Professional Documents

Culture Documents

ISO 10816 Vibration Severity Levels PDF

ISO 10816 Vibration Severity Levels PDF

Uploaded by

JonathanFigueroaOñateOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ISO 10816 Vibration Severity Levels PDF

ISO 10816 Vibration Severity Levels PDF

Uploaded by

JonathanFigueroaOñateCopyright:

Available Formats

BAppendix B

General Severity Level Guidelines

When considering severity levels, be aware that standards

can only provide general guidelines to determine initial

alarm settings. Such guidelines should never substitute

experience and good judgement. The most reliable method

of determining alarm settings is to trend vibration readings

over time, establish baseline values and alarm settings

above baseline values.

Vibration measured in Velocity

For vibration velocity, ISO standards, such as ISO 10816,

First Edition 1995, or VDI 2056 guidelines, are generally

accepted. ISO 10816 with the title ‘Mechanical vibration –

Evaluation of machine vibration by measurements on non-

rotating parts’ consists of six parts. Part 1 (10816-1)

determines general guidelines and is followed by the

additional parts of ISO 10816, for example Part 2 (10816-

2) for land-based steam turbines and generators in excess of

50 MW with normal operating speeds of 1500 RPM, 1800

RPM, 3000 RPM and 3600 RPM.

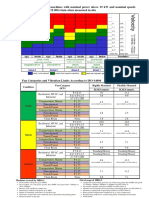

The following severity chart is in accordance with the ISO

10816-2 guidelines. For exceptions to this guideline and

for more information, reference the ISO 10816-2

document.

Machine Condition Transmitter (MCT) B-1

User Manual

General Severity Level Guidelines

Vibration measured in Velocity

ISO 10816-2 Steam Turbines and Generators

Speed (RPM) 1500 or 1800 3000 or 3600

Velocity

mm/sec RMS

Damage occurs

11.8

10.0

8.5

7.5

Restricted Operation

5.3

3.8

Unrestricted Operation

2.8

1.4

Newly Commissioned

0.0

Machinery

Table B - 1.

Vibration Severity Chart ISO 10816-2.

Industrial machines with nominal power above 15 kW and

nominal speeds between 120 RPM and 15000 RPM when

measured in position are covered by ISO 10816-3.

The machines are separated into 4 different groups:

Group 1: Large machinery and electrical machines with

shaft height greater than 315 mm that are normally

equipped with sleeve bearings.

Group 2: Medium-size machines and electrical machines

with shaft height between 160 mm and 315 mm that are

normally equipped with rolling element bearings and

operate at speeds above 600 RPM.

Group 3: Pumps with multivane impellers and separate

drivers with rated power above 15 kW. Machines of this

B-2 Machine Condition Transmitter (MCT)

User Manual

General Severity Level Guidelines

Vibration measured in Velocity

group may be equipped with sleeve or rolling element

bearings.

Group 4: Pumps with multivane impellers and with

integrated drivers that are equipped with sleeve or rolling

element bearings.

ISO 10816-3 Machinery Group Machinery Group

2&4 1&3

Rated Power 15 kW – 300 kW Group 1: 300 kW – 50 MW

Group 3: above 15 kW

Velocity

mm/sec Damage occurs

RMS

11.0

7.1

4.5 Restricted Operation

3.5

2.8 Unrestricted Operation

2.3

1.4

0.7 Newly Commissioned Machinery

0.0

Foundation Rigid Flexible Rigid Flexible

Table B - 2.

Vibration Severity Chart ISO 10816-3.

Mechanical Condition Transmitter (MCT) B-3

User Manual

General Severity Level Guidelines

Vibration Enveloped Acceleration Measurements

Vibration Enveloped Acceleration Measurements

Severity levels for machine vibration and bearing defect

detection by means of the enveloping technique are needed

to classify the machine condition according to standards

and practical guidelines.

For enveloped acceleration in all forms, severity levels are

related to speed and bearing size. The bearing size is

generally related to the load capabilities of the machine.

The higher the speed, the higher the energy generated by

impacts as elements roll over bearing damage.

The relation: Maximum shaft speed times shaft diameter

has a maximum, depending on the bearing technology.

Notice that for bigger bearings the speed is limited, and

therefore, the severity levels are also limited. Carefully

select the severity levels for enveloped acceleration using

machine knowledge. Sensor location and sensor

installation is important for successful machine monitoring.

