Professional Documents

Culture Documents

Pumps PDF

Pumps PDF

Uploaded by

Lieu Dinh Phung0 ratings0% found this document useful (0 votes)

3 views28 pagesOriginal Title

Pumps.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views28 pagesPumps PDF

Pumps PDF

Uploaded by

Lieu Dinh PhungCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 28

Pumps

Dynamic (Centrifugal) pumps

Positive-Displacement pumps

Group introduction

Abid Hussain

PG-M10-20

M. Yaqoob

CE-M10-32

Abdul Sattar

PG-M10-13

Adnan Ali

CE-M10-40

Table of Contents:

• Introduction

• Types

• Positive displacement Pumps

• Reciprocating/Rotary

• Construction & Working

• Selection

• Pumps terminologies

• Power & Efficiency

• Operational Problems

• Limitations

Introduction:

• Pump is used to transform mechanical work

into fluid energy.

• It is a mechanical device which is used to:

i. Move liquids from lower elevation to higher elevation

ii. Move liquids from lower pressure areas to areas of higher pressure

iii. Increase the flow rate of a liquid

Types:

• Dynamic • Positive-displacement

(Centrifugal Pumps) a) Reciprocating:

(piston, plunger and diaphragm)

b) Rotary:

(gear, lobe, screw, vane)

Centrifugal Pump

• The centrifugal pump is the

most used pump type in the

world. The principle is

simple, well-described and

thoroughly tested, and the

pump is robust, effective

and relatively inexpensive to

produce. There is a wide

range of variations based on

the principle of the

centrifugal pump and

consisting of the same basic

hydraulic parts.

Types of P.D Pumps

(Reciprocating)

• Plunger pumps -

a reciprocating

plunger pushes

the fluid through

one or two open

valves, closed by

suction on the

way back.

Diaphragm Pump

• Diaphragm pumps

• similar to plunger pumps,

where the plunger

pressurizes hydraulic oil

which is used to flex a

diaphragm in the pumping

cylinder.

• Diaphragm valves are used

to pump hazardous and

toxic fluids.

Piston Pump

• Piston

• Displacement pumps

• usually simple

devices for pumping

small amounts of

liquid or gel

manually.

• The common hand

soap dispenser is

such a pump.

Rotary Pumps

Gear pump

• This is the simplest of rotary

positive displacement pumps

• It consists of two meshed gears

that rotate in a closely fitted

casing

• The tooth spaces trap fluid and

force it around the outer

periphery

• The fluid does not travel back on

the meshed part, because the

teeth mesh closely in the center

• Gear pumps see wide use in car

engine oil pumps and in

various hydraulic power packs

Screw Pump

• The screws are mounted on

parallel shafts

• That have gears that mesh

so the shafts turn together

and everything stays in place.

• One screw turns clockwise

and the other

counterclockwise.

• The screws turn on the shafts

and drive fluid through the

pump.

Lobe Pump

• This lobe pump displaces the

liquid trapped between two long

helical rotors

• Each fitted into the other when

perpendicular at 90°, rotating

inside a triangular shaped sealing

line configuration

• This design produces a continuous

flow with equal volume and no

vortex

• It can work at low pulsation rates,

and offers gentle performance

that some applications require

Vane pump

• A rotary vane pump is a positive-

displacement pump that consists of

vanes mounted to a rotor that

rotates inside of a cavity.

• In some cases these vanes can be

variable length and/or tensioned to

maintain contact with the walls as

the pump rotates.

Working Principle:

Centrifugal Pumps Positive-Displacement Pumps

• Liquid is forced into an impeller either by • liquid is taken from one end and positively

atmospheric pressure discharged at the other end for every

• In case of a jet pump by artificial pressure revolution

• The vanes of impeller pass kinetic energy • P.D pumps are widely used for pumping

to the liquid, thereby causing the liquid to fluids other than water, mostly viscous

rotate fluids

• The liquid leaves the impeller at high • a fixed quantity of liquid is pumped after

velocity each revolution

• The impeller is surrounded by a volute • If the delivery pipe is blocked, the

casing or in case of a turbine pump a pressure rises to a very high value, which

stationary diffuser ring can damage the pump

• The volute or stationary diffuser ring

converts the kinetic energy into pressure

energy

Construction of Centrifugal Pumps

A. Packing

B. Stuffing Box

C. Shaft

D. Shaft Sleeve

E. Vane

F. Casing

G. Eye of Impeller

H. Impeller

I. Casing Wear Ring

K. Discharge Nozzle

Construction of P.D Pumps

A. Compact cast-iron power frame

B. Taper roller bearings

C. Spur timing gears

D. Heavy-duty duplex stainless steel shaft

E. Oil lubrication of bearings and timing gears

F. Timing gears and shaft assemblies

G. rotor-face and back-face clearance

Selection Criteria:

