” for accepting

quotation/offer with ` YES` or `NO` or `offered parameter` only and submit along with the

offer, without this the offer shall not be considered.

2) The offer will be accepted only when the firm is accepting to supply the material as per

`Specification and compliance sheet` and meeting `Prequalification Criteria`.

Signature of Bidder

34000 / PC-E-654 August, 2017

NUCLEAR POWER CORPORATION OF INDIA LIMITED

(A Government of India Enterprise)

Page No. 8 of 8

TECHNICAL SPECIFICATION ON CARBON DIOXIDE AND OXYGEN GAS CYLINDERS FOR ANNULUS GAS SYSTEM Revision No. 1

Annexure-2

QUALITY ASSURANCE PLAN (QAP)

PURCHASER : NUCLEAR POWER CORPORATION OF INDIA LTD., MAIN VENDORS :

PURCHASER P.O. NO. : MAIN VENDOR’S REF. P.O. NO. :

REF. NO. : SUB-VENDOR, IF ANY :

: SUB-VENDOR REF. JOB NO. :

SCOPE AND PURPOSE

The purpose of this Quality Assurance Plan (QAP) is to describe general practices, resources and sequence of activities (such as inspection, testing, control, etc.) to be

performed during the manufacture of the above equipment. This QAP is a generic document and should be tailored by suitable additions, deletions or modifications for

specific contract keeping in mind the capabilities of the manufacturere/fabricator and the requirement of NPC. Accordingly “P” / “W” / “V” should be decided by the

Vendor and the Purchaser. Vendor / Sub-Vendor shall prepare and submit detailed QAP, including for items / activities, those which are not included in this Annexure, for

approval from Purchaser. WHILE FOLLOWING THIS QAP ABBREVIATIONS AND NOTES MENTIONED ON LAST PAGE OF THIS ANNEXURE SHOULD

BE REFERRED.

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10) (11)

Sl. Quantum of Reference Acceptance Format of Agency Remarks

Component and Operation Characteristics Class Type of Check

No. Check Document Norm Record P W V

A CO2 Gas

1.0 Gas Inspection

1.1 Verification of Vendor1s gas - Major Verification gas of 100% ISBT standard ISBT standard QCR 3 - 1.2 CHP

sample analysis report through purification process

ISBT approved laboratory ( not

older than One year) meeting

ISBT requirement.

1.2 Analysis of CO2 in the bulk Lab/ online Major Quantification of the One sample Gas Gas Specification QCR 2 2,1 1 CHP

containers at manufacturer’s analysis measured content per tank Specification

bottle filling station for items in

Table-2 in clause-7.0

1.3 Analysis of cylinders gas at Lab/ online Major Quantification of the As per Gas Gas Specification QCR 2 2.1 1 CHP, (See note-

manufacturer’s bottle filling analysis measured content Table-2 of Specification vi,vii). Cylinder

station for items in Table-2 in IS:307-1966 selection by NPCIL

clause-7.0. QA

34000 / PC-E-652 August, 2017

NUCLEAR POWER CORPORATION OF INDIA LIMITED

(A Government of India Enterprise)

Page No. 9 of 8

TECHNICAL SPECIFICATION ON CARBON DIOXIDE AND OXYGEN GAS CYLINDERS FOR ANNULUS GAS SYSTEM Revision No. 1

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10) (11)

Sl. Quantum of Reference Acceptance Format of Agency Remarks

Component and Operation Characteristics Class Type of Check

No. Check Document Norm Record P W V

1.4 Verification of accuracy and Lab/ online Major Qualification of 100% Gas Gas Specification QCR 2 2 1

calibration check of analysis Instrument Specification

instruments/testing method..

1.5 Cylinder conditioning if - Major Conditioning of 100% NPCIL NPCIL approved QCR 2 2.1 1

cylinders are Hydrostatic cylinder approved procedure

tested/any cylinder valve repair procedure

carried out.

A O2 Gas

2.0 Gas Inspection

2.1 O2 gas sample analysis at Lab/ online Major Quantification of the As per Gas Gas Specification QCR 3 2 1 CHP Cylinder

NABL approved Laboratory analysis measured content Table-2 of Specification selection by NPCIL

IS:307-1966 QA

2.2 Test results verification/cross Verification Major Quantification of the 100% Gas Gas Specification QCR - - 1 CHP, (See note-

checking of O2 gas purity measured content Specification viii).

specification with “report of

NABL approved lab test result

and certificate provided by

supplier.”

