Professional Documents

Culture Documents

SPI HSE FR 03 Stringing Checklist

Uploaded by

Chandan KumarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SPI HSE FR 03 Stringing Checklist

Uploaded by

Chandan KumarCopyright:

Available Formats

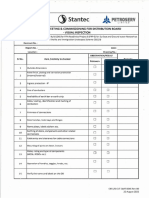

Doc Ref No: SPI-HSE-FR-03

SAFETY CHECK LIST - STRINGING Revision No: 01

Release Date:20/11/2018

Project Name: Line/section: Channel partner:

Sub-contractor: Manpower Strength: Span Length :

Date: Total Towers: Section:

Description Observations

Sl No (Yes/No) Action taken

1 Whether all site workers have been gone through Tool Box talk prior to start of work?

2 Whether Gang evaluation has been done properly and are all fit for their job?

3 Whether all fitters have been gone through medical examination & having height pass?

4 Have all required PPEs been provided to all concern workers as per requirements?

5 Whether Sufficient Manpower (Fitter & ground helper) has been engaged for stringing work?

6 Is the work being properly and effectively supervised?

Is the work area suitably cordoned off? Adequate signage, posters, banners & caution tape are present at

7

site for public address?

8 Is adequate first-aid box available at site & emergency contact No. available with gang?

Whether all Tools & tackles (Pulley, D-Shackles, PP Ropes, Equalizer pulley, Automatic clamp, bull dog

9 clamp, steel wire ropes, crow-bars, etc.) have been inspected, validated & found in healthy condition and

in sufficient qty. present at site?

10 Is final checking & tac welding of all towers have been done prior to start of the stringing work?

11 Are adequate nos. of persons deputed in every span & wherever required to control the visitor/villagers?

Is proper communication arrangement (walkie-talkie) have been made available & in sufficient quantity and

12 trained for their use? Are tensioner & puller operators communicating properly to each other?

Before starting the stringing work, survey done & data collected for Nos.of LT/HT lines & roads coming in the

13 span?

If any EHV/HT/LT is coming, PTW obtained from the competent authority & proper earthing of existing lines

14

have been done. Is Site Eng./Supervisor present at site to ensure proper earthing done in their presence at both

ends of section? Check condition of Earthing Equipment (Electrical tested) and quantity?

15 Whether EHV/HT/LT shut down is taken after verification of line by concern authority & it is verified?

16 Before returning the PTW, all Tools, Discharge rod & manpower removed from line & line is restored as it was?

If any road is coming, traffic controller or proper scaffolding provided (or both) and all safety measures taken

17 near Road crossing?

18 Whether corridor is properly cleared from trees, bamboo..etc, to avoid any disturbance during stringing?

Is ascending on and descending on from the tower done through the steps bolts with using Fall Arrestor

19 clamp. Is Fall arrestor clamp provided in sufficient quantity? Is practice of ascending on and descending

from the tower through the tower members stopped?

20 Are retractable fall arrestor being used while working on insulator?

Whether TSE machine /winch machine are properly back stayed & being operated by authorized & trained

21 operator?

Are proper size of steel wire rope (18mm dia) & turn buckle (10mT capacity) being used for back stay? Is Dead

mint wood of correct size (i.e. dia 12 inch or more, length 5 feet) and dead mint pit shall be minimum 6 feet

22 depth. Also Back stay has been done in safe direction to balance proper load & Bull dog clamp ( Min 3) provided

in sufficient no.?

23 Whether all drum jacks have been placed at equal surface & their locks are properly locked?

24 Is final sag operation is being done through winch machine & not through couple of tractors?

25 Are Sag board properly fixed as per sag chart?

26 During final sagging, Are all fitter being staying to the main body of the tower & not to the cross arm?

During lower of materials (clamp, lefty, pulley, sling) proper care is being taken, should not drop / throw from

27 height?

28 Are all workmen working at heights using properly secured safety harness and helmets?

Whether work is being done in day light only & in suitable weather condition?

