Professional Documents

Culture Documents

PreStressing Methodology.123

PreStressing Methodology.123

Uploaded by

Anup SrivastavaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PreStressing Methodology.123

PreStressing Methodology.123

Uploaded by

Anup SrivastavaCopyright:

Available Formats

METHOD STATEMENT OF PRE-STRESSING

IS 14268 : 1995

Uncoated stress relieved low Relaxation seven-Ply strand for Pre-stressed concrete-

Specification

1.0 Reference Documents:

IS 14268 : 1995

Uncoated stress relieved low Relaxation seven-Ply strand for Pre-stressed

concrete- Specification

IRC:22-2015

Standard Specifications and Code of Practice for Road Bridges, Section VI – Composite

Construction (Limit States Design) (Third Revision) Durability Provisions for Reinforced &

Pre stressed Concrete Structures” by Indian Institution of Bridge Engineers- 1994.

Note; IRC Codes and Guidelines maybe subject to review

01. Prestressing Steel

The pre stressing system used shall be VSL system or DSI system or any other equivalent

approved system. The following are defined for the pre stressing system:• Multi-strand

system comprising the required number of strands in a circular duct. • Anchorage and

coupling system for the anchoring of the pre stressing forces at the ends or for continuing

the force by coupling. • Internal tendons comprising of High Density Polyethylene (HDPE)

sheathing around the strands of bars, external to the concrete shall be used. Once the force

is locked off, the orifice is filled with cementitious grout for corrosion protection as well as

for bonding of the strands to the concrete to form a bonded system. For pre stressing

strands, 7 wire low-relaxation strands complying with IS: 14268-1995 or

IRC 112-2011 whichever appropriate, will be used. The following strand types are proposed

to be used on the project according to the details and design requirements for various

structure types. Material property Normal Strands Strand Type Uncoated stress relieved low

relaxation Class II conforming to IS 14268 Yield strength (MPa) 1560 Ultimate strength

(MPa) 1770 The breaking strength 0.2 % proof load Young’s Modulus (GPa) 195 Relaxation

(After 1000h) Maximum 4.5% Other Design Parameters of Strands shall be as per IRC 112.

You might also like

- Design of Transient Protection Systems: Including Supercapacitor Based Design Approaches for Surge ProtectorsFrom EverandDesign of Transient Protection Systems: Including Supercapacitor Based Design Approaches for Surge ProtectorsNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- C645 Nonstructural Steel Framing PDFDocument6 pagesC645 Nonstructural Steel Framing PDFkatubelitos100% (1)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- LMK CatalogueDocument21 pagesLMK Cataloguebignose93gmail.comNo ratings yet

- Bridge Technology: Post-Tensioning Tendon Installation and Grouting ManualDocument91 pagesBridge Technology: Post-Tensioning Tendon Installation and Grouting Manualvikasharma_eeNo ratings yet

- HKKJRH Ekud HKKJRH Ekud HKKJRH Ekud HKKJRH Ekud HKKJRH EkudDocument16 pagesHKKJRH Ekud HKKJRH Ekud HKKJRH Ekud HKKJRH Ekud HKKJRH EkudRajesh GangwalNo ratings yet

- Prestressing Principles TypesDocument19 pagesPrestressing Principles TypeshimanshiNo ratings yet

- Aalami CI Mar03 PaperDocument7 pagesAalami CI Mar03 PaperWalter CastilloNo ratings yet

- Chapter 2 - Post-Tensioning.Document13 pagesChapter 2 - Post-Tensioning.SaiMinMinNo ratings yet

- 16 PTIRecommendationsforStayCableDesignTestingandInstallationDocument23 pages16 PTIRecommendationsforStayCableDesignTestingandInstallationBeratErtekin100% (1)

- PSC Lecture NotesDocument32 pagesPSC Lecture NotesHaider Shah100% (1)

- FREYSSINET Prestress ManualDocument53 pagesFREYSSINET Prestress Manualras_deep100% (2)

- Helvetas NepalDocument2 pagesHelvetas NepalThapaliya BishalNo ratings yet

- 11 RDSOSpec3 - 4 - 5 - 6Document80 pages11 RDSOSpec3 - 4 - 5 - 6Anubhav Hem Kumar JainNo ratings yet

- EN14399-HS Bolted Assemblies For PreloadingDocument8 pagesEN14399-HS Bolted Assemblies For Preloadinggabimaier31No ratings yet

- 2.ti SPC Ohe Inscom 1071Document45 pages2.ti SPC Ohe Inscom 1071suresh kumarNo ratings yet

- Is 9523Document78 pagesIs 9523Anonymous XBq5J840% (1)

- Section05 PDFDocument140 pagesSection05 PDFDr. MOHAMED ALZAINNo ratings yet

- Lab Mannual PRC Final 1Document32 pagesLab Mannual PRC Final 1Khalil AhmedNo ratings yet

- Ti SPC Ohe Inscom 107Document44 pagesTi SPC Ohe Inscom 107mukeshhNo ratings yet

- Section - 15140 Supports&AnchorsDocument11 pagesSection - 15140 Supports&AnchorsNana DelgadoNo ratings yet

- Section-Viii: Composite Long Rod InsulatorDocument33 pagesSection-Viii: Composite Long Rod Insulatorsaravanan jNo ratings yet

- Rail - Design and Rating PDFDocument7 pagesRail - Design and Rating PDFCK TangNo ratings yet

