Professional Documents

Culture Documents

SAFE WORK PERMIT (SWP) INSTALLATION

Uploaded by

Jhon Luther POriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SAFE WORK PERMIT (SWP) INSTALLATION

Uploaded by

Jhon Luther PCopyright:

Available Formats

SAFE WORK PERMIT (SWP)

Facility: ______________________________________ Emergency Number: +62081295670089__

SECTION I – GENERAL SWP SWP Max Duration = 24 hours or 2 shifts, whichever is shorter

1. What is the scope and location of permitted work? (Work limited to Scope, Location, Description, Tasks, Area/Equipment, Tools and Boundaries described)

A. Intervesi electrical, B. installation piping AHU C. welding piping AHU D. installation AHU E. intallation ducting ___

Tools : Hand Tools, Cup Suction Holder, Manual Cutting Tools, grinding machine, scaffolding, ladder, senai machine, welding machine ___

Location at WTC Building 3 ___

___

Does the scope of work include the following? If yes, complete the additional Sections of the SWP

Isolation of Energy Sources (Section II) Yes N/A Heavy Equipment (Section XII) Yes N/A

Confined Space Entry (Section IX) Yes N/A Hot Work (Section VI) Yes N/A

Electrical Work (Section X) Yes N/A Hydroblasting (Section XIII) Yes N/A

Excavation (Section XI) Yes N/A Pressure Washing (Section XIII) Yes N/A

Fall Prevention (Section VIII) Yes N/A Line & Equipment Opening (Section VII) Yes N/A

Critical Lift Yes N/A Small Unmanned Aerial System (Section XIV) Yes N/A

Additional SWP Issuer Comments, Information or Instructions: Danger Of installation work ( Dust, fall accidentally, electric shock, emergency preperanes)

2. Have all people working under this SWP received the necessary facility and/or site orientation? Yes

Emergency procedures, alarms, evacuation routes, assembly points, and location of nearest safety shower(s), eye bath(s), fire

extinguisher(s) and telephone and/or intercom are reviewed with, and understood by, the worker(s)? Yes

Scope and boundaries of any work that could potentially impact the permitted work has been reviewed and is understood? Yes N/A

Other workers in adjacent areas were notified if this permitted work could impact their work/area? Yes N/A

All equipment to be worked on is properly prepared, identified and is ready to work on? Yes N/A

For demolition or renovation work, has the work area been inspected for asbestos? Yes N/A

Portable electrical equipment used has a GFCI/RCD (EWP-10) or follows an approved Assured Grounding Program (EWP-10) Yes N/A

Will the work create holes, unprotected edges or other fall hazards? If triggers for elevated work are met, complete Section VIII Yes N/A

Do workers have specialty training as required? [ ] HAZWOPER [ ] Asbestos [ ] Lead [ ] Silica [ V ] Other: Emergency Yes N/A

3. Additional information, permits and/or checklists used (based on scope and type of work) are attached to the SWP? JSA Yes N/A

4. Field Tests/Monitoring needed (other than that specified in Hot Work VI or CSE Section IX)? (e.g., noise, etc.) Yes No If yes,

describe the Scope of Monitoring:__________________________________________________________________________________________________

Monitoring performed by: ____________________________ Date: _____________ Time_____________

Field Tests and/or Monitoring Results:______________________________________________________________________________________________

5. Chemical Hazards List the chemical hazards of the work area, and/or process chemical(s) last contained in equipment, and any job Doesn’t Apply [ ]

specific chemicals used. See SDS(s) for health & safety hazard(s).

Chemical(s) Name:__ Compound_______________________________ [ ] Flammable [ ] Corrosive [ ] Reactive [ ] Toxic [ ] Carcinogen

[ ] Sensitizer [ ] Asphyxiation [V ] Skin Irritant [ ] Inhalation [ ] Other: ____________________________________________________

If chemical hazards exist, describe safeguard(s) used: Use Face shield, ear plug, heavy duty leathergloves, safety glasses, safety shoes, safety

helmet, long sleeves, Dust mask ___________________________________________________________________

6. Physical Hazards List the hazards of the work, area, equipment and tools used, e.g., Doesn’t Apply [ ]

[ ] Oxygen Deficient Atmosphere [V ] Vibration [ ] Pressure [ V ] Noise (>85dBA) [ ] Radiation [ V ] Sharp Edges

[ ] Electricity/High Voltage [ ] Shock Hazard [ ] Arc Flash [ ] Heights [ V ] Falling Objects [ ] Flying Debris [ V ] Pinch Points

[ ] Congested Area [ ] Heat/Cold Stress [ V ] Burns [ V ] Dust [ ] Line of Fire [ ] Other: ______________________

If physical hazards exist, describe safeguard(s) used: Use Face shield, ear plug, heavy duty leathergloves, Chemical Resistant

