Professional Documents

Culture Documents

Substation Earth System Injection Testing SWP: 1. Purpose and Scope

Uploaded by

Jarrett MathewsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Substation Earth System Injection Testing SWP: 1. Purpose and Scope

Uploaded by

Jarrett MathewsCopyright:

Available Formats

SUBSTATION EARTH SYSTEM INJECTION TESTING SWP

Check this is the latest Process Zone version before use. Page 1 of 10 Standard Work Practice SP0510 Ver 2

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

1. PURPOSE AND SCOPE

The purpose of this Standard Work Practice (SWP) is to

standardise and prescribe implementing an 'Earth System

Injection Test' for the purpose of determining the Current

Distribution, Earth Potential Rise (EPR) and Personnel Safety at a

particular site. Personnel Safety includes the determination of

possible Step, Touch and Transfer voltage hazards.

This applies to the testing of new and existing earthing systems,

with the purpose of validating the adequacy of the earthing system

to meet design and safety criteria.

2. STAFFING RESOURCES

a) EFM competent in the use of test equipment.

b) Safety Observer (required for all live work as defined in the

ESO Code of Practice for Electrical Work).

Both are required to -

- Be trained in switchboard rescue and resuscitation and manual

handling techniques.

- Have appropriate Switching & Access authorisations for the

roles they are required to perform and have the ability to

assess and maintain relevant exclusion zones from exposed

live electrical apparatus.

- Hold current licences for any vehicles and equipment they may

be required to operate.

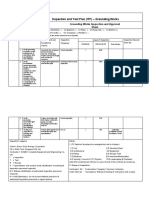

Required Training and Certificates

Regulatory Training

Course Code

Course Description Regulatory Training

2120 Cardio-Pulmonary Resuscitation

2130 Low Voltage/Switchboard Rescue

2140 Pole Top Rescue (if required)

2160 EWP Rescue and Escape (if required)

3131 Pole Testing for Safe Access (if required)

Additional Training

Course Code Course Description Additional Training

4445 Switching Operator and Authorised

4440 Switching Operator Assistant and Authorised

4430

Safe Entry to High Voltage Enclosures and

Authorised

SUBSTATION EARTH SYSTEM INJECTION TESTING SWP

Check this is the latest Process Zone version before use. Page 2 of 10 Standard Work Practice SP0510 Ver 2

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

3. DOCUMENTATION

CS000501F115. Daily/Task Risk Management Plan

ES000901R102. Health and Safety Risk Control Guide

SP0510R01 Substation Earth Testing J ob Safety Analysis

SP0510C01 Earth System Current Distribution Test Report

SP0510C02 Earth System Voltage Gradient Test Report

SP0510C02R01 Earth System Voltage Gradient end point

(calculation spreadsheet0

SP510C03 Step and Touch Potential Test Report

SP0506 Carry Out Field Testing SWP

Maps and site plans use these for marking where test readings

were taken, these may include but not be limited to:

Local map Can give useful information on surrounding area

Civil Works - Site Clearing Plan

Civil Works - Earth Grid Plan

Test Reports

Fault levels for all voltages at substation or site these are used

to calculate estimated Step and Touch voltages under fault

conditions. For Ergon sites, these are normally obtained from

NP&D group.

Clearing times for faults use these to determine 'Allowable

Prospective Voltage Criteria'. For Ergon sites, these are obtained

from the Protection Group.

Earth Resistivity Test results

Test Equipment Manuals

4. KEY TOOLS AND EQUIPMENT

All equipment used is to be calibrated and within test due date.

Current Distribution

Frequency tuneable voltmeter or Spectrum Analyser

Godowsky coil

Earth Potential Rise

Frequency tuneable voltmeter or Spectrum Analyser

Spool(s) of cable (distance required will depend on recorded

measurements) up to 1km may need to be available.

Earth test electrode (stake)

Step and Touch Potential

Frequency tuneable voltmeter or Spectrum Analyser

Two earth test electrodes (stakes)

5m test leads

Switching and Access Operating Equipment PEDs, Live Line

Tester, Class 0 gloves. All equipment to be inspected and

confirmed within test date prior to use

Suitable barriers and warnings signs for erection at the source and

the remote end to prevent inadvertent contact with 'LIVE' equipment

PPE including full-length protective cotton clothing, safety footwear,

helmet. Additional PPE as required: brim for safety helmet, leather

work gloves, class 00 gloves, hearing protection, safety eyewear,

high visibility clothing when working on or near roadways. All PPE

to be inspected and confirmed within test date (where applicable)

prior to use.

