Professional Documents

Culture Documents

Are bigger thermocompressors always better

Uploaded by

N. Andrade0 ratings0% found this document useful (0 votes)

15 views45 pagesThe document discusses various ways that paper mills can improve the energy efficiency of their dryer sections. It addresses questions about properly sizing thermocompressors, installing dryer bars on low and high-speed machines, controlling steam pressures and differentials, recovering flash steam, replacing aging equipment, and monitoring ventilation systems. The key ideas are that mills should ensure their dryer equipment is optimized to minimize steam and electrical usage without compromising production or quality.

Original Description:

paper drying energy tips

Original Title

energy ebook

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses various ways that paper mills can improve the energy efficiency of their dryer sections. It addresses questions about properly sizing thermocompressors, installing dryer bars on low and high-speed machines, controlling steam pressures and differentials, recovering flash steam, replacing aging equipment, and monitoring ventilation systems. The key ideas are that mills should ensure their dryer equipment is optimized to minimize steam and electrical usage without compromising production or quality.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views45 pagesAre bigger thermocompressors always better

Uploaded by

N. AndradeThe document discusses various ways that paper mills can improve the energy efficiency of their dryer sections. It addresses questions about properly sizing thermocompressors, installing dryer bars on low and high-speed machines, controlling steam pressures and differentials, recovering flash steam, replacing aging equipment, and monitoring ventilation systems. The key ideas are that mills should ensure their dryer equipment is optimized to minimize steam and electrical usage without compromising production or quality.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 45

© 2016 Kadant Inc. or its affiliates. All rights reserved.

Are bigger thermocompressors always

better?

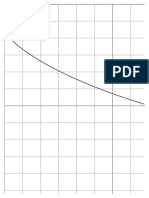

Thermocompressors use high-pressure (“motive”) steam to raise the pressure of a

low-pressure (“suction”) steam for subsequent use in the dryer section. They must

be sized to match the application. Bigger is not always better. Properly sized

thermocompressors minimize the amount of motive steam that is used to

compress the suction steam.

A large thermocompressor requires significant motive flow to simply start the

compression cycle. It is not uncommon to find thermocompressors that are so

large that they operate with inadequate control, or, in the worst case, end up with a

negative control response – opening when they should be closing. This control

response results in excess motive steam flow and steam venting from the dryer

section.

Will dryer bars affect energy consumption on

low-speed machines?

Yes, dryer bars can affect energy consumption on low-speed dryers, specifically

electrical energy consumption. Dryer bars (the Kadant Johnson trademark is

"Turbulator bars") are normally installed in paper dryers running at high speeds,

but they can also be installed in dryers that are running just below the normal

condensate rimming speed. The rimming speed for most dryers is around 1000

fpm.

A dryer with Turbulator™ bars, however, has a lower rimming speed - closer to 600-

700 fpm. Once the condensate is rimming, the drive power drops significantly.

Therefore, the installation of dryer bars in slow-speed dryers can reduce energy

consumption by reducing the drive load. The reduction in drive load also reduces

the stress and wear on dryer drive gears.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

Are high vacuum levels in the dryer section

steam condensers better?

Generally, no. The condensers in the dryer steam system are used to assist draining

wet end, low-pressure dryers and in condensing excess blow-through steam from

wet end and after-section dryers. Ideally, the condenser cooling water is heated to

a level that is of value in other mill operations. Higher vacuum levels require more

cooling water and result in a lower discharge water temperature. The vacuum

condenser should be controlled to match the required dryer differential pressure.

To save energy and water, do not run at a vacuum greater than is necessary to drain

the dryers.

If you are not venting steam through the

roof, do you have an efficient dryer section?

Not necessarily. You may be venting steam to a condenser. Although you have not

lost the condensate, you have lost the energy in the steam to the water. This energy

is wasted if the cooling water is not used elsewhere in the papermaking process.

Balancing the dryer steam sections and reducing the amount of blow-through

steam using managed dryer differential pressure control can greatly reduce the

amount of steam that goes to condensers.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

Are there opportunities to reduce energy

costs when the machine is not producing

paper?

Yes. Dryers that are idling during warm-up cycles, sheet breaks, and maintenance

downs can consume as much as 20-30% of the steam used when paper is being

produced. To reduce these losses, dryer steam pressures and differential pressures

should be adjusted automatically during start-ups, shutdowns, grade changes,

sheet breaks, and normal operation.

How can a condensate flash tank be used to

reduce energy costs?

When high-pressure condensate is collected in an atmospheric tank, a portion of

the condensate “flashes” back into steam. The temperature of the condensate

drops to 212 F and energy is lost with the flash steam. This energy, however, can be

recovered. By adding a separator (a condensate flash tank), the flash steam can be

collected and used in steam showers, shower water heaters, air heaters, and stock

heating systems. This can be a low-cost way to save a lot of energy.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

How can the operation of a size press affect

energy costs, production, and quality?

With a conventional puddle size press, the starch solids must be reduced to limit

starch pick-up when the machine speed is increased. A film metering size press,

however, is able to control starch pick-up independently of machine speed. This

allows the starch solids to be increased which in turn greatly reduces the amount of

water that must be evaporated in the after-dryer section. But this is only the start.

The starch pick-up is much less dependent on base sheet moisture profile, so it is

no longer necessary to over-dry the sheet to produce a uniform pick-up. This

further reduces the amount of energy required for production and significantly

increases the drying capacity of the main dryer section. As an added bonus, more

of the sizing remains on the surface of the sheet, increasing surface strength and

sheet stiffness.

What is the value of replacing older rotary

steam joints and dryer syphons?

It is more than you may think. Leaking steam joints waste both energy and valuable

condensate. Dryers that are valved off reduce the drying capacity of the machine.

Older styles of steam joints have shorter seal life which increases the frequency for

replacing parts, the labor to install them, and the downtime required for the work.

If the syphons are oversized or eroded, the amount of steam that blows through

the dryers will be greatly increased, often resulting in steam venting from the

machine. If the dryer steam joints and syphons are over 20 years old, there is likely

to be an opportunity for improvement.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

What is “choked flow” for a dryer section

thermocompressor?

Thermocompressors use high-pressure (“motive”) steam to raise the pressure of

low-pressure (“suction”) steam for re-use in the dryer section or for heating process

water. As the actuator opens the thermocompressor, more motive steam enters the

nozzle and more suction steam is entrained. Eventually, however, the motive steam

fills the throat of the thermocompressor and restricts the amount of suction steam

that is entrained. This condition is called, “choked flow”. Once the

thermocompressor reaches this point, further increases in the motive flow actually

reduces the flow of low-pressure steam.

With conventional thermocompressor control schemes, the actuator will increase

the motive flow to the maximum with a corresponding loss of suction flow,

pressure control, and efficiency. The Kadant Johnson Dryer Management System

controls keep the actuator in range to prevent this from happening.

Energy costs give an indication of energy

efficiency, right?

Not quite. As production (tons per day) increases, the amount of water that must

be evaporated in the dryer section also increases. The best indication of energy

efficiency is the ratio of the energy cost to the machine production. It is better to

monitor steam flow per ton of paper produced than simply the steam flow rate.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

Will dryer bars affect energy consumption on

high-speed machines?

Not directly. Dryer bars can be installed in paper dryers running at any speed, but

they have the greatest impact when the machine is operating at high speeds.

Dryer bars greatly increase the rate at which heat can be transferred to the paper

when the condensate is rimming on the inside of the dryer. If the higher heat

transfer capability is used to increase production, then the amount of water that

must be evaporated will also be increased. This increases the amount of energy

that is used in drying the paper.

If the production is not increased, then the higher heat transfer capability will result

in lower operating steam pressures. Lower operating steam pressures could result

in increased electrical production in a cogeneration facility. This can represent a

very significant improvement in energy efficiency. There is another secondary

benefit: Dryer bars will normally improve the cross-machine moisture profile.