APPREVIATIONS

MAJOR : The characteristics of a gas content, process or operation whose failure may cause operation failure which cannot be readily corrected at site or

cause substandard performance, increased repair and maintenance cost, reduced life.

MINOR : The characteristics of a component, process or operation whose failure neither materially reduced the usability of the product in operation, nor

does it affects the aesthetic aspects.

TR : TEST REPORT TC : TEST CERTIFICATE R : REVIEW

QCR : QUALITY CONTROL RECORD CHP : CUSTOMER HOLD POINT P : PERFORMED BY

W : WITNESS V : VERIFICATION OF REPORT 3 : SUB-VENDOR / APPROVED LAB

1 : CUSTOMER (NPCIL, QS) 2 : CONTRACTOR(C)

“Failure” of a characteristic means failure to meet the “Acceptance norms”.

34000 / PC-E-652 August, 2017

NUCLEAR POWER CORPORATION OF INDIA LIMITED

(A Government of India Enterprise)

Page No. 10 of 8

TECHNICAL SPECIFICATION ON CARBON DIOXIDE AND OXYGEN GAS CYLINDERS FOR ANNULUS GAS SYSTEM Revision No. 1

NOTES :

i) All TR, TC and QCR shall be reviewed by NPCIL, QS. All the TR, TC & ACR and other documents shall be reviewed by the Contractor (C) before submitting the same

for review by NPCIL, QS.

ii) Sample selection, for random witnessing of the inspection, examination, testing shall be done by NPCIL, QS.

iii) Wherever witness is indicated as “1” only, Contractor shall also witness 100% along with NPCIL, QS. Wherever witnessing is indicating as “1,2”, Contractor shall

witness 100% and NPCIL witnessing will be on random basis. Purchaser reserve the right to witness on random basis.

iv) QAP, documents and all the procedures for inspection, examination and testing, including for qualification of the items shall be reviewed, stamped and signed by Sub-

Vendors (if any) and Vendor’s representatives, responsible for preparation, checking and finalizing QAP, documents & procedures before submitting the QAP

documents & procedures for Purchaser’s approval.

v) Calibrated equipment / instruments shall be used during inspection, examination and testing.

vi) All 100% conditioned cylinders would be tested for contents of Table-2.

vii) If any of the randomly selected sample is not meeting requirements of table-2, all 100% cylinders shall be tested for the contents as per Table-2.

viii) If any of the randomly selected sample is not meeting Oxygen purity specification as per report/certificate of NABL, then all 100% cylinders shall be tested at NABL

lab.

34000 / PC-E-652 August, 2017

You might also like

- IGS-M-CH-38 (1) Oct IGS. Iranian Gas Standards $ - &' (! ! Odorant To Be Used For Odorization of Natural Gas-1Document12 pagesIGS-M-CH-38 (1) Oct IGS. Iranian Gas Standards $ - &' (! ! Odorant To Be Used For Odorization of Natural Gas-1KHALED KHALEDNo ratings yet

- Specifications: Carbon DioxideDocument2 pagesSpecifications: Carbon DioxideShofi100% (1)

- Annex 8Document24 pagesAnnex 8Nnadozie KennethNo ratings yet

- 6 Tech Spec AMOC Final V2Document26 pages6 Tech Spec AMOC Final V2bvdbNo ratings yet

- GB 15892-2009Document25 pagesGB 15892-2009dewi wulansariNo ratings yet

- 1994 K01 Hydrocarbon Mixture Equations of State and Their Impact On Gas Flow Starling University of OklahomaDocument9 pages1994 K01 Hydrocarbon Mixture Equations of State and Their Impact On Gas Flow Starling University of OklahomaMostafa ShipishlyNo ratings yet

- Is 13072Document39 pagesIs 13072sameerNo ratings yet

- Koc MP 018Document17 pagesKoc MP 018Subhajit BhattacharyaNo ratings yet

- Adeco Adblue EngDocument2 pagesAdeco Adblue EngviktorqNo ratings yet

- Technical Specification On Oxygen Gas Cylinders For Annulus Gas System Annexure 1 2 21103Document3 pagesTechnical Specification On Oxygen Gas Cylinders For Annulus Gas System Annexure 1 2 21103Shivam PandeyNo ratings yet