Sun protection to be used when working outdoors.

SUBSTATION EARTH SYSTEM INJECTION TESTING SWP

Check this is the latest Process Zone version before use. Page 3 of 10 Standard Work Practice SP0510 Ver 2

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

5. TASK STEPS

5.1. On Site Risk Assessment

Prior to performing this activity any hazards associated with

prerequisite tasks at the worksite shall be identified and assessed

with appropriate control measures implemented and documented

in accordance with Daily/Task Risk Management Plan

CS000501F115 and using reference document Health and Safety

Risk Control Guide ES000901R102.

If any risks cannot be managed or reduced to an acceptable level,

do not proceed with the task and seek assistance from your

Supervisor.

Measurement of current distribution, earth potential rise and step

and touch potential is carried out when current is injected into the

earth grid under test. The normal configuration is that an injection

source (generator) is connected to the substation earth grid under

test and also to an out of service feeder that is shorted to a remote

earth grid. In this way a current is circulated through the earth grid

under test, through the earth, through the remote earth grid to

return along the feeder to the source. The length of the line used

for remote injection must be at least 10 times the diagonal length

of the substation earth grid to avoid interference to measurements

from the remote earth grid. It is preferred that a line length of 50

times the diagonal be used (for a theoretical accuracy of 98.5%)

A generator capable of maintaining a stable frequency off 50Hz is

used as an injection source to avoid errors introduced by any

standing 50 Hz ground current. Typically 48 or 52Hz is used.

Problems have occurred with smaller generators (~7kVA) as they

have not been able to be 'tuned' to an off 50Hz frequency

successfully. 30 kVA is usually a reasonable size. To achieve a

reasonable current level a step up transformer and/or series tuning

capacitors may be required depending on the impedance of the

earthmats and the feeder used for injection. The injection voltage

may therefore be in the order of 1-2 kV.

Errors are minimised by using an injection current significantly

higher than any standing 50 Hz ground current. 20 A to 30 A is

preferred, however as low as 10 A is suitable providing a stable

frequency injection source (eg solid state) is used with a high

selectivity voltmeter/spectrum analyser.

5.2. Hazards and Controls

- The feeder connected to the remote earth grid must be either

decommissioned / uncommissioned or under a Test Permit as

defined in the operate the Network Procedures

- The injection source voltage may have to be increased to a

high level to get sufficient earth current for accurate

measurements. Appropriate barriers and warning signs must

be erected at the injection source to prevent inadvertent

contact with dangerous voltages.

- This voltage will also be transferred to the remote earth grid,

and can also be considered dangerous (particularly in the case

of a high earth resistance or bad earth connection).

Appropriate barriers and warning signs must be erected at the

remote earth grid as well as the earth grid under test at the

point of connection of the feeder to the earth grid.

- Dangerous voltages with respect to remote earths may be

transferred out of the substation. Areas to watch are where

there is a low impedance connection to a remote earth such as

telephone cabling, feeder cable sheaths, overhead earths on

other feeders, buried metallic pipes.

SUBSTATION EARTH SYSTEM INJECTION TESTING SWP

Check this is the latest Process Zone version before use. Page 4 of 10 Standard Work Practice SP0510 Ver 2

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

- The mobile generator and coupling transformer used for

current injection may present manual handling hazards. Use

appropriate mechanical assistance such as trailer mounted

equipment, vehicle loading crane etc.

- The injection current should not pass through any current

transformers that may inadvertently operate protection (eg line

CT bus differential cores)

- Three-phase remote injection will cause balanced currents in

each phase and negligible earth current.

- If one phase of a three-phase generator is used as the

injection source, out of balance loading will cause overheating

of the generator. A de-rating factor of 10 should be used,

although it is preferable to use a single-phase generator

instead.

- There may be significant current and/or voltage induced in the

feeder used for the remote injection from another feeder in the

same easement or on the same structures (double circuit line).

Always maintain an earth on one end of the injection feeder,

and verify that the voltage on the other end is safe for the

connection of injection equipment.

- Tests should not be carried out in poor weather conditions

when a system fault on incoming or outgoing feeders could

cause earth potential rise at the earth grid under test. Similarly,

tests should not be carried out in poor weather conditions

where the feeder being used for injection could be subjected to

faults. For long feeders, it is necessary to use aids like the

lightning tracker and/or weather radar to ensure good

conditions exist for the entire length of the feeder.

