Professional Documents

Culture Documents

Course Code: INT 207 Itsj/Rw - 17 / 1325 Fourth Semester B. E. (Industrial Engineering) Examination

Uploaded by

MithileshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Course Code: INT 207 Itsj/Rw - 17 / 1325 Fourth Semester B. E. (Industrial Engineering) Examination

Uploaded by

MithileshCopyright:

Available Formats

Course Code : INT 207 ITSJ/RW – 17 / 1325

Fourth Semester B. E. (Industrial Engineering) Examination

METHODS ENGINEERING

Time : 3 Hours ] [ Max. Marks : 60

Instructions to Candidates :—

(1) All questions carry marks as indicated.

(2) Due credit will be given to neatness.

(3) Assume suitable data wherever necessary.

(4) Illustrate answers with the help of neat sketches wherever necessary.

1. (a) What is Method Study ? How will you identify the areas that need method

study applications in an industry ? 5 (CO 1)

(b) Describe the Taylor's and Gilberth's contribution to the development of work

study. 5 (CO 1)

2. (a) The inspection of existing system of loading and unloading in a cold storage

is as follows :

(1) Two men unload potato bags from truck to trolley which take

3.5 Minutes.

(2) Another Two men push the trolley to weighing machine which

take 3 minutes.

(3) Weighing time is 1.5 minutes

(4) Another two men push trolley to storage which take 2.5 minutes

(5) Another three men unload bags to rack which take 4.5 minutes.

(6) Another one man returns trolley to truck 3.5 minutes

Make a Multiple activity chart fort the above activity. Suggest an improved

method for minimizing labour cost. 7 (CO 2)

(b) Discuss suitable recording techniques which can be employed for developing

a better method of flow and handling of material. 3 (CO 2)

ITSJ/RW-17 / 1325 Contd.

3. (a) Describe the concept of normal and maximum working area in the application

of workplace design with suitable example. 5 (CO 3)

(b) Under what circumstances is it feasible to make a micromotion analysis

of a job ? Explain. 5 (CO 3)

4. (a) Explain the general procedure for developing the time standards by stop

watch time study. 5 (CO 4)

(b) Define briefly: Element, Work cycle, Occasional element, Governing element

and Foreign element with example. 5 (CO 4)

5. (a) Following data shows the observation obtained in a stop watch time study.

Element times are shown in seconds for an operation.

Cycle Elements (Observed Time)

1 2 3 4 5

1 35 30 25 40 20

2 38 50 25 46 28

3 45 34 25 43 25

4 36 40 25 39 30

5 40 42 25 41 22

(1) Element 3 is machine element

(2) Operator is rated at 85%

(3) Abnormal reading ( —

+ 25% of average value) should be discarded.

(4) Allowances are :

∗ Personal need = 5%

∗ Contingency allowance = 4%

Determine standard time. 6 (CO 4)

(b) Why is it necessary to apply rating to actual time which an operator takes

to perform an operation ? 4 (CO 4)

ITSJ/RW-17 / 1325 2 Contd.

6. (a) ''Incentives are necessary for smooth and efficient running of a factory'' discuss.

State important incentive schemes. 5 (CO 4)

(b) Three workers P, Q and R working on identical machines produced 280,

320 and 200 units of the job in a day whose standard production is

35 units per hour.

Following are the particulars of wage incentive scheme :

(1) Labour hourly rate = Rs. 50.

(2) Rate differential to be employed :

) 80% of the standard piece rate for below standard performance

) 120% of the standard piece rate for standard and above standard

performance.

Calculate earning of workers P, Q and R if workers work for 8 hours

in a day. 5 (CO 4)

ITSJ/RW-17 / 1325 3 15

You might also like

- Thinking Machines: Machine Learning and Its Hardware ImplementationFrom EverandThinking Machines: Machine Learning and Its Hardware ImplementationNo ratings yet

- Flat Panel Display ManufacturingFrom EverandFlat Panel Display ManufacturingJun SoukNo ratings yet

- Final Exam Semester I 2017/2018 Operations ManagementDocument7 pagesFinal Exam Semester I 2017/2018 Operations ManagementSyahnaz KANo ratings yet

- 5902r09-Automation in ManufacturingDocument2 pages5902r09-Automation in ManufacturingDr-Asit Kumar ParidaNo ratings yet

- Industrial ManagementDocument2 pagesIndustrial ManagementSayantan DexNo ratings yet

