Professional Documents

Culture Documents

Fall Protection Equipment Inspection Checklist

Uploaded by

CristinaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fall Protection Equipment Inspection Checklist

Uploaded by

CristinaCopyright:

Available Formats

Fall Protection Equipment Inspection Checklist INFC Safety

INSTRUCTIONS FOR USE: An annual inspection by a competent inspector must be performed for each piece of

fall protection equipment. Using one of the checklists below, fully inspect each piece of equipment. If the

equipment fails the inspection, it must be destroyed and discarded. After completing the inspection:

1. Indicate on the equipment inspection tag the date of inspection and the initials of the inspector.

2. Indicate on the Fall Protection Equipment Inventory the date of inspection and the name of the

inspector. If equipment fails inspection indicate the date the equipment was destroyed and discarded.

3. Indicate on the Equipment Safety Inspection Matrix the date all inspections are complete and the login

of the inspector. When all equipment is inspected, indicate the inspection is complete on the

Equipment Safety Inspection Matrix and upload it to the Safety Compliance Calendar.

Full Body Harness Inspection Self-Retracting Lifeline Inspection Lanyard Inspection

Manufacture Date Manufacture Date Manufacture Date

Model Number Model Number Model Number

Serial Number Serial Number Serial Number

Lot Number Lot Number Lot Number

1. Hardware: Inspect for _____ Accepted 1. Impact Indicator: Inspect _____ Accepted 1. Hardware (includes snap _____ Accepted

damage, distortion, sharp indicator for activation (rupture hooks, adjusters, keepers,

edges, burrs, cracks, and _____Rejected of red stitching, elongated _____Rejected thimbles, and D-Rings): _____Rejected

corrosion (includes D-Ring) indicator, etc…) Inspect for damage,

distortion, sharp edges, burrs,

cracks, corrosion, and proper

operation

2. Webbing: Inspect for _____ Accepted 2. Screws / Fasteners: Inspect _____ Accepted 2. Webbing: Inspect for cuts, _____ Accepted

cuts, burns, tears, abrasion, for damage and ensure all burns, tears, abrasion, frays,

frays, excessive soiling, and _____Rejected screws and fasteners are tight _____Rejected excessive soiling, and _____Rejected

discoloration discoloration

3. Stitching: Inspect for _____ Accepted 3. Housing: Inspect for _____ Accepted 3. Stitching: Inspect for pulled _____ Accepted

pulled or cut stitches distortion, cracks and other or cut stitches

_____Rejected damage. Inspect anchoring loop _____Rejected _____Rejected

for distortion and damage

4. Labels: Inspect to ensure _____ Accepted 4. Lifeline: Inspect for cuts, _____ Accepted 4. Synthetic Rope: Inspect for _____ Accepted

all labels are securely held burns, tears, abrasion, frays, pulled or cut yarns, burns,

in place and are legible _____Rejected excessive soiling, discoloration, _____Rejected abrasion, knots, excessive _____Rejected

and broken wires (see Impact soiling, and discoloration

Indicator Section)

5. Locking Action: Inspect for _____ Accepted 5. Wire Rope: Inspect for _____ Accepted

proper lock-up of brake broken wires, corrosion, kinks,

mechanism _____Rejected and separation of strands _____Rejected

6. Retraction / Extension: _____ Accepted 6. Energy Absorbing _____ Accepted

Inspect spring tension by Component: Inspect for

pulling life line out fully and _____Rejected elongation, tears, and _____Rejected

allowing it to retract fully (no excessive soling

slack)

7. Hooks / Carabineers: Inspect _____ Accepted 7. Labels: Inspect to ensure all _____ Accepted

for physical damage, corrosion, labels are securely held in

proper operation, and markings _____Rejected place and are legible _____Rejected

8. Reserve Lifeline: Inspect _____ Accepted

reserve lifeline retention

systems for deployment _____Rejected

Labels: Inspect to ensure all _____ Accepted

labels are securely held in place

and are legible _____Rejected

Comments: Comments: Comments:

Overall Disposition _____ Accepted Overall Disposition _____ Accepted Overall Disposition _____ Accepted

_____Rejected _____Rejected _____Rejected

Inspection Date Inspection Date Inspection Date

Inspector Name Inspector Name Inspector Name

Fall Protection Equipment Inspection Checklist INFC Safety

You might also like

- 3M Fall Pro Inspection Checklist LogsDocument9 pages3M Fall Pro Inspection Checklist LogsAnto MaryadiNo ratings yet