The boundaries between different states of severity

conditions are less defined. Comparative and relative

judgement methods are preferred above absolute judgement

and the application of standards.

For creating a comparative measurement, the process

control system is able to create a trend of the vibration

signal. This signal can be compared against a ‘baseline’

overall measurement of that measurement point, with the

knowledge that the machine is running under normal

conditions.

In many cases, periodic measurements have been

performed on equipment before a permanent monitor (such

as the MCT system) is installed. The knowledge of those

measurements and the machine behavior provides a good

indication of effective alarm level settings.

B-4 Machine Condition Transmitter (MCT)

User Manual

General Severity Level Guidelines

Vibration Enveloped Acceleration Measurements

100 33.3

To be used with CMSS793, 797 accelerometers

CMVA55, CMVA320, filter 3, fmax=30,000 CPM, pk-pk reading.

(Scale is 1/3 of Danger Scale)

Danger Setting (gE)

Alert Setting (gE)

3600

3000

10 1800 3.30

1500

1200 RPM

900

600

400

200

1 100 0.33

0.1 0.03

10 100 1000

Shaft Diameter (mm)

Figure B - 1.

Enveloped Acceleration Alarm Guidelines (Fmax = 60,000 CPM).

To utilize the above chart, the following parameters must

be known:

• Bearing bore diameter in mm (indicates load)

• Shaft speed in RPM

Assumptions for using the above chart are necessary as

deviations from standardized data collection greatly affect

enveloped acceleration readings. Assumptions are as

follows:

• Filter 3 = 500-10,000 Hz

• Fmax = 60,000 CPM / 1,000 Hz

A scaling factor is required for other

Fmax values. A scaling equation is

provided in Part II.

• Sensor = CMSS793 or CMSS797 or MCD probe

• Detection = Peak to Peak

Mechanical Condition Transmitter (MCT) B-5

User Manual

General Severity Level Guidelines

Vibration Enveloped Acceleration Measurements

Perform measurements with the machine operating under

normal conditions. For example, when the rotor and the

main bearings have reached their normal steady operating

temperatures and with the machine running under its

normal rated condition (at rated voltage, flow, pressure, and

load).

To obtain the most accurate readings, enveloped

acceleration measurements require probe placement in the

maximum load zone, or as close as possible to the

maximum load zone within the measured bearing or gear

box.

Example

Bearing bore diameter: 100 mm

Shaft speed: 1800 RPM

Fmax: 60,000 CPM

Use the chart in Figure B-1 to determine this enveloped

acceleration measurement’s alert and danger alarm settings:

• Locate 100 mm on the shaft diameter axis.

• Follow the vertical line representing 100 mm to the

point where it intersects the 1800 RPM running speed

line. This is your reference point.

• From your reference point, follow the horizontal lines

left to the danger settings axis to determine your

initial danger alarm setting (7.5 gE).

• From your reference point, follow the horizontal lines

right to the alert settings axis to determine your initial

alert alarm setting (2.5 gE).

• Use the Scaling Factor chart (Figure B-2).

B-6 Machine Condition Transmitter (MCT)

User Manual

General Severity Level Guidelines

Vibration Enveloped Acceleration Measurements

1.40

1.20

Scaling Factor

1.00

0.80

0.60

0.40

0.20

0.00

0 500 1000 1500 2000

Fmax (Hz)

Figure B - 2.

Scaling Factor for Fmax Compensation for Enveloped Acceleration

Measurements.

The definition for an alarm condition for the enveloped

acceleration transmitter module also depends on the

application. Alarms can be a warning that a certain

condition has occurred and that further analysis is required.

Based upon those results, a decision must be made on

further required actions. The MCT is then used as a

monitoring device.

The alarm condition can also be used to take direct action.

In this case the MCT module is fulfilling a protective task

together with the process control / relay system.

The software CMSW5000 ‘Atlas For

Windows’ features a calculator for

enveloped acceleration alarm settings and

is based on identical assumptions.