Gloves, safety glasses, safety shoes, safety helmet, long sleeves, Dust mask

________________________________________________________________________________

7. Biological Hazards, e.g., [ ] Water or waste contaminated with potentially infectious materials Doesn’t Apply [ V ]

[ ] Insects [ ] Animals [ ] Microorganisms [ ] Harmful/Poisonous Plants [ ] Other: ______________________

If biological hazards exist, describe safeguard(s) used:

8. Environmental Considerations, e.g., [ ] Waste Disposal [V] Housekeeping [ ] Lead Paint Doesn’t Apply [ ]

[ ] Waste generation (solid waste / wastewater) [ ] Management of generated waste [ ] Impact to air, ground or water [ ] Other:____________

If environmental considerations exist, describe safeguard(s) used: Provide construction junk area and Construction junk shall be evacuated out from

Metropolitan complex daily

9. Ergonomic Considerations, e.g., [ V ] Bending [ V ] Lifting [ ] Awkward Posture/Position Doesn’t Apply [ ]

[ ] Pushing/Pulling [ ] Forceful Exertion [ V ] Repetitive Motion [ ] Heavy Object(s) [ V ] Manual Handling [ V ] Inadequate Lighting

[ ] Other: If ergonomic considerations exist, describe safeguard(s) used: use Back Corset, trolley, safety talk about material handling,

provide standing lights

10. Personal Protective Equipment (PPE) PPE below is not inclusive of all PPE available. Refer to Facility / Business PPE Grids and SDSs as needed

Face/Head Respiratory Protection Hands Body Feet/Legs

[ V ] Face Shield, Type: [ ] Air Pack (SCBA) [ ] Chemical Resistant [ ] Apron [ ] Composite Toe Shoes

_________________ [ V ] Dust Mask Gloves [ ] Chemical Resistant Suit [ ] Dielectric Boots

[ ] Hood, Type: [ ] Escape Respirator [ V ] Cotton Gloves [ ] Cooling PPE:___________ [ ] Knee Pads

_________________ [ ] Full Face Cartridge [ V ] Cut Resistant [ ] Fire Resistant Clothing [ ] Metatarsal Boots rated for

[ ] Welding Hood [ ] Half Face Cartridge Gloves [ ] High Visibility Clothing/Vest pressure being used

[ V ] Other: Cartridge Type: [ V ] Leather Gloves [ ] Personal Flotation Device [ ] Protective Leggings

Helm___________ __________ [V ] Rubber Gloves [ ] Tyvek Suit [ ] Rubber Boots

________________ [ ] Full Face Air Supply [ ] Welding Gloves [ V ] Other: Long sleeve T-shirt & [ V ] Steel Toe Shoes

[ ] Other: [ ] Other: Vest [ ] Other:

Eyes Ears Arms Electrical

[ ] Chemical Goggles Hearing Protection: [ V ] Long Sleeves [ ] Rubber Insulating Blanket/Matting [ ] Rubber Insulating Cover(s)

[ ] Cutting Goggles [ ] Single [ ] Double [ ] Protective Sleeves, [ ] Arc Flash PPE (EWP-21) [ ] Voltage-rated Tools (EWP-32)

[ V ] Safety Glasses with [ ] Limit time exposure: Cut Resistant [V ] Electrical Rubber Insulating Gloves (EWP-22)

Side Shields ____________________ [ ] Protective Sleeves,

[ ] FRP Live-line Tools (EWP-32) [ ] Temporary Protective Grounds

[ ] Other: ___________ [ V ] Other:<85 Dba : ear Leather

plug [ V ] Other: Non electrical contact_______________________

[ ] Other:

DOW RESTRICTED - For internal use only

SAFE WORK PERMIT (SWP)

Facility: ______________________________________ Emergency Number: +62081295670089__

Specify if, or when, the PPE to be used is task specific, e.g., “face shield and ear plugs needed only when cutting”: Use the basic PPE when start any

construction steps, Face shield, ear plug, heavy duty leathergloves,rubber gloves, safety glasses, safety shoes, safety helmet, long sleeves, Dust

mask needed only when cutting

11. Barricades needed? Yes No If yes, describe method and barricade distance(s): ___________________________________________________

Warning Signs: [ V ] Caution [ ] Danger [ ] Hydroblast [ ] Splash Guards [ ] Nitrogen Purge [ ] X-Ray [ ] Respiratory [ ] Hearing

[ ] Abrasive Blast [ ] Traffic control (e.g., Fork Lift Trucks, Heavy Equipment) [ ] Other:

SECTION II Isolation of Energy Sources (IOES) Doesn’t Apply [ V ]

1. Master Red Tag System Used? Yes No 1. Individual Red Tag System Used? Yes No

Red Tag Master (RTM) #(s):___________________________ Scope of Isolation:_____________________________________

