Professional Documents

Culture Documents

Trunnion Trim Code Guide

Uploaded by

sanjayOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Trunnion Trim Code Guide

Uploaded by

sanjayCopyright:

Available Formats

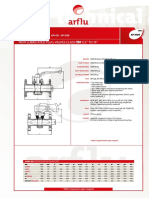

TRUNNION MOUNTED BALL VALVES 03

TRIM CODE GUIDE

Size

2, 3, 4, 6, 8, 10, 12, 14, 16, 18, 20, 22, 24, 30, 36

Bore

6 – Full Port

5 – Reduced Port

Pressure

15 – Class 150 90 – Class 900

30 – Class 300 50 – Class 1500

60 – Class 600 25 – Class 2500

Body

5 – CS A216 WCB or A105

6 – SS CF8M or A182 F316

7 – CS LCC or A350LF2 (Low Temp)

8 – Duplex SS

Model

T2 – 2 Pc Cast T3 – 3 Pc Forged

Trim

5 – CS/ENP WCB or A105

6 – SS CF8M or A182 316SS

7 – CS/ENP (3 Mil) LCC or A350 LF2

8 – Duplex SS

Seats

D – Devlon N – Nylon

T – RTFE P – Peek

Seals

H – HNBR V – VITON

A – AFLAS E – ELAST-O-LION

B – BUNA

Ends

R – RF WR – W x RF

J – RTJ WJ – W x RTJ

W – Weld End

Operation

L – Lever

G – Gear Operator

B – Bare Stem

8 6 60 5 T2 5 D H R G NOTE: All Warren Trunnion Mounted Ball Valves meet

NACE MR 0175/ISO 15156 Latest Edition and API 607

Fire Safe as a standard.

Example

You might also like

- Factory & Office Tel. 055-325-5612 4 Fax. 055-325-5615 E-Mail: Cephas@cephasvalve - Co.kr Seoul OfficeDocument12 pagesFactory & Office Tel. 055-325-5612 4 Fax. 055-325-5615 E-Mail: Cephas@cephasvalve - Co.kr Seoul OfficeFahmi HaidiNo ratings yet

- Sullivan & Sons Type H Control Valve PDFDocument4 pagesSullivan & Sons Type H Control Valve PDFAntonella EspinozaNo ratings yet

- Parker Pneumatic LV / EZ Series Lockout Valves: Material Specifications Operating InformationDocument2 pagesParker Pneumatic LV / EZ Series Lockout Valves: Material Specifications Operating InformationSoriSori2008No ratings yet

- Model Identification Code - Waste Water PumpsDocument1 pageModel Identification Code - Waste Water Pumpsbookos89No ratings yet

- Cais Book Assembly Manual Cantilever L 1.0.0Document19 pagesCais Book Assembly Manual Cantilever L 1.0.0أحمد صبريNo ratings yet

- The Carbon Brush: ExchangeDocument5 pagesThe Carbon Brush: ExchangeJorge Morejon BuenoNo ratings yet

- Catalogos Contactores Trifasicos 220-440VDocument12 pagesCatalogos Contactores Trifasicos 220-440VkennyvjjNo ratings yet

- Tabla Americana de Avances de Accesorios... RAUL SUAREZDocument9 pagesTabla Americana de Avances de Accesorios... RAUL SUAREZJulio Enrique Oliver CuelloNo ratings yet

- Isv-Bt3b-Sb210.7 Val Bola TrunnionDocument4 pagesIsv-Bt3b-Sb210.7 Val Bola TrunnionBureau VeritasNo ratings yet

- CBVDocument48 pagesCBVBANGGANo ratings yet

- DLVT - PG1 - 180412 PDFDocument1 pageDLVT - PG1 - 180412 PDFMechanical2022No ratings yet

- 02 - AutomationValves - Modentic 6 Jun 18Document88 pages02 - AutomationValves - Modentic 6 Jun 18Deby NrsNo ratings yet

- Instruction Manual: Please Read This Manual Before Installation and UseDocument14 pagesInstruction Manual: Please Read This Manual Before Installation and UseCuong PhanNo ratings yet

- BoqDocument4 pagesBoqShashi RanjanNo ratings yet

- One Way Slab 1Document15 pagesOne Way Slab 1ahmedanyNo ratings yet

- Valves 1234Document13 pagesValves 1234Goutham KSNo ratings yet

- Cooling FansDocument1 pageCooling Fansסילרם קורNo ratings yet

- Datasheet - Mục III.6 Tuabin Và BOP -68Shinkawa LS-200TU Là Cảm Biến Chuyển VịDocument3 pagesDatasheet - Mục III.6 Tuabin Và BOP -68Shinkawa LS-200TU Là Cảm Biến Chuyển Vịnamdongvan8143No ratings yet