5.3. Preliminary Tests

It is assumed at this stage that preliminary tests have already

been completed. These are an Earth Grid Continuity Test to prove

that all connections to the earth grid under test are sound, and a

Soil Resistivity Test. If the injection test is being performed with no

prior investigations of the soil structure then the soil resistivity

around the installation should be determined at the time of the

injection testing.

Current Distribution

Determining the current distribution throughout the earthing

system under test is vital in determining:

1. What components are independent or dependant of the

earthing system under various fault scenarios.

2. Likely voltage hazards.

3. Assessing individual component performance and

identification of critical system components.

CAUTION

There is a possibility that a system earth fault will occur

when tests are carried out, thereby exposing test staff to

dangerous step, touch and transfer voltages. Insulated

leads and class 00 insulated gloves should therefore be

used when carrying out voltage measurements relative to

a remote earth. Class 00 gloves are required for step and

touch measurements only if the allowable step and touch

voltage limits are exceeded.

SUBSTATION EARTH SYSTEM INJECTION TESTING SWP

Check this is the latest Process Zone version before use. Page 5 of 10 Standard Work Practice SP0510 Ver 2

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

Measuring the current within a component of the earthing system

and tracing that current until it exits the system or passes beyond

the system boundary constitutes a current distribution test. Points

or paths of consideration are metallic systems passing beyond the

boundary of the earthing installation, such as:

- Overhead Earth Wires (OHEW)

- Cable sheaths, power and communications

- Pipelines (water, gas)

- Telecommunications systems

- LV neutrals

- Structures (railway lines, conveyor systems)

Using an existing drawing or one prepared on site, document all

possible paths for current to flow (Figure 1). Using the Rogowski

Coil and frequency tuneable voltmeter, determine the dispersion of

the test current throughout the test site noting current measured

and turns used on Rogowski Coil. Results should be recorded on

the Earth System Current Distribution Test Report Form

SP0510C01. From this test you should be able to accurately

determine the current flowing into the earth grid via the earth (I

grid

)

It may not be practicable to identify every path of current leaving

the earthmat, however assuming that 100% of the injected current

is exiting via the earthmat under test will result in a calculated

earthmat impedance lower than the actual value. It is therefore

essential that the current flow in all accessible connections be

determined.

Figure 1: Earthing System with Commonly Found Associated Additions

Earth Potential Rise (EPR)

The EPR test is used to determine the impedance of the earth grid

under test. Using the results of the Current Distribution test we are

able to quantify the percentage of injection current actually

entering the site earth grid via the ground. With this knowledge

and the result from the EPR test we can calculate the earth grid

impedance which will be used to find the EPR under fault

conditions.

The method that used is called "Fall-of-Potential Method". Figure

2 shows the basic circuit.

O

V

E

R

H

E

A

D

T

R

A

N

S

M

I

S

S

IO

N

L

IN

E

O.H.E.W.

S

H

E

A

T

H

U

N

D

E

R

G

R

O

U

N

D

C

AB

L

E

S

T

E

L

E

C

O

M

C

A

B

L

E

P

IP

E

L

IN

E

(W

A

T

E

R

/G

A

S

)

FENCING

SUBSTATION EARTH SYSTEM INJECTION TESTING SWP

Check this is the latest Process Zone version before use. Page 6 of 10 Standard Work Practice SP0510 Ver 2

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

Figure 2: Basic Circuit for Fall-of-Potential Method

The EPR is found by measuring the voltage difference between

the site earth grid and "Remote Earth". This is achieved by taking

measurements between an earth test stake and the site earth grid

under test at increasing distances. The stake need only be driven

to a depth that will support it. The test lead used to measure the

EPR of a system should be run at either 90 or less to the injection

loop, as at these angles the induced voltage is additive and hence

a conservative result will be obtained. However, leads run at

angles greater than 90 are influenced by magnetic end effects

and this is not easily calculated.

Measurement distances should increase until a definite plateau in

results is observed. No less than three lots of results within a few

percent of each other should be interpreted as a plateau. This is

where extra reels of cable may be necessary to get the required

result. Figure 3 shows a typical EPR curve. At the most remote

measurement location it is required to take a reading from a RMS

indicating voltmeter (e.g. fluke) to double check the results of

either the spectrum analyser or the frequency tuneable voltmeter.

