Professional Documents

Culture Documents

Bis-Dk-Ut 1152 - 1200-24-VC01

Uploaded by

TomasPavlovicOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bis-Dk-Ut 1152 - 1200-24-VC01

Uploaded by

TomasPavlovicCopyright:

Available Formats

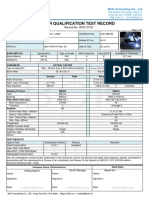

Ultrasonic (Wall Thickness) Inspection Report

Inspection Details

Client INEOS Report No. BIS-DK-UT 1152

Project CS-2038891 Location SIRI

Contract No. TBC PO/Request No. 4501070170

Test Date 25.04.2022 Workpack No. RBI 2022

Part Description UT inspection of 1200-24-VC01 Glycol reboiler

Drawing No. N/A Line No. 1200-24-VC01 Glycol reboiler

P & ID Drawing No. C080-DONG-EM405-P-XC-2402-01 Location / System Level 1

Material Type Carbon Steel Material Thickness TBC

External Coating Painted Surface Temperature 220 deg celcius

Equipment, Technique & Application Method

Procedure No. SAL-INP-NDT-PRO-059: UT Thickness Measurement Ver No. 5

Technique No. T/EN/UT/01A - Spot Check Thickness Measurement Ver No. 5

Technique Std BS EN ISO 16809 Acceptance Criteria as per Client

Temp. Correction N/A Test Mode(s) N/A

Test Restrictions Tempetrature

Manufacturer Model SAL ID Couplant

Flaw Detector Equipment

Olympus Epoch M600 20083 UCA 2

Calibration Block Type SAL ID

5-25mm Carbon Steel Stepwedge 20/21/01

Calibration Block Type

Reference Block Type SAL ID

Basic Transfer Scan

Crystal Size Frequency Timebase

Serial No. Type Angle (°) Sensitivity Correction Sensitivity

(mm) (MHz) Range (mm)

(db) (db) (db)

38390 TC 5/10 0 10 5 50

Control Checks

✘ Visual Angle Index ✘ Sig/Noise Ratio ✘ Vertical Linearity ✘ Pulsed Duration

By marking the equipment/probe check boxes you are confirming the checks have been carried out in accordance

with the applicable procedure appendix and that the results are satisfactory for all equipment and probes used.

Inspection Summary

Scope - Brief Summary of task

UT inspection was carried out on the glycol reboiler for corrosion monitoring

Result Summary - Overview of inspection findings

The UT inspection shows no significant corrosion spots

Restrictions - Elaborate on test restrictions

No restrictions

Technician (Print) Technician Signature Qualifications Date

Morgan Ehrlich Morgan Ehrlich PCN L2 25.04.2022

Client (Print) Client Signature Management Approval

UNCONTROLLED IF PRINTED

Inspection NDT SAL-INP-NDT-TEM-022 V 2 Application as from 21/12/2021

Applicable Procedure Ref Multiple UT Technical Procedues

Page 1 of 6

Ultrasonic (Wall Thickness) Inspection Report

Bilfinger UK Ltd, 4 Greenhole Place, Bridge of Don, Aberdeen, AB23 8EU | Tel: +44 1224 246100

UNCONTROLLED IF PRINTED

Inspection NDT SAL-INP-NDT-TEM-022 V 2 Application as from 21/12/2021

Applicable Procedure Ref Multiple UT Technical Procedues

Page 2 of 6

Ultrasonic (Wall Thickness) Inspection Report

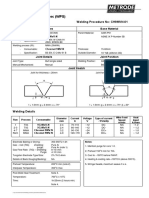

UT Results Table

Client INEOS Report No. BIS-DK-UT 1152

Min Reading Location

Examination Point / Test Surface Nominal Fresh Thickness Min WT

EWL cat. TWL cat. X Y Comments

Feature ID Geometry Condition WT (mm) (mm) (mm) Datum

(mm) (mm)

N1 P F - - - 15.6 14 Missing NT

N4 P F - - - 6.2 5.8 Missing NT

H1 S F - - - 14.8 14 Missing NT

H2 S F - - - 16 15.3 Missing NT

S2 S F - - - 23.2 22.8 Missing NT

S3 S F - - - 23.2 23 Missing NT

R1 S F - - - 22.5 22.2 Missing NT

M1 S F - - - 15.6 15.2 Missing NT

Key to Acronyms

B = Bend P = Pipe Straight EXC = External Corrosion LAM = Laminations R = Restriction due to….