This often results in less over-drying. Less over-drying results in less drying and less

energy.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

What are some simple ways to monitor dryer

section ventilation systems?

Two important dryer ventilation parameters are the supply air temperature rise

across the heating coils and the exhaust air temperature drop across the heat

recovery system. A change in these values often indicates that the filters are dirty,

the heaters are plugged, or the steam coils are not draining properly. The Kadant

Johnson DMS™ control technology can monitor these parameters and send a

maintenance alert when the parameters are out of normal operating range.

Does it make any difference whether the

steam pressure used to dry paper is taken

from a high-pressure header or a low-

pressure header?

It might. Paper dries the same whether the steam was originally at 60 psi or at 160

psi. In a cogeneration plant, however, additional electrical energy can be generated

from the high pressure steam if it is delivered to the dryer section at a lower

pressure. It is much better to drop the steam pressure through a turbine-generator

than across a pressure-reducing valve. Whenever possible, use the lowest source of

steam pressure to meet the drying requirements.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

What is the best steam pressure for dryers

that do NOT contact the sheet?

Dryers that do not contact the sheet should be disconnected from steam service.

Bottom unorun dryers, return run fabric dryers, and Feeney dryers (intermediate

dryers that do not contact the sheet) contribute very little to drying. Modern

fabrics do not carry water and do not have to be dried by separate dryers.

Although condensing loads are very low in non-contacting dryers, a lot of steam

blows through the dryers, only to be vented from the steam system.

Ideally, fabric and Feeney dryers should be removed from the machine or at least

disconnected from the steam system and blanked off. This saves steam joint

maintenance and reduces energy consumption.

Note: Unheated bottom unorun dryers will be smaller in diameter than the heated

top dryers. To avoid stress on the drive gears, bottom unorun dryers should be

disconnected from the gear train by removing idler gears. This can be done on

many dryer configurations, leaving the bottom dryers to be driven through the

fabric.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

What affect does thermocompressor

efficiency have on energy consumption in

drying?

Thermocompressors use high-pressure (“motive”) steam to raise the pressure of

low-pressure (“suction”) steam for subsequent use in the dryer section. Motive

steam flow can be reduced by properly matching the size of the thermocompressor

to the dryer syphon flow requirements.

It can be further reduced by using a high-efficiency thermocompressor. High-

efficiency thermocompressors require less motive steam flow to boost the suction

steam pressure. This reduces the potential for steam venting from the dryer section

during normal operation as well as during sheet breaks. Reducing the flow rate of

motive steam will also have a positive effect on mill-wide energy costs in a

cogeneration facility. The powerhouse can often use the extra high-pressure motive

steam to generate additional electrical energy.

Do you see steam venting through the roof

of your paper mill?

If so, you have found an opportunity for reducing energy costs. Follow the vent line

and determine its source. Improving the dryer steam system balance, using

condensate flash steam, and installing high-efficiency thermocompressors can

greatly reduce the likelihood (and cost) of venting steam. And you save the

condensate at the same time.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

Do high dryer hood temperatures increase

drying capacity and energy efficiency?

No. The dryer hood air temperature must be high enough to prevent sweating and

dripping, but higher air temperatures contribute very little to drying capacity. High

air temperatures do, however, greatly increase the amount of energy that is

consumed. In general, energy is being wasted if the dryer hood is operated at

temperatures over 180-200 F (82 - 93 C). It takes only an adjustment of the

temperature set point to begin saving money.

If the dryer internals are not making any

noise, are they okay?

Not necessarily. Syphon shoes and syphon pipes can be badly eroded without the

syphon components being loose inside the dryer. Eroded syphons result in high

operating differential pressures, high blow-through steam flow rates, and flooded

dryers. During annual dryer inspections, look specifically for eroded syphon pipes,

syphon shoes, and syphon elbows (particularly those made of cast iron).

© 2016 Kadant Inc. or its affiliates. All rights reserved.

What are dryer “steam bleeds”?

Dryer steam bleeds are valved pipes that vent steam from the inside of the dryer

cylinders to the air in the dryer hood. Steam bleeds were common in the 1960's on

dryers that were suffering from accumulation of air inside the dryers. Air

accumulation would reduce the heating capacity of the dryers and the uniformity

of the sheet moisture profiles.

Today, boiler make-up water treatment is greatly improved so there is less air in the

steam. Further, there are fewer tendencies for air to accumulate in dryers with

modern dryer syphons. In most cases, these steam bleeds can be eliminated. This

reduces the loss of steam energy and the amount of ventilation air flow required to

prevent the dryer hood from sweating.

In steam systems with a thermocompressor that recirculates blow-through steam

back to the dryers, the steam system can be periodically purged of air. The Kadant

Johnson DMS® steam system control technology is programmed to provide

periodic and automatic venting of air from dryers in thermocompressor loop

systems.zzz

Does it make any difference where the sheet

is trimmed?

Yes, it does. Whenever possible, trim the sheet at the wet end rather than at the dry

end. This avoids drying paper that will not be sold. The best way to conserve

energy is not to use the energy in the first place.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

What is the impact of sheet breaks and grade

changes on energy consumption?

Significant. A machine wastes 1 to 2 tons of steam for every ton of broke that it

produces. Reducing sheet break time helps. Eliminating sheet breaks helps even

more. And getting back on grade as quickly as possible is particularly important for

machines that have frequent grade changes.

Unfortunately, getting back on grade is not easy. The thermal response of the dryer

section is very slow. It takes a long time to change the temperature of 500 tons of

iron. Solutions using Dryer Management System® control software can reduce

sheet break recovery times up to 20% using feed-forward control and other

strategies. By monitoring the drying process, the target steam pressures and

differential pressures can be set even before the moisture scanner is back on line.

Are bigger dryer syphons always better?

Not necessarily. Dryer syphons can be too large as well as too small. The syphon

size should be based on the dryer speed, condensing load, steam pressure, and

style of syphon. Many rotating syphons that were installed in the 1970-1980’s had

syphon pipes that were too large for their applications. Even when operating at

recommended differential steam pressures, the high blow through flow rates

coming from these syphons can result in an inefficient steam system operation.

Check your syphon sizing to be sure it is correct for your current operation.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

Should the dryer air exhaust be run at its

design limit?

Generally not. Excessive air exhaust wastes energy. However, inadequate exhaust

results in the hood panels sweating and water dripping on the sheet.

The exhaust should be adjusted to match the drying load. More exhaust is required

when the drying load increases. Less exhaust is required when the drying load

decreases. Very little exhaust is required during sheet breaks.

To minimize energy consumption and prevent sweating during heavy drying

conditions (e.g., when producing higher basis weight grades), it is necessary to

monitor drying loads, calculate the air exhaust requirements, and adjust the

exhaust fans or dampers accordingly. The drying load can be calculated and the

exhaust flow adjusted automatically using a Dryer Management System® control

technology.

What is the best way to reduce energy costs?

The best way is not to use the energy in the first place. Increasing the dryness out

of the last press nip by 1% can reduce the energy used in drying by 4%. Increasing

press loads, optimizing press fabric design and operating life, installing shoe

presses, and increasing the web temperature before the last nip will all help

increase sheet dryness.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

Can I do something to eliminate flash steam

loss?

Flash steam is heat energy and treated water and occurs when pressurized steam

condensate is vented to atmospheric pressure. Depending on the condensate

pressure and the amount of condensate generated, flash steam loss could result in

millions of BTUs of energy and treated water lost to atmosphere.

There are many methods to capture this energy and treated water loss. The key is

to find a source to use the flash steam. One way is to use the flash steam to heat

water. The flash steam could be directed to a water jet heater. The heated water

could be used to preheat boiler make-up or other hot water needs in your facility.