- Marks Awarded: PGDM (2019-21) Term - IDocument12 pagesMarks Awarded: PGDM (2019-21) Term - IRishab AgarwalNo ratings yet

- TIE6111201412 Design, Analysis and Control of Manufacturing SystemsDocument5 pagesTIE6111201412 Design, Analysis and Control of Manufacturing Systemstafara mundereNo ratings yet

- 15P701Document4 pages15P701rajakrishnanNo ratings yet

- BTM 3713 Set 1 - Final Exam Question Paper (v2)Document6 pagesBTM 3713 Set 1 - Final Exam Question Paper (v2)kameeneNo ratings yet

- IE UNIVERSITY MCQ MergedDocument16 pagesIE UNIVERSITY MCQ MergedChota ChatriNo ratings yet

- Work Study and Ergonomics SIRAJ PDFDocument4 pagesWork Study and Ergonomics SIRAJ PDFsirajudeen INo ratings yet

- Automation in Production MET 406 CourseDocument3 pagesAutomation in Production MET 406 CourseMubarika SabirNo ratings yet

- MS-5 Management of Machines and Materials ExamDocument3 pagesMS-5 Management of Machines and Materials Examdebaditya_hit326634No ratings yet

- JYOTHI ENGINEERING COLLEGE INDUSTRIAL ENGINEERING EXAMDocument3 pagesJYOTHI ENGINEERING COLLEGE INDUSTRIAL ENGINEERING EXAM11715070 JOSHWIN EMMANUEL JOHNSONNo ratings yet

- ADL 14 Ver2+Document9 pagesADL 14 Ver2+DistPub eLearning Solution33% (3)

- WWW Manaresults Co inDocument2 pagesWWW Manaresults Co inprinceho124No ratings yet

- M.E (2017 Pattern)Document205 pagesM.E (2017 Pattern)alan hernandez guzmanNo ratings yet

- Final Assessment Test (FAT) - May 2017: Course: - Class NBR(S) : Slot: Time: Three Hours Max. Marks: 100Document4 pagesFinal Assessment Test (FAT) - May 2017: Course: - Class NBR(S) : Slot: Time: Three Hours Max. Marks: 100ak164746No ratings yet

- Assignment 4Document4 pagesAssignment 4syed aliNo ratings yet

- Iem 102Document4 pagesIem 102Aparna DuggiralaNo ratings yet

- Optimization Techniques for Inventory ManagementDocument4 pagesOptimization Techniques for Inventory ManagementJaskaran SinghNo ratings yet

- Optimum Sequence and Minimum Elapsed TimeDocument7 pagesOptimum Sequence and Minimum Elapsed Timekabo busanangNo ratings yet

- TIE6111201301Design Analysis and Control of Manufacturing SystemsDocument8 pagesTIE6111201301Design Analysis and Control of Manufacturing Systemstafara mundereNo ratings yet

- Facilities Layout Design and Materials Handling Facmib2: B. Eng TechnologyDocument4 pagesFacilities Layout Design and Materials Handling Facmib2: B. Eng Technologyrealeboga moneiNo ratings yet

- Dec - 2006Document7 pagesDec - 2006api-19931402No ratings yet

- Karakuri - PremDocument3 pagesKarakuri - PremRicky MarkNo ratings yet

- Iem MCQ PDFDocument28 pagesIem MCQ PDFĀditya SonāvanéNo ratings yet

- K Chiteka Manufacturing Process TutorialDocument4 pagesK Chiteka Manufacturing Process TutorialKUDZANAYINo ratings yet

- Assessment 2Document7 pagesAssessment 2achumakotishiniNo ratings yet

- NR 422001 C Automation in ManufactureDocument8 pagesNR 422001 C Automation in ManufactureSrinivasa Rao GNo ratings yet

- Calculating optimal order quantity and standard time for bank tellersDocument2 pagesCalculating optimal order quantity and standard time for bank tellersSweet tripathiNo ratings yet

- CSC520 - ITC520 Final Paper.Document5 pagesCSC520 - ITC520 Final Paper.Shah MusbinNo ratings yet

- MECHBBE87252BrIndrBh - IE Term WorkDocument5 pagesMECHBBE87252BrIndrBh - IE Term WorkRoshan NeheteNo ratings yet

- Industrial Engineering: B.E. (Mechanical Engineering) Seventh Semester (C.B.S.)Document4 pagesIndustrial Engineering: B.E. (Mechanical Engineering) Seventh Semester (C.B.S.)Shashwat JainNo ratings yet