2. Have Isolator and Independent Reviewer documented their Yes 2. Isolator and Independent Reviewer documented their verification

verification of the isolation? of the isolation? Yes

3. Scope of isolation reviewed with SWP Receiver? Yes 3. Scope of isolation reviewed with SWP Receiver? Yes

4. Workers accepted the Red Tag Master? Yes 4. Workers attached their Individual Red Tag(s)? Yes

5. SWP Receiver reviewed scope of isolation with crew members? Yes 5. Workers completed their Individual Location Listing? Yes

6. SWP Receiver signed the Red Tag Master? Yes 6. SWP Receiver communicated scope of isolation to their workers? Yes

7. Did any workers use Individual Red Tags? Yes No If yes,

Are worker’s Individual Red Tag(s) attached? Yes

Did workers complete their Individual Location Listing? Yes

1. Energy Control Operating Procedure (ECOP) Used? Yes No If yes, procedure name:

SECTION III Safe Work Permit Activation

As the SWP Receiver my signature indicates I: As the SWP Issuer my signature indicates I:

1. Listed all workers working under this SWP Yes N/A 1. Reviewed this SWP with the SWP Receiver Yes

2. Reviewed the contents of this SWP with my workers Yes N/A 2. Completed the initial on-site inspection with SWP Receiver Yes

3. Confirm I/workers understand the: 3. Determined that on-site inspections ARE ARE NOT

a) Scope and requirements of this SWP including emergency needed during the permitted work. If needed, describe scope

procedures, alarms and assembly points Yes of inspection:_______________________________________________

b) Need to notify SWP Issuer if job scope or work conditions __________________________________________________________

change Yes 4. Determined that on-site close out inspection beyond those listed in

4. Confirm I/workers have necessary skills/knowledge to do the SWP Close Out Section V IS IS NOT needed. If needed,

permitted work safely and properly use PPE Yes describe scope of inspection: __________________________________

5. Non U.S. ONLY: Communicated the original isolation and any __________________________________________________________

changes to it with my workers, and I will accept/release RTM and 5. Notified joint equipment owners. Yes N/A

Isolation Forms on behalf of all workers listed below, or on the If yes, Signature of joint equipment owner: ______________________

attached SWP Crew Roster. Yes 6. Notified adjacent facilities if work could impact them. Yes N/A

Names (print) of all workers covered by this SWP: ___________________ If yes, Signature of adjacent area owner(s):______________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________or SWP Crew Roster Attached Yes N/A

SWP Receiver Name: ___FARIS SAGITA____________________________ SWP Issuer Name: _____JHON LUTHER P__________________________

SWP Receiver Signature: _______________________________________ SWP Issuer Signature: __________________________________________

Date: Time: 08:00 S/D 04:00 Date: 1 Agustus 2019_____ Start Time: ___08:00__ End Time: _24:00____

SWP Receiver Company: ___PT OMEGA MOVERINDO SUKSES____________________________________

SWP Reassigned to: SWP Receiver Name/Signature:_BUSRO JUNAIDI_________/__________________________

Date: 1 Agustus 2019 Time: 08:00

SECTION IV Safe Work Permit Change(s) Doesn’t Apply [ V ]

1. Reason for SWP Change(s): 2. Is a new SWP needed? Yes No If no,

Past SWP End Time Change in Work Scope Is information on SWP still accurate? Yes No If no,

Change in Work Condition(s) Work Stoppage, e.g., evacuation Is an on-site inspection needed? Yes No

Complete Change in Work Crew Has SWP Issuer documented and initialed all changes on SWP? Yes

Other: Has SWP Issuer reviewed all changes with SWP Receiver? Yes

SECTION V Safe Work Permit Close Out

As the SWP Receiver my signature indicates: As the SWP Issuer my signature indicates I:

1. I informed the SWP Issuer of the status of the permitted work Yes 1. Reviewed the status of the permitted work, equipment and

2. Work described in the SWP is completed Yes No the work area with the SWP Receiver Yes

If no, describe the status: ______________________________________ 2. Completed the on-site close out inspection for work that:

__________________________________________________________ Involved removal/impairment of a safeguard critical to life Yes N/A

3. I/all my workers covered by this SWP have stopped working Yes Created a hazard that required a safeguard critical to life Yes N/A

4. I acknowledge this SWP is no longer active Yes Involved erection, modification or removal of LCG’s Yes N/A

Is described in Section III Line 4 Yes N/A

3. Confirmed LCG were replaced with permanent guardrails,

flooring, grating or work area was returned to original state Yes N/A

4. Confirmed grating was inspected by a Qualified Grating Inspector if it

was reinstalled after being disturbed, removed or damaged Yes N/A

5. Notified Rope Access Rescue Team that work is complete Yes N/A

DOW RESTRICTED - For internal use only

SAFE WORK PERMIT (SWP)

Facility: ______________________________________ Emergency Number: +62081295670089__

SWP Receiver Name: ___Faris Sagita _______________________________ SWP Issuer Name: _______JHON LUTHER P________________________