- Proven: Solid Partners SolutionsDocument4 pagesProven: Solid Partners SolutionskevinNo ratings yet

- 5 m3 For STP ProposalDocument15 pages5 m3 For STP ProposalShah Newaz KabirNo ratings yet

- Executive Summary - InDAdeptGDocument5 pagesExecutive Summary - InDAdeptGAvik BhaiNo ratings yet

- Nitrogen: Experis® Ultra-High Purity Gases Technical SpecificationDocument2 pagesNitrogen: Experis® Ultra-High Purity Gases Technical Specificationgauravtech1988No ratings yet

- PTP-19.1 HandoutDocument11 pagesPTP-19.1 HandoutJayNo ratings yet

- Training OfficersDocument92 pagesTraining OfficersPriyank SutariyaNo ratings yet

- Training OfficersDocument92 pagesTraining OfficersPriyank Sutariya100% (1)

- Submitted To Radhe Engineering Services and Solutions Submitted by Mr. Kolhe R. RDocument18 pagesSubmitted To Radhe Engineering Services and Solutions Submitted by Mr. Kolhe R. RNanha-Munna swaggerNo ratings yet

- Production of Acetic Acid by Methanol CarbonylationDocument68 pagesProduction of Acetic Acid by Methanol CarbonylationNoman Aslam100% (5)

- Combustion Process Operators - Spreadsheet Tool For Reporting Emissions To AirDocument15 pagesCombustion Process Operators - Spreadsheet Tool For Reporting Emissions To AiraalfanNo ratings yet

- SSP 943003 Audi Motor Vehicle Exhaust EmissionsDocument40 pagesSSP 943003 Audi Motor Vehicle Exhaust EmissionsJorge Antonio GuillenNo ratings yet

- Training Fresh EntrantsDocument121 pagesTraining Fresh EntrantsPriyank SutariyaNo ratings yet

- ELECNRTL Rate Based NaOH ModelDocument21 pagesELECNRTL Rate Based NaOH ModelMuhammad UsmanNo ratings yet

- Final Technical Support DocumentDocument49 pagesFinal Technical Support DocumentAndres RamosNo ratings yet

- PERFORMANCE GUARANTEE REPORT Rev.0Document7 pagesPERFORMANCE GUARANTEE REPORT Rev.0Omar WardehNo ratings yet

- 5994-2138 Hydrogen Impurity Analysis Agilent 990 Micro GCDocument4 pages5994-2138 Hydrogen Impurity Analysis Agilent 990 Micro GCphoenix_lwpNo ratings yet

- Technical Code On Control of Emission of Nitrogen Oxides From Marine Diesel EnginesDocument97 pagesTechnical Code On Control of Emission of Nitrogen Oxides From Marine Diesel EnginesPradeepPrincerajNo ratings yet

- Biodeisel Using FuelProDocument4 pagesBiodeisel Using FuelProSylab InstrumentsNo ratings yet

- Internal Corrosion StudyDocument9 pagesInternal Corrosion StudyOmar WardehNo ratings yet

- Gas Analyzers 21C2 E 0005cDocument20 pagesGas Analyzers 21C2 E 0005cmohammadgouseNo ratings yet

- Cylinders Shall Be Produced As Per IS 7285 and Approved by Chief Controller of ExplosiveDocument1 pageCylinders Shall Be Produced As Per IS 7285 and Approved by Chief Controller of ExplosiveAlanka Prasad100% (1)

- DGA Test Result REFERENCEDocument3 pagesDGA Test Result REFERENCELeo Tabita Jr.No ratings yet

- NEQS Understanding: Compiled & Developed By: KHMDocument37 pagesNEQS Understanding: Compiled & Developed By: KHMHaider AbbasNo ratings yet

- Air Quality Annual 2021 EngDocument12 pagesAir Quality Annual 2021 EngVivek PuranikNo ratings yet

- Trace Impurity Analysis of Hydrogen Fuel in Fuel Cell Vehicle-Related Fields. Application Note (Shimadzu)Document2 pagesTrace Impurity Analysis of Hydrogen Fuel in Fuel Cell Vehicle-Related Fields. Application Note (Shimadzu)Maikel Perez NavarroNo ratings yet