- QB Ieq Me6i (22657) Ut 1 13022020Document5 pagesQB Ieq Me6i (22657) Ut 1 13022020Ashvin PawaraNo ratings yet

- Dba 1651 Sem IIDocument11 pagesDba 1651 Sem IIthamiztNo ratings yet

- Production and Operations ManagementDocument7 pagesProduction and Operations Managementamit rawatNo ratings yet

- Om 1Document2 pagesOm 1VaibhavrvNo ratings yet

- MS-5 Management Exam June 2008Document8 pagesMS-5 Management Exam June 2008DipeshNo ratings yet

- Sri Ramanujar Engineering College Department of Information Technology Model Exam Ii Year/Iv SemDocument2 pagesSri Ramanujar Engineering College Department of Information Technology Model Exam Ii Year/Iv SemGovarathanNo ratings yet

- 15ecsc704 576 Kle54-Ecsc704Document5 pages15ecsc704 576 Kle54-Ecsc704Aniket AmbekarNo ratings yet

- Ime February-2023Document2 pagesIme February-2023rohitchanakya76No ratings yet

- Paper 13 Operations and Project Management & Control June 2004Document5 pagesPaper 13 Operations and Project Management & Control June 2004api-19931402No ratings yet

- End Term Examination: Fifth Semester (Mca) December-2009Document4 pagesEnd Term Examination: Fifth Semester (Mca) December-2009Pratiksha TiwariNo ratings yet

- Os Major 2017Document3 pagesOs Major 2017neegaahNo ratings yet

- Seventh Semester B.Tech. Degree Examination, June 2009 03.705 Elective - V: OPERATIONS RESEARCH (H) (2003 Admission)Document6 pagesSeventh Semester B.Tech. Degree Examination, June 2009 03.705 Elective - V: OPERATIONS RESEARCH (H) (2003 Admission)loopycrowNo ratings yet

- IIT Kharagpur Human Factors Engineering examDocument3 pagesIIT Kharagpur Human Factors Engineering exambrahma2deen2chaudharNo ratings yet

- ME404 Industrial Engineering, May 2019Document2 pagesME404 Industrial Engineering, May 2019Mohammed SalaNo ratings yet

- Sathish S 18me731 2023 24 Cim Model 1Document3 pagesSathish S 18me731 2023 24 Cim Model 1srujangowdasj2002No ratings yet

- MTECH-2ND SEM-2021-Question-Paper-REAL TIME SYSTEM.docxDocument3 pagesMTECH-2ND SEM-2021-Question-Paper-REAL TIME SYSTEM.docxsingwithshimulNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityPayal ChhabraNo ratings yet

- 2 Bft-Vi - Appc - QPDocument5 pages2 Bft-Vi - Appc - QPYuvraj PahujaNo ratings yet

- Tutorial SchedulingDocument3 pagesTutorial SchedulingBrandoMonintjaNo ratings yet

- Me405 - Assign 11Document1 pageMe405 - Assign 11srikar naredlaNo ratings yet

- Universiti Teknologi Mara Final Examination: Confidential EM/MAR 2016/MEM375Document5 pagesUniversiti Teknologi Mara Final Examination: Confidential EM/MAR 2016/MEM375AmirulHanif AlyahyaNo ratings yet

- Soalan 1Document11 pagesSoalan 1Matthew ShieldsNo ratings yet

- Manage Machines & Materials ExamDocument6 pagesManage Machines & Materials Examdebaditya_hit326634No ratings yet

- Makaut Industrial Engineering Document TitleDocument4 pagesMakaut Industrial Engineering Document TitleSoumya BeraNo ratings yet

- RT31055102020Document2 pagesRT31055102020elisha emilianNo ratings yet

- JIT Lean Production Review QuestionsDocument6 pagesJIT Lean Production Review QuestionsAnuragShrivastavNo ratings yet

- Missing Dovetail RfiDocument1 pageMissing Dovetail RfiPurushotam TapariyaNo ratings yet

- Qos/Qoe Techniques For Iptv Transmissions: June 2009Document9 pagesQos/Qoe Techniques For Iptv Transmissions: June 2009Hoàng Lam SơnNo ratings yet

- Akd 736103113213Document1 pageAkd 736103113213May'Axel RomaricNo ratings yet

- Tesco AnalysisDocument12 pagesTesco Analysisdanny_wch7990No ratings yet

- "Hybrid" Light Steel Panel and Modular Systems PDFDocument11 pages"Hybrid" Light Steel Panel and Modular Systems PDFTito MuñozNo ratings yet