For more information please visit our

website www.skfcm.com, select News

and download Revolution 6, Number 2

Mechanical Condition Transmitter (MCT) B-7

User Manual

You might also like

- Volvo Penta 7748089 5.0-5.7 Engine ManualDocument176 pagesVolvo Penta 7748089 5.0-5.7 Engine ManualJohn Dahl88% (26)

- Cat IiDocument72 pagesCat Iizeroseya100% (3)

- ISO 18436 Category II Vibration Analyst TrainingDocument4 pagesISO 18436 Category II Vibration Analyst TrainingDean Lofall50% (2)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- JPS Reliability Bearing FailuresDocument14 pagesJPS Reliability Bearing FailuresAnonymous Bdt0OGh100% (1)

- Technical Associates of Charlotte PDFDocument1 pageTechnical Associates of Charlotte PDFnamhts78% (9)

- Norma Iso-10816-1Document1 pageNorma Iso-10816-1powercontrol88% (8)

- Iso 20816 8 2018 en PDFDocument11 pagesIso 20816 8 2018 en PDFEdwin Bermejo75% (4)

- Empire Floor 3577, 5077, 3588, 5088, 7088Document5 pagesEmpire Floor 3577, 5077, 3588, 5088, 7088NorthernPropaneNo ratings yet

- Vibration Analysis Measurement ManualDocument215 pagesVibration Analysis Measurement Manualronfrend100% (1)

- PeakvueDocument68 pagesPeakvueLe Thanh Hai100% (1)

- Limit Table According To ISO (10816-3 and 14694)Document1 pageLimit Table According To ISO (10816-3 and 14694)Muhammad Haroon67% (3)

- Forsthoffer’s Component Condition MonitoringFrom EverandForsthoffer’s Component Condition MonitoringRating: 4 out of 5 stars4/5 (2)

- Belt Drive Experiment PDFDocument9 pagesBelt Drive Experiment PDFFajar Rumanto100% (1)

- 2.3 CNC Milling With BoXZYDocument13 pages2.3 CNC Milling With BoXZYMike BoyesNo ratings yet

- 10816Document6 pages10816Umair MaqboolNo ratings yet

- ISO 10816-1 - Vibration at Load ConditionDocument2 pagesISO 10816-1 - Vibration at Load ConditionAZZAF ChannelNo ratings yet

- Vibration Analysis of Centrifugal FansDocument18 pagesVibration Analysis of Centrifugal FansMohd Asiren Mohd Sharif100% (4)

- 303mills PDFDocument32 pages303mills PDFfaisalNo ratings yet

- ISO 10816 Standards - Vibration Monitoring Non Rotating MachinesDocument1 pageISO 10816 Standards - Vibration Monitoring Non Rotating MachinesJoe SmithNo ratings yet

- Detect Machinery Faults by Using Peak VueDocument13 pagesDetect Machinery Faults by Using Peak VueHarold Alconz100% (2)

- Condition Monitoring of Centrifugal Blower Using Vibration Analysis PDFDocument10 pagesCondition Monitoring of Centrifugal Blower Using Vibration Analysis PDFJose PradoNo ratings yet

- Cuaderno Curso - CAT I Activity Book Spanish With CoverDocument34 pagesCuaderno Curso - CAT I Activity Book Spanish With CoverJose Raul Reyes Dominguez100% (1)

- Fan Diagnosis in The FieldDocument10 pagesFan Diagnosis in The FieldDavide LanzoniNo ratings yet

- NTN Bearing Bpfo&BpfiDocument61 pagesNTN Bearing Bpfo&BpfishantanusamajdarNo ratings yet

- Vibration Standardss ISO10816Document24 pagesVibration Standardss ISO10816Aswartha Technical Services67% (3)

- ISO 2372 WithDocument12 pagesISO 2372 WithEcruz Cruz L100% (2)

- Machine Vibration Standards and Acceptance LimitsDocument66 pagesMachine Vibration Standards and Acceptance Limitssuper2274100% (2)

- 2 Vibn Analysis BasicsDocument117 pages2 Vibn Analysis BasicsTanoj PatroNo ratings yet

- Introduction To PeakvueDocument55 pagesIntroduction To PeakvuesebastianNo ratings yet

- A Review of ISO and ANSI Standards On Machinery Vibration and Condition MonitoringDocument44 pagesA Review of ISO and ANSI Standards On Machinery Vibration and Condition Monitoringpeach5100% (3)

- CAT II Activity Book v4.0 - Letter - Answer KeyDocument7 pagesCAT II Activity Book v4.0 - Letter - Answer Keyazay_saja100% (2)