SWP Receiver Signature: _______________________________________ SWP Issuer Signature: ___________________________________________

Date: 1 Agustus 2019 Time: 19:00 Date: : 1 Agustus 2019 Time: 19:00

SECTION VI Hot Work Doesn’t Apply [V]

1. Location of Hot Work: WTC 3 Building 11. Are there other materials that can generate pressure increase or

_________________________________________ hazardous vapors upon heating? Yes No If yes, describe

2. Hot Work Area Classification: Flammable General Exempt precautions to eliminate / minimize hazards: ______________________

3. Type of Hot Work: Low Energy (complete questions 1-9) _________________________________________________________

High Energy (complete questions 1-17) ________________________________________________________

4. Line/Equipment status: In Service Drained Cleared 12. Is equipment corrosion present that can generate flammable

Cleaned Depressurized New Other:______________ materials? Yes No If yes, choose at least one of

N/A the following:

5. Line/equipment isolated with: Air Gap with Misalignment Blinds Corrosion has been removed where Hot Work will occur

Double Block & Bleed - if used, Name of Secondary Approver: Ventilate line/equipment

______________________________________________

Other: ______________________________________________

Alternative Isolation - if used, FWGL Approval, Name: ____________

13. Fire Protection needed? Yes N/A

& RCL or Delegate Approval, Name: ___________________________

Fire extinguisher type: CO2 Powder Other: _____________

N/A

Fire extinguisher is full? Yes

6. Is there potential for flammable materials to be trapped behind liners

Combustible/flammables moved at least 35 ft/11m? Yes No N/A

or in dead legs? Yes No If yes, describe

If no, choose one or more of the following as guard or shield:

method(s) to clear equipment: ________________________________

Spark Protection Water Spray Wetted Tarps

_________________________________________________________

Other: _________________________________________________

7. Purging needed? Yes N/A If yes,

Chemical sewer drains within 35 ft /11 m covered? Yes N/A

Indicate purge gas: ________________________________________

Fire protection system disabled? Yes N/A

Describe how done: _______________________________________

If yes, describe alternative fire protection:_________________________

Describe ventilation needs:_________________________________

__________________________________________________________

8. Flammable atmosphere monitoring required? Yes N/A

14. Connections & hoses checked for leaks if flammable materials

If yes, location of monitoring: _________________________________

are introduced, e.g., acetylene, cylinders? Yes N/A

Monitoring frequency: Initial Only Continuous Periodic

15. Heat exposure to gaskets, seals, liners can occur? Yes No

If periodic, describe frequency: _______________________________

If yes, describe precautions: __________________________________

Monitoring date: ___________________ Time: __________________

_________________________________________________________

Name of person who did monitoring:___________________________

16. Safety Attendant Name (for High Energy Hot Work): N/A

Meters bump tested or calibrated prior to days use? Yes

_________________________________________________________

Level of flammables detected: 0% LEL Other, describe: _____

17. Name of Secondary Approver that approved High Energy Hot N/A

_________________________________________________________

in a Flammable Area:_____________________________________

9. Nearby activities which can generate flammable atmospheres

prohibited until Hot Work is complete? Yes N/A

10. List flammable and/or combustible materials within the work

area: ____________________________________ AND last contained

in the equipment: ___________________________________________

SECTION VIII Fall Prevention

1. Method(s) workers will use to access elevated work area: 6. Pre-use check complete for: Aerial Lift: Yes N/A

Aerial Lift Scissor Lift Crane Suspended Work Platform: Yes N/A

Ladder If used, is ladder 6 ft/1.8 m or more from a guardrail Suspended Work Platform: Yes N/A

or unprotected edge? Yes No If no, 7. Methods used to store and prevent objects and equipment from falling: N/A

choose one: Fall Arrest or Extend Guardrail(s) Tool Tether/Lanyard Tool Holster Tool Pouch

Mobile Elevated Work Platform Mobile Ladder Stand Wristbands Secured Containers Nets Tool Belt

Rope Access - FWGL Approval, Name: No job Rope Access__ Toe Boards Other: ______________________________________

Scope of SWP aligns with Rope Access Work Plan? Yes 8. Method(s) used to lift equipment: N/A

Work is performed by at least two Certified Rope Access Aerial Lift Crane Hoist

Technicians, one of which is a Level III Technician? Yes Rope Other: ________________________________

Rescue workers notified before work begins? Yes 9. Describe rescue method(s) to be used: N/A

Scaffold – Approved by Competent Scaffold Builder? Yes Aerial Lift Ladder Self-Lowering Device

Scope of SWP aligns with intended use, limitations and Rescue Team Other: _______________________________

precautions marked on the scaffold? Yes 10. Method(s) for workers doing elevated work to communicate with workers

