Professional Documents

Culture Documents

Spec Sheet 3.5 DRILL PIPE 3.5

Uploaded by

alberto gomezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spec Sheet 3.5 DRILL PIPE 3.5

Uploaded by

alberto gomezCopyright:

Available Formats

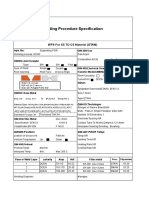

Drill Pipe Performance Sheet

9/11/2018

Pipe Body Specification Tool Joint Specification

Pipe Body OD in 3.5 Connection Type and Size NC38

Pipe Body Wall Thickness - Nominal Weight 0.368 in - 13.3 lb/ft Benchmark GPmark™

Pipe Body Grade S-135 SmoothEdge™ Height per side in N/A

Drill Pipe Length Range 2 Tool Joint SMYS psi 120,000

- Max ft 32.0 Connection OD in 5.0

- Min ft 30.0 Connection ID in 2.25

Type of Upset EU Pin Tong Length in 10.0

Max Upset OD in 3.875 Box Tong Length in 17.0

Tong Length includes hardbanding if applicable Thread Compound Friction Factor (FF) 1.0

Pipe Body Performance Tool Joint Performance

Nominal API Premium Max Make-Up Torque (Recommended) ft-lbs 14,900

80% Inspection Class 12,400

Min Make-Up Torque ft-lbs

Burst Pressure * psi 24,840 22,700

Min TJ OD (API Premium) in 4.813

Collapse Pressure * psi 25,400 21,630

Min TJ OD for Counterbore in 0.0

Slip Crushing Capacity * lbs 381,300 301,100

Drift Size in 2.125

- Assumed Slip Length in 16.5

The maximum make-up torque should be applied when possible.

- Assumed Transverse Load Factor (K) 4.2 To maximize connection operational tensile, a MUT (T4) = 12,900 should be applied.

Adjusted Weight ** lbs/ft 16.42

Fluid Displacement ** US gal/ft 0.25 Advisories and Warnings for Drill Pipe

Bbls/ft 0.006 Advisories:

Fluid Capacity ** US gal/ft 0.29 - Connection torsional strength is less than 80% pipe body torsional strength.

Bbls/ft 0.0069 Warnings:

* With no axial load or bending in string ** Best estimate with coating

Note: Oil field barrel equivalent to 42 US gal Note: Nominal burst calculated at 87.5% RBW per API

The Technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be consider as a

recommendation. The user is fully responsible for the accuracy and suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the

results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated based on uniform OD and wall

thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only

and does not represent or imply acceptable operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings,

acceptable use of the product, maintain safe operating practices, and to apply a prudent safety factor suitable for the application. For API connections that have different pin

and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

All references to any internal standards or specifications are per the current edition/revision at the point of manufacturing, unless otherwise stated. All references to any external standards or specifications are

per the current edition/revision at the original purchase order (P.O.) date, unless otherwise stated.

Grant Prideco L. P. | 10100 Houston Oaks Dr. | Houston, TX 77064 | www.nov.com/grantprideco 1

Drill Pipe Performance Sheet

9/11/2018

Combined Loading for Drill Pipe Connection Wear Table

Connection: NC38 5.0" x 2.25" (120 KSI SMYS ) Friction Factor: 1.0 Connection: NC38 5.0" x 2.25" (120 KSI SMYS ) Friction Factor: 1.0

Pipe: 3.5" OD 0.368" Wall Thickness S-135 80% Inspection Class Tool Joint OD (in) Max MUT(ft-lbs) Min MUT(ft-lbs)

At Max MUT (14900 ft-lbs ) At Min MUT (12400 ft-lbs ) 5.0 14900 12400

Operational Assembly Max Operational Assembly Max 4.932 14900 12400

Torque(ft-lbs) Tension(lbs) Torque(ft-lbs) Tension(lbs) 4.864 13700 11400

0 381900 0 381900 4.795 12400 10300

800 381700 700 381700 4.727 11200 9300

1600 381100 1300 381400 4.659 10000 8400

2300 380400 2000 380700 4.591 8900 7400

3100 379100 2600 379900 4.523 7800 6500

3900 377500 3300 378700 4.455 6700 5500

4700 375500 3900 377500 4.386 5600 4600

5500 373100 4600 375800 4.318 4500 3800

6300 370400 5200 374100 4.25 3500 2900

7000 367600 5900 371800

7800 364100 6500 369600 Elevator Capacity

8600 360100 7200 366800 Elevator Bore Diameter: 3.96875" Elevator SMYS: 110,100 psi Box Taper Angle: 18 deg

9400 355700 7800 364100 Connection: NC38 3.5" 0.368" wall EU S-135

10200 350900 8500 360600 Tool Joint OD (in.) Elevator Hoist Capacity (lbs)

10900 346300 9100 357400 No Wear 1/32" Wear Factor

11700 340500 9800 353400 5.0 799800 778300

12500 334300 10400 349600 4.932 741400 719800

13300 327500 11100 344900 4.864 683800 662200

14100 320100 11700 340500 4.795 626200 604600

14857 312500 12381 335200 4.727 570200 548600

4.659 515000 493400

4.591 460600 439000

The Technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be

consider as a recommendation. The user is fully responsible for the accuracy and suitability of use of the technical information. NOV Grant Prideco cannot assume

4.523 407000 385500

responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated 4.455 354200 332700

based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions 4.386 301400 279900

(remaining body wall) is for information only and does not represent or imply acceptable operating limits. It is the responsibility of the customer and the end user

4.318 250300 228700

to determine the appropriate performance ratings, acceptable use of the product, maintain safe operating practices, and to apply a prudent safety factor suitable

for the application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the drilling manual, it is

4.25 199900 178300

recommended that drilling torque should not exceed 80% of MUT.