- Chapter 10Document63 pagesChapter 10Hosam Abd Elkhalek100% (1)

- Iso 2372Document10 pagesIso 2372WulaNda Rika75% (4)

- Vibration Field Tehcnician Guide PDFDocument21 pagesVibration Field Tehcnician Guide PDFadnane adnane100% (1)

- Vibration ReportDocument1 pageVibration Reportnagarajasarma0% (1)

- Why Industrial Bearings Fail: Analysis, Maintenance, and PreventionFrom EverandWhy Industrial Bearings Fail: Analysis, Maintenance, and PreventionNo ratings yet

- Iso 10816Document4 pagesIso 10816spbhaskaran28100% (1)

- Vibration Analysis and Acceptance StandardDocument23 pagesVibration Analysis and Acceptance StandardEstebanRivera100% (2)

- Mech Vibrartion Lab2Document13 pagesMech Vibrartion Lab2Edryna AntasyaNo ratings yet

- High-Side Motor Current Monitoring For Over-Current ProtectionDocument3 pagesHigh-Side Motor Current Monitoring For Over-Current Protectionbookreader1968No ratings yet

- Extracto ISO 10816Document10 pagesExtracto ISO 10816clroyo9475No ratings yet

- Iso TC 108 SC 2 N 666Document58 pagesIso TC 108 SC 2 N 666Rahul B. WaghaleNo ratings yet

- Hydro Turbine Vibration MonitoringDocument8 pagesHydro Turbine Vibration MonitoringreddyloginNo ratings yet

- Machine Evaluator Series: Advanced Handheld Condition Monitoring InstrumentDocument12 pagesMachine Evaluator Series: Advanced Handheld Condition Monitoring InstrumentMohd Bahruddin Ab GhaparNo ratings yet

- VDI 2056 RefDocument4 pagesVDI 2056 RefManan Vadher0% (2)

- BS 7882 - 2008 PaperDocument25 pagesBS 7882 - 2008 PaperMohamed Naser0% (1)

- Analysis Techniques: TrendingDocument5 pagesAnalysis Techniques: TrendingVasile RaduNo ratings yet

- A 837 eDocument2 pagesA 837 eKhalida MuddasserNo ratings yet

- 10816-3 GuidelinesDocument1 page10816-3 GuidelinesThyagaraju PalisettyNo ratings yet

- Data Acquisition: Detectors: TransducersDocument11 pagesData Acquisition: Detectors: TransducersVasile RaduNo ratings yet

- Vibration StandardDocument3 pagesVibration StandardelrajilNo ratings yet

- 3G3RV V1Document76 pages3G3RV V1Omiga HatemNo ratings yet

- Ways To Measure The Force Acting On A Rotating Shaft: What Is Torque?Document5 pagesWays To Measure The Force Acting On A Rotating Shaft: What Is Torque?chandununnaNo ratings yet

- Familiarization With and Performance Check Of, Vibration Testing & Measuring EquipmentDocument33 pagesFamiliarization With and Performance Check Of, Vibration Testing & Measuring EquipmentOmar Saleem100% (1)

- Banco DresserDocument8 pagesBanco DresserEder Alonso Cardenas CepedaNo ratings yet

- Monarch 1000 ManualDocument10 pagesMonarch 1000 ManualABRIL19No ratings yet

- Expt. 1 Experimental Verification of Dynamic Balancing of Rotating MassesDocument7 pagesExpt. 1 Experimental Verification of Dynamic Balancing of Rotating MassesPranjalNo ratings yet

- UTM Regular CatalogueDocument12 pagesUTM Regular CatalogueEr Hemant Kumar SahNo ratings yet

- Article Overall Vibration Values For Reliable Wind TurbinesDocument4 pagesArticle Overall Vibration Values For Reliable Wind TurbinesManel Montesinos100% (1)

- Workshop Apc01 2006 eDocument29 pagesWorkshop Apc01 2006 eRogério PereiraNo ratings yet

- WPL 26 Shock MonitoringDocument16 pagesWPL 26 Shock MonitoringAhmed El-ShafeiNo ratings yet

- Vibration Key ChartsDocument12 pagesVibration Key ChartsgsaiprasathNo ratings yet