Can the machine Silo/Wire Pit steam control

valve position indicate excessive fresh water

consumption?

Yes, as cooler fresh water (typically referred to as mill water) is added to the

machine white water system, the silo/wire pit steam control valve must open to

maintain the target system temperature. As the volume of cooler fresh water

introduced into the white water system increases, the more the steam control valve

must open and the greater the steam demand required to maintain system

temperature. This is most often observed during machine startups or machine

upset conditions, such as sheet breaks.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

Is your dryer section ventilation system well-

managed?

It might be, but only if the supply and exhaust air flows are adjusted based on the

evaporation rate. Air flow adjustment is particularly important for paper dryer

sections that operate over a wide range of steam pressures.

Properly controlled supply and exhaust air flows can provide large energy savings,

but they must be actively managed to avoid operational problems. The exhaust

humidity should vary with paper weight and air flows should be changed slowly to

maintain machine direction and cross-machine direction uniformity.

The key to proper air flow control is the accurate measurement of the evaporation

rate. It is difficult to reliably and accurately measure exhaust air humidity in the

harsh operating environment of a dryer hood exhaust. An alternative to manually

measuring exhaust air humidity is to use the Kadant Johnson DMS® control

technology that features an advanced drying algorithm to continuously monitor,

control, and optimize the dryer air system, relieving machine operators from this

complex task and providing significant improvements in energy efficiency.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

Can dryer bars cover only a portion of the

dryer and improve the moisture profile?

In theory, yes. In practice, this can be very difficult. Dryer bars (the Kadant

Johnson trademark is "Turbulator® bars") are normally installed in paper dryers to

cover the full width of the dryer. These bars increase both the capacity and the

uniformity of heat transfer. This alone will often improve the moisture profile. If,

however, the non-uniform moisture profile is being caused by something external

to the dryer, correcting the profiles by making the heat transfer non-uniform is not

a best practice.

For example, if the basis weight profile is non-uniform, or the press nip profile is

non-uniform, or the press felts are streaky, it may be possible to improve the profile

with partial-width dryer bars, but once the external problems are solved, the poor

moisture profile returns. Unless the moisture profile non-uniformity is consistent

and persistent (over many years), it is best to maintain uniform heat transfer from

the dryers with full-width bars.

How does the sheet moisture at the reel

effect energy consumption?

The moisture profile and moisture level both have direct effects on each other and

on the resulting energy consumption. One of the often-used tools used to fight a

poor moisture profile is lowering the moisture content. This levels the moisture

profile, but it also increases the amount of water that must be evaporated. It

increases the amount of fiber that is required to achieve the specified reel weight

and it reduces the overall drying capacity (the drying rate for a dry sheet is very

low).

It is more cost-effective to achieve a uniform cross-machine moisture profile

without drying below the average moisture required to achieve the finished sheet

properties. As a bonus, basis weight profiling systems, profiling steam boxes,

moisturizing showers, and caliper profile control devices can be used to optimize

sheet properties and not used to correct for non-uniformities.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

Is there a cost associated with introducing

fresh water into the white water system?

Yes, white water systems are typically controlled to a targeted temperature. When

fresh water is introduced into the white water system, this water must be heated to

maintain the system at the desired temperature.

To calculate the annual cost (350 operational days) to heat fresh water to process

temperature with low pressure steam, one can use the following equation:

Steam Costs for 1 Hour $ = GPM*8.25*ΔT*60*$MMBTU/1,000,000

Steam Costs for 24 Hours $ = (GPM*8.25*ΔT*60*$MMBTU/1,000,000)*24

Steam Costs for 350 Days $ = (GPM*8.25*ΔT*60*$MMBTU/1,000,000)*24*350

Where:

GPM = Gallons per Minute

8.25 = Conversion Factor GPM to lbs/min

ΔT = Delta T of Inlet Temperature to Process Temperature

$MMBTU = Dollars per Million BTU

© 2016 Kadant Inc. or its affiliates. All rights reserved.

Can an energy monitoring system reduce

energy consumption?

Yes, but not directly. By definition, a monitoring system does not do anything, it

just watches what is going on. However, the first step in energy conservation

activities is monitoring energy consumption. "If you can't measure it, you can't

improve it." To properly monitor the energy consumption, flow meters, temperature

transmitters, and cost information need to be accurate.

An effective monitoring program requires the measurement of all major energy

flows (steam, condensate, water, electricity, gas, compressed air, and vacuum) and

their associated costs and the associated production. The best monitoring

programs include active benchmarking against best-in-class machines. Assigning a

person to be responsible for energy conservation in the mill can help increase

visibility and accountability of conservation efforts.

Can steam boxes reduce the amount of

energy required for making paper?

In theory, yes. In practice, maybe. Heating the sheet in the wet end or in the press

section will increase the dewatering capability and deliver a drier sheet to the dryer

section. This will reduce the amount of energy consumed in the dryer section to

achieve the desired sheet moisture.

The amount of energy saved in the drying process is often less than the amount of

energy used in heating the sheet. As a general rule, the press section will increase

the sheet dryness by one percentage point for every 10°C increase in sheet

temperature. The sheet strength, however, also increases with increasing dryness

and this helps to improve sheet runnability. An added bonus!

© 2016 Kadant Inc. or its affiliates. All rights reserved.

Can the mill DCS be used to monitor energy

consumption?

Yes. The mill Distributed Control System and process historian (process database)

are very powerful tools for monitoring and trouble-shooting machine operations.

But there may be more to the story. Not all process flows and valve positions are

measured, displayed, and recorded by the DCS. Routine operator rounds can fill in

the gaps. Operators can see when safety relief valves or vent valves are open or

leaking, when rotary steam joints are blowing steam, when condensate is being

dumped into the sewer, when compressed air lines are left open, when ventilation

systems are out of balance, where dump valves and by-pass valves are

inadvertently left open, and when seal pits are flooded over. Open drains result in

not only lost energy, but also in lost condensate and lost boiler feed water

treatment chemicals.

Thermography using infrared camera systems can be a very effective tool in finding

energy losses that are not visible to the eye: steam leaks, hot spots in insulated

panels, pipes, separators, and valves, and the ubiquitous defective steam traps. An

observant operator, DCS displays, process historian data, and an infrared camera

are all integral parts of a complete energy management program.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

How do stationary syphons help to reduce

papermaking energy consumption?

Stationary syphons can be used to drain condensate from steam-heated paper

dryers. They do this with lower differential steam pressures and lower "blow-

through" steam flows than that required for draining dryers with a rotating syphon.

In a cascade steam system, this results in less blow-through steam being vented to

atmosphere or to a condenser.

In a thermocompressor system, this results in less high-pressure (motive) steam to

recompress the steam for re-use. When properly sized and installed, they can also

greatly reduce the tendency for the dryers to load up with condensate ("flood").

Stationary syphons also reduce the amount of upset that occurs during a sheet

break and correspondingly reduces the tendency for venting.

Does the type of rotary steam joint affect

energy consumption?

Yes, the type of rotary joint does affect the consumption of energy. Older style

rotary joints, self-supported joints and many lug-supported joints, use internal

steam pressure to apply load to the carbon sealing ring. It takes high torque to

rotate these "pressure joints", particularly when the steam pressure is high.

Modern compensated steam joints, such as the Kadant Johnson PTX® steam joint,

require much less torque. For example, the drive power for a machine running at

1750 fpm with (80) 60" diameter dryers could be reduced by 80 hp simply by

converting from pressure joints to PTX steam joints. At an electrical energy cost of

$0.07 per kWhr, this would be a savings of over $35,000 per year. The elimination of

steam leaks and rotary joint maintenance makes the savings even larger.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

Does machine clothing selection affect

energy consumption?