C = Cap R = Reducer IP = Internal Pitting NT = No Test Due to…

S = Tank Shell V = Vessel IC = Internal Corrosion

F = Flange T = Tee MII = Minor Isolated Inclusions

Surface Condition

G = GOOD F = FAIR P = POOR VP = VERY POOR

As or close to original Condition ≥90% Minor deterioration - approximately 75-90% Deterioration resulting in approximately 50- Significant deterioration resulting in <50% test

Coverage achievable test coverage achievable 75% test coverage achievable coverage achievable

UNCONTROLLED IF PRINTED

Inspection NDT SAL-INP-NDT-TEM-022 V 2 Application as from 21/12/2021

Applicable Procedure Ref Multiple UT Technical Procedues

Page 3 of 6

Ultrasonic (Wall Thickness) Inspection Report

Bilfinger UK Ltd, 4 Greenhole Place, Bridge of Don, Aberdeen, AB23 8EU | Tel: +44 1224 246100

UNCONTROLLED IF PRINTED

Inspection NDT SAL-INP-NDT-TEM-022 V 2 Application as from 21/12/2021

Applicable Procedure Ref Multiple UT Technical Procedues

Page 4 of 6

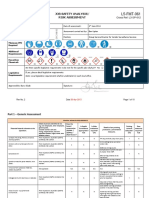

Ultrasonic (Wall Thickness) Inspection Report

Photograph Page

Client INEOS Report No. BIS-DK-UT 1152

Photo 1 - Stand-off picture of the vessel Photo 2 - close-up picture of the cladding removed

Photo 3 - Showing the cladding removed on the nozzle Photo 4 -

Photo 5 - Photo 6 -

UNCONTROLLED IF PRINTED

Inspection NDT SAL-INP-NDT-TEM-022 V 2 Application as from 21/12/2021

Applicable Procedure Ref Multiple UT Technical Procedues

Page 5 of 6

Ultrasonic (Wall Thickness) Inspection Report

Bilfinger UK Ltd, 4 Greenhole Place, Bridge of Don, Aberdeen, AB23 8EU | Tel: +44 1224 246100

UNCONTROLLED IF PRINTED

Inspection NDT SAL-INP-NDT-TEM-022 V 2 Application as from 21/12/2021

Applicable Procedure Ref Multiple UT Technical Procedues

Page 6 of 6

You might also like

- CWI - Part A Fundamentals Examination (Full) PDFDocument43 pagesCWI - Part A Fundamentals Examination (Full) PDFJulian Ramirez Ospina100% (4)

- Welding Procedure Qualification Record: Shipyard LogoDocument4 pagesWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- JSA For Rope Access Services (24-Sep-14)Document8 pagesJSA For Rope Access Services (24-Sep-14)TomasPavlovic100% (1)

- Material Inspected This Visit Item Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoDocument3 pagesMaterial Inspected This Visit Item Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoRahul MoottolikandyNo ratings yet

- Procurement Services: Industry & Facilities DivisionDocument6 pagesProcurement Services: Industry & Facilities DivisionVikas Mani TripathiNo ratings yet

- Bluewater MIR Roc Master CPP IR 003 (Jun.20 PDFDocument8 pagesBluewater MIR Roc Master CPP IR 003 (Jun.20 PDFANIL PLAMOOTTIL100% (1)

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 pagesCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNo ratings yet

- Sabari Engineering PQRDocument3 pagesSabari Engineering PQRAdvanced Quality Centre AQC100% (1)

- 2037-PL-PL-0058-FR-T-025 Dated 18.12.19Document12 pages2037-PL-PL-0058-FR-T-025 Dated 18.12.19Dadaso Baburao JamdarNo ratings yet

- Native Inspection - Report - CleanedDocument6 pagesNative Inspection - Report - CleanedPrathamesh OmtechNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- WPS DetailsDocument7 pagesWPS DetailsMAT-LIONNo ratings yet

- WPS SAW D1.1 2015 FormDocument1 pageWPS SAW D1.1 2015 FormHoque AnamulNo ratings yet