29

30 Whether Permit to Work at Height has been taken?

31 Whether Dynamometer is available to measure the tension?

32 Whether the winch is having a safe load display system?

Channel Partner Engineer/ Supervisor (Name & signature) SPTL

Name & signature

You might also like

- SPI HSE FR 02 Tower Erection ChecklistDocument1 pageSPI HSE FR 02 Tower Erection ChecklistChandan KumarNo ratings yet

- SPI HSE FR 01 Foundation ChecklistDocument1 pageSPI HSE FR 01 Foundation ChecklistChandan KumarNo ratings yet

- Sop of StringingDocument7 pagesSop of Stringingshubham shindeNo ratings yet

- 16950s01 HV Testing ProceduresDocument1 page16950s01 HV Testing ProceduresVICTOR JOSE VILORIANo ratings yet

- 1 Hse Management ResponsibilityDocument13 pages1 Hse Management ResponsibilityRATAN BHATIANo ratings yet

- Substation Earth System Injection Testing SWP: 1. Purpose and ScopeDocument10 pagesSubstation Earth System Injection Testing SWP: 1. Purpose and ScopeJarrett MathewsNo ratings yet

- SG3125HV: Turnkey Station For SystemDocument2 pagesSG3125HV: Turnkey Station For SystembajrangNo ratings yet

- MOS-Construction of OHTL From SS 8768 Layla PVDocument45 pagesMOS-Construction of OHTL From SS 8768 Layla PVEngr Muhammad Azam ThaheemNo ratings yet

- PSK Checklist New Elec E01 - 18 HT CablingDocument1 pagePSK Checklist New Elec E01 - 18 HT CablingBAHARUDIN BURAHNo ratings yet

- ChecklistDocument35 pagesChecklistShashi Kant Singh100% (1)

- Attachment 3 - Bolt Tensioning Task PlanDocument4 pagesAttachment 3 - Bolt Tensioning Task Planchancele nguepdjopNo ratings yet

- Troubleshooting ChecklistDocument4 pagesTroubleshooting ChecklistIrma KnuttNo ratings yet

- Suspended Scaffold Inspection ChecklistDocument3 pagesSuspended Scaffold Inspection ChecklistSamantha Meril PandithaNo ratings yet

- Stringing T&P Reqd For A606 765 KV Dc-ZebraDocument3 pagesStringing T&P Reqd For A606 765 KV Dc-Zebraprithvirajd20No ratings yet

- Checklist For Pile Foundation: Name of The Project: Specification RemarksDocument2 pagesChecklist For Pile Foundation: Name of The Project: Specification RemarksDilip Kumar MandalNo ratings yet

- JSA For Scaffolding Erection Dismantling and Modification WorkDocument30 pagesJSA For Scaffolding Erection Dismantling and Modification Workkmohamedkeita906No ratings yet

- NC-FRM-DRA 6-1 Rev.0 Lorry Mounted Cranes (HIAB)Document1 pageNC-FRM-DRA 6-1 Rev.0 Lorry Mounted Cranes (HIAB)Patrick Bibila NdansiNo ratings yet

- 17.scafold Inspection UNISCO (PF) - 17Document2 pages17.scafold Inspection UNISCO (PF) - 17Benasher IbrahimNo ratings yet

- Installation of Beacon - Hooter - Manual Call Point (Fire & Gas) Check ListDocument1 pageInstallation of Beacon - Hooter - Manual Call Point (Fire & Gas) Check ListZulfequar R. Ali Khan100% (1)

- Dokgoro K1785 Method StatementDocument6 pagesDokgoro K1785 Method StatementJackie van SchalkwykNo ratings yet

- KBR Inspection Test Plan For Bus Duct: NO. Inspection Activity 1 Pre-Inspection Meeting 2 Documentation ReviewDocument2 pagesKBR Inspection Test Plan For Bus Duct: NO. Inspection Activity 1 Pre-Inspection Meeting 2 Documentation ReviewkamlNo ratings yet

- 3 2 Rigging of Transmission Line Towers PDFDocument5 pages3 2 Rigging of Transmission Line Towers PDFsauravkafle1No ratings yet