Centrifugal Pumps Positive-Displacement Pumps

• Flow Rate and Pressure Head • Flow Rate and Pressure Head

• has varying flow depending on the system • has more or less a constant flow

pressure or head regardless of the system pressure or head

• Capacity and Viscosity • Generally gives more pressure than

Centrifugal Pump's

• The flow is reduced when the viscosity is

increased • Capacity and Viscosity

• Inefficient at even modest viscosity • The flow is increased when viscosity is

increased

• Mechanical Efficiency

• higher volumetric efficiency and a P.D

• Changing the system pressure or head has

Pump is better suited for high viscosity

a dramatic effect on the flow rate

applications

• Net Positive Suction Head - NPSH

• Mechanical Efficiency

• function of flow determined by pressure

• Changing the system pressure or head has

little or no effect on the flow rate

• Net Positive Suction Head – NPSH

• function of flow determined by speed

Pump Head

• Head is the height of liquid

• The static head corresponding to any specific

pressure is dependent upon the weight of the liquid

according to the following formula

𝑃𝑟𝑒𝑠𝑠𝑢𝑟𝑒 𝑖𝑛 𝑝𝑠𝑖 𝑋 2.31

Head in feet =

𝑆𝑝𝑒𝑐𝑖𝑓𝑖𝑐 𝑔𝑟𝑎𝑣𝑖𝑡𝑦

Suction lift

• Suction Lift Atmospheric pressure

It exists when the source of

supply is below the center line

of the pump.

• Static Suction Lift

It is the vertical distance in feet

from the centerline of the pump

to the free level of the liquid to

be pumped.

Suction Head

• Suction head

It exists when the source of supply is

above the centerline of the pump.

• Static suction head

It is the vertical distance in feet A

from the centerline of the pump

to the free level of the liquid to

be pumped

Discharge Head

• Static discharge head

It is the vertical distance in feet between

the pump centerline and the point of

free discharge or the surface of the liquid

in the discharge tank.

• Total static head

It is the vertical distance in feet between

the free level of the source of supply and

the point of free discharge or the free

surface of the discharge liquid.

Net Positive Suction Head (NPSH)

NPSH Available:

Absolute pressure at the pump suction, changed into head minus the vapour

pressure of the liquid being pumped, changed to head.

NPSH Required:

Minimum head needed at the suction to get the liquid into the impeller without

vaporizing

NPSHa must always be greater than

Absolute pressure at Pump suction − Vapor pressure at pump temp

NPSH =

Specific Gravity x 0.433

How to increase NPSH?

• Raise the suction tank (or level in the tank).

• Lower the pump.

• Increase the pressure in the suction tank.

• Cool the liquid to reduce vapor pressure.

• Modify the suction piping. - Increase pipe diameter -

• reduce the length - change fittings - modify valve type - reduce

number.

Power & Efficiency

• Brake horsepower (bhp)

• Actual horsepower delivered to the pump shaft

• Hydraulic horsepower (whp)

• The liquid horsepower delivered by the pump

Operational Problems

• Cavitation:

• A reduction in pump capacity

• A reduction in the head of the pump

• The formation of bubbles in a low pressure area of the pump

• A noise that can be heard when the pump is running

• Damaged that can be seen on the pump impeller and volute

• cavitation is an abnormal condition that can

result in loss of production, equipment

damage and worst of all, personnel injury

Limitations

Centrifugal Positive-Displacement

• Single stage will not develop • dynamic problems with

high pressure check valves when

applicable

• Low efficiency

• higher maintenance costs

• Priming

• construction is in general

• NRV more complex

• Can not handle viscous • need for safety relieve valve

liquid efficiently to protect the piping

• Poor sucking power against exceeding the

design pressure of the

system

You might also like

- Operator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowFrom EverandOperator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowRating: 2 out of 5 stars2/5 (1)

- Know Your Equipment - Centrifugal PumpDocument93 pagesKnow Your Equipment - Centrifugal Pumpsgupta_615796100% (1)