FWGL Approval, Name: _______________________ if erecting, on the ground: Radios Verbal Hand Signal

modifying, dismantling scaffold that is cantilevered, a scaffold Other:_________________________________________________

tent, uses building/structure for support with gap > 1 ft/30 cm, 11. Workers are available on the ground to operate the controls of

or is a scaffold bridge longer than 25 ft/7.5 m elevated work equipment? Yes N/A

Suspended Work Platform - FWGL Approval, Name: ____________ 12. Will Life Critical Guards (LCG) be erected/modified/removed? Yes N/A

Checked by Competent Person? Yes FWGL Approval, Name (if erected or modified):________________________

If suspended from crane, Crane Operator is certified? Yes Safety Attendant(s) used? (max 2 hrs) Yes N/A

Other: Work on surface_______________________________________

2. Fall Prevention to be used: Guardrail(s) Cover(s) Work on Roof(s) Doesn’t Apply [V]

Life Critical Guards (LCGs) with labels 13. Will work occur within 6 ft./1.8 m of the edge of a flat or low

Fall Restraint System Fall Arrest System Safety Net sloped roof? Yes N/A

Other: __________________________________ If yes, choose one or more of the following:

3. Identify Approved Anchor Point(s) to be used: N/A Guardrails Fall Restraint Fall Arrest Safety Net

Structural Steel Approved Piping 14. NON U.S. ONLY: Will work occur between 6 ft / 1.8 m and 15 ft / 4.5 m

Insulated Pipe – FWGL Approval, Name: _____________________ of the edge of a low sloped roof? Yes N/A

Scaffold Components – Competent Scaffold Builder Approval, If yes, choose one or more of the following:

Name: _______________________________________________ Guardrails Fall Restraint Fall Arrest Safety Net

Mobile Anchor Point - Checked by Competent Person prior Warning lines made of rope, wires or chains, and stanchions

DOW RESTRICTED - For internal use only

SAFE WORK PERMIT (SWP)

Facility: ______________________________________ Emergency Number: +62081295670089__

to use? Yes placed at least 6 ft/1.8 m from the roof edge

Vertical Lifeline Horizontal Lifeline 15. U.S. ONLY: Will work occur between 6 ft and 15 ft of the edge of a

Mobile Crane Hook flat or low sloped roof? Yes N/A

Other - Approved by Qualified Person: _______________________ If yes, choose one or more of the following:

4. Will workers/equipment be on surfaces not designed for walking or Guardrails Fall Restraint Fall Arrest Safety Net

working? Yes No If yes, Warning lines made of rope, wires or chains, and stanchions

describe method(s) to address hazards: Distribute Weight placed close to the work area but no less than 6 ft from the roof edge

Barricade Fall Arrest Other (recommended by (if work is infrequent and temporary and is not construction)

Structural Engineer): ____________________________________ 16. U.S. ONLY: Will work occur greater than 15 ft from the edge of a

_____________________________________________________ flat or low sloped roof? Yes N/A

FWGL Approval, Name: __________________________________ If yes, choose one or more of the following:

5. Will equipment be used to lift workers? Yes No If yes, Guardrails Fall Restraint Fall Arrest Safety Net

does equipment have crush protection or is it an electrically insulated Warning lines made of rope, wires or chains, and stanchions

bucket truck with guarded controls & spotter? Yes No If no, placed close to the work area but no less than 6 ft from the roof edge

describe administrative controls used: ______________________ A work rule that restricts access to within 15 ft of roof edge

_________________________________________________ and (if work is infrequent and temporary and is not construction)

FWGL Signature: ______________________________________ 17. Will work occur on a steep sloped roof? Yes N/A

Equipment can be operated from the ground? Yes If yes, choose one or more of the following:

Will equipment lifting workers enter tight or restricted Guardrails Fall Arrest Safety Net

space(s)? Yes No If yes,

FWGL or EHS Delivery Leader or Project Leader Approval, Name:

_____________________________________________________

DOW RESTRICTED - For internal use only

You might also like

- Delayed Coker Safety During ShutdownsDocument38 pagesDelayed Coker Safety During ShutdownsMIGUELONOFRENo ratings yet

- Blasting Painting Report (Example)Document1 pageBlasting Painting Report (Example)DoddyNo ratings yet

- Corrective Action Log TemplateDocument20 pagesCorrective Action Log Templatendayiragije JMVNo ratings yet

- Lecture 3 - Process SafetyDocument79 pagesLecture 3 - Process SafetyDivyashini MohanNo ratings yet

- Training Plan Including On-The-Job Training of NigeriansDocument5 pagesTraining Plan Including On-The-Job Training of NigeriansLaohoria YamallahNo ratings yet

- JSA Installation of Platform and Guard Rails On Crawler CraneDocument5 pagesJSA Installation of Platform and Guard Rails On Crawler CraneDann TanNo ratings yet

- Activity - Communication PlanDocument5 pagesActivity - Communication Planwaqeeh arshadNo ratings yet