Yes! Forming fabric design has a direct effect on drainage rate, sheet formation,

and sheet properties. The fabric permeability may affect the vacuum load and air

flow requirements- and perhaps the frictional drag over stationary forming

elements, but these are typically smaller effects. Dryer fabric tension, permeability,

and (to a lesser degree) fabric construction can affect the drying rate and drying

capacity, but dryer fabrics do not have a direct effect on the amount of energy

required for drying.

Press fabrics, on the other hand, have a direct and significant effect on energy

consumption. The press fabric construction, wet permeability, and re-wet control

directly affect the dryness of the sheet leaving the press. A one percentage point

change in the moisture content of the sheet leaving the last press nip can result in

a 4 to 5% reduction in the amount of water that must be removed in the drying

process.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

Does machine runnability affect energy

consumption?

Most people would say that runnability does not have a direct effect on energy

consumption. But they are only partially right. If the press draw is long or the sheet

edges are curling or there are signs of sheet wrinkles, folds, tears, or edge cracks,

the machine speed is reduced to avoid the resulting sheet breaks. As long as there

are no sheet breaks, there is no energy loss associated with sheet breaks. But when

there is a sheet break, the energy consumption remains high and there is no

resulting production.

During a dry end sheet break, for example, pumps, drives, fans, showers, and

heaters continue to run, using the same amount of energy, and the dryers waste 1-

2 tons of steam energy for every ton of broke. Anything that can be done to

improve machine runnability (unorun dryer sections, blow boxes, suction pick-up

rolls, ventilation air control, threading devices, supervisory control systems) will

help to reduce the amount of energy consumption.

Is a dryer fabric cleaning system required for

high energy efficiency?

Clean dryer fabrics do not directly increase or decrease the amount of energy

required to dry the paper web. However, dryer fabrics that have a lot of build-up of

fiber, filler, and stickies will reduce the uniformity of heat transfer, the effectiveness

of the dryer pocket ventilation system, and sheet runnability. These lead indirectly

to more demands on the cross-machine profiling devices, reduced drying capacity,

and more sheet breaks. These all result in reduced energy efficiency.

Fabrics can be cleaned by a number of methods, either during a shut-down or on-

the-run. On-the-run devices use a series of high-pressure water jets and an integral

system for capturing and removing the debris cleaned off of the dryer fabrics.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

Vacuum Condenser Energy Monitoring

Many dryer drainage systems discharge wet end dryers and differential vent valves

to a vacuum condenser. Water is circulated through the heat exchanger to

condense the discharged steam and create a vacuum. Monitoring the vacuum

condenser is an excellent way to track dryer section energy efficiency. Any steam

vented to the vacuum condenser is a loss from the system and should be

considered a waste. A well designed dryer drainage system will have losses to the

condenser less than 3% of the total steam flow to the dryer section. Many machines

have losses that are in the range of 1% to 2%.

How is energy loss to the vacuum condenser monitored? By measuring the heat

gained by the cooling water. The heat gain can be calculated from the cooling

water flow, water temperature into the condenser, and water temperature out of

the condenser. These measurements can be made with a portable water flow meter

and a thermometer. Many machines are installing permanent devices to measure

and record the information in a data historian. The trend line will quickly show

when the energy efficiency of the system is changing. Low energy efficiency can be

caused by something as simple as a poorly maintained vent valve from one of the

steam sections or something more complicated like mis-sized syphons or

thermocompressors.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

Piping Insulation - The Rodney Dangerfield

of Energy Conservation

Many paper mills will have hundreds of feet of exposed steam and condensate

pipes. Insulation may have been removed for maintenance work or is in such poor

condition that it provides little insulation value. A perception exists that the energy

loss is not significant and the lack of good pipe insulation is often overlooked

when assessing energy conservation opportunities. Like Rodney, piping insulation

gets no respect.

For example, a ten foot length of 6" pipe handling 100 psig steam will have a heat

loss of 14,100 Btu/hr. This can be reduced to 865 Btu/hr with proper insulation. If

the energy cost is $6 per million Btu, the savings would be $600 per year. Insulation

of exposed piping can quickly add up to significant savings. Insulation has the

added benefit of improving the machine room operating temperature and

providing a safer working environment.

The Department of Energy has free software available called 3E Plus. This software

can be used to assess the value of insulation of pipes and tanks. It can be accessed

at the Dept. of Energy website. Look for the Steam System Tool Suite. There are

other useful free tools at this site to help with energy conservation efforts.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

Are cooling towers the best approach to

reduce temperature of recirculated seal water

for liquid ring vacuum pumps?

Low temperature seal water improves liquid ring vacuum pump efficiency which

can improve the paper machine performance.

Many paper mills use cooling towers to lower seal water temperature. Cooling

towers remove heat from the seal water through evaporative cooling. This valuable

heat is then lost to atmosphere. Cooling towers also require electrical energy to

maintain air movement, fresh water to maintain level, chemicals to prevent

biological growth, and maintenance to keep the towers clean and functioning.

Heat exchangers can be an energy efficient alternative for reducing vacuum pump

seal water temperature and heating process water. Modern spiral heat exchangers

can even operate with lean white water without plugging or extensive

maintenance. With the right heat exchanger configuration, the energy (heat) that

was previously lost to atmosphere can be recovered and the costs of operating a

cooling tower are eliminated.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

Can cold pump, agitator, and refiner seal

water impact paper machine wet end steam

use?

Yes, it can. Typically, cool fresh water is used for paper machine seal water systems.

Over 30% of seal water used for pumps, agitators, and refiners enters the

papermaking process. Altogether, this represents a significant amount of fresh

water that must eventually be heated up to process water temperature.

For example, a seal water system that supplies 400 gpm to pumps, agitators, and

refiners will add over 170,000 gallons per day of cool fresh water to the whitewater

system. And this amount can easily be much more.

Many seal water lines have only a manually adjusted ball valve to regulate seal

water flow. These valves are often found operating completely open when only a

fraction of the flow rate is really required for the seal.

A much better approach is to use flow meters on the seal water lines to each pump,

agitator, and refiner. Maintenance can use these flow meters to adjust the seal

water flow to each device to the manufacturers' design specifications. This will have

a significant impact on overall water and energy consumption.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

What is the optimum operating tension for a

dryer fabric?

It depends. Dryer fabrics hold paper in tight contact with dryer surfaces to increase

the drying rate and heat transfer uniformity. On some paper machines, dryer fabrics

are also used to drive dryer cylinders. Dryer fabrics can also reduce the cross-

directional shrinkage of the paper web. Despite these positive effects, there is a

point of diminishing return. Excessive tension can damage the fabrics and paper

machinery with no practical gain in drying capacity, drivability, sheet handling, or

sheet restraint. Fabric tensions should never exceed those recommended by the

fabric supplier or the equipment manufacturer. That said, the minimum fabric

tension is about 4 pli and felt tensions in the range of 10-20 pli would normally

give high drying rates, stable fabric guiding, and good machine runnability. Slightly

higher values may be required on machines with runnability components such as

blow boxes and vacuum boxes.

What is the correct operating differential

pressure for a dryer section?

The correct operating differential pressure for maintaining dryer drainage depends

on a number of parameters. Some of the more important variables are: dryer

section steam pressure, steam condensing rate, type of dryer syphon (rotating,

stationary, or scoop), syphon pipe sizes, machine speed, and dryer diameter. When

it comes to setting the operating differential pressure, unlike the Ron Popeil 4000

rotisserie, operators cannot just "set it and forget it". The operating differential

pressures must be adjusted to reflect changes in operating conditions that come

with start-ups, shut-downs, grade changes, and sheet breaks. Operators can make

these changes manually, or they can use a supervisory control system, to make the

changes automatically.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

What is the recommended frequency for

dryer inspections?

