Professional Documents

Culture Documents

Uploaded by

rezaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Uploaded by

rezaCopyright:

Available Formats

CRC Industries, Inc.

Technical Data Sheet

885 Louis Drive Warminster PA 18974

RTV Silicone Adhesive - Red

I. Product Description

CRC Red RTV (Room Temperature Vulcanizing) Silicone Adhesive is the simple way to seal, protect, bond,

insulate and waterproof. Superb for forming instant, custom-shaped gaskets, Red RTV Silicone adheres to most

materials used in the industrial, electrical, metalworking and construction industries. Red RTV Silicone is a high

temperature, high pressure, low odor, non-corrosive gasket sealant for use in a variety of applications that require no

sag or shrinkage at continuous temperatures ranging from -80ºF to 500ºF (600ºF intermittently).

II. Applications

Recommended and designed for a wide range of sealing, bonding, protection and water proofing in HVAC, electrical,

construction, metal working and many more applications. Use as a heavy duty industrial gasket adhesive for filling

gaps between mating parts, gear boxes, pumps, motors and for general gasket sealing.

III. Features & Benefits

Seals, Bonds, Waterproofs and Protects.

Cures at Room Temperature. No special curing methods required.

Chemically Stable. Shows little change in physical properties after exposure to sunlight (UV rays), rain,

snow, ozone, temperature extremes and weathering.

High Temperature Rating. Recommended for high temperature, high pressure applications.

Non-Corrosive. Excellent for use on metal to metal contacts.

Low Odor. Improves worker comfort.

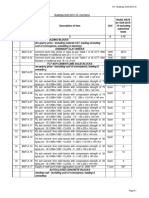

IV. Physical Properties without propellant

Flash Point Not Applicable Boiling Point Not Applicable

Odor Slight Solubility None in water

Appearance Red Paste % Volatile Not Determined

Vapor Density >1 (air=1) Specific Gravity 1.05

VOC Content (Fed) <3% Temperature range -80F To 500F

Sara Title III, Sect. 313 Chemicals No 600ºF intermittent

Prop 65 No Propellant- 14059 only Nitrogen

V. Specifications and Approvals

When fully cured and washed, CRC Red RTV Silicone Adhesive meets the following regulations:

TT-S-001543A, Class B

TT-S-0230C, Type 2, Class B

ASTM C 920

VI. Performance Characteristics

Cure Time (Total) 24 hours

Elongation Rate 400%

Dielectric Strength 18 KV/mm

Tensile Strength 250 psi

Durometer Hardness (Shore A) 30

RTV Silicone Adhesive - Red

VII. Directions

Clean and dry all surfaces. Remove any oil and grease prior to application. Sealant adheres best to clean,

unpainted surfaces.

For a smooth seal, apply sealant at a 45º angle. Dispense RTV Silicone from the pressurized tube by pressing

finger to nozzle to tilt sideways. RTV Silicone in the cartridge must be dispensed using a caulk gun. Cut tip of

cartridge, screw-on applicator nozzle and cut nozzle to desired bead size.

If further tooling is required, complete within 5 minutes. Remove excess sealant immediately with a dry paper

towel.

Normally sealant “skins” in 10 minutes, dries to the touch in one hour and fully cures and bonds in 24 hours.

Optimum strength is achieved in 7 days.

If gasket is not used in assembly, apply sealant to surface of one part and allow skin to form before assembling

parts.

After sealant is completely cured, excess material can be removed by trimming with a sharp blade. Avoid

undercutting the sealant.

Pressurized tube is resealable. If contents are not completely used, extrude 3/8” bead of sealant beyond the tube

opening. When ready to re-use, simply pull out the cured plug.

Not recommended for use involving continuous immersion in gasoline.

VIII. Package Description

Part Number Container Size

14059 8 oz Pressurized Tube

14075 12 oz Cartridge

IX. Disposal

Disposal requirements vary by state and local jurisdiction. All used and unused product should be disposed of in

conformance with local, state and federal regulations.

X. Special Use Warnings

Aerosol Cans

Do not puncture, incinerate or store above 120F. Exposure to high temperatures may cause can to burst. Do not

place in direct sunlight or near any heat source. Aerosol cans will conduct electricity. Keep away from all live

electrical sources including battery terminals, solenoids, electrical panels and other electronic components. Failure to

observe this warning may result in serious injury from flash fire and/or electrical shock.