- ChecklistDocument10 pagesChecklistbharat ghantaNo ratings yet

- Blanking and Blinding PracticeDocument8 pagesBlanking and Blinding PracticeBabyface888100% (1)

- Workplace Hazard Inspection ChecklistDocument3 pagesWorkplace Hazard Inspection ChecklistWisnu KertaningnagoroNo ratings yet

- Dust and EmissionsDocument112 pagesDust and Emissions0808276kNo ratings yet

- Director Manager Environmental Health Safety in Nashville TN Resume Neil SchwartzDocument2 pagesDirector Manager Environmental Health Safety in Nashville TN Resume Neil SchwartzNeilSchwartzNo ratings yet

- 508 Access Fullbook Industrial PSM Training Ed. 2.0 January 2014 PDFDocument235 pages508 Access Fullbook Industrial PSM Training Ed. 2.0 January 2014 PDFwaheed2286No ratings yet

- Saferad LTD: Health, Safety and Environmental Targets - 2016 2018Document3 pagesSaferad LTD: Health, Safety and Environmental Targets - 2016 2018AkhilNo ratings yet

- Observation Card ReportDocument32 pagesObservation Card Reportob8y100% (1)

- Regular Board Meeting Agenda Package - April 7, 2020Document29 pagesRegular Board Meeting Agenda Package - April 7, 2020Jess PetersNo ratings yet

- EGA SETP TT-CSM 13 Prequal Questionnaire v2.00Document6 pagesEGA SETP TT-CSM 13 Prequal Questionnaire v2.00shijadNo ratings yet

- REGDOC2 1 2 Safety Culture Final EngDocument31 pagesREGDOC2 1 2 Safety Culture Final Engnagatopein6No ratings yet

- FY12 New Comp PlanDocument6 pagesFY12 New Comp PlanhousingworksNo ratings yet

- Central EHS meeting performance highlightsDocument4 pagesCentral EHS meeting performance highlightsakshay aryaNo ratings yet

- Procedure For OffloadingDocument10 pagesProcedure For OffloadingStansilous Tatenda Nyagomo100% (1)

- Solar Permitting GuidelinesDocument12 pagesSolar Permitting GuidelinesDanielNo ratings yet

- Section 942-BR Area Coating GIIDocument31 pagesSection 942-BR Area Coating GIIchristian gordonNo ratings yet

- SWP 03 Heavy EquipmentDocument7 pagesSWP 03 Heavy Equipmentমমিন মানব100% (1)

- JHA 001 Welding OperationsDocument3 pagesJHA 001 Welding OperationsAhmad alwaelyNo ratings yet

- Job Safety Analysis Sheet: FacilityDocument1 pageJob Safety Analysis Sheet: FacilityHelza RahmanniaNo ratings yet

- Cold Work PermitDocument1 pageCold Work PermitherdianNo ratings yet

- SWP-07 For Office Safety and Health DaimanDocument1 pageSWP-07 For Office Safety and Health DaimanHassan AbdullahNo ratings yet

- Qcs 2010 Section 11 Part 2.3.11 She Procedures - Permit To Work SysteDocument20 pagesQcs 2010 Section 11 Part 2.3.11 She Procedures - Permit To Work Systebryanpastor106No ratings yet

- Annual Training Calender Eti 12Document1 pageAnnual Training Calender Eti 12anand shankarNo ratings yet

- PT BUMI MOROWALI UTAMA HSE Monthly ReportDocument9 pagesPT BUMI MOROWALI UTAMA HSE Monthly ReportHifni GhazaliNo ratings yet

- Ho 89Document1 pageHo 89Shanmugam AnnamalaiNo ratings yet

- IAEA PPE SpecificationDocument4 pagesIAEA PPE SpecificationRoberto CarlosNo ratings yet

- Part Submission WarrantDocument4 pagesPart Submission WarrantSam AnuNo ratings yet

- EOHSMS-02-F06 Hot Work PermitDocument2 pagesEOHSMS-02-F06 Hot Work PermitHassan AbdullahNo ratings yet

- Welding Workshop Layout GuideDocument1 pageWelding Workshop Layout GuideAna Rosel Olaran AtonNo ratings yet

- LCAM Whitepaper 204 PDFDocument7 pagesLCAM Whitepaper 204 PDFShashank JainNo ratings yet

- Fall Protection Equipment Inspection ChecklistDocument2 pagesFall Protection Equipment Inspection ChecklistCristinaNo ratings yet

- What Is PSMDocument2 pagesWhat Is PSMChawki Zerrouki100% (1)

- SOP 4 - Coal Bed Leveling in PGPDocument18 pagesSOP 4 - Coal Bed Leveling in PGPfaraz ahmedNo ratings yet

- Lab Design Guide ChecklistDocument9 pagesLab Design Guide ChecklistTanveer AzizNo ratings yet

- Blasting & Painting Report: Surface PreparationDocument1 pageBlasting & Painting Report: Surface PreparationSandra SandersNo ratings yet