- 014 - Site Safety & Health Induction ChecklistDocument2 pages014 - Site Safety & Health Induction ChecklistRosli Bin Abdul Shukor100% (1)

- How To Conduct An Incident InvestigationDocument4 pagesHow To Conduct An Incident Investigationkenoly123No ratings yet

- Hand & Finger ProtectionDocument2 pagesHand & Finger ProtectionJonasNo ratings yet

- Dust and EmissionsDocument112 pagesDust and Emissions0808276kNo ratings yet

- JSA-Piling or Concreting For Foundations & BuildingDocument2 pagesJSA-Piling or Concreting For Foundations & BuildingSanjeet SinghNo ratings yet

- Full Body Harness ChecklistDocument1 pageFull Body Harness Checklistmohammad sarfarazNo ratings yet

- 10 Rules Hand SafetyDocument1 page10 Rules Hand SafetyRoman StreliaievNo ratings yet

- SWP Grinder Bench AS520Document1 pageSWP Grinder Bench AS520Tosif AliNo ratings yet

- CL #06 CPTW PDFDocument11 pagesCL #06 CPTW PDFmoNo ratings yet

- Soldering SafetyDocument2 pagesSoldering SafetyOrlando OcampoNo ratings yet

- Deutz TCG2032 Limit ValuesDocument19 pagesDeutz TCG2032 Limit ValuesKhokon Kumer SahaNo ratings yet

- 011 - JSA (Tower Crane) With Comments 12-9-06Document15 pages011 - JSA (Tower Crane) With Comments 12-9-06sattiNo ratings yet

- Workplace Vocabulary for Esl Students: With Exercises and TestsFrom EverandWorkplace Vocabulary for Esl Students: With Exercises and TestsNo ratings yet

- Safe Ladder Use RefresherDocument22 pagesSafe Ladder Use RefresherKheireddine AounallahNo ratings yet

- 17.scafold Inspection UNISCO (PF) - 17Document2 pages17.scafold Inspection UNISCO (PF) - 17Benasher IbrahimNo ratings yet

- Problems With Safety Observation Reporting - A Construction Industry Case StudyDocument34 pagesProblems With Safety Observation Reporting - A Construction Industry Case StudyRadger Teddy ManuelNo ratings yet

- Monthly HSE Activities Report For May - 05Document8 pagesMonthly HSE Activities Report For May - 05MyolwinooNo ratings yet

- Everythingohs Workplace Inspection ChecklistDocument4 pagesEverythingohs Workplace Inspection ChecklistsandyskadamNo ratings yet

- Toolbox Safety EssentialsDocument8 pagesToolbox Safety Essentialsbeng acostaNo ratings yet

- FMS - EOC ChecklistDocument6 pagesFMS - EOC Checklisthany winihastutiNo ratings yet

- SPI HSE FR 02 Tower Erection ChecklistDocument1 pageSPI HSE FR 02 Tower Erection ChecklistChandan KumarNo ratings yet

- Company Name: Sacffold Location Completed By: Date: TimeDocument1 pageCompany Name: Sacffold Location Completed By: Date: Timesadashiv puneNo ratings yet

- Suspended Scaffold Inspection ChecklistDocument3 pagesSuspended Scaffold Inspection ChecklistSamantha Meril PandithaNo ratings yet

- Eg - Series ElgiDocument134 pagesEg - Series ElgiParthaGuhaNo ratings yet

- SSWP Civil Engineering FormDocument6 pagesSSWP Civil Engineering FormSanjeet SinghNo ratings yet

- Presentation On Safety For E1 E2 PDFDocument84 pagesPresentation On Safety For E1 E2 PDFdalalanup90No ratings yet

- Job Hazard Analysis DemolishDocument4 pagesJob Hazard Analysis Demolishyajid bustomiNo ratings yet

- Bench Shears SafetyDocument2 pagesBench Shears Safetyvasu_suva100% (2)

- 22 Hand Tool SafetyDocument8 pages22 Hand Tool SafetyAlma Tomas-CafeNo ratings yet

- 04 Risk ManagementDocument21 pages04 Risk ManagementMuhammad Shiraz KhalidNo ratings yet

- PPE Checklist: PT Thermax International IndonesiaDocument1 pagePPE Checklist: PT Thermax International Indonesiaadam rizkiNo ratings yet

- PPE and Material Inspection FormDocument2 pagesPPE and Material Inspection FormRaj Engineering ServicesNo ratings yet