Results should be recorded on the Earth System Voltage

Gradient Test Report Form SP0510C02. Spreadsheet

SP0510C02R01 can be used to estimate the earthmat potential

rise at an infinite distance, i.e. the true EPR.

Figure 3: Typical Fall-of Potential Curve

Step and Touch Voltages

The safety of a substation earthing system depends on the step,

touch and mesh voltages being less than the allowable voltages

specified at the end of this SWP. The allowable voltage depends

on various parameters such as fault clearing time, permissible

Vm

POTENTIAL

ELECTRODE

EARTH

IMPEDANCE

SOURCE

EARTHING

SYSTEM

Is

CURRENT

ELECTRODEOR

REMOTE

EARTHING

SYSTEM

Zg

INJECTEDCURRENT If

Vm

x(m)

X

X

X

X

X

X

X X

SUBSTATION EARTH SYSTEM INJECTION TESTING SWP

Check this is the latest Process Zone version before use. Page 7 of 10 Standard Work Practice SP0510 Ver 2

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

current by body weight, the earth resistance between hand and

two feet in parallel (touch voltage) and the earth resistance

between feet (step voltage).

Figure 4: Step, Touch, Mesh and Transfer Voltages

Possible step, touch and transfer voltage hazard locations

associated with metalwork in or adjacent to an earthing system,

must be identified and measured to ensure safety for power

authority personnel and the public. Recommended locations to

conduct touch, step and mesh voltage measurements include:

Within Substation

Within the substation the following voltages should be measured:

- In the centre of large grid meshes (mesh voltage)

- Corner meshes (adjacent to corner at 1 and 2 m spacing)

- Adjacent to equipment that may be operated (water taps,

operating handles etc). It is required to obtain at least one

measurement from every outdoor bay in the substation.

External to Substation

Design verification can be made at a number of locations external

to the substation including:

- External perimeter fence corners

- Frequented areas (such as fence gates opened out if possible)

- Nearby towers (if connected to the grid)

- Any section of the perimeter fence that the public may come into

contact with.

- Any metallic pipelines or fences in close proximity to the earthing

system. These can often be the worst measurements recorded

during a test because a fence or pipeline can be insulated from

the ground for a significant distance and therefore transfer a

remote earth potential into (or adjacent to) the substation under

test.

With the 'Earth Grid Plan' and Step and Touch Potential Test

Report SP0510C03, measurements will be taken using two

potential electrodes (1m apart) to determine step potential. Touch

potential is taken by having a potential electrode 1 m from the

plant or apparatus that will be touched. It is important that the

potential electrode is NOT driven into the earth more than a few

centimetres, merely enough to support the electrode. Results

should be recorded on the Step and Touch Potential Test Report

SP0510C03.

Vstep

VTouch

VMesh

VTransfer

Grid Conductors

Surface VoltageGradient

External Wire Fence

InsulatingPosts

SubstationFence

SUBSTATION EARTH SYSTEM INJECTION TESTING SWP

Check this is the latest Process Zone version before use. Page 8 of 10 Standard Work Practice SP0510 Ver 2

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

To check that your whole site would be safe under fault conditions,

find the highest Touch, Step and Mesh voltages from your

measurements and use the following formula to determine actual

voltages.

Using I

grid

(i.e. the proportion of the injection current that enters the

earth grid under test) from the 'Current Distribution' test and the

measured EPR find Z

grid

.

grid

grid

I

EPR

Z =

Using the Fault Level (I

FL

) and the ratio of I

grid

and I

inject

you can

find the current into the grid under fault conditions (I

f

).

inject

grid

FL f

I

I

I I =

EPR

f

is the EPR under fault conditions and is calculated by:

grid f f

Z I EPR =

Substituting for I

f

and Z

grid

.

inject

FL

grid inject

grid

FL

grid f f

I

EPR I

I

EPR

I

I

I

Z I EPR

=

=

=

To find the highest step, touch or mesh voltage (V

stm

) under fault

conditions use the highest voltage for each from the tests in the

formula:

measured

inject

FL

measured

f

V

I

I

EPR

V

EPR Vstm

=

=

If the highest is below the calculated 'Allowable Prospective

Voltage Criteria' then no further investigation is required.

Always use the appropriate Fault Level (I

FL

) in the above

calculation. For example, a fault at a step-down substation on the

HV system will cause significant earthmat potential rise, whereas

an LV fault at the same substation, even though the fault level may

be higher, will cause negligible earthmat potential rise because the

fault is contained within the substation. An external LV fault will

cause earthmat potential rise, however the fault level decreases

rapidly as the distance to the fault increases.