- Job Safety Analysis: JSA Basic DataDocument5 pagesJob Safety Analysis: JSA Basic DataPrabhu DivakaranNo ratings yet

- Complacency - Safety Toolbox Talks Meeting TopicsDocument2 pagesComplacency - Safety Toolbox Talks Meeting TopicsqhseNo ratings yet

- Activity-Based Risk Assessment BesmarDocument9 pagesActivity-Based Risk Assessment Besmardwi_6188No ratings yet

- HSE Inspection Checklist: 1 Safety PromotionDocument4 pagesHSE Inspection Checklist: 1 Safety PromotionRanjan PrNo ratings yet

- HSE Safety Permit to Work ProcedureDocument32 pagesHSE Safety Permit to Work Proceduregobi100% (1)

- Audit ChecklistDocument25 pagesAudit ChecklistMaria Luciana GusmãoNo ratings yet

- EHS 2-F8 PTW LiftingDocument2 pagesEHS 2-F8 PTW LiftingLee Xiao YuNo ratings yet

- Augustine - O - Olumoye - 16 - Yrs Oil Gas - HSE MANAGERDocument4 pagesAugustine - O - Olumoye - 16 - Yrs Oil Gas - HSE MANAGERTheophilus Muyiwa100% (1)

- IGN 07 Working at Height and Working at Height Rescue PlanDocument75 pagesIGN 07 Working at Height and Working at Height Rescue Planin123No ratings yet

- TPIP ManualDocument53 pagesTPIP ManualMurugananthamParamasivamNo ratings yet

- Habits of Effective Safety ManagersDocument7 pagesHabits of Effective Safety ManagersNiraNo ratings yet

- Installer Instructions: WWW - Etnice.co - ZaDocument20 pagesInstaller Instructions: WWW - Etnice.co - ZaJack SmithNo ratings yet

- Electric Arc Welder Risk ManagementDocument9 pagesElectric Arc Welder Risk ManagementpankajNo ratings yet

- Welding Shop Environmental PolicyDocument1 pageWelding Shop Environmental PolicyMuhammad UmarNo ratings yet

- PSI Inspection SheetDocument9 pagesPSI Inspection SheetSalman BankariNo ratings yet

- SWP - 21!06!2019 (Demolish Existing Ceiling & Raised Floor)Document4 pagesSWP - 21!06!2019 (Demolish Existing Ceiling & Raised Floor)Jhon Luther PNo ratings yet

- Safety Pre-Task AssignmentDocument2 pagesSafety Pre-Task AssignmentSathiya SeelanNo ratings yet

- 08C Supbook STADocument2 pages08C Supbook STAMohammed MinhajNo ratings yet

- Weekly Repot 20 Juli - 26 JuliDocument6 pagesWeekly Repot 20 Juli - 26 JuliJhon Luther PNo ratings yet

- Weather Report: Month: May-22 Project: AAJ - Marunda Location: Marunda - Jakarta UtaraDocument1 pageWeather Report: Month: May-22 Project: AAJ - Marunda Location: Marunda - Jakarta UtaraJhon Luther PNo ratings yet

- Weather Report: Month: Apr-22 Project: AAJ - Marunda Location: Marunda - Jakarta UtaraDocument1 pageWeather Report: Month: Apr-22 Project: AAJ - Marunda Location: Marunda - Jakarta UtaraJhon Luther PNo ratings yet

- Weekly - Report - HSE - 5 JULI-12 - JuLI - 2019Document9 pagesWeekly - Report - HSE - 5 JULI-12 - JuLI - 2019Jhon Luther PNo ratings yet

- Hse Workplace Condition Inspection (Wci) Hazard / Non-Conformance FormDocument9 pagesHse Workplace Condition Inspection (Wci) Hazard / Non-Conformance FormJhon Luther PNo ratings yet

- HDL 1 September 2019Document1 pageHDL 1 September 2019Jhon Luther PNo ratings yet

- Office door installation notesDocument1 pageOffice door installation notesJhon Luther PNo ratings yet

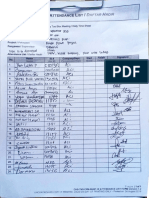

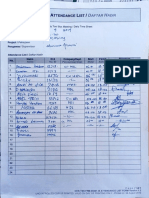

- 7 September 2019 Attendance ListDocument2 pages7 September 2019 Attendance ListJhon Luther PNo ratings yet

- HDL 3 Agustus 2019Document3 pagesHDL 3 Agustus 2019Jhon Luther PNo ratings yet

- SWP - 21!06!2019 (Demolish Existing Ceiling & Raised Floor)Document4 pagesSWP - 21!06!2019 (Demolish Existing Ceiling & Raised Floor)Jhon Luther PNo ratings yet

- Weekly Repot 20 Juli - 26 JuliDocument6 pagesWeekly Repot 20 Juli - 26 JuliJhon Luther PNo ratings yet