There may not be pressure vessel code, local jurisdictional, or other regulatory

requirements for periodic dryer inspection, but it is a good practice to formally

inspect dryers every five years. To make this process more manageable, mills and

their insurance carriers will often adopt a program in which 20% of the dryers are

inspected each year so that all dryers are inspected on a five-year cycle. These

inspections include magnetic particle testing of dryer heads, ultrasonic testing of

head bolts, dryer shell thickness measurements, acoustic emissions examination,

and external and internal visual inspections.

Internal visual inspections should identify grooves in the shell, erosion under

syphon shoes, loose dryer bars, loose dryer balance weights, visible casting flaws,

and erosion or damage to syphon piping. Eroded syphon shoes, eroded syphon

elbows, and leaks past syphon flange gaskets can lead to poor condensate

evacuation, increased operating differential pressures, and high blow-through

steam flows. These in turn reduce the energy efficiency of the drying process.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

Why are dryer surface temperatures

measured in a dryer study?

The surface temperature of a dryer is a good indicator of dryer performance. The

temperature of the surface is compared to the temperature of supply steam (the

"saturation" temperature that corresponds to the dryer steam pressure). The

difference between the dryer surface temperature and the steam temperature is an

indication of heat transfer efficiency from steam through the condensate in the

dryer, the cast iron dryer shell, contamination on the inside and outside of the

dryer, and any other resistance between the steam and sheet.

Interpretation of these results, however, requires some care. High dryer surface

temperatures, for example, can be the result of very good heat transfer from the

steam to the dryer shell, but they can also be the result of poor thermal contact

between the dryer shell and the sheet. When used in conjunction with other

measurements (machine speed, trim width, grade, steam pressures, condensing

load, fabric tensions, etc.), the dryer surface temperature measurements can

provide valuable information on areas for potential improvement.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

What is the difference between sensible heat

and latent heat?

"Sensible" heat is energy that results in a change in temperature, that is, energy

transfer that can be sensed. "Latent" heat is energy that is required for a change in

state, for example, to evaporate water without any change in the water

temperature. Latent heat is also known as "heat of evaporation" or "heat of

condensation". When drying paper, some of the drying energy is required to

increase the temperature of the sheet, without evaporating any water. This is called

sensible heating. The majority of the energy required for drying paper is the energy

required to evaporate the water. This is called the latent heat.

It takes about 30 Btu (British Thermal Units) of energy to increase the temperature

of one pound of water from 182°F to 212°F. It takes 970 Btu to evaporate that same

pound of water with no change in its temperature. The least amount of energy is

required to dry the paper when the wet web is not over-dried (that is, when it is not

over-heated) and when the amount of water that must be evaporated is minimized,

for example, by having higher exiting press dryness or a higher reel moisture

content.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

What is the difference between sensible heat

and Does the grouping of dryers affect

energy efficiency? heat?

The grouping of dryer cylinders in separate steam groups does not directly

increase or decrease the amount of energy required to dry the paper web. The

grouping of dryers does, however, have a direct effect on the design and ultimately

on the performance of the dryer steam system. In a thermocompressor steam

system, for example, each thermocompressor must be sized to match the number

of dryers in the section, their operating steam pressures, the differential steam

pressures, and the resulting blow-through steam flow.

In a cascade steam system, the down-stream dryer groups must be sized to use the

blow-through steam flows from the up-stream dryer groups. The last of the steam

groups must also be properly sized so that its blow-through steam is either used in

a low-pressure process or low enough in quantity to be discharged to a condenser.

Without a proper grouping of dryers, the steam energy will be lost, either through

vent valves to the atmosphere or to condensers.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

Is it important that differential pressure

transmitters be calibrated?

Proper calibration of instrumentation is at the heart of any efficient dryer section

operation. If a process parameter cannot be properly measured, it cannot be

properly controlled. Differential pressure transmitters are particularly important.

Dryer drainage depends on it. Dryers with rotary syphons will flood if the

differential pressure is not high enough and they will pass excessive amounts of

blow-through steam if the differential pressure is too high. Even with modern

stationary syphons, accurate differential pressure measurement is very important.

Only 3-4 psi differential pressure is needed to drain the dryers with a stationary

syphon, but with a measurement error of only 2 psi, the blow-through flow will

easily be either inadequate or excessive.

It does not end there, the differential pressure transmitters may be properly

calibrated, but the pressure sensing lines may not be delivering the right pressure

to the transmitter. Over half of the dryer sections surveyed by Kadant Johnson had

sensing lines that were improperly designed, installed, and maintained.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

Where do you start in optimizing a dryer

section?

The dryer section consumes large amounts of energy and it can have a dramatic

impact on both sheet quality and profitability. The drying process, like other

papermaking unit operations, is a complex matrix of interacting systems: Pocket

ventilation, steam system, drive system, tail threading, sheet handling, energy

recovery, and fabric conditioning, guiding, and tensioning.

A good way to start an evaluation of the dryer section is to contact a drying

systems supplier, consultant, or engineering firm for a dryer audit. A professional

dryer audit should include a complete set of dryer section measurements, an

analysis of equipment sizing, recommendations for operational improvements,

recommendations for equipment upgrades, lists of short-term and long-term

improvement projects, and an analysis of the expected return for each project.

Typical returns come from energy savings, increased drying capacity, reliable dryer

drainage, reliable dryer drainage equipment, improved dryer section runnability,

and enhanced drying uniformity. A comprehensive report identifies improvement

opportunities and quantifies the associated benefits.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

What is the role of monitoring in optimizing

a dryer section?

Optimizing a dryer section begins with monitoring the dryer section operation and

developing a baseline for dryer section performance. The baseline can be

compared to the performance of similar machines producing similar grades. This

baseline can also be used to evaluate the impact of changes made on the machine.

Improvements, however, require an active program that follows and acts on the

data. Daily production meetings should include a review of energy efficiency

readings. This will help to identify losses as they occur.

For example, an increase in steam going to a condenser may indicate the

differential steam pressures are too high. A vent valve opening up may indicate a

thermocompressor is running in a choked flow condition. An increase in the dryer

steam flow (per ton of product) may indicate the exiting press moisture is

increasing and it is time to change one of the press felts. An increase in steam

pressure to the air heaters may indicate air filters are plugged and need to be

replaced. Again, the first step is monitoring. The next steps involve acting on the

results.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

How do condensate traps impact energy

efficiency?

Traps indeed impact the energy efficiency of a steam system. Condensate traps are

applied to the drain lines of various types of steam heating equipment such as

steam coils, heat exchangers, and unit heaters. They are also frequently applied to

keep steam mains free of condensate.

The purpose of condensate traps is to allow condensate to drain to a lower-

pressure condensate collection system while disallowing the flow of steam to the

lower-pressure system. There are many types of condensate traps, but nearly all are

designed such that if they fail, they fail open. If a trap fails open, the equipment

served by the trap will normally continue to function trouble-free. But, the failed

trap will allow live steam to flow to the downstream condensate receiving system.

This normally has negative impact on energy efficiency because the live steam

going to the receiving system usually is not put to good use. It might be vented to

atmosphere or, worse yet, it might cause the condensate receiving system to

pressurize which will potentially cause drainage problems for other users leading to

various operational problems.

To ensure condensate traps are functioning properly, they should be surveyed

every two to four years by a trained professional. Most of the trap suppliers offer

trap survey services.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

Are the non-condensable bleeds on

thermocompressor sections necessary?

Most thermocompressor sections are equipped with a non-condensable bleed

(NCB) which are are applied to thermocompressor sections to prevent

accumulation of non-condensable gases in the dryers. If allowed to accumulate, the

non-condensable gases will diminish heat transfer rates for paper dryers in the

steam section and cause non-uniform cross direction dryer surface temperature

profile. This will lead to non-uniform cross direction sheet moisture profile.