- BIM Implementation - Brenner Base Tunnel ProjectDocument10 pagesBIM Implementation - Brenner Base Tunnel ProjectHichemNo ratings yet

- Gmail - DFA Passport Appointment System - Confirmation Notification PDFDocument2 pagesGmail - DFA Passport Appointment System - Confirmation Notification PDFGarcia efrilNo ratings yet

- Blockchain For IBMers - Eng Model v2.01Document25 pagesBlockchain For IBMers - Eng Model v2.01ayanmukherjee1No ratings yet

- CRM Vendors, Vendor SelectionDocument7 pagesCRM Vendors, Vendor SelectionsanamkmNo ratings yet

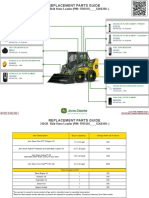

- 312GR Skid Steer Loader PIN 1T0312G G366358 Replacement Parts GuideDocument3 pages312GR Skid Steer Loader PIN 1T0312G G366358 Replacement Parts GuideNelson Andrade VelasquezNo ratings yet

- 5442 - FVRDocument100 pages5442 - FVRKrishna Chaitanya DeepalaNo ratings yet

- Automotive Transmission-ShaftDocument7 pagesAutomotive Transmission-Shaftfileuse.fNo ratings yet

- The Threat Landscape Quiz ResultsDocument5 pagesThe Threat Landscape Quiz ResultsKaskusemail88 EmailNo ratings yet

- Thk2e BrE L3 Vocabulary Standard Unit 3Document2 pagesThk2e BrE L3 Vocabulary Standard Unit 3Suki ChuahNo ratings yet

- Loading Arms and Their Control Panels BrochureDocument5 pagesLoading Arms and Their Control Panels Brochureminah22No ratings yet

- Network Fundamentals - Chapter 4 Exam AnswersDocument4 pagesNetwork Fundamentals - Chapter 4 Exam AnswersBart AbraasNo ratings yet

- 1-Principles and Practice of Ground Improvement-Wiley (2015) - 20Document1 page1-Principles and Practice of Ground Improvement-Wiley (2015) - 20Ahmed KhedrNo ratings yet

- Petron Corporate PresentationDocument46 pagesPetron Corporate Presentationsivuonline0% (1)

- Solution Manual For Macroeconomics 7th Edition Olivier BlanchardDocument38 pagesSolution Manual For Macroeconomics 7th Edition Olivier Blanchardilvaitekabassou7k10tNo ratings yet

- Motion in A Straight Line: Initial PositionDocument7 pagesMotion in A Straight Line: Initial PositionEngelbert Bicoy AntodNo ratings yet

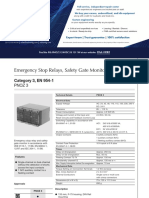

- Pilz PNOZ 3 DatasheetDocument5 pagesPilz PNOZ 3 DatasheetIsrael De LeonNo ratings yet

- Literature Review On School AdministrationDocument6 pagesLiterature Review On School Administrationea7sfn0f100% (1)

- OSN 9800 U64, U32, U16, UPS Installation GuideDocument157 pagesOSN 9800 U64, U32, U16, UPS Installation GuidedonekeoNo ratings yet

- Carbozinc 11Document4 pagesCarbozinc 11DuongthithuydungNo ratings yet

- Kick Control: BY: Naga Ramesh D. Assistant Professor Petroleum Engineering Dept. KlefDocument13 pagesKick Control: BY: Naga Ramesh D. Assistant Professor Petroleum Engineering Dept. Klefavula43No ratings yet

- Dual Rectifier Solo HeadDocument11 pagesDual Rectifier Solo HeadВиктор АлимовNo ratings yet

- Combinational CircuitsDocument18 pagesCombinational CircuitsSalil TimalsinaNo ratings yet

- Content Analysis Research Paper ExampleDocument5 pagesContent Analysis Research Paper Examplefvfzfa5d100% (1)

- Cambridge IGCSE: PHYSICS 0625/62Document12 pagesCambridge IGCSE: PHYSICS 0625/62yuNo ratings yet

- Unit 7 Chapter 7 International Marketing NotesDocument7 pagesUnit 7 Chapter 7 International Marketing NotesGv HarishNo ratings yet