- Weekly Repot 20 Juli - 26 JuliDocument6 pagesWeekly Repot 20 Juli - 26 JuliJhon Luther PNo ratings yet

- Absensi Juni & Juli 2019: JL Pejompongan Dalam No. 16 Bendungan Hilir, Tanah Abang TLP 021 57901232 Fax 021 52906772Document1 pageAbsensi Juni & Juli 2019: JL Pejompongan Dalam No. 16 Bendungan Hilir, Tanah Abang TLP 021 57901232 Fax 021 52906772Jhon Luther PNo ratings yet

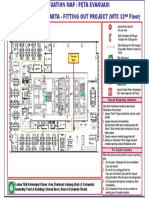

- EVACUATION MAPDocument1 pageEVACUATION MAPJhon Luther PNo ratings yet

- Boll Filter Protection System ProgramDocument38 pagesBoll Filter Protection System ProgramsridarNo ratings yet

- Sds - Bengalac Woodprimer - English (Uk) - DubaiDocument5 pagesSds - Bengalac Woodprimer - English (Uk) - DubaiBalasubramanian AnanthNo ratings yet

- Lactarin® DX 2017 Carrageenan - FMC CorporationDocument8 pagesLactarin® DX 2017 Carrageenan - FMC CorporationAna RidaoNo ratings yet

- 3094 User Manual XP KongsbergDocument200 pages3094 User Manual XP KongsbergRadoNo ratings yet

- Isobutanol PDFDocument11 pagesIsobutanol PDFElías VillegasNo ratings yet

- MES-Service-Manual Indeco PDFDocument141 pagesMES-Service-Manual Indeco PDFFastcross Honda100% (2)

- Incident Reporting ProcedureDocument24 pagesIncident Reporting ProcedureAiza Tancinco Bautista100% (1)

- Emergency Contact Information: Your Name Address City, State, Zip Telephone Special DirectionsDocument2 pagesEmergency Contact Information: Your Name Address City, State, Zip Telephone Special DirectionsVictor Hugo Calvanapón SalasNo ratings yet

- 492 MSDSDocument5 pages492 MSDSsrinivignaNo ratings yet

- JSA Mechanical Plant and Machinery SafetyDocument8 pagesJSA Mechanical Plant and Machinery SafetyMazlan AshaariNo ratings yet

- Uniform TCC Final 2024-2025Document31 pagesUniform TCC Final 2024-2025satriaNo ratings yet

- 5 PpeDocument81 pages5 PpeShiella Marie PacturanNo ratings yet

- MTU 2000 M94 OperationDocument153 pagesMTU 2000 M94 OperationDimas Saputro100% (1)

- Sebu7147-05 SDocument19 pagesSebu7147-05 SingjoseosunaNo ratings yet

- MSDS - FlourDocument4 pagesMSDS - FlourMichael RujuwaNo ratings yet

- Workplace Inspection Checklist BlankDocument7 pagesWorkplace Inspection Checklist BlanksifuclenNo ratings yet

- MS-BA400-v3 ENGDocument234 pagesMS-BA400-v3 ENGLabor PrimaNo ratings yet

- File 1416992597Document9 pagesFile 1416992597Roberto BrionesNo ratings yet

- Aircraft Hangar Safety Checklist - Protect Your STDocument8 pagesAircraft Hangar Safety Checklist - Protect Your STMohamad Abu hayyehNo ratings yet

- Twinson Composite Decking InstallationDocument17 pagesTwinson Composite Decking InstallationpbrilhanteNo ratings yet

- JSA-003 Excavation & BackfillingDocument3 pagesJSA-003 Excavation & Backfillingba ratnaparkhe100% (1)

- MSDS - Alkyd Enamel Paint (Cat Avian) PDFDocument11 pagesMSDS - Alkyd Enamel Paint (Cat Avian) PDFbumisetraNo ratings yet

- Rtaf SVX001C en - 11252015Document106 pagesRtaf SVX001C en - 11252015Thiraviam AyyappanNo ratings yet

- POW Montealegre (Final) 3Document131 pagesPOW Montealegre (Final) 3Leah Mamanao100% (1)

- Study Guide for Safety SupervisorsDocument240 pagesStudy Guide for Safety SupervisorsAsif Hussain92% (13)

- DPWHDocument276 pagesDPWHjovitangel100% (4)

- Disaster in Nursing 2Document70 pagesDisaster in Nursing 2wulanNo ratings yet

- Safety MagnalenzDocument29 pagesSafety MagnalenzBruno ThiemeNo ratings yet

- Compact Gas Ramp - Product Manual - enDocument38 pagesCompact Gas Ramp - Product Manual - enSalman Khalid ChauhanNo ratings yet

- Memorandum of Agreement For Work Immersion PartnershipDocument9 pagesMemorandum of Agreement For Work Immersion PartnershipAilene Heramil Ponio100% (5)