- ISO VA DocumentDocument20 pagesISO VA DocumentgsaiprasathNo ratings yet

- ISO 10816 Vibration Severity LevelsDocument7 pagesISO 10816 Vibration Severity Levelsgsaiprasath100% (2)

- Ge Severity Chart PDFDocument1 pageGe Severity Chart PDFgsaiprasathNo ratings yet

- Gaging Tips Micrometer Accuracy Tec enDocument2 pagesGaging Tips Micrometer Accuracy Tec enpviccNo ratings yet

- OMRON NT620S NT620C Operation ManualDocument338 pagesOMRON NT620S NT620C Operation Manualordense0% (1)

- Hager Stylea BrochureDocument16 pagesHager Stylea BrochureJurutera Perunding FRM Sdn. Bhd.No ratings yet

- Electronic Parts Catalog - Option DetailDocument3 pagesElectronic Parts Catalog - Option DetailmunhNo ratings yet

- Parts List - KTZ411-61Document4 pagesParts List - KTZ411-61Mahmoud ElboraeNo ratings yet

- 26jul2010094254 - Immobilizer Reg (Fortuner, Hilux&Innova)Document8 pages26jul2010094254 - Immobilizer Reg (Fortuner, Hilux&Innova)mikaelarikuntoNo ratings yet

- CSS ExamDocument7 pagesCSS ExamRobert ColomaNo ratings yet

- ZAPI AC-1 ManualDocument62 pagesZAPI AC-1 ManualMarcos Gregorio da SilvaNo ratings yet

- Cuptor DO308Document38 pagesCuptor DO308Dumitru Marius0% (1)

- VW M3-02. LSC Directional Control Valves in Monoblock DesignDocument8 pagesVW M3-02. LSC Directional Control Valves in Monoblock Designparahu ariefNo ratings yet

- STM32 Tutorial 04 - I2C Module (Pca9685) Using HAL (And FreeRTOS)Document6 pagesSTM32 Tutorial 04 - I2C Module (Pca9685) Using HAL (And FreeRTOS)Quocdt Ngoc100% (1)

- Mircom FHS340RWP Data SheetDocument4 pagesMircom FHS340RWP Data SheetJMAC SupplyNo ratings yet

- 555 Timer TutorialDocument43 pages555 Timer TutorialcprofesionalNo ratings yet

- Bee Fuse2 (Nishant Sir)Document2 pagesBee Fuse2 (Nishant Sir)Md Ali AhmadNo ratings yet

- INT-P081-En-0!02!18 Fluido Technical TrainingDocument63 pagesINT-P081-En-0!02!18 Fluido Technical TrainingJef RobinsonNo ratings yet

- Junior Explorer 6 - 1. Keep in Touch Klucz OdpowiedziDocument4 pagesJunior Explorer 6 - 1. Keep in Touch Klucz OdpowiedziantekmatyniakNo ratings yet

- 10x1 DiSEqC ReviewDocument4 pages10x1 DiSEqC ReviewvewevreNo ratings yet

- Fastest Finger First Mini Project Using 8051 MicrocontollerDocument5 pagesFastest Finger First Mini Project Using 8051 MicrocontollerPavanJangid50% (2)

- OpenSimwheel TutorialDocument33 pagesOpenSimwheel TutorialznamNo ratings yet

- Cleaning PDFDocument1 pageCleaning PDFsalman arefinNo ratings yet

- URS Part 4 Electrical StandardDocument36 pagesURS Part 4 Electrical StandardSushil RajputNo ratings yet

- HD Maintenance and LubricationDocument42 pagesHD Maintenance and LubricationCarloVanZylNo ratings yet

- 2019 Dec. EE309-F - Ktu QbankDocument2 pages2019 Dec. EE309-F - Ktu QbankmasterjiynNo ratings yet

- Samsung Tech Talk: Samsung Soft Skills Training Now Live On Plus 1!Document23 pagesSamsung Tech Talk: Samsung Soft Skills Training Now Live On Plus 1!Roberto Augusto Aristizabal MorenoNo ratings yet

- Digest 176 NEC TablesDocument1 pageDigest 176 NEC TablesHernan Dario Alvarez BenitezNo ratings yet

- User Manual: Apg Dynamic ProcessorsDocument10 pagesUser Manual: Apg Dynamic ProcessorsElla MariaNo ratings yet