All references to any internal standards or specifications are per the current edition/revision at the point of manufacturing, unless otherwise stated. All references to any external standards or specifications are

per the current edition/revision at the original purchase order (P.O.) date, unless otherwise stated.

Grant Prideco L. P. | 10100 Houston Oaks Dr. | Houston, TX 77064 | www.nov.com/grantprideco 2

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Bis-Dk-Ut 1152 - 1200-24-VC01Document6 pagesBis-Dk-Ut 1152 - 1200-24-VC01TomasPavlovicNo ratings yet

- 2012 - Coyote Catalogue PDFDocument10 pages2012 - Coyote Catalogue PDFtareq.sefatNo ratings yet

- Psychrometric Chart EditedDocument1 pagePsychrometric Chart EditedMelord RoneNo ratings yet

- AC100 Training Manual Ver 2 0 PDFDocument382 pagesAC100 Training Manual Ver 2 0 PDFما ضاقت الا لتفرج80% (5)

- 49HR Typical UndercarriageDocument4 pages49HR Typical UndercarriageJuan Pablo GutierrezNo ratings yet

- Application Note Synchronous Motors For Air Separation EN 9AKK105807 122012 FINAL LR PDFDocument2 pagesApplication Note Synchronous Motors For Air Separation EN 9AKK105807 122012 FINAL LR PDFksvvijNo ratings yet

- Electric Motor EE ST and L - EEA Comment Attended 22 July 2015Document193 pagesElectric Motor EE ST and L - EEA Comment Attended 22 July 2015gomeraNo ratings yet

- Transport Phenomena PaperDocument4 pagesTransport Phenomena Paperbhaskar5377100% (1)

- 600 KN Towing Winch ManualDocument173 pages600 KN Towing Winch ManualMartellusNo ratings yet

- Welding Procedure Specification: WPS For SS TO CS Material (GTAW)Document1 pageWelding Procedure Specification: WPS For SS TO CS Material (GTAW)Lipika GayenNo ratings yet

- Manual Book Dryer HRD350 PDFDocument112 pagesManual Book Dryer HRD350 PDFGoswandi0% (1)

- SaeDocument8 pagesSaeahmadNo ratings yet

- Sheet #6Document2 pagesSheet #6AHMED BAKRNo ratings yet

- Nota RobotDocument26 pagesNota RobotpnroslindaNo ratings yet

- Operation, Installation & Maintenance Manual For Diesel Engine Fire Pump Controller Automatic Controller Model GPDDocument74 pagesOperation, Installation & Maintenance Manual For Diesel Engine Fire Pump Controller Automatic Controller Model GPDAnoirNo ratings yet

- Poynting EffectDocument13 pagesPoynting EffectFernandocf90No ratings yet

- Ode - 21a2kv25Document2 pagesOde - 21a2kv25meomimi9457No ratings yet

- L001-04050-CX-4018-100239-1200 - SHT 354 of 400Document1 pageL001-04050-CX-4018-100239-1200 - SHT 354 of 400pawanNo ratings yet

- XE55DA: Hydraulic ExcavatorDocument2 pagesXE55DA: Hydraulic Excavatorproject adminNo ratings yet

- Fin Plate To Column Flange - LRFDDocument23 pagesFin Plate To Column Flange - LRFDkalpanaadhiNo ratings yet

- Hi-Lo and PRO-1 Pan Feeder PartsDocument86 pagesHi-Lo and PRO-1 Pan Feeder Partssergiu20No ratings yet

- Uk - Datasheets - 18032010vsmall FileDocument60 pagesUk - Datasheets - 18032010vsmall FileEka Jayalaksana0% (1)

- P01 24Document4 pagesP01 24Mohammad KhNo ratings yet

- Ficha TensoresDocument4 pagesFicha TensoresedgarNo ratings yet

- Wabco TEBS E2 ManualDocument238 pagesWabco TEBS E2 ManualVincent Price100% (2)

- Full File at Https://testbanku - eu/Solution-Manual-for-Engineering-Mechanics-Dynamics-2nd-Edition-by-TongueDocument273 pagesFull File at Https://testbanku - eu/Solution-Manual-for-Engineering-Mechanics-Dynamics-2nd-Edition-by-TongueMontoya UrquizaNo ratings yet

- 15056-Builder's WorkDocument5 pages15056-Builder's WorkAdamNo ratings yet

- Experiment - 06 - ViscosityDocument7 pagesExperiment - 06 - Viscosityadimegha0% (1)

- Medium & High Voltage and High Speed Motors PDFDocument16 pagesMedium & High Voltage and High Speed Motors PDFSandeep SinghNo ratings yet

- Removing and Installing Toothed BeltDocument12 pagesRemoving and Installing Toothed BeltJulien VasilevNo ratings yet