- QA&QC-DT-FRMC-014 Mouting Structure Material RecordDocument1 pageQA&QC-DT-FRMC-014 Mouting Structure Material RecordTariq Ali SialNo ratings yet

- Excavation Work Checklist: Saline Water Desalination Plant On The West CoastDocument2 pagesExcavation Work Checklist: Saline Water Desalination Plant On The West CoastBRC HSE Dept.No ratings yet

- Work Method Statement For Live 33kv Distribution Line CrossingDocument12 pagesWork Method Statement For Live 33kv Distribution Line CrossingEngr Muhammad Azam ThaheemNo ratings yet

- Transformer 1 MosDocument5 pagesTransformer 1 MosMohamedAhmedFawzyNo ratings yet

- Cable Trench and Bedding Quality Control and Inspection Report FormDocument1 pageCable Trench and Bedding Quality Control and Inspection Report FormHesham Helal100% (1)

- Test Results & Reports SubmittalDocument1 pageTest Results & Reports SubmittalromahiNo ratings yet

- DC Cable LayingDocument8 pagesDC Cable LayingAhamed UmarNo ratings yet

- Pre Installationfor Opgw 48 FDocument5 pagesPre Installationfor Opgw 48 FMayank PorwalNo ratings yet

- Night Work Inspection ChecklistDocument1 pageNight Work Inspection ChecklistAdarsh sNo ratings yet

- Procurement Requisition: Form No. Version No. 5.1Document1 pageProcurement Requisition: Form No. Version No. 5.1loveson glariyansNo ratings yet

- 3.sop of StringingDocument8 pages3.sop of StringingVenkateswarlu BoduguNo ratings yet

- p021.46 Db54 Mat Mep Mech 022 Ventilation FansDocument95 pagesp021.46 Db54 Mat Mep Mech 022 Ventilation Fansp4p7 projectsNo ratings yet

- DB ChecklistDocument4 pagesDB ChecklistJabinNo ratings yet

- Sample Manufacturing Quality Plan Format: (Logo of Manufacturer)Document12 pagesSample Manufacturing Quality Plan Format: (Logo of Manufacturer)P.Manna100% (1)

- Tps OHLDocument88 pagesTps OHLNaseem AhmedNo ratings yet

- Method Statement For Gypsum Panels WorkDocument8 pagesMethod Statement For Gypsum Panels WorkNikita KasyanovNo ratings yet

- Installation - A - EarthmatDocument11 pagesInstallation - A - Earthmatpdky yadavNo ratings yet

- QA&QC-DT-FRMC-020 Foundation Work of Transmission LineDocument2 pagesQA&QC-DT-FRMC-020 Foundation Work of Transmission LineTariq Ali SialNo ratings yet

- QA&QC DT FRMC 005 Non Conformance ReportDocument3 pagesQA&QC DT FRMC 005 Non Conformance ReportTariq Ali SialNo ratings yet

- ITP Transformer Testing and CommissioningDocument1 pageITP Transformer Testing and CommissioningguspriyNo ratings yet

- Ms For Tele Tower ErectionDocument12 pagesMs For Tele Tower ErectionSahabzada AamirNo ratings yet

- SWP CHECKLISTS - Welding Cutting and HeatingDocument3 pagesSWP CHECKLISTS - Welding Cutting and HeatingSrinivas Dumpala HSE100% (1)

- RFI Checklist Site BELOPARANG (Infill - SSul37)Document5 pagesRFI Checklist Site BELOPARANG (Infill - SSul37)Adhyatma RaufNo ratings yet

- WMS Electrical Working On or Near Exposed Energised Electrical EquipmentDocument7 pagesWMS Electrical Working On or Near Exposed Energised Electrical EquipmentFresly PatriaNo ratings yet

- Part Submission WarrantDocument4 pagesPart Submission WarrantSam AnuNo ratings yet

- Fire Procedure 20041108Document43 pagesFire Procedure 20041108Lucas TobingNo ratings yet

