Professional Documents

Culture Documents

SPI HSE FR 02 Tower Erection Checklist

Uploaded by

Chandan KumarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SPI HSE FR 02 Tower Erection Checklist

Uploaded by

Chandan KumarCopyright:

Available Formats

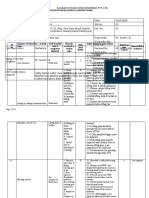

Doc Ref No: SPI-HSE-FR-02

SAFETY CHECK LIST - TOWER ERECTION Revision No: 01

Release Date:20/11/2018

Project Name: Line/section: Channel partner:

Sub-contractor: Manpower Strength: Tower Type :

Date: Loc No.:

Description Observations (Yes

Sl No Action taken

/ No)

1 Whether all site workers have been gone through Tool Box talk prior to start of work?

2 Whether Gang evaluation has been done properly and are all fit for their job?

3 Whether all fitters have been gone through medical examination & having height pass?

4 Have all required PPEs been provided to all concern workers as per requirements?

5 Whether Sufficient Manpower (Fitter & ground helper) has been engaged for erection work?

6 Is the work being properly and effectively supervised?

Is the work area suitably cordoned off? Adequate signage, posters, banners & caution tape are

7

present at site for public address?

8 Is adequate first-aid box available at site & emergency contact No. available with gang ?

If any, LT/HT is coming near to erection work, proper shut down has been taken and discharge

9

rod anchored properly?

If any road is coming near to erection activity, traffic controller should be deployed on both side

10

of the road?

Whether all Tools & tackles (Pulley, D-Shackles, PP Ropes, Derrick poles, steel wire ropes,

11 crow-bars, etc) have been inspected, validated & found in healthy condition and in sufficient

qty. present

Whether at site

Derrick ? is checked for any defect and properly tighten / fitted & it is provided as

Pole

12 per tower type & color code (green) done?

Derrick pole properly tied with tower leg & during lifting of tower materials appropriate angle

13 is maintained between leg & derrick?

14 Whether back filing of tower was properly done prior to start of erection work

Is ascending on and descending on from the tower done through the steps bolts with using Fall

Arrestor clamp. Is Fall arrestor clamp provided in sufficient quantity? Is practice of ascending on

15

and descending from the tower through the tower members stopped?

16 Whether retractable fall arrestor provided in sufficient nos.?

Whether Assembly of tower parts is being done outside of tower & No one is allowed to work

17

under suspended load ?

Are lifting of Assembled Tower parts carry out by steel wire rope(12 mm) and power Winch

18 machine only and member of tower is being lifted with proper guying and also maintain safe

work load during lifting?

All tower material should be lifted from outside of tower and if any part is being lifted from

19

inside of tower, it is being lifted from center of the tower and not through diagonals?

20 Is proper Backstay arrangements done for winch machine?

21 Is winch machine being operated by trained operator & has a valid ID card?

Whether winch machine has load indicator & placed at suitable distance from where proper

22 communication is easily made to fitter & operator?

Whether a signalman with flag has been deputed for proper communication between winch

23

operator & fitters?

Are 3 guy ropes for derrick pole made and also been checked for the proper size of the PP ropes

24

and crowbars which been fixed at hard surface in case of sandy or loose soil?

Whether all guys ropes have been anchored to at least two or three crowbars arrangements at

25

45 degree & each guy is anchored with separate same arrangement?

Are all guys ropes & crowbars been checked & verified for any malfunction by any external

26

person prior to start of work on daily basis?

Are all pulleys tied to the leg members through wire rope & sharp edges of tower members been

27 protected by providing a padding of old tyres / folded gunny bags? Are all pulley having latches

or close type?

Are towers being erected in sequential manner; like work on upper section must not be allowed

28 to start until all the members and bracings of lower tower section been fully erected and nut

bolts are properly tightened?