Note that the Powerlink test procedure divides EPR

f

and V

stm

calculated above by K

2

(shielding factor of the injection feeder).

This assumes a worst case scenario that the feeder used to inject

the test current does not have any earth current return via its

overhead earth during a fault at maximum fault level I

G

.

If the Allowable Prospective Voltage Criteria are exceeded,

measurements should be repeated using the simulated personnel

method instead of the open circuit measurements described

above. For the simulated personnel method, the body impedance

is simulated by a 1000 ohm resistor, and the foot to ground

contact resistance by a 20 kg 8 cm radius disc weight. The ground

contact area should be wetted down to simulate worst case

conditions.

SUBSTATION EARTH SYSTEM INJECTION TESTING SWP

Check this is the latest Process Zone version before use. Page 9 of 10 Standard Work Practice SP0510 Ver 2

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

REFERENCES

ESAA EG1 2000 "Substation Earthing Guide"

ANSI/IEEE Std 80 1986

For co-ordination of earthmat injection testing with Telstra, contact

David Lister from Telstra Power Co-ordination

dave.j.lister@team.telstra.com

Useful Formula

Allowable Prospective Voltage Criteria (Open Circuit)

Prospective Touch

Voltages

Prospective Step

Voltages

50 kg body weight

(to be used in areas

with public access)

t

C

s s

174 . 0 116+

t

C

s s

696 . 0 116+

70kg body weight

(to be used in

restricted areas

within a substation)

t

C

s s

236 . 0 157+

t

C

s s

942 . 0 157+

where

C

s

=Derating factor relating to surface layer thickness and

resistivity (=1 when crushed rock resistivity is equal to soil

resistivity).

s

=Resistivity of surface material (Om)

t =Duration of shock current (seconds). [Clearance time of

protection plus circuit breaker opening time]

( )

(m) layer rock crushed of thickness

m) ( y resistivit soil

m) ( y resistivit rock crushed

factor reflection

08 . 0 / 2 1

2 1

96 . 0

1

1

2

=

O =

O =

+

=

=

(

(

+

+ =

=

s

s

s

s

n

s

n

s

h

K

h n

K

C

As an alternative simplification (as per IEEE Std 80 Eq 27):

(

(

(

(

=

09 . 0 2

1

09 .. 0 1

s

s

s

h

C

These formulas are available in the spreadsheet SP0510R02

Earth System IEEE 80 Formula. This spreadsheet is an extract

from Design Standard SS-1-7.1 Substation Earthing and uses the

following guidelines:

SUBSTATION EARTH SYSTEM INJECTION TESTING SWP

Check this is the latest Process Zone version before use. Page 10 of 10 Standard Work Practice SP0510 Ver 2

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

Inside the substation: 70kg person, primary protection time

Outside the substation: 50 kg person, backup protection time

Surface layer resistivity (saturated): 3000 ohm-m

Allowable Simulated Personnel Voltage Criteria (Loaded)

Allowable

Body

Current

(amps)

Maximum Simulated

Personnel Voltage (V)

(assuming 1000 ohm

resistor, valid for step or

touch measurements)

50 kg body

weight

(to be used in

areas with

public access)

t

116 . 0

t

0 . 116

70kg body

weight

(to be used in

restricted

areas within a

substation)

t

157 . 0

t

0 . 157

You might also like

- Motor Load and Efficiency PDFDocument16 pagesMotor Load and Efficiency PDFwfjerrNo ratings yet

- Cable Testing GuideDocument34 pagesCable Testing GuideManoj Kumar PadmanabanNo ratings yet

- Ieee - C37.2-2008Document1 pageIeee - C37.2-2008DANIEL3991No ratings yet

- IEC Standard For Switchgear and ControlgearDocument11 pagesIEC Standard For Switchgear and ControlgearULTG PAYAKUMBUHNo ratings yet

- Scaffold PR6269POGC001Document57 pagesScaffold PR6269POGC001Jarrett MathewsNo ratings yet

- Working at Height SOPDocument6 pagesWorking at Height SOPJarrett MathewsNo ratings yet

- Working at Height SOPDocument6 pagesWorking at Height SOPJarrett MathewsNo ratings yet

- Industrial Battery Charger Different Philosophy PDFDocument6 pagesIndustrial Battery Charger Different Philosophy PDFdip461No ratings yet