- Butterfly Valves - CatalogDocument30 pagesButterfly Valves - CatalogRamzi BEN AHMEDNo ratings yet

- Soplador K04-MS-3-3Document2 pagesSoplador K04-MS-3-3Héctor RomeroNo ratings yet

- Technical ManualDocument32 pagesTechnical ManualMihaiNo ratings yet

- Tabla Americana de Avances de Accesorios... RAUL SUAREZDocument9 pagesTabla Americana de Avances de Accesorios... RAUL SUAREZJose Cerezo TapiaNo ratings yet

- AC Axial FanDocument20 pagesAC Axial FansunhuynhNo ratings yet

- Perar WCWB Trunnion Welded BodyDocument19 pagesPerar WCWB Trunnion Welded BodyAlexandra HarperNo ratings yet

- Catalogue Stainless-High-Alloy-Steel-Valves-E-150-10Document86 pagesCatalogue Stainless-High-Alloy-Steel-Valves-E-150-10Nhật Quang PhạmNo ratings yet

- 10ft 6 Bar Cryogenic Tanks4Document3 pages10ft 6 Bar Cryogenic Tanks4Dymac IndiaNo ratings yet

- Bar Bending Calc r2Document14 pagesBar Bending Calc r2Sana Ullah HashemiNo ratings yet

- Resistors Resistors Terminations Att T Attenuators: Catalogue 2008 2009 G ForDocument59 pagesResistors Resistors Terminations Att T Attenuators: Catalogue 2008 2009 G ForAndy NGNo ratings yet

- Sewage Pump DASDocument11 pagesSewage Pump DASindra putraNo ratings yet

- Deluge Solenoid Control Valve (Energize To Open) : MODEL 215-4DVDocument5 pagesDeluge Solenoid Control Valve (Energize To Open) : MODEL 215-4DVmuthuvelaaNo ratings yet

- Hydraulic Overload Protector PumpDocument5 pagesHydraulic Overload Protector PumphaisamnagyNo ratings yet

- Precision - Heavy - Duty - Limit - Switches 10 AmpDocument6 pagesPrecision - Heavy - Duty - Limit - Switches 10 AmpHimindra ChaaubeNo ratings yet

- Catalog C v5Document80 pagesCatalog C v5Sivi NallamothuNo ratings yet

- Catalog C v5 PDFDocument80 pagesCatalog C v5 PDFAshokNo ratings yet

- Dynaflex CatalogDocument99 pagesDynaflex CatalogLuis Carlos MayorgaNo ratings yet

- Aftermarketcatalog WebDocument82 pagesAftermarketcatalog WebCarlos AnticonaNo ratings yet

- Class 150-19Document1 pageClass 150-19LUIS VAZQUEZNo ratings yet

- Lube Oil Cooler of Hydraulic Coupling GADocument2 pagesLube Oil Cooler of Hydraulic Coupling GAarunrajmech09No ratings yet

- Hyosung MV GISDocument7 pagesHyosung MV GISghosh.s hitechNo ratings yet

- PSCDocument29 pagesPSChuzefahussain745No ratings yet

- ASD DrawingsDocument4 pagesASD DrawingsumairNo ratings yet

- Vickers DG4V-3-6C Electrovalve PDFDocument16 pagesVickers DG4V-3-6C Electrovalve PDFSteven EsquivelNo ratings yet

- DCCDocument43 pagesDCCSharungomesNo ratings yet

- Manual Valvula de Alivio RciDocument3 pagesManual Valvula de Alivio RciGonzalo DominguezNo ratings yet

- Drawing For 8kw Duct Heater (1.5kwx4,1kwx2)Document9 pagesDrawing For 8kw Duct Heater (1.5kwx4,1kwx2)Balamurugan ArumugamNo ratings yet

- CT Nut Forged GGCDocument32 pagesCT Nut Forged GGCanderson_bicudoNo ratings yet

- Williams Valve Pipeline Gate Valves How To OrderDocument1 pageWilliams Valve Pipeline Gate Valves How To OrderNabeel MohammedNo ratings yet

- Service: Non Corrosive Hydrocarbons - Glycol - Blow Down - Vents - Drains (T 120°C)Document1 pageService: Non Corrosive Hydrocarbons - Glycol - Blow Down - Vents - Drains (T 120°C)AliZenatiNo ratings yet

- Celestion 2-Way 10 Inch MonitorDocument12 pagesCelestion 2-Way 10 Inch MonitorAnthony CuervoNo ratings yet

- SpecificationDocument6 pagesSpecificationHector0412No ratings yet

- 095.en BDocument8 pages095.en BlesonspkNo ratings yet

- Mining Product Specifications For HMS, Ers, and Draglines Pebj0031.Document65 pagesMining Product Specifications For HMS, Ers, and Draglines Pebj0031.Enso E Rosales F100% (1)