- Job Safety Observer Form-AATDocument2 pagesJob Safety Observer Form-AATNinkung07No ratings yet

- The Highest Efficiency Turbo Blower: Oilless Gearless Vibrationless StainlessDocument13 pagesThe Highest Efficiency Turbo Blower: Oilless Gearless Vibrationless Stainlessxiong du100% (1)

- Niversity of Eicester: P W P R E & F M DDocument27 pagesNiversity of Eicester: P W P R E & F M DFOZCANNo ratings yet

- Personal Protective Equipment: For: Date: Conducted byDocument2 pagesPersonal Protective Equipment: For: Date: Conducted byMahdi JasimNo ratings yet

- 130 X2 BRAZIL PARTS BOOK - CoverDocument524 pages130 X2 BRAZIL PARTS BOOK - CoverLuis Jesus100% (2)

- Job Safety Analysis: JSA Basic DataDocument5 pagesJob Safety Analysis: JSA Basic DataPrabhu DivakaranNo ratings yet

- Wilmar Group Indonesia: 7S Audit Guide MeetingDocument9 pagesWilmar Group Indonesia: 7S Audit Guide MeetingNur CahyantiiNo ratings yet

- DSE Assessment DT TemplateDocument11 pagesDSE Assessment DT TemplateJulien CambonNo ratings yet

- Form 13Document4 pagesForm 13Jayendra NaiduNo ratings yet

- Ev02 - Brief Program For New Work at Height CampaignDocument2 pagesEv02 - Brief Program For New Work at Height CampaignFrancis Enriquez TanNo ratings yet

- 980 Behavior Based Safety Program PDFDocument2 pages980 Behavior Based Safety Program PDFherik0% (1)

- Electrical Safety TrainingDocument73 pagesElectrical Safety Trainingmark magpaleNo ratings yet

- Ppe Issue RegisterDocument1 pagePpe Issue RegisterAnsarMahmoodNo ratings yet

- Consolidated Construction Consortium LTD.: DOC No.:CCCL/HSE/003 OCP No.31 DateDocument1 pageConsolidated Construction Consortium LTD.: DOC No.:CCCL/HSE/003 OCP No.31 DateradhouaneNo ratings yet

- EGA SETP TT-CSM 13 Prequal Questionnaire v2.00Document6 pagesEGA SETP TT-CSM 13 Prequal Questionnaire v2.00shijadNo ratings yet

- Rebar Impalement HazardsDocument2 pagesRebar Impalement HazardsamizanNo ratings yet

- Asian Paints - Prem Gloss EnamelDocument1 pageAsian Paints - Prem Gloss EnamelwilliumstNo ratings yet

- Electrical Hazards Awareness Briefing for Non-Electrical PersonnelDocument39 pagesElectrical Hazards Awareness Briefing for Non-Electrical PersonnelvsrslmNo ratings yet

- Ptw-Lifting Operation (Daily) : General Information OMC Permit NoDocument2 pagesPtw-Lifting Operation (Daily) : General Information OMC Permit NoPHP DEVELOPERNo ratings yet

- Workplace Transport Checklist: Management of Workplace Transport Safety Yes No Action RequiredDocument7 pagesWorkplace Transport Checklist: Management of Workplace Transport Safety Yes No Action RequiredUlviyye ElesgerovaNo ratings yet

- Metal Lathe SWPDocument2 pagesMetal Lathe SWPwealth osiobeNo ratings yet

- Attachment 7 Scaffolding PermitDocument2 pagesAttachment 7 Scaffolding PermitAviects Avie JaroNo ratings yet

- Pera JackhammerDocument7 pagesPera Jackhammerjumansyahamid1988No ratings yet

- HSE 16 Incident Near Miss ReportDocument1 pageHSE 16 Incident Near Miss ReportBa N NhimNo ratings yet

- Ryobi Kiso SWP titleDocument2 pagesRyobi Kiso SWP titleHassan AbdullahNo ratings yet

- 17 HSE Alert Material Fall From HeightDocument1 page17 HSE Alert Material Fall From HeightAbdulKatherNo ratings yet

- D.1 HS012 - Emergency CoordinatorDocument1 pageD.1 HS012 - Emergency CoordinatorRetselisitsoe100% (1)

- MSDS - Asada Threading Oiil Red - ENDocument7 pagesMSDS - Asada Threading Oiil Red - ENnghiaNo ratings yet