29 Are all workmen working at heights using properly secured safety harness and helmets?

30 Whether Horizontal life line is being used properly by fitters?

31 Whether all fitters secured their tools and Nut & Bolt to prevent from falling?

Whether Tac welding is going on:-

i) The Welding machine should be effectively grounded to protect against any leakage of current

32

ii) Welding should be carried out by trained welder

iii) Welder must wear welding shield

iv) Welding cable with lugs should be properly tightened in the secondary terminal

Channel Partner Engineer/ Supervisor (Name & signature) SPTL

Name & signature

You might also like

- Method Statement - PilingDocument16 pagesMethod Statement - Pilinguebdennis100% (1)

- Daily Scaffold Safety Checklist - BLANK PDFDocument1 pageDaily Scaffold Safety Checklist - BLANK PDFSajid MahmoodNo ratings yet

- Ms For Tele Tower ErectionDocument12 pagesMs For Tele Tower ErectionSahabzada AamirNo ratings yet

- JSA Formet New Blasting & PaintingDocument5 pagesJSA Formet New Blasting & Paintingsakthi venkatNo ratings yet

- Accident Investigation Form SampleDocument2 pagesAccident Investigation Form Sample811 - 813100% (2)

- Man Basket Cert 7101Document1 pageMan Basket Cert 7101Mac-Ross Cordova100% (1)

- Safety Audit Checklist - Stringing ActivityDocument3 pagesSafety Audit Checklist - Stringing ActivitysAuRaBhNo ratings yet

- SPI HSE FR 01 Foundation ChecklistDocument1 pageSPI HSE FR 01 Foundation ChecklistChandan KumarNo ratings yet

- High Risk Activities: GD11 Excavations ChecklistDocument2 pagesHigh Risk Activities: GD11 Excavations ChecklistIdada EzekielNo ratings yet

- Night Work Inspection ChecklistDocument1 pageNight Work Inspection ChecklistAdarsh sNo ratings yet

- 1 Hse Management ResponsibilityDocument13 pages1 Hse Management ResponsibilityRATAN BHATIANo ratings yet

- 014 - Site Safety & Health Induction ChecklistDocument2 pages014 - Site Safety & Health Induction ChecklistRosli Bin Abdul Shukor100% (1)

- Consolidated Construction Consortium LTD.: DOC No.:CCCL/HSE/003 OCP No.31 DateDocument1 pageConsolidated Construction Consortium LTD.: DOC No.:CCCL/HSE/003 OCP No.31 DateradhouaneNo ratings yet

- 17.scafold Inspection UNISCO (PF) - 17Document2 pages17.scafold Inspection UNISCO (PF) - 17Benasher IbrahimNo ratings yet

- Construction Scaffolding ChecklistDocument3 pagesConstruction Scaffolding ChecklistChayank TiwariNo ratings yet

- Visitor Safety BriefingDocument2 pagesVisitor Safety BriefingDoni TriatmojoNo ratings yet

- Daily Safety Report TemplateDocument1 pageDaily Safety Report TemplateMarkNo ratings yet

- Hougang Town Building Works Daily ChecklistDocument1 pageHougang Town Building Works Daily ChecklistALFREDO JR. ARIOS CLARONo ratings yet

- Excavation Work Checklist: Saline Water Desalination Plant On The West CoastDocument2 pagesExcavation Work Checklist: Saline Water Desalination Plant On The West CoastBRC HSE Dept.No ratings yet

- Mobile Scaffold Inspection ChecklistDocument3 pagesMobile Scaffold Inspection Checklistanthony murphyNo ratings yet

- Site Risk Register Summarizes Facility HazardsDocument4 pagesSite Risk Register Summarizes Facility HazardsvatasaNo ratings yet

- Inspection Sheet For Roller and ConveyorDocument2 pagesInspection Sheet For Roller and ConveyorPaintsil BrightNo ratings yet