- Marine Auxiliary Machinery: 4 Positive Displacement PumpsDocument36 pagesMarine Auxiliary Machinery: 4 Positive Displacement PumpsJoshua HicksNo ratings yet

- Types of PumpsDocument26 pagesTypes of PumpsMaunish Shah100% (3)

- PumpsDocument85 pagesPumpsdenizkund100% (2)

- PumpsDocument46 pagesPumpsRiyadh SalehNo ratings yet

- On-Line Duralobe Classic SQ RTP Sterilobe Acculobe Tra10 Tra20Document173 pagesOn-Line Duralobe Classic SQ RTP Sterilobe Acculobe Tra10 Tra20kamchorepkNo ratings yet

- Centrifugal PumpDocument38 pagesCentrifugal PumpAbdullah Azzam100% (2)

- Centrifugal Pump MaintenanceDocument32 pagesCentrifugal Pump Maintenancemersium100% (1)

- Centrifugal Pump PDFDocument20 pagesCentrifugal Pump PDFSumedh Singh100% (1)

- Pump Troubleshooting: Ahmed Abdullah ZayedDocument514 pagesPump Troubleshooting: Ahmed Abdullah Zayedاشرينكيل مسونكيل0% (1)

- PUMP TrainingDocument130 pagesPUMP TrainingTirta Budiawan100% (4)

- Pump and Compressor 2Document52 pagesPump and Compressor 2SaravananRamasamy100% (3)

- Pumps OverviewDocument106 pagesPumps Overviewcemekaobi100% (2)

- Problem Solving - Centrifugal PumpsDocument40 pagesProblem Solving - Centrifugal PumpsEtemadiNo ratings yet

- Pumps Centrifugal and ReciprocatingDocument24 pagesPumps Centrifugal and ReciprocatingumarNo ratings yet

- Al-Salam Higher Institute For: by Abdelaal Mohamed Khttap Cairo 2014Document28 pagesAl-Salam Higher Institute For: by Abdelaal Mohamed Khttap Cairo 2014عبدوخطابNo ratings yet

- Troubleshooting HydraulicsDocument54 pagesTroubleshooting HydraulicsM.nour El-din100% (3)

- Fundamentals of Centrifugal PumpsDocument70 pagesFundamentals of Centrifugal PumpsFrancisco García100% (1)

- How To Read A Load Chart - CraneDocument6 pagesHow To Read A Load Chart - CraneDanny A SandhyNo ratings yet

- Reciprocating Pump PratishthaDocument13 pagesReciprocating Pump Pratishthamike rosaNo ratings yet

- Apco Air Release Valves Arv Arv Air Release Valves Sales 600Document4 pagesApco Air Release Valves Arv Arv Air Release Valves Sales 600RashedNo ratings yet

- Industrial Hydraulic CircuitsDocument43 pagesIndustrial Hydraulic CircuitsFidel Garcia GarciaNo ratings yet

- Troubleshooting PumpDocument54 pagesTroubleshooting PumpM.nour El-din100% (3)

- Hydraulics and Pneumatic SystemDocument59 pagesHydraulics and Pneumatic SystemNidhi Bharatiya100% (1)

- Rim and Face - Alignment KnowledgeDocument20 pagesRim and Face - Alignment Knowledgepk cfctk100% (1)

- GearboxDocument5 pagesGearboxrnaNo ratings yet

- PumpsDocument124 pagesPumpsantonyale90% (10)

- AlignDocument42 pagesAlignSumit Gupta100% (2)

- Training PumpDocument52 pagesTraining Pumparis mulyana100% (1)

- Presentation On - : Horizontal Centrifugal PumpDocument78 pagesPresentation On - : Horizontal Centrifugal Pumplifemillion2847100% (1)

- Tubular Casing Pumps by KSBDocument16 pagesTubular Casing Pumps by KSBGogy0% (1)

- Centrifugal PumpsDocument24 pagesCentrifugal PumpsHari Babu DharmavarapuNo ratings yet

- Pump Maintenance Procedures 1Document7 pagesPump Maintenance Procedures 1Shraddha Raut100% (1)

- PumpDocument30 pagesPumpPriyoProtikNo ratings yet

- Mechanical SealsDocument54 pagesMechanical Sealsajitkk79100% (2)

- Mechanical Seal Plan - Pocket Guide (John Crane)Document62 pagesMechanical Seal Plan - Pocket Guide (John Crane)Tarun Chandra100% (5)

- PumpDocument34 pagesPumpsoha89100% (1)