- Ocp BatchingDocument1 pageOcp BatchingAarya Mishra TiwariNo ratings yet

- 3M Fall Pro Inspection Checklist LogsDocument9 pages3M Fall Pro Inspection Checklist LogsWafrika TechnologiesNo ratings yet

- Safetynetworkme ConstructionDocument11 pagesSafetynetworkme ConstructionMuhammad HasbiNo ratings yet

- Making A PCB: Report and PPT - PresentationDocument6 pagesMaking A PCB: Report and PPT - PresentationKaranSinghNo ratings yet

- Lenovo - Flex - 3-1130 - BM5488 - SCH - SVT - v1.4 FPCDocument52 pagesLenovo - Flex - 3-1130 - BM5488 - SCH - SVT - v1.4 FPCМакс67% (3)

- 50 Years of Crane Component ExcellenceDocument32 pages50 Years of Crane Component ExcellenceMahnooshNo ratings yet

- Understanding Motor Controls 3rd Edition Herman Test BankDocument4 pagesUnderstanding Motor Controls 3rd Edition Herman Test BankDebits100% (5)

- Awqaf Aae SD Hvac Mec 003 2Document1 pageAwqaf Aae SD Hvac Mec 003 2Ahmad Saleem AlawwadNo ratings yet

- Spartan-3A DSP FPGA Family: Data Sheet: Introduction and Ordering InformationDocument102 pagesSpartan-3A DSP FPGA Family: Data Sheet: Introduction and Ordering InformationUmar AnjumNo ratings yet

- Technical Service Information: THM 4T65EDocument10 pagesTechnical Service Information: THM 4T65EJose garcua vargas 2006401321No ratings yet

- Reel Craft GS3050Document5 pagesReel Craft GS3050kherlambangNo ratings yet

- HP-9020 Ink TankDocument3 pagesHP-9020 Ink TankKshitij TrivediNo ratings yet

- Accident StoryDocument2 pagesAccident StoryMa. Aiza SantosNo ratings yet

- Conext™ MPPT 60 150 Solar Charge Controller: MPPT Multi-Stage Charging, Better Battery LifeDocument2 pagesConext™ MPPT 60 150 Solar Charge Controller: MPPT Multi-Stage Charging, Better Battery LifeIdham HawariNo ratings yet

- Control 3-Phase Motors with Digistart Soft StartersDocument15 pagesControl 3-Phase Motors with Digistart Soft StartersriqkeNo ratings yet

- RV Series Pressure Relief Valves: Key FeaturesDocument2 pagesRV Series Pressure Relief Valves: Key FeaturesJoel VeraNo ratings yet

- Rizal Technological University College of Engineering and Industrial Technology Boni Avenue, City of MandaluyongDocument4 pagesRizal Technological University College of Engineering and Industrial Technology Boni Avenue, City of MandaluyongTech ProfessorNo ratings yet

- Index - . - . - .: Automatic Railway GateDocument28 pagesIndex - . - . - .: Automatic Railway GateSamudrala Mani KamalNo ratings yet

- LP008Document20 pagesLP008Rojas RudyNo ratings yet

- Copeland AC Scroll R22Document16 pagesCopeland AC Scroll R22Subbu RmNo ratings yet

- Rickly AquaCMD BrochureDocument2 pagesRickly AquaCMD BrochureCompras FisicoquimicoNo ratings yet

- 04-1-MHTOOL CD1 Rope Hoist Catalogue-1Document7 pages04-1-MHTOOL CD1 Rope Hoist Catalogue-1miguel contrerasNo ratings yet

- TEC1 12705 English PDFDocument3 pagesTEC1 12705 English PDFTony CefaiNo ratings yet

- GC 53113901Document204 pagesGC 53113901baracauda69No ratings yet

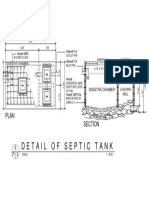

- Septic tank design with inlet and outlet pipesDocument1 pageSeptic tank design with inlet and outlet pipesar. berna quiambaoNo ratings yet

- Hi Tech ApplicatorDocument13 pagesHi Tech ApplicatorSantosh JayasavalNo ratings yet

- Computer Organisation SyllabusDocument2 pagesComputer Organisation SyllabusRadhika JaganathanNo ratings yet

- Tusb1210 q1Document67 pagesTusb1210 q1MauroNo ratings yet

- 1470 Sas 2Document2 pages1470 Sas 2tallervaleras2020No ratings yet