- Checklist For Scaffolding: Project: SL# Description Observation Yes/No/ NA Remarks & RecommendationsDocument4 pagesChecklist For Scaffolding: Project: SL# Description Observation Yes/No/ NA Remarks & RecommendationsDeshbandhu Aman PandeyNo ratings yet

- JSA For Erection & Dismantling of ScaffoldingDocument4 pagesJSA For Erection & Dismantling of ScaffoldingNoe AranelNo ratings yet

- Workplace Transport Checklist: Management of Workplace Transport Safety Yes No Action RequiredDocument7 pagesWorkplace Transport Checklist: Management of Workplace Transport Safety Yes No Action RequiredUlviyye ElesgerovaNo ratings yet

- Pre Mob Flatbed Truck Daily Inspection Checklist FormDocument3 pagesPre Mob Flatbed Truck Daily Inspection Checklist Formagusbudianto.dk168No ratings yet

- Permit To Excavate: Section - I Contact DetailsDocument1 pagePermit To Excavate: Section - I Contact DetailsBig Zaddy0% (1)

- SOP 4 - Coal Bed Leveling in PGPDocument18 pagesSOP 4 - Coal Bed Leveling in PGPfaraz ahmedNo ratings yet

- Rumaila Working at Height PermitDocument2 pagesRumaila Working at Height PermitMohammed KadhimNo ratings yet

- Checklist 011 - Visitor InductionDocument1 pageChecklist 011 - Visitor InductionHolly Smith50% (2)

- Excavation Risk Assessment and PermitDocument3 pagesExcavation Risk Assessment and Permituditha_ranatungeNo ratings yet

- Suspended Scaffold Inspection ChecklistDocument3 pagesSuspended Scaffold Inspection ChecklistSamantha Meril PandithaNo ratings yet

- SWP-22 Lock Out Tag Out DaimanDocument2 pagesSWP-22 Lock Out Tag Out DaimanHassan AbdullahNo ratings yet

- Manual Handling ChartDocument20 pagesManual Handling ChartTatak Bay Ahmed100% (1)

- ExcavationDocument9 pagesExcavationabidNo ratings yet

- EHS 2-F8 PTW LiftingDocument2 pagesEHS 2-F8 PTW LiftingLee Xiao YuNo ratings yet

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 4Document6 pagesThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 4Nitesh KumarNo ratings yet

- Plant EQUIPMENT Check SheetDocument1 pagePlant EQUIPMENT Check SheetSparrow Green StudiosNo ratings yet

- 1 Excavations and TrenchesDocument2 pages1 Excavations and TrenchesAruNo ratings yet

- Visitors HSES InductionDocument30 pagesVisitors HSES InductionPradeep KunduNo ratings yet

- Current Total Summary: Sec Ehvpd Woa & Soa Project Rectification RegistryDocument3 pagesCurrent Total Summary: Sec Ehvpd Woa & Soa Project Rectification RegistryAhsan MumtazNo ratings yet

- Fire Fighting Equipments Checklist: No. Items Inspected Status (Yes or No) Fire PumpDocument4 pagesFire Fighting Equipments Checklist: No. Items Inspected Status (Yes or No) Fire PumpAbeSanNo ratings yet

- Lifting PermitDocument1 pageLifting PermitManesh MNo ratings yet

- F.hse.07 Work PermitDocument4 pagesF.hse.07 Work PermitMOJIBNo ratings yet

- Construction Job Hazards Analysis: This Is A TEMPLATEDocument1 pageConstruction Job Hazards Analysis: This Is A TEMPLATETamNo ratings yet

- Working Safely at HeightsDocument3 pagesWorking Safely at HeightsRachel NoraNo ratings yet

- 167-QHSE-ST167 QHSE-Oil Spill Kit Inspection ChecklistDocument1 page167-QHSE-ST167 QHSE-Oil Spill Kit Inspection ChecklistVigneshwaraNo ratings yet

- Weekly Report ExampleDocument3 pagesWeekly Report Examplewawan setiawanNo ratings yet