- Ultrasonic Test Report: Before AfterDocument7 pagesUltrasonic Test Report: Before AfterMenad SalahNo ratings yet

- 10.LPI. Report FormatDocument1 page10.LPI. Report FormatEr Sumant Kumar SinghNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- Oil India Tender for Supply of Drill PipesDocument13 pagesOil India Tender for Supply of Drill Pipesifebrian100% (1)

- Review of GTAW Welding ParametersDocument14 pagesReview of GTAW Welding Parameterskervyn SáenzNo ratings yet

- CV of Engineer MD Sazid Alam1Document8 pagesCV of Engineer MD Sazid Alam1Alam MD SazidNo ratings yet

- Dodsal Pte Ltd Q-Chem Project Doha, Qatar Job No 7979 Welder Qualification RecordDocument1 pageDodsal Pte Ltd Q-Chem Project Doha, Qatar Job No 7979 Welder Qualification RecordproxywarNo ratings yet

- 21.02.15 Tuv Visit ReportDocument5 pages21.02.15 Tuv Visit ReportssmullaNo ratings yet

- Coflexip Hose (Tr1-031851clm301)Document1 pageCoflexip Hose (Tr1-031851clm301)RonniNo ratings yet

- P. WpsDocument14 pagesP. WpsIsmiArdyNo ratings yet

- Wheel Loader Forklift Thorough Exam ReportDocument2 pagesWheel Loader Forklift Thorough Exam ReportRanjithNo ratings yet

- Material Receiving Inspection Report: Project TitleDocument2 pagesMaterial Receiving Inspection Report: Project TitleGomathyselviNo ratings yet

- RFI Welding TestDocument18 pagesRFI Welding TestDimas agungNo ratings yet

- Weld Repairs:: 1) Production Repairs 2) In-Service RepairsDocument4 pagesWeld Repairs:: 1) Production Repairs 2) In-Service RepairsEhsan KhanNo ratings yet

- Ir 5073 Ppa 005Document6 pagesIr 5073 Ppa 005ValiNo ratings yet

- 2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDDocument9 pages2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDSripathi SeetharamanNo ratings yet

- Duqm Refinery Project EPC Package 2 - Utilities and OffsitesDocument2 pagesDuqm Refinery Project EPC Package 2 - Utilities and OffsitesDadaso Baburao JamdarNo ratings yet

- IRN - 18.07.2019 - Harshad Panchal - Revision-0 - Furnace Fabrica - JNK - PORVAIR - RIL PDFDocument3 pagesIRN - 18.07.2019 - Harshad Panchal - Revision-0 - Furnace Fabrica - JNK - PORVAIR - RIL PDFsaptarshi jashNo ratings yet

- Welder Qualification Test Record for NDBDocument1 pageWelder Qualification Test Record for NDBAli HammoudaNo ratings yet

- Near Bit Stabilizer PDS 6716 ...Document1 pageNear Bit Stabilizer PDS 6716 ...khalilNo ratings yet

- WPS - 006Document13 pagesWPS - 006MAT-LIONNo ratings yet

- REPORT-MT 21.10.2022 (Test)Document2 pagesREPORT-MT 21.10.2022 (Test)Nhien ManNo ratings yet

- WPS - 008Document11 pagesWPS - 008MAT-LIONNo ratings yet

- Variable E SE NE Description of Variable As in Code 2011a QW SMAW Welding Variables For WPS - ASME Sec IX 2011aDocument7 pagesVariable E SE NE Description of Variable As in Code 2011a QW SMAW Welding Variables For WPS - ASME Sec IX 2011aSaut Maruli Tua SamosirNo ratings yet

- E-Mail Transmission: TO: Transmittal Ref. No.Document7 pagesE-Mail Transmission: TO: Transmittal Ref. No.Rahul MoottolikandyNo ratings yet

- STIR (Surface Treatment Inspection) Qaqc-003Document1 pageSTIR (Surface Treatment Inspection) Qaqc-003AliDadKhanNo ratings yet

- WeldDocs WPSDocument2 pagesWeldDocs WPSMDSIKKU_2005No ratings yet

- Flash Report-2016-2-16Document3 pagesFlash Report-2016-2-16sujinlongNo ratings yet