- CTO Rohini 2023Document6 pagesCTO Rohini 2023environment NK AreaNo ratings yet

- Annexure 1 - Is 16087 - 2016 PDFDocument5 pagesAnnexure 1 - Is 16087 - 2016 PDFashishjawale7100% (1)

- CICGPC Ceramic Tile Ver1.0aDocument16 pagesCICGPC Ceramic Tile Ver1.0aNick NgNo ratings yet

- Odalog L2 1407995247 LDocument2 pagesOdalog L2 1407995247 LAmeenudeenNo ratings yet

- Dissolved Gas Analysis (DGA) : Basic Theory Sample Collection Extraction of Gases Analysis of Gases ActionDocument45 pagesDissolved Gas Analysis (DGA) : Basic Theory Sample Collection Extraction of Gases Analysis of Gases Actionsantoshnarinoi241100% (1)

- Yadav AdBlueDocument9 pagesYadav AdBlueguilherme lacerdaNo ratings yet

- SF-43 Standard DieselDocument2 pagesSF-43 Standard DieselClaudiu PanaNo ratings yet

- Operating Manual GsuDocument89 pagesOperating Manual GsuVijendra Kumar GuptaNo ratings yet

- Manual Medidor RotativoDocument32 pagesManual Medidor RotativonduenasNo ratings yet

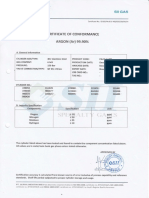

- COC Ar30 40L 02-03-XII-14 PDFDocument1 pageCOC Ar30 40L 02-03-XII-14 PDFTirtana PrasetiaNo ratings yet

- Max Bev CO2 Purity Monitoring System ds56385 enDocument2 pagesMax Bev CO2 Purity Monitoring System ds56385 enTaylorNo ratings yet

- Is 8112 2013 PDFDocument13 pagesIs 8112 2013 PDFMD QUASIDNo ratings yet

- URS - Tanauan Factory WWTP Upgrade PDFDocument23 pagesURS - Tanauan Factory WWTP Upgrade PDFVer AmorosoNo ratings yet

- Appnote Icpoes 0013 enDocument8 pagesAppnote Icpoes 0013 enejvelazcorNo ratings yet

- g210 Product Datasheet - LogoDocument4 pagesg210 Product Datasheet - Logocalibration aragoncalibrations.comNo ratings yet

- Report On Combustion Test Gramtech, TeamDocument26 pagesReport On Combustion Test Gramtech, TeamYousufNo ratings yet

- (BS 1715-2.3 - 1989) - Analysis of Soaps. Quantitative Test Methods. Method For Determination of Free Caustic Alkali ContentDocument8 pages(BS 1715-2.3 - 1989) - Analysis of Soaps. Quantitative Test Methods. Method For Determination of Free Caustic Alkali ContentamazondayNo ratings yet

- 920 Multi-Gas Analyzer: Product Data SheetDocument2 pages920 Multi-Gas Analyzer: Product Data Sheetlaoying qdNo ratings yet

- Koc MP 019Document19 pagesKoc MP 019Ravi MahetoNo ratings yet

- FieldGuide Heating enDocument100 pagesFieldGuide Heating encnita77No ratings yet

- TS 61Document2 pagesTS 61mohamed aliNo ratings yet

- Gas Sweetening and Processing Field ManualFrom EverandGas Sweetening and Processing Field ManualRating: 4 out of 5 stars4/5 (7)

- Axa Health Insurance-Prestige DetailsDocument2 pagesAxa Health Insurance-Prestige DetailsgnkameshNo ratings yet

- World Energy Insight 2013Document100 pagesWorld Energy Insight 2013gnkameshNo ratings yet

- Electricity Supply Options Sustainable DDocument88 pagesElectricity Supply Options Sustainable DgnkameshNo ratings yet

- Hydrogen Safety OverviewDocument2 pagesHydrogen Safety OverviewgnkameshNo ratings yet

- Thyroid ControlDocument3 pagesThyroid ControlgnkameshNo ratings yet

- MIT ArticlesDocument30 pagesMIT ArticlesgnkameshNo ratings yet

- Sic Her He Its Hand BuchDocument85 pagesSic Her He Its Hand BuchgnkameshNo ratings yet

- Manual de Miller Maquina de SoldarDocument108 pagesManual de Miller Maquina de Soldaredgarlimas100% (1)