- Pump MaintenanceDocument9 pagesPump Maintenancemvbm3150% (2)

- Piping TheoryDocument20 pagesPiping Theorysonud4u100% (4)

- Centrifugal PumpDocument41 pagesCentrifugal PumpAbdallah MansourNo ratings yet

- Centrifugal Pumps: PARAN, John Lloyd MACASAET, Alwin MALABUYOC, Lean ErnestDocument74 pagesCentrifugal Pumps: PARAN, John Lloyd MACASAET, Alwin MALABUYOC, Lean ErnestMeryL Ang100% (1)

- Centrifugal Pumps: Training Program at Petronet LNGDocument30 pagesCentrifugal Pumps: Training Program at Petronet LNGAditya Mahajan100% (1)

- SKF SphericalDocument72 pagesSKF SphericalNath BoyapatiNo ratings yet

- Compiled by RabinDocument110 pagesCompiled by RabinRabinNo ratings yet

- Centrifugal Pump OverloadingDocument2 pagesCentrifugal Pump OverloadingAbdul AlimNo ratings yet

- Rotary Pumps: Internal Gear PumpDocument15 pagesRotary Pumps: Internal Gear PumpanbuvrpNo ratings yet

- Compressor GATE Mechanical EngineerDocument45 pagesCompressor GATE Mechanical Engineersap2279100% (1)

- Hydraulic Pumps and MotorsDocument24 pagesHydraulic Pumps and MotorsMohammed Al-OdatNo ratings yet

- Pump BasicsDocument96 pagesPump BasicsDhanasekaran SivasamyNo ratings yet

- Pumps BasicsDocument3 pagesPumps Basicshmid007No ratings yet

- PneumaticsDocument193 pagesPneumaticsvarungoldy100% (6)

- Control Valves: Dr. Ashraf SaleemDocument24 pagesControl Valves: Dr. Ashraf SaleemSharif Mohammad AdwanNo ratings yet

- Compressor Preventive MaintenanceDocument26 pagesCompressor Preventive MaintenanceMohamed Hamed100% (1)

- Rotating Equipment MeasurementDocument15 pagesRotating Equipment MeasurementAndinata SitepuNo ratings yet

- Fluid TransportationDocument63 pagesFluid TransportationAijaz Ahmed Khoso100% (1)

- Pumps and Industrial ApplicationDocument19 pagesPumps and Industrial Applicationdevasree reddyNo ratings yet

- Chapter 3 Fluid Power TechnologyDocument37 pagesChapter 3 Fluid Power Technologymuhammad irfan hakimi bin nor yazidNo ratings yet

- PumpsDocument45 pagesPumpsMehmood Ul Hassan100% (1)

- Module 7Document63 pagesModule 7Agilan ChellaramNo ratings yet

- 20 Questions Identify Probable Causes For High FCC Catalyst LossDocument0 pages20 Questions Identify Probable Causes For High FCC Catalyst Lossanshug1016No ratings yet

- Dry Gas Seal 4Document8 pagesDry Gas Seal 4anshug1016No ratings yet

- Dry Gas Seal1Document8 pagesDry Gas Seal1anshug1016100% (1)

- FCCDocument69 pagesFCCanshug1016No ratings yet

- UCBDocument4 pagesUCBJAYAPRAKASH SALIANNo ratings yet

- Impossible... For The Current Physics - Rupert Sheldrake's Reply To The Open Letter by Giuseppe Sermonti 3Document3 pagesImpossible... For The Current Physics - Rupert Sheldrake's Reply To The Open Letter by Giuseppe Sermonti 3AngieNo ratings yet

- The Reading Apprenticeship Framework (Excerpt From Reading For Understanding, 2nd Edition)Document5 pagesThe Reading Apprenticeship Framework (Excerpt From Reading For Understanding, 2nd Edition)Jossey-Bass EducationNo ratings yet

- Penticton Athletics Track and Field Club Registration Form UpdatedDocument1 pagePenticton Athletics Track and Field Club Registration Form Updatedapi-256034770No ratings yet

- 2016 03 31 Basa Pilipinas Quarter 1 Grade 1 Ilokano Teacher's Guide (Third Edition)Document213 pages2016 03 31 Basa Pilipinas Quarter 1 Grade 1 Ilokano Teacher's Guide (Third Edition)Renato Luna100% (2)