Today, most boilers generate steam with extremely low levels of non-condensable

gases and some producers seem to "get by" with no NCB's on their

thermocompressor sections. Still, most steam system suppliers advocate having a

NCB to safeguard against costly operational problems.

The discharge from NCB's is usually directed to atmosphere or a condenser. In this

case, the presence of the bleed has negative effect on energy efficiency. In some

cases the need for a NCB is avoided by arranging an individually controlled dryer

(that drains to a condenser) to draw its steam from a thermocompressor section.

Where allowable, this is an advantageous concept.

The most prevalent improvement opportunity for NCB's is to gain an appropriate

flow rate. For a typical thermocompressor section, an NCB flow of 100 to 200 lbs/hr

is generally considered adequate to protect against accumulation of non-

condensable gases. To ensure the desired flow rate is achieved, the bleed should

be equipped with a properly sized stainless steel orifice plate.

When it comes to NCB's, avoiding excessive flow rate will save steam. Your mill

might benefit from a review of your NCB's.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

What common metrics are used for

measuring paper drying efficiency?

Two common metrics for measuring paper drying efficiency are drying load

(amount of water evaporated per hour) and steam consumption (amount of steam

used per hour). The Technical Association of the Pulp and Paper Industry (TAPPI)

recommends these metrics be indexed by the dryer surface area (resulting in

pounds of water evaporated per hour per square feet of dryer surface area) and by

the amount of water evaporated (resulting in pounds of steam per hour per pound

of water evaporated). The indexed values are better indicators of dryer

performance and overall energy efficiency of the drying process. Indexed values

can be compared to similar machines as a benchmark of performance.

Is there an accurate, reliable, and safe way to

determine the out-going press dryness?

Yes, there is. The out-going press moisture can be determined from a mass and

energy balance of the dryer section. By knowing the paper weight, width, speed,

and reel moisture and the amount of steam used for drying, the out-going press

moisture can be calculated using an analytical model of the dryer section. This is

much simpler than a water balance that requires accurate measurement of many

water flow rates around the press section. It is also much safer than attempting to

get a "grab" sample of the sheet on the front side of the press section. It is also less

costly than a cross-machine moisture scanner. And the result is more accurate than

all of these alternatives. For a "tight" well-managed dryer steam system, the sheet

dryness can be determined within 0.1-0.2 dryness percent.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

Is there a better way of measuring energy

efficiency in paper drying?

Yes, there is. Rather than measuring the amount of steam that you use, measure the

amount of steam that you lose. The steam consumption (amount of steam used per

hour) is, by itself, an inadequate measure. A high value could be the result of either

drying a lot of paper or venting a lot of steam. One is good. The other is bad.

Indexing the amount of steam used with amount of water evaporated (pounds of

steam per hour per pound of water evaporated) is a better metric, but significant

amount of energy can easily be lost in the "noise" of this metric.

A better approach is to simply look for the steam losses. Specifically, look for steam

that is vented to the atmosphere or vented to condenser tanks. Look for

condensate that is dumped to a sewer and look for hot air that is exhausted from

the dryer hood to the atmosphere. These are direct measurements of energy losses

and they are direct indications of potential areas for energy recovery.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

Evaluating Dryer Drainage System Energy

Use

Steam flows are commonly measured to monitor dryer section energy

consumption. The total steam flow, however, does not provide enough information

to assess energy efficiency. Measures that consider steam consumption in terms of

production or output can be used to evaluate the efficiency of steam use in the

dryer section. There are three common metrics to evaluate steam use efficiency:

pounds of steam per pound of paper produced, pounds of steam per pound of

water evaporated, and percent of energy loss from the system.

Pounds of steam per pound of paper produced is not a good metric to use when

attempting to benchmark energy efficiency. Dryer energy consumption is directly

related to the amount of water evaporated. Differences in press moisture entering

the dryer section will affect the benchmark. Each 1% difference in press moisture

will change the dryer section energy consumption by approximately 4%. Machines

with different pressing efficiencies will have different steam consumption

benchmarks. Therefore, it is difficult to benchmark energy efficiency against other

machines using this metric.

Pounds of steam per pound of water evaporated is a better way to assess energy

efficiency. This metric requires an accurate value for the press moisture to calculate

the water evaporation for a given production condition. Obtaining an accurate

press moisture can be difficult. Grab samples and press section water balances are

often used. The press moisture will also vary depending on grade, speed, furnish,

and other unique characteristics of the machine. A good value for this metric is 1.2

lbs of steam per pound of water evaporated.

Energy losses from the system is a highly usable and appropriate metric to use to

assess steam utilization and evaluate energy efficiency. Any steam that is not

condensed in the dryers to dry paper should be considered a loss from the system.

The losses typically consist of the steam that is vented to the condenser or

atmosphere. This can be tracked by valve position in a process historian. The loss

can also be calculated by measuring the water flow and temperature around the

vacuum condenser. A well designed dryer drainage system will have an energy

loss of 1% to 3% of the total steam supplied to the dryer section.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

Tracking Energy Losses From A Dryer

Drainage System

One method to evaluate dryer section energy efficiency is to track the losses from

the dryer drainage system. Any steam not condensed in the dryers to dry paper

should be considered a loss. A well designed system will have a loss of no more

than 1% to 3% of the total steam supply to the dryer section.

Many dryer drainage systems are designed with a vacuum system that condenses

steam vented from the system. The energy consumed by the vacuum condenser

represents the loss from the system. Measuring water flow, the water temperature

in and out of the heat exchanger allows the energy loss to be calculated. This can

be done with three field instruments and provides a valuable online energy

monitoring system. The heat loss from the system can be trended against the

steam flow to the dryer section to calculate the percent loss from the system.

This method of energy monitoring will quickly show any change in efficiency of the

dryer drainage system. A leaking vent valve or improper system setting will show

up as an increase in the percent loss from the system.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

Do Turbulator bars improve the energy

efficiency of a dryer section?

The amount of energy required to dry a paper web depends on the amount of

moisture entering and leaving the dryer section, machine speed, sheet width, and

sheet weight. Turbulator bars do not directly affect the amount of energy required

to dry the paper, but they can have a major impact on other operating parameters:

Turbulator bars increase the heat transfer capacity. This can be used either to

reduce the dryer steam pressures or increase the amount of paper produced.

Turbulator bars improve the uniformity of heat transfer. This improves the cross-

directional moisture profile.

Turbulator bars increase the responsiveness to changes in dryer steam pressure.

This results in less out-of-spec paper being produced during grade changes.

The increased uniformity and drying response improve sheet runnability and

machine efficiency.

Turbulator bars force the condensate in the dryers to rim at a lower speed. This

reduces the power required to drive the dryer cylinders.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

Do high-efficiency thermocompressors save

steam?

High-efficiency thermocompressors do offer a higher entrainment ratio which

means a lower motive steam (high-pressure) flow is required to recompress the

same amount of suction steam (low-pressure) flow or conversely pull a higher

amount of suction flow for the same amount of motive flow for a given set of

pressure condition.

A high-efficiency thermocompressor will offer an operating cost advantage if the

source of the motive steam bypasses a cogeneration turbine or if the source of

motive steam is produced on a high-pressure boiler separate from the source of

low-pressure steam. In these cases, the motive steam will have a higher cost than

the make-up steam. Minimizing the motive steam required will maximize the

make-up steam flow and the power generation.

For tissue machine applications where the motive flow is limited to the Yankee's

condensing rate, the higher entrainment ratio provides the benefit of increased

blowthrough flow for the same amount of motive steam flow and for this reason,

high-efficiency thermocompressors have become the industry standard for Yankee

dryers.