General

Use only in well ventilated area. Ventilation may be improved by opening a window or door or providing mechanical

assistance. Avoid continuous breathing of vapor and spray mist. Avoid contact with skin and eyes. If ventilation is

not adequate, respiratory protection should be worn. For more information regarding short term and long term

exposure, review this product’s Safety Data Sheet.

DISCLAIMER: This information is accurate to the best of CRC Industries’ knowledge or obtained from sources believed by CRC to be

accurate. Before using any product, read all warnings and directions on the label. All products should be tested for suitability on a particular

application prior to actual use. CRC Industries, Inc. makes no representations or warranties of any kind concerning this data.

CRC Industries, Inc. Industrial Products Division Warminster, PA 18974

Technical Service: (800)521-3168 Customer Service: (800)272-4620 CRC On-Line: (215)442-6260

Literature Reorder #TDS122 CRC On-Line # 122 REV. 7/13

You might also like

- Castiglianos Theorem GEREDocument14 pagesCastiglianos Theorem GEREpgp655484100% (2)

- AASHTO Guide Specifications For Design of Pedestrian Bridges 2009 (Draft)Document17 pagesAASHTO Guide Specifications For Design of Pedestrian Bridges 2009 (Draft)Laurence Arcon Banal0% (1)

- Accessible Gangways and Landside ConnectionsDocument14 pagesAccessible Gangways and Landside Connectionssimonorr17No ratings yet

- Surface Prep & Primer PaintingDocument4 pagesSurface Prep & Primer PaintingrajuNo ratings yet

- PW-3 Part Design For Ultrasonic Welding (Single PGS) HRDocument8 pagesPW-3 Part Design For Ultrasonic Welding (Single PGS) HRHugoAlvarez100% (1)

- Carboguard 890 PDSDocument2 pagesCarboguard 890 PDSLinnie McleodNo ratings yet

- CVEN 444 - Homework 5 - Concrete beam and slab design problemsDocument9 pagesCVEN 444 - Homework 5 - Concrete beam and slab design problemsOmar Calisaya RamosNo ratings yet

- 015 - NH - 1003 Thermal and Acoustic InsulationDocument26 pages015 - NH - 1003 Thermal and Acoustic InsulationSaif AhmedNo ratings yet

- RTV Silicone Adhesive - Red: I. Product DescriptionDocument2 pagesRTV Silicone Adhesive - Red: I. Product DescriptionrezaNo ratings yet

- Gasket Remover (DS) 125-03017Document2 pagesGasket Remover (DS) 125-03017Teguh RiswantoNo ratings yet

- Ficha de Seguridad SapolinDocument2 pagesFicha de Seguridad Sapolinkelly stephanie castaño boteroNo ratings yet

- Di-Electric Grease CRCDocument2 pagesDi-Electric Grease CRCKeinerNo ratings yet

- CRC 2043Document3 pagesCRC 2043pubudu inrajithNo ratings yet

- Acrabond KE45 Type RTV Silicone SealantDocument5 pagesAcrabond KE45 Type RTV Silicone SealantdrvikaasNo ratings yet

- Anti-Corrosion Heavy Wax FilmDocument2 pagesAnti-Corrosion Heavy Wax FilmsalamrefighNo ratings yet

- TDS Contact Cleaner Precision 2000Document2 pagesTDS Contact Cleaner Precision 2000german llanoNo ratings yet

- Zinc It 2085 TdsDocument3 pagesZinc It 2085 TdsajuhaseenNo ratings yet

- Ficha Técnica Lubricante Multo PropósitoDocument2 pagesFicha Técnica Lubricante Multo Propósitogerman llanoNo ratings yet

- RTV157 and RTV159: Technical Data SheetDocument7 pagesRTV157 and RTV159: Technical Data SheetMichael McQueenNo ratings yet

- Technical Data - CRC Cable CleanDocument2 pagesTechnical Data - CRC Cable CleanAHMED YOUSEFNo ratings yet

- High-performance synthetic air compressor oilDocument2 pagesHigh-performance synthetic air compressor oilToppy ToppyNo ratings yet

- Sikafloor - 264 EngDocument5 pagesSikafloor - 264 Engbassem kooliNo ratings yet

- Dion FR 7721-00Document3 pagesDion FR 7721-00Vasu DevanNo ratings yet

- Carbocoat 8215 PDS 6-10Document2 pagesCarbocoat 8215 PDS 6-10Mayur PatelNo ratings yet

- Silirub IS Technical Data SheetDocument2 pagesSilirub IS Technical Data SheetGomathi SankarNo ratings yet