- Sample Wps Carbon Steel GTAW SMAW PDFDocument2 pagesSample Wps Carbon Steel GTAW SMAW PDFirwanNo ratings yet

- 1.wash Pipe 8-1-8 SN NNDocument1 page1.wash Pipe 8-1-8 SN NNMuhammad Rijal sembiringNo ratings yet

- Alstom IRDocument4 pagesAlstom IRkasi reddyNo ratings yet

- API Welding ProcedureDocument2 pagesAPI Welding ProcedureSamarakoon BandaNo ratings yet

- Liquid Penetrant Test Record: Examinaion DetailsDocument1 pageLiquid Penetrant Test Record: Examinaion DetailschandraNo ratings yet

- INSPECTION REPORTDocument3 pagesINSPECTION REPORTsheikmoinNo ratings yet

- Summary TER of 13 Unit 20FT ISO Dry ContainerDocument219 pagesSummary TER of 13 Unit 20FT ISO Dry ContainerGhilman0529No ratings yet

- Dye Penetrant Inspection - Wikipedia, The Free EncyclopediaDocument5 pagesDye Penetrant Inspection - Wikipedia, The Free Encyclopediaviswamanoj100% (1)

- Journal BeringDocument8 pagesJournal BeringpelakupasarNo ratings yet

- Procedure Qualification Record (PQR) FormDocument1 pageProcedure Qualification Record (PQR) FormEarl HarbertNo ratings yet

- Welding Procedure Specifications for P91 Butt WeldsDocument6 pagesWelding Procedure Specifications for P91 Butt WeldssrinivasanNo ratings yet

- WPS - 007Document11 pagesWPS - 007MAT-LIONNo ratings yet

- WQT Form (ASME) 04-23Document1 pageWQT Form (ASME) 04-23hanz bermejoNo ratings yet

- NTPC Ge Power Services PVT LTD: Liquid Penetrant Examination ReportDocument2 pagesNTPC Ge Power Services PVT LTD: Liquid Penetrant Examination ReportBalkishan DyavanapellyNo ratings yet

- Industry & Facilities Inspection ReportDocument10 pagesIndustry & Facilities Inspection Reportkbpatel123No ratings yet

- Dimensional Check-Form 3TDocument3 pagesDimensional Check-Form 3Tlempeng durianNo ratings yet

- WPQT FormatDocument176 pagesWPQT FormatRafiqKu50% (2)

- WPS for Groove Welds in ASTM A36 SteelDocument2 pagesWPS for Groove Welds in ASTM A36 SteelNuril VS theWorldNo ratings yet

- Proposed Welding Procedure Specification (PWPS) : REV:A3Document1 pageProposed Welding Procedure Specification (PWPS) : REV:A3Shanawas Abdul RazakNo ratings yet

- Bis-Dk-Ut 1149 - C081-Ip2022-Na-1Document6 pagesBis-Dk-Ut 1149 - C081-Ip2022-Na-1TomasPavlovicNo ratings yet

- Ultrasonic Inspection ReportDocument3 pagesUltrasonic Inspection ReportTomasPavlovicNo ratings yet

- 1200 26 PV 13 API CML Markup and TableDocument6 pages1200 26 PV 13 API CML Markup and TableTomasPavlovicNo ratings yet

- Bis-Dk-Rt-1051 - Ip2022-NaDocument2 pagesBis-Dk-Rt-1051 - Ip2022-NaTomasPavlovicNo ratings yet

- Bis-Dk-Rt-1051 - Ip2022-NaDocument2 pagesBis-Dk-Rt-1051 - Ip2022-NaTomasPavlovicNo ratings yet

- Ultrasonic Inspection ReportDocument3 pagesUltrasonic Inspection ReportTomasPavlovicNo ratings yet

- Bis-Dk-Rt-1051 - Ip2022-NaDocument2 pagesBis-Dk-Rt-1051 - Ip2022-NaTomasPavlovicNo ratings yet

- Bis-Dk-Rt-1051 - Ip2022-NaDocument2 pagesBis-Dk-Rt-1051 - Ip2022-NaTomasPavlovicNo ratings yet

- Bis-Dk-Rt-1049 - Ip2022-CeDocument2 pagesBis-Dk-Rt-1049 - Ip2022-CeTomasPavlovicNo ratings yet