- Cookware - Pressure Cookers For Domestic Use: British Standard Bs en 12778:2002Document30 pagesCookware - Pressure Cookers For Domestic Use: British Standard Bs en 12778:2002طه اللوذعيNo ratings yet

- 121 Ch11 QuizDocument3 pages121 Ch11 QuizPrince PalashNo ratings yet

- NBK TA Brochure 2016-EmailDocument11 pagesNBK TA Brochure 2016-EmailPietrus NimbusNo ratings yet

- Week 1b.iiDocument5 pagesWeek 1b.iiMarck Joseph CabreraNo ratings yet

- Navigation DataDocument64 pagesNavigation DataAna-Maria NeculăescuNo ratings yet

- Fema306 PDFDocument270 pagesFema306 PDFSuhas MangaloreNo ratings yet

- Architects Certificate 3Document3 pagesArchitects Certificate 3Sethia DarshanNo ratings yet

- The Dimensionality of Right-Wing Authoritarianism - Lessons From The Dilemma Between Theory and MeasurementDocument25 pagesThe Dimensionality of Right-Wing Authoritarianism - Lessons From The Dilemma Between Theory and MeasurementRichNo ratings yet

- Solution Key of Quiz 3 Statistics - Mathematics For Management Spring - 2023 MBA 1A 22052023 021548pmDocument6 pagesSolution Key of Quiz 3 Statistics - Mathematics For Management Spring - 2023 MBA 1A 22052023 021548pmAimen ImranNo ratings yet

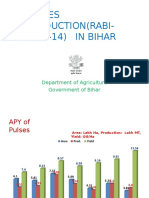

- Pulses Production (Rabi-2013-14) IN BIHAR: Department of Agriculture Government of BiharDocument13 pagesPulses Production (Rabi-2013-14) IN BIHAR: Department of Agriculture Government of BiharviewpawanNo ratings yet

- Essential Management SkillsDocument45 pagesEssential Management SkillsChavez RamonNo ratings yet

- Artificial Intelligence ICS461 Fall 2010: Lecture #11 - Planning in The Real World OutlineDocument12 pagesArtificial Intelligence ICS461 Fall 2010: Lecture #11 - Planning in The Real World OutlineHimanshu Aswal HimuNo ratings yet

- Invoice 1Document1 pageInvoice 1ajgrcommunity302 SirohiNo ratings yet

- A Look at The Lithium Clay Projects - Trabajo Rec Reservas Litio Arcillas y MetalurgiaDocument10 pagesA Look at The Lithium Clay Projects - Trabajo Rec Reservas Litio Arcillas y Metalurgiaigor colladoNo ratings yet

- (MacDonald Betty) Hello, Mrs Piggle-WiggleDocument132 pages(MacDonald Betty) Hello, Mrs Piggle-WiggleГалинаЧугаевская90% (10)

- IPC-TM-650 Test Methods ManualDocument3 pagesIPC-TM-650 Test Methods ManualBushra ShaukatNo ratings yet

- Course BUILDERS QUANTITIES AND ESTIMATING IDocument3 pagesCourse BUILDERS QUANTITIES AND ESTIMATING Ihafiz hilmiNo ratings yet

- HSC ICT Sheet Chapter 03Document22 pagesHSC ICT Sheet Chapter 03Muhammad Masum Hosen100% (1)

- TVL Ict 110 Academic AwardsDocument12 pagesTVL Ict 110 Academic AwardsnerenNo ratings yet

- Renewable Energy: By: Kaoutar Esbayou Randa Ettalbi Younes Alouani Mehdi HassouniDocument12 pagesRenewable Energy: By: Kaoutar Esbayou Randa Ettalbi Younes Alouani Mehdi HassouniJaouad ElamriNo ratings yet

- Functional Description of LSC System 11.00 CDocument8 pagesFunctional Description of LSC System 11.00 CStasNo ratings yet

- Pedagogical Analysis of The Subject of Commerce On The Topic ofDocument18 pagesPedagogical Analysis of The Subject of Commerce On The Topic ofsurajrtkNo ratings yet

- Booklet On DAD Guest House - Transit Facilities PDFDocument35 pagesBooklet On DAD Guest House - Transit Facilities PDFSURAJ PRASADNo ratings yet

- Grinding Wheels, Honing Stones and Turning BitsDocument6 pagesGrinding Wheels, Honing Stones and Turning BitsSamer SalibaNo ratings yet

- Era Summer Course On Data ProtectionDocument422 pagesEra Summer Course On Data ProtectionRocco SiffrediNo ratings yet