- Polyclad 975 H PDSDocument2 pagesPolyclad 975 H PDSLinnie McleodNo ratings yet

- SYNTHETIC ROZP PRIMER 12744 SPECDocument2 pagesSYNTHETIC ROZP PRIMER 12744 SPECmahotkatNo ratings yet

- Folheto Tecnico - Molykote 7400 Anti-Friction Coating 71-0073E-01Document2 pagesFolheto Tecnico - Molykote 7400 Anti-Friction Coating 71-0073E-01marcosNo ratings yet

- Momentive RTV 630 TDS 2019Document7 pagesMomentive RTV 630 TDS 2019crushergaming1804No ratings yet

- Thermaline 450 PDFDocument2 pagesThermaline 450 PDFNageswara Rao BavisettyNo ratings yet

- TDS Food Grade Chain LubeDocument2 pagesTDS Food Grade Chain LubeJavier PinzonNo ratings yet

- Technical Data Sheet: Page 1 of 5 HCD-10316 (Rev. 2012-04-24 2:24 PM)Document5 pagesTechnical Data Sheet: Page 1 of 5 HCD-10316 (Rev. 2012-04-24 2:24 PM)Sami LAHMIDINo ratings yet

- CIKOjoint Plyflex 1200Document3 pagesCIKOjoint Plyflex 1200Vaittianathan MahavapillaiNo ratings yet

- Technical Data Sheet: Page 1 of 6 HCD-10307 (Rev. 2011-11-03 2:00 PM)Document6 pagesTechnical Data Sheet: Page 1 of 6 HCD-10307 (Rev. 2011-11-03 2:00 PM)Pedro NavarroNo ratings yet

- Sika SanisilDocument4 pagesSika SanisilA GlaumNo ratings yet

- 1312571wire Rope LubricantDocument2 pages1312571wire Rope LubricantsriabolfazlNo ratings yet

- CT-90 Cutting Fluid Multi-UseDocument2 pagesCT-90 Cutting Fluid Multi-UsePaulNo ratings yet

- Sila Tech RD TdsDocument2 pagesSila Tech RD TdsChemicalProgrammerNo ratings yet

- CRC Galvanizado en FrioDocument2 pagesCRC Galvanizado en Friojedd021873No ratings yet

- Ambersil Copper High Temperature Anti Seize Paste TDSDocument2 pagesAmbersil Copper High Temperature Anti Seize Paste TDSjawnuolisNo ratings yet

- Kester 977 Soldering Flux en 17feb21 TBDocument4 pagesKester 977 Soldering Flux en 17feb21 TBhugoavchavezNo ratings yet

- Carbomastic 15 LT: Selection & Specification DataDocument3 pagesCarbomastic 15 LT: Selection & Specification Datasrinath vNo ratings yet

- D9 SB ZINC SILICATE Inorganic Zinc Primer Data SheetDocument2 pagesD9 SB ZINC SILICATE Inorganic Zinc Primer Data SheetPrashant MalveNo ratings yet

- Build: Builders Silicone SealantsDocument3 pagesBuild: Builders Silicone SealantsAhmed KhameisNo ratings yet

- DC 688 Technical Data SheetDocument3 pagesDC 688 Technical Data SheetHoang ThiNo ratings yet

- Silver Zinc Guard - PROTECT TDS ENDocument3 pagesSilver Zinc Guard - PROTECT TDS ENYouyouNo ratings yet

- Adhesives Cyanoacrylates Apollo 2150Document2 pagesAdhesives Cyanoacrylates Apollo 2150Vinaya Almane DattathreyaNo ratings yet

- Ece-3650 Sylgard Hvic BrochureDocument4 pagesEce-3650 Sylgard Hvic Brochurekamal_khan85No ratings yet

- iKOTE AC 40 (DEC-2023) V1.3Document2 pagesiKOTE AC 40 (DEC-2023) V1.3nguyen hoang AnhNo ratings yet

- Advanced Rust Preventive FluidDocument2 pagesAdvanced Rust Preventive FluidmiteshNo ratings yet

- JOINLEADER 880 Weatherproof Silicone Sealant TDSDocument5 pagesJOINLEADER 880 Weatherproof Silicone Sealant TDSdasaNo ratings yet

- TDS Food Grade Machine OilDocument2 pagesTDS Food Grade Machine OilJavier PinzonNo ratings yet