- Industrial Battery Charger Different Philosophy PDFDocument6 pagesIndustrial Battery Charger Different Philosophy PDFdip461No ratings yet

- Transformer: Quality Assurance PlanDocument9 pagesTransformer: Quality Assurance PlanRadhakrishnan VNo ratings yet

- Electric Vehicle Conductive Charging SystemDocument38 pagesElectric Vehicle Conductive Charging SystemSharath KumarNo ratings yet

- Erection Methodoly Electrical 50 MWPDocument21 pagesErection Methodoly Electrical 50 MWPInaam Ullah MughalNo ratings yet

- LV Panel ChecklistDocument1 pageLV Panel ChecklistvaradharajanNo ratings yet

- Installation, Testing and Jointing of LT and HT Power Cables Up To 33 KVDocument7 pagesInstallation, Testing and Jointing of LT and HT Power Cables Up To 33 KVanjum araNo ratings yet

- NSC-400-CE-3220-ITP-02-A-Transmission Line Conductor - Stringing & InstallationDocument2 pagesNSC-400-CE-3220-ITP-02-A-Transmission Line Conductor - Stringing & InstallationElisco Pher SalmasanNo ratings yet

- Protection Relays Guide 2012-Schneider ElectricDocument56 pagesProtection Relays Guide 2012-Schneider ElectricPradeep_Vashist100% (1)

- FQP CONDUITING, WIRING and LIGHTING FIXTURESDocument1 pageFQP CONDUITING, WIRING and LIGHTING FIXTURESPramod Kumar YadavNo ratings yet

- Cognitive Spokenenglish: Study Material of NLRC Spoken EnglishDocument45 pagesCognitive Spokenenglish: Study Material of NLRC Spoken Englishsekar p91% (11)

- Cognitive Spokenenglish: Study Material of NLRC Spoken EnglishDocument45 pagesCognitive Spokenenglish: Study Material of NLRC Spoken Englishsekar p91% (11)

- Bifacial Modules: There Are Two Sides To Every Solar Panel: Will PorterDocument5 pagesBifacial Modules: There Are Two Sides To Every Solar Panel: Will PorterManikanta rajaNo ratings yet

- SH1 DHI P0100 GE M01 PRO 5304 - Plant Startup & Shutdown Procedure - Rev.3 (Replace)Document45 pagesSH1 DHI P0100 GE M01 PRO 5304 - Plant Startup & Shutdown Procedure - Rev.3 (Replace)nguyễn hữu trườngNo ratings yet

- Automatic Reactive Power Compensation SystemDocument7 pagesAutomatic Reactive Power Compensation SystemDolyNo ratings yet

- Function Checks Is Not Applicable For This Panel: Switchgear Functional TestDocument3 pagesFunction Checks Is Not Applicable For This Panel: Switchgear Functional Testeswaran005No ratings yet

- ITP For Testing and Commissioning of ACSDocument1 pageITP For Testing and Commissioning of ACSRommel Espinosa ParasNo ratings yet

- Larsen & Toubro Limited MSQ Up Gradation (Epcc 1) Project: LT/MSQ/P/UT/011Document11 pagesLarsen & Toubro Limited MSQ Up Gradation (Epcc 1) Project: LT/MSQ/P/UT/011punitg_2No ratings yet

- ITP Transformer Testing and CommissioningDocument1 pageITP Transformer Testing and CommissioningguspriyNo ratings yet

- SP0507Document9 pagesSP0507karimiNo ratings yet

- Inspection Requisition / ReportDocument2 pagesInspection Requisition / ReportHanuman RaoNo ratings yet

- List of Is StandardsDocument4 pagesList of Is StandardsAnantha NarayananNo ratings yet

- MV MCC Testing and Commissioning Field InspectionDocument3 pagesMV MCC Testing and Commissioning Field InspectionSandro CuetoNo ratings yet

- 16950s01 HV Testing ProceduresDocument1 page16950s01 HV Testing ProceduresVICTOR JOSE VILORIANo ratings yet

- Cost Data FY2022-23Document110 pagesCost Data FY2022-23Thilak SagarNo ratings yet

- Tender No: 1/2011 - Amran Project: SubstationDocument5 pagesTender No: 1/2011 - Amran Project: SubstationMais AlyanNo ratings yet

- SG II QUALITY Annex 24.12.2015Document89 pagesSG II QUALITY Annex 24.12.2015parthaNo ratings yet