- Zurn FV-ZW4100Document3 pagesZurn FV-ZW4100Carlitos Way Golden BrainNo ratings yet

- ISO 9001, ISO 14001: LG Low Voltage Air Circuit BreakersDocument24 pagesISO 9001, ISO 14001: LG Low Voltage Air Circuit BreakersDong BachNo ratings yet

- Try 2Document1 pageTry 2JP Ang GagamboyNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- L.) UNIT - 12 - NANOTECH PDFDocument28 pagesL.) UNIT - 12 - NANOTECH PDFMummy HartiniNo ratings yet

- Sample Question Paper Job 232Document7 pagesSample Question Paper Job 232VenuGopalNaiduNo ratings yet

- CIR Vs Gen FoodsDocument12 pagesCIR Vs Gen FoodsOlivia JaneNo ratings yet

- Aris Vs NLRCDocument3 pagesAris Vs NLRCgmelbertmNo ratings yet

- Field Work ReportDocument20 pagesField Work ReportShahibu Shabani73% (11)

- Evaluation of Neighbours, Friends & FamiliesDocument55 pagesEvaluation of Neighbours, Friends & FamiliesKevin Anthony OndunaNo ratings yet

- Biometric SystemDocument8 pagesBiometric SystemAayush SrivastavaNo ratings yet

- DHA Procedure InformationDocument3 pagesDHA Procedure InformationShan Shani60% (5)

- Cbjesccq14 PDFDocument9 pagesCbjesccq14 PDFHilsa Das Hilsa DasNo ratings yet

- Design Calculations MalidduwaDocument72 pagesDesign Calculations MalidduwaUmesg100% (1)

- Termination of Employment in The PhilippinesDocument7 pagesTermination of Employment in The PhilippinesGerry MalgapoNo ratings yet

- Filter Command UnixDocument13 pagesFilter Command UnixAmit PatelNo ratings yet

- The Solar XXI Building in Lisbon, PortugalDocument4 pagesThe Solar XXI Building in Lisbon, PortugalSagar GheewalaNo ratings yet

- Po NPN 5053104338 KrisbowDocument2 pagesPo NPN 5053104338 Krisbowryan vernando manikNo ratings yet

- Speeduino 0.4.3D Part ListDocument1 pageSpeeduino 0.4.3D Part ListRicardo LealNo ratings yet

- GPC1-10000-AF™ Gas Pressure Controller: Operation and Maintenance ManualDocument40 pagesGPC1-10000-AF™ Gas Pressure Controller: Operation and Maintenance ManualjlbayonaNo ratings yet

- Trim Heater PDFDocument2 pagesTrim Heater PDFsaadashfaq100% (1)

- JCB Loadall 532: High Performance by DesignDocument4 pagesJCB Loadall 532: High Performance by Designkarijoseph02No ratings yet

- Speaking Templates For All 8 Parts of CELPIP. Structure & SamplesDocument11 pagesSpeaking Templates For All 8 Parts of CELPIP. Structure & SamplesPiyush Sharma100% (2)

- Case Study Horosho enDocument4 pagesCase Study Horosho enMaster ManojNo ratings yet

- Fortuner UP16DP3495Document1 pageFortuner UP16DP3495BOC ClaimsNo ratings yet

- PVC Pipe Industry Analysis in PakistanDocument4 pagesPVC Pipe Industry Analysis in PakistanOlufemi MoyegunNo ratings yet

- Division Memorandum No. 469, s.2020Document5 pagesDivision Memorandum No. 469, s.2020Nolan T. AlzolNo ratings yet

- Pre Requisite Programs Main PresentationDocument19 pagesPre Requisite Programs Main PresentationASIF EJAZNo ratings yet

- Integrative ReviewDocument16 pagesIntegrative Reviewapi-353789245No ratings yet

- Milestone - Applied StatisticsDocument2 pagesMilestone - Applied StatisticsSachin BhardwajNo ratings yet

- Proglaze® SSG: Single-Component, Neutral-Cure, Silicone Sealant For Structural GlazingDocument2 pagesProglaze® SSG: Single-Component, Neutral-Cure, Silicone Sealant For Structural GlazingTung ThanhNo ratings yet

- Environmental Clearance For Construction Projects - OptimaDocument11 pagesEnvironmental Clearance For Construction Projects - OptimaSiddharth ChoksiNo ratings yet

- Terra Et Aqua 153 CompleteDocument44 pagesTerra Et Aqua 153 CompleteCarlos PicalugaNo ratings yet

- Link Belt Bucket ElevatorDocument36 pagesLink Belt Bucket ElevatorCARLOSNo ratings yet