- Shop primer data sheetDocument2 pagesShop primer data sheetKarthimeena MeenaNo ratings yet

- Soudaflex Construction FCDocument2 pagesSoudaflex Construction FCAvijitSinharoyNo ratings yet

- Sikasil PoolDocument4 pagesSikasil PoolRockweed InternationalNo ratings yet

- PolyguardDocument2 pagesPolyguardJack MayNo ratings yet

- SILASTIC™ HV 1551-55P Liquid Silicone Rubber: Features & BenefitsDocument3 pagesSILASTIC™ HV 1551-55P Liquid Silicone Rubber: Features & Benefitsabdulbaset alselwiNo ratings yet

- Protect PCB Moisture GuideDocument2 pagesProtect PCB Moisture Guidemuti_khan20006003No ratings yet

- Bitumastic 300MDocument2 pagesBitumastic 300Mtharman749781No ratings yet

- Description: Fix & Seal High TackDocument2 pagesDescription: Fix & Seal High TackTung ThanhNo ratings yet

- Carboguard 89dfsfs0 PDSDocument2 pagesCarboguard 89dfsfs0 PDSMayur PatelNo ratings yet

- Securea SCDocument2 pagesSecurea SCAutumn HernandezNo ratings yet

- MOLYKOTE 3400A Anti-Friction Coating LF 80-3061C-01Document2 pagesMOLYKOTE 3400A Anti-Friction Coating LF 80-3061C-01MAHESH BELENo ratings yet

- Intertherm 972: Product DescriptionDocument4 pagesIntertherm 972: Product DescriptionRohit RathiNo ratings yet

- Sikagard®-203 W: Product Data SheetDocument4 pagesSikagard®-203 W: Product Data SheetKhin Sandi KoNo ratings yet

- VcweddefefffefdfdfDocument2 pagesVcweddefefffefdfdfrezaNo ratings yet

- VfbnnnnmmmvvvgggbnnnnjyhthDocument2 pagesVfbnnnnmmmvvvgggbnnnnjyhthrezaNo ratings yet

- VfbnnnnmmmvvvgggbnnnnjyhthDocument2 pagesVfbnnnnmmmvvvgggbnnnnjyhthrezaNo ratings yet

- JijuroigjfjkgjdsfdbjdhfdflggDocument3 pagesJijuroigjfjkgjdsfdbjdhfdflggrezaNo ratings yet

- Rtttthhhhfffdddduuuuur 5 TRGFRGFDocument3 pagesRtttthhhhfffdddduuuuur 5 TRGFRGFrezaNo ratings yet

- Rtttthhhhfffdddduuuuur 5 TRGFRGFDocument3 pagesRtttthhhhfffdddduuuuur 5 TRGFRGFrezaNo ratings yet

- G 25 D 5 DCVDVDVBVFBFBFBDocument3 pagesG 25 D 5 DCVDVDVBVFBFBFBrezaNo ratings yet

- NGBNFBFVBDGFDFDocument2 pagesNGBNFBFVBDGFDFrezaNo ratings yet

- FFF33FFRT5T454FGFGRRFE4DEDEDEDDocument3 pagesFFF33FFRT5T454FGFGRRFE4DEDEDEDrezaNo ratings yet