- New Org Chart - LNT PowerDocument1 pageNew Org Chart - LNT Powerpunitg_2No ratings yet

- Grounding Works ITP Inspection PlanDocument2 pagesGrounding Works ITP Inspection PlanElisco Pher SalmasanNo ratings yet

- The Earthing System: Sometimes Simply Called Earthing', Is The Total Set ofDocument10 pagesThe Earthing System: Sometimes Simply Called Earthing', Is The Total Set ofDaily FunNo ratings yet

- Demonstrate Knowledge of Electric Switchboard Testing: Level 4 Credits 3 PurposeDocument4 pagesDemonstrate Knowledge of Electric Switchboard Testing: Level 4 Credits 3 Purposemagdy473No ratings yet

- MOS-Construction of OHTL From SS 8768 Layla PVDocument45 pagesMOS-Construction of OHTL From SS 8768 Layla PVEngr Muhammad Azam ThaheemNo ratings yet

- 04-2-TS vOL-II, Sec-IV, FQP R1 PDFDocument20 pages04-2-TS vOL-II, Sec-IV, FQP R1 PDFsanjeevchhabraNo ratings yet

- MQAP - Long Rod InsulatorDocument8 pagesMQAP - Long Rod InsulatorRajitha BoppaNo ratings yet

- Pre-Commissioning Report and Cable TestingDocument4 pagesPre-Commissioning Report and Cable TestingsidharthNo ratings yet

- PresentationDocument16 pagesPresentationதுரைராஜ் இலட்சுமணன்No ratings yet

- Side Runner & Purlin DesignDocument5 pagesSide Runner & Purlin DesignArun KesbhatNo ratings yet

- T14166-4 Report 31.03.2021Document49 pagesT14166-4 Report 31.03.2021mayur dhandeNo ratings yet

- Cold Shrink Splicing Kit Qs-Iii: InstructionsDocument16 pagesCold Shrink Splicing Kit Qs-Iii: InstructionspennacchiettiNo ratings yet

- Schneider Automatic Circuit Recloser SWP: 1. Purpose and ScopeDocument7 pagesSchneider Automatic Circuit Recloser SWP: 1. Purpose and ScopeJairo WilchesNo ratings yet

- Test of 66 KV Incoming Line LA: 1) Insulation Resistance Test of LADocument2 pagesTest of 66 KV Incoming Line LA: 1) Insulation Resistance Test of LAArul KumarNo ratings yet

- Section-Iii: Technical SpecificationDocument35 pagesSection-Iii: Technical SpecificationVarun BhardwajNo ratings yet

- Busbar CalDocument7 pagesBusbar Calajay cabreraNo ratings yet

- Waaree Energies LTD Post-Commissioning Checklist For 3kwroof Top ProjectDocument8 pagesWaaree Energies LTD Post-Commissioning Checklist For 3kwroof Top ProjectvvrrdyNo ratings yet

- Current Transformer Testing SWP: 1. Purpose and ScopeDocument9 pagesCurrent Transformer Testing SWP: 1. Purpose and ScopeDEADMANNo ratings yet

- SOP-14 AGEL-P02-SP02-Module Mounting Structure - Installation of MMSDocument159 pagesSOP-14 AGEL-P02-SP02-Module Mounting Structure - Installation of MMSVikas SinghNo ratings yet

- Pre Energization Check ListDocument2 pagesPre Energization Check Listilyaskhan77No ratings yet

- Standard Operating Procedure For Piling On HT Cable Trench 1Document3 pagesStandard Operating Procedure For Piling On HT Cable Trench 1ARUN RAWATNo ratings yet

- LOG-563-03 Receiving Inspection Checklist Rev.1Document1 pageLOG-563-03 Receiving Inspection Checklist Rev.1Emy SumartiniNo ratings yet

- Installation and commissioning of Serveron make Transformer online DGA monitorDocument3 pagesInstallation and commissioning of Serveron make Transformer online DGA monitorcrazy devilNo ratings yet

- Power Transformer Testing ProceduresDocument4 pagesPower Transformer Testing Proceduresyadav_sctNo ratings yet

- Soil Resistivity ProcedureDocument7 pagesSoil Resistivity Procedurephelo1100% (1)

- 06 Design Implementation Highly Efficient PDFDocument10 pages06 Design Implementation Highly Efficient PDFEdamEdamNo ratings yet

- Solar Power Plant ManagementDocument39 pagesSolar Power Plant ManagementVenrick CamposNo ratings yet