- HSE Alert - LTI Fall From Heights TBTDocument12 pagesHSE Alert - LTI Fall From Heights TBTrodman823No ratings yet

- Site Environmental Control ReportDocument5 pagesSite Environmental Control ReportJasonTeeNo ratings yet

- Job Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectDocument5 pagesJob Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectShilpiengg SafetyNo ratings yet

- Working at Height PresentationDocument11 pagesWorking at Height PresentationAbdul Hameed OmarNo ratings yet

- NASDA WIND POWER SUB-STATION EXCAVATION SAFETYDocument2 pagesNASDA WIND POWER SUB-STATION EXCAVATION SAFETYRaza Muhammad SoomroNo ratings yet

- General Work PermitDocument2 pagesGeneral Work Permitloganathan0% (1)

- Health and Safety Induction Training SheetDocument2 pagesHealth and Safety Induction Training Sheetnil thaeuNo ratings yet

- Non-Routine Hazards and Risk Assessment SummaryDocument42 pagesNon-Routine Hazards and Risk Assessment SummaryGanesh Murugesan0% (1)

- Fan InstallationDocument2 pagesFan InstallationKrishna PatilNo ratings yet

- JSO Cable Drum (02 Sept.'07)Document2 pagesJSO Cable Drum (02 Sept.'07)Francis Enriquez TanNo ratings yet

- SPI HSE FR 03 Stringing ChecklistDocument1 pageSPI HSE FR 03 Stringing ChecklistChandan KumarNo ratings yet

- SPI HSE FR 04 Overhead Crossing ChecklistDocument1 pageSPI HSE FR 04 Overhead Crossing ChecklistChandan KumarNo ratings yet

- SPI HSE FR 05 Certificate Medical ExaminationDocument1 pageSPI HSE FR 05 Certificate Medical ExaminationChandan KumarNo ratings yet

- SPI HSE FR 04 Overhead Crossing ChecklistDocument1 pageSPI HSE FR 04 Overhead Crossing ChecklistChandan KumarNo ratings yet

- SPI HSE FR 03 Stringing ChecklistDocument1 pageSPI HSE FR 03 Stringing ChecklistChandan KumarNo ratings yet

- SPI HSE FR 02 Tower Erection ChecklistDocument1 pageSPI HSE FR 02 Tower Erection ChecklistChandan KumarNo ratings yet

- SPI HSE FR 04 Overhead Crossing ChecklistDocument1 pageSPI HSE FR 04 Overhead Crossing ChecklistChandan KumarNo ratings yet

- SPI HSE FR 05 Certificate Medical ExaminationDocument1 pageSPI HSE FR 05 Certificate Medical ExaminationChandan KumarNo ratings yet

- SPI HSE FR 03 Stringing ChecklistDocument1 pageSPI HSE FR 03 Stringing ChecklistChandan KumarNo ratings yet

- SPI HSE FR 01 Foundation ChecklistDocument1 pageSPI HSE FR 01 Foundation ChecklistChandan KumarNo ratings yet

- A B C D: Far Eastern UniversityDocument1 pageA B C D: Far Eastern UniversityIsylle VillafloresNo ratings yet

- RDHDTDocument10 pagesRDHDTKiran ShresthaNo ratings yet

- Bricks Messonary Work Job Hazard AnalysisDocument2 pagesBricks Messonary Work Job Hazard AnalysisMc Evans Magallanes100% (1)

- Ministry of Education flexible learning space upgrade design reportDocument18 pagesMinistry of Education flexible learning space upgrade design reportFei XiongNo ratings yet

- 13-Division 2-Section 02500 Roadworks and Paving-Version 2.0Document6 pages13-Division 2-Section 02500 Roadworks and Paving-Version 2.0Avaan IvaanNo ratings yet