- Instructions: Motoweld-Rl350Document153 pagesInstructions: Motoweld-Rl350gsNo ratings yet

- 510 User Manual V0.6 A5Document24 pages510 User Manual V0.6 A5PrzemekNo ratings yet

- Eiga-36 - 19 (2019)Document120 pagesEiga-36 - 19 (2019)JDNo ratings yet

- Safety Assessment Questions and AnswersDocument234 pagesSafety Assessment Questions and Answerspradeepdce100% (1)

- 631265N0 Rheem Installation and Operation GuideDocument44 pages631265N0 Rheem Installation and Operation GuideJanVR100% (1)

- English Plasma Manual HPR 260 BPLHDocument165 pagesEnglish Plasma Manual HPR 260 BPLHnafis2u67% (3)

- KFS FE13 Design Manual PDFDocument88 pagesKFS FE13 Design Manual PDFWilliam Segundo Matheus Torres100% (1)

- List of Nepal StandardsDocument22 pagesList of Nepal Standardssurendra_panga0% (1)

- Handler 210MVPDocument56 pagesHandler 210MVPHobart Welding Products100% (1)

- FM200 System MaintenanceDocument3 pagesFM200 System MaintenanceJohn CarloNo ratings yet

- Health and Safety in WeldingDocument46 pagesHealth and Safety in Weldingegn2007No ratings yet

- Fire Suppression DesignDocument196 pagesFire Suppression DesignDanny Dukeran100% (3)

- Oxygen Booster ManualDocument27 pagesOxygen Booster ManualAldo Tolaba Quiroga100% (3)

- Ebs1 Fsfa00 HSGH Gdhs 1002 g01 Health Safety PlanDocument80 pagesEbs1 Fsfa00 HSGH Gdhs 1002 g01 Health Safety PlanAsaad AdnanNo ratings yet

- Wilhelmsen Wall Chart Safety Checklist For Welding Aug22Document1 pageWilhelmsen Wall Chart Safety Checklist For Welding Aug22Unitor ChrisNo ratings yet

- As 2337.1-2004 Gas Cylinder Test Stations General Requirements Inspection and Tests - Gas CylindersDocument9 pagesAs 2337.1-2004 Gas Cylinder Test Stations General Requirements Inspection and Tests - Gas CylindersSAI Global - APACNo ratings yet

- Appen E - Work in Progress Audit Checklist ExampDocument9 pagesAppen E - Work in Progress Audit Checklist ExampGovind Shriram ChhawsariaNo ratings yet

- Bridon Training PresentationDocument55 pagesBridon Training PresentationAlam DooNo ratings yet

- Airframe Stock ListDocument546 pagesAirframe Stock List2yp4sj97vcNo ratings yet

- Manual Operation Aas Aa6300 PDFDocument325 pagesManual Operation Aas Aa6300 PDFDewa SubamiaNo ratings yet

- Get Msds by External UrlDocument11 pagesGet Msds by External Urlkin hung chanNo ratings yet

- NEBOSH International General Certificate in Occupational Health and SafetyDocument20 pagesNEBOSH International General Certificate in Occupational Health and SafetysuleeshNo ratings yet

- STDE-PRD-009 - R0 (Puff Test)Document5 pagesSTDE-PRD-009 - R0 (Puff Test)Tommaso ZerneriNo ratings yet

- Clark CQ20 25 30L CQ20 25 30GDocument287 pagesClark CQ20 25 30L CQ20 25 30GMarcio100% (2)

- Lincoln Manual-Part Book VANTAGE 500 11467 PDFDocument76 pagesLincoln Manual-Part Book VANTAGE 500 11467 PDFMauricio Garcia100% (3)

- Ga Machine Slide11Document94 pagesGa Machine Slide11Wong KinYouNo ratings yet

- Sigma 2 Type 2: AS/NZS1716: 2012 - Respiratory Protective Devices Lic 5021 BSI BenchmarkDocument16 pagesSigma 2 Type 2: AS/NZS1716: 2012 - Respiratory Protective Devices Lic 5021 BSI BenchmarkErkan OzturkNo ratings yet

- SPEC. FGS Rev.2 - 16-20Document5 pagesSPEC. FGS Rev.2 - 16-20kepuren loroNo ratings yet

- DS1353 SV Series Marine FM-200Document20 pagesDS1353 SV Series Marine FM-200kidmuNo ratings yet