On booster thermocompressor applications, a high-efficiency thermocompressor

will reduce the ratio of motive to suction steam flow for a fixed discharge flow.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

Is separator tank size and design critical to

the proper operation of dryer cans?

Absolutely! Undersized separator tanks generally result in high velocities of steam

and condensate flow through the inlet separator nozzle, through the shell of tank

and through the outlet blowthrough steam nozzle. High velocities do not provide

the basis for good separation of the steam and condensate and as a result, the

blowthrough steam will tend to carryover some condensate. High velocities will

also erode the baffles and impingement plates inside the tank much quicker,

especially with 2-phase steam and condensate flow potentially causing short-

circuiting between the inlet and outlet nozzles. Condensate carryover will

accelerate the erosion of downstream piping and thermocompressors and increase

the condensate load for the syphons to remove from the dryers. Undersized

separator tanks also tend to have poor level control. Separator tanks must be sized

based on achieving a low vapor velocity through the tank and adequate liquid

retention time.

The issues associated with undersized separator tanks will cause poor operation of

the thermocompressor and dryer control equipment. Venting and steam waste is

common when condensate separator tanks are undersized.

© 2016 Kadant Inc. or its affiliates. All rights reserved.

Looking for more energy saving ideas?

Subscribe to Kadant’s Optimization Tips email and

you will receive not just energy optimization tips but

also maintenance tips, best practices and technical

know-how. A new tip will be delivered each month to

your email.

Visit www.kadant.com/tips to sign up today!

www.linkedin.com/company/kadant-inc-

www.facebook.com/kadant

www.twitter.com/kadant

www.youtube.com/kadantinc

blog.kadant.com

© 2016 Kadant Inc. or its affiliates. All rights reserved.

You might also like

- The Ultimate Almanac of World Beer RecipesDocument222 pagesThe Ultimate Almanac of World Beer RecipesCaetanoJunior100% (4)

- Mechanics of Materials Formulas and Problems Engineering Mechanics 2 PDFDocument219 pagesMechanics of Materials Formulas and Problems Engineering Mechanics 2 PDFN. Andrade100% (1)

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Ancient Indian WeaponsDocument25 pagesAncient Indian WeaponsjasmineNo ratings yet

- Von Seggern, David Henry - CRC Standard Curves and Surfaces With Mathematica - (2016)Document460 pagesVon Seggern, David Henry - CRC Standard Curves and Surfaces With Mathematica - (2016)N. AndradeNo ratings yet

- StrategyDocument299 pagesStrategyLe Van Canh100% (5)

- PEERLEES Fire Pump PDFDocument175 pagesPEERLEES Fire Pump PDFN. AndradeNo ratings yet

- The End of SilosDocument15 pagesThe End of SilosN. AndradeNo ratings yet

- 14BBG - Sec16 - NPRHD NQR NRR Diesel Cab Chassis Electrical-0215113 FinalDocument34 pages14BBG - Sec16 - NPRHD NQR NRR Diesel Cab Chassis Electrical-0215113 FinalIgmar Franco Negrete100% (2)

- Corn Tastes Better On The Honor System - Robin Wall KimmererDocument53 pagesCorn Tastes Better On The Honor System - Robin Wall Kimmerertristram59100% (1)

- A Guide to Chemical Classification of Common Volcanic RocksDocument26 pagesA Guide to Chemical Classification of Common Volcanic RocksPepeeJh VaargasNo ratings yet

- Energyebook16 160812144329 PDFDocument45 pagesEnergyebook16 160812144329 PDFArun twitNo ratings yet

- Low Pressure Air Drying Whitepaper LR InekoDocument10 pagesLow Pressure Air Drying Whitepaper LR InekoGandhiNo ratings yet

- Stop Flooding Your Dryer Section 1Document4 pagesStop Flooding Your Dryer Section 1Krishna ReddyNo ratings yet

- Principle Steam Ejector Pipe FlowDocument4 pagesPrinciple Steam Ejector Pipe FlowOky Adi PurnomoNo ratings yet

- Hiross Polestar PST 075-1800 - Esite EngDocument18 pagesHiross Polestar PST 075-1800 - Esite EngJosé MoránNo ratings yet

- wpd - steamcondensate (Hơi sấy)Document28 pageswpd - steamcondensate (Hơi sấy)Hoang TranNo ratings yet

- Condenser Vacuum MarEDocument4 pagesCondenser Vacuum MarEMayeiaElenorNo ratings yet

- 8 - Control ApplicationsDocument251 pages8 - Control ApplicationsChikin PedrosoNo ratings yet

- TYPES OF COMPRESSORS AND THEIR APPLICATIONSDocument7 pagesTYPES OF COMPRESSORS AND THEIR APPLICATIONSWade Coleman100% (1)

- 114 Paper Industry en 170705Document12 pages114 Paper Industry en 170705Christian MendozaNo ratings yet

- WPD SteamcondensateDocument28 pagesWPD SteamcondensateJhoan Fernando Acevedo EspinosaNo ratings yet

- 10 WAYS TO MAXIMIZE YOUR COMPRESSOR'S ENERGY EFFICIENCYDocument7 pages10 WAYS TO MAXIMIZE YOUR COMPRESSOR'S ENERGY EFFICIENCYKamel NefziNo ratings yet

- Thermocompressor CatalogueDocument4 pagesThermocompressor CataloguePrashant Singh100% (1)

- Steam TrapDocument76 pagesSteam TrapAhmed RamzyNo ratings yet

- Suction Line PressureDocument15 pagesSuction Line Pressurejayadarsini2113No ratings yet

- Basics - Dew Point Measurement - P60 P63 PDFDocument4 pagesBasics - Dew Point Measurement - P60 P63 PDFAnonymous o38k1iEKFNo ratings yet

- Improve Energy Efficiency with Effective Steam System Condensate RemovalDocument1 pageImprove Energy Efficiency with Effective Steam System Condensate RemovalJohn UrdanetaNo ratings yet

- GSA Company Introduction ENG 2021Document16 pagesGSA Company Introduction ENG 2021AyahKenzieNo ratings yet

- Drum Dryer Heat Transfer Heat RecoveryDocument3 pagesDrum Dryer Heat Transfer Heat RecoveryRajendra GuptaNo ratings yet

- Best Practices and Tips For Compressed Air Piping SystemsDocument19 pagesBest Practices and Tips For Compressed Air Piping SystemsAnonymous 70lCzDJvNo ratings yet

- Boiler Soot-Blowing in Power Plants - Compressed Air Best PracticesDocument8 pagesBoiler Soot-Blowing in Power Plants - Compressed Air Best PracticesRoland NicolasNo ratings yet

- Optimum number of evaporator effects and steam jet ejector designDocument6 pagesOptimum number of evaporator effects and steam jet ejector designfais verianNo ratings yet

- Latest Best PracticeDocument4 pagesLatest Best PracticeJohn Kennedy FernandesNo ratings yet

- Inlet Air Chillers Inlet Air Chillers: Turbine Performance ChartDocument12 pagesInlet Air Chillers Inlet Air Chillers: Turbine Performance ChartdsoNo ratings yet

- Steam and Kondensat For PapermachineDocument33 pagesSteam and Kondensat For PapermachinesakarisoNo ratings yet

- Compressed Air Installation GuideDocument24 pagesCompressed Air Installation Guidesauro100% (1)

- 5 Common Misconceptions Lyo2Document3 pages5 Common Misconceptions Lyo2DholakiaNo ratings yet

- Parker PSTDocument16 pagesParker PSTmaxigas120No ratings yet

- Screw Comp VS Reciproctng CompDocument2 pagesScrew Comp VS Reciproctng CompKRUNALNo ratings yet

- Why Do Compressed Air Systems Need Drying?Document4 pagesWhy Do Compressed Air Systems Need Drying?maddukuri jagadeesh babuNo ratings yet