- ITEM 564.00010001 - Bridge Hanger Fabrication and InstallationDocument14 pagesITEM 564.00010001 - Bridge Hanger Fabrication and InstallationKY PengNo ratings yet

- HKKJRH Ekud HKKJRH Ekud HKKJRH Ekud HKKJRH Ekud HKKJRH EkudDocument16 pagesHKKJRH Ekud HKKJRH Ekud HKKJRH Ekud HKKJRH Ekud HKKJRH EkudOMEGA CONSULTANT SERVICESNo ratings yet

- Design of RCC Building ComponentsDocument66 pagesDesign of RCC Building Componentsasdfg1h78% (9)

- Specification For 1070 SeriesDocument16 pagesSpecification For 1070 SeriesHesham FandyNo ratings yet

- Method Statement For Manufacturing and Standard Specifications For P.C PilesDocument2 pagesMethod Statement For Manufacturing and Standard Specifications For P.C PilesPriodeep ChowdhuryNo ratings yet

- APTRANSCO Spec - 11KV Polymer Insulators (C&T) RevisedDocument13 pagesAPTRANSCO Spec - 11KV Polymer Insulators (C&T) RevisedAshutosh SharmaNo ratings yet

- Modeling Pre and Post Tensioned Concrete: 14 International LS-DYNA Users ConferenceDocument22 pagesModeling Pre and Post Tensioned Concrete: 14 International LS-DYNA Users ConferenceSony JsdNo ratings yet

- specSPCT00rev01 PDFDocument10 pagesspecSPCT00rev01 PDFharsh_1582No ratings yet

- Design Philosophy JHANSIDocument6 pagesDesign Philosophy JHANSIManinder ChaudharyNo ratings yet

- Tieback Anchors - 1.24.11Document7 pagesTieback Anchors - 1.24.11xcvNo ratings yet

- VicRoads Bridge Design Technical NotesDocument111 pagesVicRoads Bridge Design Technical NotesJunnoKaiserNo ratings yet

- Annexure 2A - Prestressing - VOLUME 5-69-84Document16 pagesAnnexure 2A - Prestressing - VOLUME 5-69-84ManukantShrotriyaNo ratings yet

- Pipe Supports IP 4-2-2: ScopeDocument3 pagesPipe Supports IP 4-2-2: ScopeSixto Gerardo Oña AnaguanoNo ratings yet

- Foundation Design Calculation GondaDocument6 pagesFoundation Design Calculation GondaManinder ChaudharyNo ratings yet

- Design Philosophy GONDADocument6 pagesDesign Philosophy GONDAManinder Chaudhary0% (1)

- Connection TypeDocument9 pagesConnection Typesmelihates100% (1)

- Iso 6935 3 1992Document9 pagesIso 6935 3 1992alfred112352No ratings yet

- Design of Composite BridgeDocument10 pagesDesign of Composite BridgeHarold Jackson MtyanaNo ratings yet

- Freyssibar: The Prestressing Bar For Civil WorksDocument12 pagesFreyssibar: The Prestressing Bar For Civil WorksJustin CorbettNo ratings yet

- A Case Study On Pre-Tensioning & Post Tensioning Systems of A Prestressed ConcreteDocument6 pagesA Case Study On Pre-Tensioning & Post Tensioning Systems of A Prestressed ConcreteSHEKHARNo ratings yet

- Prestressed Concrete StructuresDocument32 pagesPrestressed Concrete StructuresMâjñù MâjñúNo ratings yet

- Laying of DWC PipesDocument56 pagesLaying of DWC Pipessatyam50% (2)

- Tower AccessoriesDocument2 pagesTower AccessoriesmulualemNo ratings yet

- Oib Technical Spec 21,22,23Document586 pagesOib Technical Spec 21,22,23kali highNo ratings yet

- PrestressingDocument44 pagesPrestressingPravin100% (1)

- Prestressing Concept and Prestressing System by Mohammed Mudabir Ul HaqueDocument32 pagesPrestressing Concept and Prestressing System by Mohammed Mudabir Ul HaqueMudabirNo ratings yet

- Info Iec61109 (Ed1.0) en D.imgDocument8 pagesInfo Iec61109 (Ed1.0) en D.imgbagheldhirendraNo ratings yet

- Is 7098 Part I 1998Document17 pagesIs 7098 Part I 1998Sanjeev DhariwalNo ratings yet

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

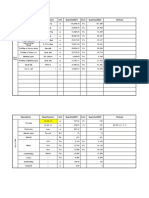

- TYPE-1 Total Nos. of Segments: 556Document1 pageTYPE-1 Total Nos. of Segments: 556Anup SrivastavaNo ratings yet

- 1.2 BOQ of SeawallDocument18 pages1.2 BOQ of SeawallAnup SrivastavaNo ratings yet

- Main Bridge 2-2, Total Nos. of Segments: 278X2 556 (Lws & RWS) Both SideDocument2 pagesMain Bridge 2-2, Total Nos. of Segments: 278X2 556 (Lws & RWS) Both SideAnup SrivastavaNo ratings yet

- PPN Network - Declaration by Patient/patient's AttendantDocument20 pagesPPN Network - Declaration by Patient/patient's AttendantAnup SrivastavaNo ratings yet

- Machine ReportDocument13 pagesMachine ReportAnup SrivastavaNo ratings yet

- PPN Network - Declaration FormDocument1 pagePPN Network - Declaration FormAnup SrivastavaNo ratings yet

- MS of Segment Casting - 12345Document7 pagesMS of Segment Casting - 12345Anup SrivastavaNo ratings yet