- Gastone Petrini: Strutture e Costruzioni Autarchiche Di Legno in Italia e Colonie Caratteri e CriterDocument9 pagesGastone Petrini: Strutture e Costruzioni Autarchiche Di Legno in Italia e Colonie Caratteri e CriterPier Pasquale TrausiNo ratings yet

- P304 - Wood Acoustic FenceDocument1 pageP304 - Wood Acoustic FencesarthibhavsarNo ratings yet

- Proper gas appliance installation instructionsDocument35 pagesProper gas appliance installation instructionsMark NelsonNo ratings yet

- Chirag 123Document28 pagesChirag 123Krishna MittalNo ratings yet

- Central Workshop Manual For Mechanical Workshop CourseDocument60 pagesCentral Workshop Manual For Mechanical Workshop Courseankitbugalia56No ratings yet

- Concrete BlockDocument3 pagesConcrete BlockredNo ratings yet

- Engineering Studies Report - Yr12 2018Document12 pagesEngineering Studies Report - Yr12 2018Three Went DownNo ratings yet

- NHB00001317 - NHBC Workbook On Different Types of Cladding Systems.Document42 pagesNHB00001317 - NHBC Workbook On Different Types of Cladding Systems.WylieNo ratings yet

- Pafriw Hardware Product Catalogue 9th MayDocument68 pagesPafriw Hardware Product Catalogue 9th MayBarbaraNo ratings yet

- EPN 6082 7582N UM EN EN62841 V12printDocument24 pagesEPN 6082 7582N UM EN EN62841 V12printMustafa KutanisNo ratings yet

- CE 486 Preliminary Report - DenizyukcenDocument28 pagesCE 486 Preliminary Report - DenizyukcenNasyrBekNo ratings yet

- Emergency Estimate $72,590.61Document19 pagesEmergency Estimate $72,590.61Corporate OfficeNo ratings yet

- BS en 13139 PDFDocument10 pagesBS en 13139 PDFanilkumar_bojja97600% (1)

- 0621 SIKA Waterproofing - Wet AreasDocument12 pages0621 SIKA Waterproofing - Wet AreasstarykltNo ratings yet

- Rekapitulasi: Bill of QuantityDocument13 pagesRekapitulasi: Bill of QuantityKall RozvelNo ratings yet

- Competency-Based Curriculum A. Course Design: TESDA-OP-CO-01-F11Document44 pagesCompetency-Based Curriculum A. Course Design: TESDA-OP-CO-01-F11RYDENNo ratings yet

- Architectural Connections GuideDocument70 pagesArchitectural Connections GuideTSGSSNo ratings yet

- CFSB1 - Guide For Handling, Installing, Restraining & Bracing TrussesDocument2 pagesCFSB1 - Guide For Handling, Installing, Restraining & Bracing TrussesTodd HenryNo ratings yet

- TherraWood CatalogDocument58 pagesTherraWood Catalogmjd ellafiNo ratings yet

- 3ce 323 NotesDocument42 pages3ce 323 NotesRicsmith SocobosNo ratings yet

- Fixgrid18 Fixgrid18: Product Sheet Product SheetDocument8 pagesFixgrid18 Fixgrid18: Product Sheet Product SheetCesar Santiago Zambrano DiazNo ratings yet

- Design Preboard Exam NOV 2021Document17 pagesDesign Preboard Exam NOV 2021Glaiza Marie100% (1)

- Test Bank For Essentials of Strategic Management: The Quest For Competitive Advantage, 7th Edition, John Gamble Margaret PeterafDocument33 pagesTest Bank For Essentials of Strategic Management: The Quest For Competitive Advantage, 7th Edition, John Gamble Margaret Peterafknobbyettinjn4u4f100% (17)

- Mumbai Company DataDocument96 pagesMumbai Company DataMuskan ThakurNo ratings yet

- Product Specifications CUBO 2023 Bulacan Smart 10.07.22Document16 pagesProduct Specifications CUBO 2023 Bulacan Smart 10.07.22jose mari TrinidadNo ratings yet