- As Built ReportDocument1 pageAs Built ReportWakil AhmadNo ratings yet

- Checklist For Lift WorksDocument3 pagesChecklist For Lift WorksVikas YamagarNo ratings yet

- 980 Behavior Based Safety Program PDFDocument2 pages980 Behavior Based Safety Program PDFherik0% (1)

- Check List For Sub Main Distribution Board InstallationDocument2 pagesCheck List For Sub Main Distribution Board InstallationNaing Win TunNo ratings yet

- 04-2-TS vOL-II, Sec-IV, FQP R1 PDFDocument20 pages04-2-TS vOL-II, Sec-IV, FQP R1 PDFsanjeevchhabraNo ratings yet

- Silica Gel Blue MSDSDocument5 pagesSilica Gel Blue MSDSRajesh GalgalikarNo ratings yet

- ITP For Testing and Commissioning of ACSDocument1 pageITP For Testing and Commissioning of ACSRommel Espinosa ParasNo ratings yet

- Overhead Lines Andy PMDocument3 pagesOverhead Lines Andy PMengrandyNo ratings yet

- Lifting Calculation Per LocationDocument1 pageLifting Calculation Per LocationSubzone ThreeNo ratings yet

- Right Factorz Projects PVT LTD Checklist For Cable InstallationDocument9 pagesRight Factorz Projects PVT LTD Checklist For Cable InstallationRajesh RaghunathanNo ratings yet

- JHA For Concreting WorkDocument3 pagesJHA For Concreting WorkRavi thokalNo ratings yet

- SPI HSE FR 04 Overhead Crossing ChecklistDocument1 pageSPI HSE FR 04 Overhead Crossing ChecklistChandan KumarNo ratings yet

- SPI HSE FR 05 Certificate Medical ExaminationDocument1 pageSPI HSE FR 05 Certificate Medical ExaminationChandan KumarNo ratings yet

- SPI HSE FR 02 Tower Erection ChecklistDocument1 pageSPI HSE FR 02 Tower Erection ChecklistChandan KumarNo ratings yet

- SPI HSE FR 04 Overhead Crossing ChecklistDocument1 pageSPI HSE FR 04 Overhead Crossing ChecklistChandan KumarNo ratings yet

- SPI HSE FR 05 Certificate Medical ExaminationDocument1 pageSPI HSE FR 05 Certificate Medical ExaminationChandan KumarNo ratings yet

- SPI HSE FR 04 Overhead Crossing ChecklistDocument1 pageSPI HSE FR 04 Overhead Crossing ChecklistChandan KumarNo ratings yet

- SPI HSE FR 01 Foundation ChecklistDocument1 pageSPI HSE FR 01 Foundation ChecklistChandan KumarNo ratings yet

- SPI HSE FR 03 Stringing ChecklistDocument1 pageSPI HSE FR 03 Stringing ChecklistChandan KumarNo ratings yet

- CH 1 Viscous Fluid Flow Part 1Document29 pagesCH 1 Viscous Fluid Flow Part 1Ammar WahabNo ratings yet

- Ferrero A.M. Et Al. (2015) - Experimental Tests For The Application of An Analytical Model For Flexible Debris Flow Barrier Design PDFDocument10 pagesFerrero A.M. Et Al. (2015) - Experimental Tests For The Application of An Analytical Model For Flexible Debris Flow Barrier Design PDFEnrico MassaNo ratings yet

- P6 - TT2 - Revision Test 2021-2022 Page 1 of 11Document11 pagesP6 - TT2 - Revision Test 2021-2022 Page 1 of 11Nilkanth DesaiNo ratings yet

- Teamcenter 10.1: Publication Number PLM00015 JDocument122 pagesTeamcenter 10.1: Publication Number PLM00015 JmohanNo ratings yet

- Very Hungry Caterpillar Clip CardsDocument5 pagesVery Hungry Caterpillar Clip CardsARTGRAVETO ARTNo ratings yet

- Or HandoutDocument190 pagesOr Handoutyared haftu67% (6)