- List of Abbreviations and Solar Home System ComponentsDocument36 pagesList of Abbreviations and Solar Home System Componentsra_b_inNo ratings yet

- IMS 448-EQCL - Transformer Installation Checklist Rev01Document1 pageIMS 448-EQCL - Transformer Installation Checklist Rev01zhangjieNo ratings yet

- Method Statement For Testing & Commissioning of Central Battery SystemDocument6 pagesMethod Statement For Testing & Commissioning of Central Battery SystemBabuNo ratings yet

- Turbo Generator at NalcoDocument13 pagesTurbo Generator at NalcoSanjay Kumar PandaNo ratings yet

- 11kV Cable Diversion Method StatementDocument6 pages11kV Cable Diversion Method StatementMuneeswaran BalaguruNo ratings yet

- Wind Turbine Generator System Safety and Function Test Report For The Ventera VT10 Wind TurbineDocument37 pagesWind Turbine Generator System Safety and Function Test Report For The Ventera VT10 Wind Turbineashish sahaNo ratings yet

- QA&QC DT FRMC 005 Non Conformance ReportDocument3 pagesQA&QC DT FRMC 005 Non Conformance ReportTariq Ali SialNo ratings yet

- Techno-Economic Feasibility of Grid-Connected Photovoltaic Power Plant in Qeshm Island, IranDocument6 pagesTechno-Economic Feasibility of Grid-Connected Photovoltaic Power Plant in Qeshm Island, IranjhonNo ratings yet

- Transformer QuoteDocument3 pagesTransformer QuoterameshNo ratings yet

- Commissioning Checks for LV Load Panel at King Abdul-Aziz AirportDocument3 pagesCommissioning Checks for LV Load Panel at King Abdul-Aziz Airporteswaran005No ratings yet

- Components CatalogueDocument44 pagesComponents CatalogueJarrett Mathews100% (1)

- TEA Motor and Gearbox Enquiry Form PDFDocument2 pagesTEA Motor and Gearbox Enquiry Form PDFJarrett MathewsNo ratings yet

- 3005 150936391 00 000Document2 pages3005 150936391 00 000Jarrett MathewsNo ratings yet

- Binário de ApertoDocument1 pageBinário de ApertomiguelfpintoNo ratings yet

- Binário de ApertoDocument1 pageBinário de ApertomiguelfpintoNo ratings yet

- ANSI Codes PDFDocument3 pagesANSI Codes PDFelectrical_1012000100% (2)

- Al-Mamoori 2019 IOP Conf. Ser. Mater. Sci. Eng. 518 042019Document8 pagesAl-Mamoori 2019 IOP Conf. Ser. Mater. Sci. Eng. 518 042019Jarrett MathewsNo ratings yet

- Sub Station EquipmentDocument9 pagesSub Station EquipmentGaurav kumarNo ratings yet

- Appolo Hospital PDFDocument6 pagesAppolo Hospital PDFA Surya TejaNo ratings yet

- 6/14/02 Chapter 14: Use of Electrical Test Equipment 1/20Document20 pages6/14/02 Chapter 14: Use of Electrical Test Equipment 1/20LeonardNo ratings yet

- Wilo USA 2015 Product CatalogDocument24 pagesWilo USA 2015 Product CatalogJarrett MathewsNo ratings yet

- Work at Height Procedure Aug 2017 V1.3Document15 pagesWork at Height Procedure Aug 2017 V1.3Jarrett MathewsNo ratings yet

- Wilo USA 2015 Product CatalogDocument24 pagesWilo USA 2015 Product CatalogJarrett MathewsNo ratings yet

- Toolbox Talks Hotwork EnglishDocument1 pageToolbox Talks Hotwork EnglishZaki Adamou100% (2)

- Working at Heights Guideline PDFDocument13 pagesWorking at Heights Guideline PDFJarrett MathewsNo ratings yet

- Toolbox Talks Hotwork EnglishDocument1 pageToolbox Talks Hotwork EnglishZaki Adamou100% (2)

- 07 OPSAF-12-004 Operation of HV SystemDocument23 pages07 OPSAF-12-004 Operation of HV SystemJarrett MathewsNo ratings yet

- Electrical PR82POGC001Document14 pagesElectrical PR82POGC001Jarrett MathewsNo ratings yet

- OHS PR HighVoltageAccessDocument28 pagesOHS PR HighVoltageAccessFoad MirzaieNo ratings yet