- Flash TanksDocument3 pagesFlash TanksnincitoNo ratings yet

- Steam29 Use SteamDocument2 pagesSteam29 Use SteamAhsan AbroNo ratings yet

- How Choose Vacuum DryerDocument4 pagesHow Choose Vacuum DryerGomatheeswariNo ratings yet

- Guide Compressed Air BasicsDocument20 pagesGuide Compressed Air BasicsKaten MistryNo ratings yet

- Power Plant Instrumentation Unit 3Document4 pagesPower Plant Instrumentation Unit 3Mohit RanaNo ratings yet

- Turbine Glands Steam CondenserDocument6 pagesTurbine Glands Steam Condenserryan hardiantoNo ratings yet

- LMW Lakshmi Latest Machines: Pneumatic Air CompressorDocument8 pagesLMW Lakshmi Latest Machines: Pneumatic Air CompressorMuhammad JunaidNo ratings yet

- Why Do You Need An Air Receiver?Document21 pagesWhy Do You Need An Air Receiver?Himanshi SharmaNo ratings yet

- Modern steam trap survey and leak calculation sheet reduces annual steam losses by 95,000 RsDocument5 pagesModern steam trap survey and leak calculation sheet reduces annual steam losses by 95,000 Rsintania66No ratings yet

- Vacuum EjectorDocument6 pagesVacuum EjectorAmol KadamNo ratings yet

- Wet SealsDocument8 pagesWet Sealsasadiqbal127100% (1)

- Gas Turbine Air Filter System OptimizationDocument10 pagesGas Turbine Air Filter System Optimizationsevero97No ratings yet

- Pressure Control For Vacuum SystemsDocument4 pagesPressure Control For Vacuum SystemsnasirmuzaffarNo ratings yet

- Data Beban Motor BU.G Shared HODocument36 pagesData Beban Motor BU.G Shared HORangga PutraNo ratings yet

- Ejector FundamentalsDocument6 pagesEjector FundamentalscordobaluisfNo ratings yet

- Ejectors: Wide Uses & Selection GuideDocument6 pagesEjectors: Wide Uses & Selection Guidehappale2002No ratings yet

- Static Pressure Calculation SheetDocument24 pagesStatic Pressure Calculation SheetSreekanth MadakaNo ratings yet

- Cascade Non Refrigeration 1.3 WebDocument16 pagesCascade Non Refrigeration 1.3 WebHua Hidari Yang100% (1)

- Vapor Compression Refrigeration System Explained in 40 CharactersDocument5 pagesVapor Compression Refrigeration System Explained in 40 CharactersANKUR GOGOINo ratings yet

- CA 2006-3 TipsheetcaefficiencymeasuresDocument3 pagesCA 2006-3 TipsheetcaefficiencymeasuresrahmatNo ratings yet

- Dew Point Demand Switching RetrofitsDocument5 pagesDew Point Demand Switching RetrofitsMuhammad ImranNo ratings yet

- StallDocument16 pagesStallbhalchandrak1867100% (1)

- Thermodynamics-2 ECP Work SampleDocument5 pagesThermodynamics-2 ECP Work SampleMuhammad IbrahimNo ratings yet

- A New Approach: To Gas Turbine CleaningDocument2 pagesA New Approach: To Gas Turbine CleaningJohn SmeethNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- (Econometric Society Monographs) Rakesh V. Vohra - Mechanism Design - A Linear Programming Approach (2011, Cambridge University Press)Document185 pages(Econometric Society Monographs) Rakesh V. Vohra - Mechanism Design - A Linear Programming Approach (2011, Cambridge University Press)N. Andrade0% (1)

- Reglamento de Prevenci... Teccion Contra Incendios Del MiesDocument115 pagesReglamento de Prevenci... Teccion Contra Incendios Del MiesN. AndradeNo ratings yet

- Development of Extruded Mixtures of Green BananaDocument34 pagesDevelopment of Extruded Mixtures of Green BananaN. AndradeNo ratings yet

- Hu T.C. - Linear and Integer Programming Made EasyDocument151 pagesHu T.C. - Linear and Integer Programming Made EasyGaurav SinghNo ratings yet

- Build A Precision Crosscutting SledDocument6 pagesBuild A Precision Crosscutting SledMinhNo ratings yet

- Freudtools Router Bit Feed and Speed For CNC 20170822Document3 pagesFreudtools Router Bit Feed and Speed For CNC 20170822MARCO ANTONIO BERNAL GOMEZNo ratings yet

- Surf Board Example de Boardcad PDFDocument10 pagesSurf Board Example de Boardcad PDFN. AndradeNo ratings yet

- Build A Precision Crosscutting SledDocument6 pagesBuild A Precision Crosscutting SledMinhNo ratings yet

- Design Calculation Sheet: 1-AbbreviationsDocument3 pagesDesign Calculation Sheet: 1-Abbreviationsmayukhguha1988No ratings yet

- A Mathematical TapestryDocument308 pagesA Mathematical TapestryN. AndradeNo ratings yet

- Structures SteelDocument429 pagesStructures SteelN. AndradeNo ratings yet

- Trimble Software Precision Agriculture Solutions EbookDocument7 pagesTrimble Software Precision Agriculture Solutions EbookN. AndradeNo ratings yet

- Dust Collector: Frequently Asked QuestionsDocument8 pagesDust Collector: Frequently Asked QuestionsN. AndradeNo ratings yet

- Pumps MagazineDocument76 pagesPumps MagazineN. AndradeNo ratings yet

- Cerveceria Artesana - Business Model CanvasDocument1 pageCerveceria Artesana - Business Model CanvasN. AndradeNo ratings yet

- 6-1 Homework Team 7Document3 pages6-1 Homework Team 7Edgar ValenciaNo ratings yet

- Welcome To Primary 1!Document48 pagesWelcome To Primary 1!Zoe WangNo ratings yet

- Vegan Starter KitDocument53 pagesVegan Starter KitGabriela GarciaNo ratings yet

- VOLLEYBALL HISTORY AND RULESDocument12 pagesVOLLEYBALL HISTORY AND RULESJennybelle MolinaNo ratings yet

- Troubleshooting GuideDocument88 pagesTroubleshooting GuideFrancisco Diaz56% (9)

- Fishing and Hunting Gear From Osseous Raw Materials in The Early Neolithic From SerbiaDocument12 pagesFishing and Hunting Gear From Osseous Raw Materials in The Early Neolithic From SerbiaDanaGrujićNo ratings yet

- Process Flow ChartDocument4 pagesProcess Flow Chartchacko chiramalNo ratings yet

- Microflow Air Sampler User ManualDocument31 pagesMicroflow Air Sampler User Manualira rahmaNo ratings yet

- (Ebook - PDF - Hack) Advanced Hardware HackingDocument20 pages(Ebook - PDF - Hack) Advanced Hardware HackingogmpsqjuNo ratings yet

- Prof (1) F P Kelly - ProbabilityDocument78 pagesProf (1) F P Kelly - ProbabilitycoolmohitNo ratings yet

- Psychological Theories of Crime ChartDocument1 pagePsychological Theories of Crime ChartTayyaba HafeezNo ratings yet

- NetWorking Flashcards - QuizletDocument262 pagesNetWorking Flashcards - QuizletGB ReddyNo ratings yet

- Literature Review Kangaroo Mother CareDocument7 pagesLiterature Review Kangaroo Mother CareafdtuwxrbNo ratings yet

- Drug Treatment of AnemiaDocument6 pagesDrug Treatment of Anemiavingul2006No ratings yet

- LP Series: Airless Paint SprayerDocument31 pagesLP Series: Airless Paint SprayerFrancisco Jose Domenech SalaNo ratings yet