- CHAPTER I Lesson II Seven Environmental PrinciplesDocument17 pagesCHAPTER I Lesson II Seven Environmental PrinciplesTrixie jade DumotNo ratings yet

- Nationalism, Feminism, and Modernity in PalestineDocument26 pagesNationalism, Feminism, and Modernity in PalestinebobandjoerockNo ratings yet

- Rare Watches (Christie's) 16. 05. 2016.Document236 pagesRare Watches (Christie's) 16. 05. 2016.Simon LászlóNo ratings yet

- QSasDocument50 pagesQSasArvin Delos ReyesNo ratings yet

- Immobilization of Rhodococcus Rhodochrous BX2 (An AcetonitriledegradingDocument7 pagesImmobilization of Rhodococcus Rhodochrous BX2 (An AcetonitriledegradingSahar IrankhahNo ratings yet

- KM170, KM171, KM172, F3A21, F3A22: 3 SPEED FWD (Lock Up & Non Lock Up)Document4 pagesKM170, KM171, KM172, F3A21, F3A22: 3 SPEED FWD (Lock Up & Non Lock Up)krzysiek1975No ratings yet

- Nbme NotesDocument3 pagesNbme NotesShariq AkramNo ratings yet

- Defining The Standards For Medical Grade Honey PDFDocument12 pagesDefining The Standards For Medical Grade Honey PDFLuis Alberto GarcíaNo ratings yet

- Pizza Restaurant PowerPoint TemplatesDocument49 pagesPizza Restaurant PowerPoint TemplatesAindrila BeraNo ratings yet

- (Polish Journal of Sport and Tourism) The Estimation of The RAST Test Usefulness in Monitoring The Anaerobic Capacity of Sprinters in AthleticsDocument5 pages(Polish Journal of Sport and Tourism) The Estimation of The RAST Test Usefulness in Monitoring The Anaerobic Capacity of Sprinters in AthleticsAfizieNo ratings yet

- Adigwe J. C.: ATBU, Journal of Science, Technology & Education (JOSTE) Vol. 3 (1), January, 2015 ISSN: 2277-0011Document16 pagesAdigwe J. C.: ATBU, Journal of Science, Technology & Education (JOSTE) Vol. 3 (1), January, 2015 ISSN: 2277-0011AnnyNo ratings yet

- Chrysler CDS System - Bulletin2Document6 pagesChrysler CDS System - Bulletin2Martin Boiani100% (1)

- NA ReadingStrategies U5M11L03Document1 pageNA ReadingStrategies U5M11L03Lila AlwaerNo ratings yet

- Half Yearly Examination, 2017-18: MathematicsDocument7 pagesHalf Yearly Examination, 2017-18: MathematicsSusanket DuttaNo ratings yet

- A Method For Prediction of Gas/Gas Ejector PerformanceDocument6 pagesA Method For Prediction of Gas/Gas Ejector PerformancedhavaleshNo ratings yet

- ProjectDocument32 pagesProjectroshan jaiswalNo ratings yet

- All Nobel Prizes in LiteratureDocument16 pagesAll Nobel Prizes in LiteratureMohsin IftikharNo ratings yet

- LP Pe 3Q - ShaynevillafuerteDocument3 pagesLP Pe 3Q - ShaynevillafuerteMa. Shayne Rose VillafuerteNo ratings yet

- Performance Task 2Document3 pagesPerformance Task 2Edrose WycocoNo ratings yet

- IPC PL 11 006 MS Auditors Issue 7.05Document32 pagesIPC PL 11 006 MS Auditors Issue 7.05saladinNo ratings yet

- Lesson Plan Letter SDocument4 pagesLesson Plan Letter Sapi-317303624100% (1)

- Operator's ManualDocument110 pagesOperator's ManualAdam0% (1)

- HPSC HCS Exam 2021: Important DatesDocument6 pagesHPSC HCS Exam 2021: Important DatesTejaswi SaxenaNo ratings yet

- 2017LR72 - SUMMARY REPORT Final 03052020Document72 pages2017LR72 - SUMMARY REPORT Final 03052020Dung PhamNo ratings yet