- Bis-Dk-Mt 2107 - Eq 10520337Document5 pagesBis-Dk-Mt 2107 - Eq 10520337TomasPavlovicNo ratings yet

- Games Are Exciting BookDocument61 pagesGames Are Exciting BookctjazilaNo ratings yet

- L5-FMT-086 (Rev 2) Residential Inspection TimesheetDocument2 pagesL5-FMT-086 (Rev 2) Residential Inspection TimesheetTomasPavlovicNo ratings yet

- JSA For Painting and Coating Activities (24-Sep-14)Document6 pagesJSA For Painting and Coating Activities (24-Sep-14)TomasPavlovic100% (1)

- Bis-Dk-Rt-1047 - Ip2022-CeDocument2 pagesBis-Dk-Rt-1047 - Ip2022-CeTomasPavlovicNo ratings yet

- Bis-Dk-Ut 1149 - C081-Ip2022-Na-1Document6 pagesBis-Dk-Ut 1149 - C081-Ip2022-Na-1TomasPavlovicNo ratings yet

- Applus Velosi Code of Conduct PolicyDocument3 pagesApplus Velosi Code of Conduct PolicyTomasPavlovicNo ratings yet

- Installing Your Smart Thermostat by Yourself: Good To KnowDocument1 pageInstalling Your Smart Thermostat by Yourself: Good To KnowTomasPavlovicNo ratings yet

- L6-OGN-113 (Rev 0) Travel SecurityDocument14 pagesL6-OGN-113 (Rev 0) Travel SecurityTomasPavlovicNo ratings yet

- L1-POL-03 (Rev 6) Discrimination PolicyDocument3 pagesL1-POL-03 (Rev 6) Discrimination PolicyTomasPavlovicNo ratings yet

- L6-TGN-070 (Rev 1) TransducersDocument7 pagesL6-TGN-070 (Rev 1) TransducersTomasPavlovicNo ratings yet

- JSA For Vendor Surveillance Services (04-Jun-14)Document10 pagesJSA For Vendor Surveillance Services (04-Jun-14)TomasPavlovicNo ratings yet

- L1-POL-02 Narcotics Alcohol and Intoxicating Substances Abuse RevDocument2 pagesL1-POL-02 Narcotics Alcohol and Intoxicating Substances Abuse RevTomasPavlovicNo ratings yet

- Bridges & Potentiometers Inspection GuideDocument6 pagesBridges & Potentiometers Inspection GuideTomasPavlovicNo ratings yet

- L6-TGN-073 (Rev 1) Electronic Measuring EquipmentDocument7 pagesL6-TGN-073 (Rev 1) Electronic Measuring EquipmentTomasPavlovicNo ratings yet

- L6-TGN-102 (Rev 1) Types of Test Certificates-ReportsDocument32 pagesL6-TGN-102 (Rev 1) Types of Test Certificates-ReportsTomasPavlovicNo ratings yet

- L6-TGN-100 (Rev 1) Oil Wells Offshore PlatformsDocument26 pagesL6-TGN-100 (Rev 1) Oil Wells Offshore PlatformsTomasPavlovicNo ratings yet

- L6-TGN-096 (Rev 0) Inspection in ManufacturingDocument6 pagesL6-TGN-096 (Rev 0) Inspection in ManufacturingTomasPavlovicNo ratings yet

- Inspect Power Supplies GuidelineDocument10 pagesInspect Power Supplies GuidelineTomasPavlovicNo ratings yet

- L6-TGN-103 (Rev 1) Pipe (Fluid Conveyance)Document14 pagesL6-TGN-103 (Rev 1) Pipe (Fluid Conveyance)TomasPavlovicNo ratings yet

- L6-TGN-096 (Rev 0) Inspection in ManufacturingDocument6 pagesL6-TGN-096 (Rev 0) Inspection in ManufacturingTomasPavlovicNo ratings yet

- Oil Well Drilling Methods: University of Karbala College of Engineering Petroleum Eng. DepDocument8 pagesOil Well Drilling Methods: University of Karbala College of Engineering Petroleum Eng. DepAli MahmoudNo ratings yet