- VBCXDFDFDFDFDFDFDFDFDFDocument2 pagesVBCXDFDFDFDFDFDFDFDFDFrezaNo ratings yet

- RedfswdddddfgghghhjkDocument3 pagesRedfswdddddfgghghhjkrezaNo ratings yet

- NbgggbbefecfdcdcdccDocument2 pagesNbgggbbefecfdcdcdccrezaNo ratings yet

- FRGHBNNBVBVVVDocument2 pagesFRGHBNNBVBVVVrezaNo ratings yet

- RedfswdddddfgghghhjkDocument3 pagesRedfswdddddfgghghhjkrezaNo ratings yet

- DDDDF 4 R 4 R 4 TDocument2 pagesDDDDF 4 R 4 R 4 TrezaNo ratings yet

- RGFHBF 5 SZDocument2 pagesRGFHBF 5 SZrezaNo ratings yet

- Erwq 2 QQQQQQDocument3 pagesErwq 2 QQQQQQrezaNo ratings yet

- IuhhgvbbnDocument2 pagesIuhhgvbbnrezaNo ratings yet

- HFF 32 EssrfrfDocument3 pagesHFF 32 EssrfrfrezaNo ratings yet

- 4333 EeerretrgtggggDocument3 pages4333 EeerretrgtggggrezaNo ratings yet

- GGTR 545 GGDocument2 pagesGGTR 545 GGrezaNo ratings yet

- GGGGDocument3 pagesGGGGrezaNo ratings yet

- LKKJHNNHNDocument3 pagesLKKJHNNHNrezaNo ratings yet

- SCCCCDocument3 pagesSCCCCrezaNo ratings yet

- VBVDCVCDocument3 pagesVBVDCVCrezaNo ratings yet

- 3333 EeeeeeeDocument3 pages3333 EeeeeeerezaNo ratings yet

- LKKJHNNHNDocument3 pagesLKKJHNNHNrezaNo ratings yet

- 85 FDFDFDocument3 pages85 FDFDFrezaNo ratings yet

- 4 RTFFDocument3 pages4 RTFFrezaNo ratings yet

- Bew 2 CCDocument4 pagesBew 2 CCrezaNo ratings yet

- XFEM Analysis in ABAQUS - Simplified Finite ElementsDocument3 pagesXFEM Analysis in ABAQUS - Simplified Finite ElementsFaizan RashidNo ratings yet

- Superswell 47BDocument4 pagesSuperswell 47BMuhd Abd MalikNo ratings yet

- Concrete Deck SlabDocument24 pagesConcrete Deck SlabRichard ChavezNo ratings yet

- Seismic Analysis of G+5 Framed Structures With and Without Floating Columns Using ETABS-2013 SoftwareDocument8 pagesSeismic Analysis of G+5 Framed Structures With and Without Floating Columns Using ETABS-2013 SoftwareArifsalimNo ratings yet

- Air Tightness of Building Envelope Design SystemDocument7 pagesAir Tightness of Building Envelope Design SystemYolanda SelgaNo ratings yet

- E-Notification No. 67, Dated March 9, 2017: Typical Section Without BackwallDocument3 pagesE-Notification No. 67, Dated March 9, 2017: Typical Section Without Backwallجميل عبد الله الحماطيNo ratings yet

- Gabions - Matteres PVC Gabions - Mattress Malaysia, Johor, Batu Pahat Manufacturer, Supplier, Supplies, Supply - CHUN HOE TRADING SDN BHDDocument12 pagesGabions - Matteres PVC Gabions - Mattress Malaysia, Johor, Batu Pahat Manufacturer, Supplier, Supplies, Supply - CHUN HOE TRADING SDN BHDSab RiNo ratings yet

- Reinforced Concrete Basement Retaining Wall DesignDocument7 pagesReinforced Concrete Basement Retaining Wall DesignSeifeldin Ali MarzoukNo ratings yet

- RF BUILDINGSDocument122 pagesRF BUILDINGSMadhu KrishnaNo ratings yet

- Tacmina Dosing Pump Cs2Document8 pagesTacmina Dosing Pump Cs2rosiNo ratings yet

- ChillersDocument7 pagesChillersBRANDONNo ratings yet

- Rotor Hot Spot Treatment PDFDocument10 pagesRotor Hot Spot Treatment PDFramnadh803181No ratings yet

- CL10 (May 2012)Document22 pagesCL10 (May 2012)uddinnadeemNo ratings yet

- GTT Mark III PlaquetteDocument4 pagesGTT Mark III PlaquetteAlexandros HatzisNo ratings yet

- End of Line Flame Arrester Model 310 8 InchDocument3 pagesEnd of Line Flame Arrester Model 310 8 InchfelixNo ratings yet

- EOF: The Reliable Choice For Indian "Start-Up" Steel PlantsDocument8 pagesEOF: The Reliable Choice For Indian "Start-Up" Steel PlantsRitesh KumarNo ratings yet

- ME678 Sheet Metal Forming Yield LocusDocument20 pagesME678 Sheet Metal Forming Yield LocusKalpesh JadhavNo ratings yet

- Hydrostatic Extrusion, Theory and ApplicationsDocument6 pagesHydrostatic Extrusion, Theory and ApplicationsKarthik SholayNo ratings yet

- Al2O3 Material Properties GuideDocument3 pagesAl2O3 Material Properties GuideRing MasterNo ratings yet

- NTP 20Document1 pageNTP 20RBV DESIGN & BUILD SERVICESNo ratings yet

- 10908Document305 pages10908loginxscribdNo ratings yet

- PT SLAB VERIFICATIONDocument6 pagesPT SLAB VERIFICATIONAashu chaudharyNo ratings yet