- Kitne PakistanDocument2 pagesKitne PakistanAnkurNo ratings yet

- Pharmaceutical and Software Development ProjectsDocument6 pagesPharmaceutical and Software Development ProjectsAlexandar123No ratings yet

- Does Cash App Have Business Accounts - Google SeaDocument1 pageDoes Cash App Have Business Accounts - Google SeaAdedayo CrownNo ratings yet

- Daftar Obat Alkes Trolley EmergencyDocument10 pagesDaftar Obat Alkes Trolley EmergencyMaya AyuNo ratings yet

- Herbivoría y Cristales de CaOxDocument33 pagesHerbivoría y Cristales de CaOxBrain LongwoodNo ratings yet

- Zero-Force Members: Hapter Tructural NalysisDocument3 pagesZero-Force Members: Hapter Tructural NalysistifaNo ratings yet

- Rogers Lacaze Case InfoDocument1 pageRogers Lacaze Case InfomakeawishNo ratings yet

- Importance of Plants in Our LivesDocument47 pagesImportance of Plants in Our LivesAlanie Grace Beron TrigoNo ratings yet

- Three Thousand Years of Longing 2022Document93 pagesThree Thousand Years of Longing 2022Ppper pepperNo ratings yet

- Parenteral Fluid Therapy: Types of Intravenous SolutionDocument18 pagesParenteral Fluid Therapy: Types of Intravenous SolutionKathleen Joy Costales Magtanong100% (1)

- Example For Chapter - 2Document16 pagesExample For Chapter - 2sahle mamoNo ratings yet

- Solution Map For Mining ppt3952 PDFDocument29 pagesSolution Map For Mining ppt3952 PDFHans AcainNo ratings yet

- Lauren Tarshis - (I Survived 05) - I Survived The San Francisco Earthquake, 1906Document66 pagesLauren Tarshis - (I Survived 05) - I Survived The San Francisco Earthquake, 1906Olga de Ramos100% (1)

- Literature Review On OscilloscopeDocument5 pagesLiterature Review On Oscilloscopedhjiiorif100% (1)

- Salon Lesson Plan 233-1Document7 pagesSalon Lesson Plan 233-1api-264569989No ratings yet

- Drewry Capability StatementDocument9 pagesDrewry Capability Statementmanis_sgsNo ratings yet

- Pharmaco-pornographic Politics and the New Gender EcologyDocument14 pagesPharmaco-pornographic Politics and the New Gender EcologyMgalo MgaloNo ratings yet

- A-PDF Watermark DEMO Purchase RemoveDocument4 pagesA-PDF Watermark DEMO Purchase RemoveGaurav JoshiNo ratings yet

- Valvula Contrabalance CBV1 10 S O A 30Document21 pagesValvula Contrabalance CBV1 10 S O A 30Judith Daza SilvaNo ratings yet

- The Impact of Interest Rates On Economic Growth in KenyaDocument41 pagesThe Impact of Interest Rates On Economic Growth in KenyaSAMUEL KIMANINo ratings yet

- Knowledge, Attitudes and Practices of Nursing Students on Dengue FeverDocument9 pagesKnowledge, Attitudes and Practices of Nursing Students on Dengue FeverElinNo ratings yet

- ECF/SSF : 08 : 11: Rotex Double Rack and Pinion Actuator SeriesDocument20 pagesECF/SSF : 08 : 11: Rotex Double Rack and Pinion Actuator SeriesProcess Controls & ServicesNo ratings yet

- German UnificationDocument40 pagesGerman UnificationJosephlangeloNo ratings yet

- Case StudiesDocument19 pagesCase StudiesSorin MarkovNo ratings yet

- Physics Universe ModelsDocument14 pagesPhysics Universe ModelsTracy zorca50% (2)

- Feminist Criticism in Frankenstein, Equus and The Turn of The ScrewDocument4 pagesFeminist Criticism in Frankenstein, Equus and The Turn of The ScrewLucia ToledoNo ratings yet

- Palm Kernel Reinforced Composites for Brake Pad ApplicationsDocument18 pagesPalm Kernel Reinforced Composites for Brake Pad ApplicationsSachin SukumaranNo ratings yet

- Unofficial Fanbook Made With Permission - Incar-NationDocument24 pagesUnofficial Fanbook Made With Permission - Incar-NationBrockPetersdorf-Nelson100% (1)