Professional Documents

Culture Documents

SRM TRP Engineering College Trichy

Uploaded by

MANI KANDANOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SRM TRP Engineering College Trichy

Uploaded by

MANI KANDANCopyright:

Available Formats

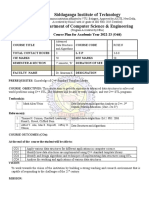

SRM TRP ENGINEERING COLLEGE

TRICHY

COURSE PLAN TEMPLATE FOR DELIVERY OF OUTCOME BASED EDUCATION

Institute: SRM TRP ENGINEERING COLLEGE Department: MECHANICAL

Name of Faculty: D.MANIKANDAN Dept. of Faculty: MECHANICAL

Course Code & Name: ME 6703 & CIM Regulation: 2013

UG/PG Academic Year & Semester: 2019-20 & VII & Odd/ Even

No. of times the faculty has delivered the course before: 0 /1 /2/3 /4 /5 />5 (please tick)

University Syllabus for the Course (Please insert Syllabus Here)

Regulation:2013 Credits: 3 Total periods/hours: 45

Objectives:

Unit – I

To gain knowledge about the basic fundamental of CAD. To gain knowledge on how computers

are integrated at various levels of planning and Manufacturing understand computer aided

planning and control and computer Monitoring.

Unit – II

To understand the data transmission methods in CIM.

Unit – III

To acquire the basic knowledge in grouping of manufacturing processes and machines.

Unit – IV

To Apply the integration of manufacturing activities to ease factory floor management.

Unit – V

To implement the computer aided planning, control and monitoring.

Content beyond syllabus (if required): Videos related to recent trends in Automation of various industries

(Example: Poultry Industry Video), Recent Trends in Robotics Videos

Course Outcomes:

To understand the application of computers in various aspects of Manufacturing viz., Design,

Proper planning, Manufacturing cost, Layout & Material Handling system.

Text Books:

1. Mikell.P.Groover “Automation, Production Systems and Computer Integrated Manufacturing”,

Prentice Hall of India, 2008.

2. Radhakrishnan P, Subramanyan S.and Raju V., “CAD/CAM/CIM”, 2nd Edition, New AgeInternational

(P) Ltd, New Delhi, 2000.

SRMTRPEC/ IQAC/ OBE Template/ May 2019 Page 1 of 13

Reference Books:

1. Kant Vajpayee S, “Principles of Computer Integrated Manufacturing”, Prentice Hall India, 2003.

2. Gideon Halevi and Roland Weill, “Principles of Process Planning – A Logical Approach” Chapman &

Hall, London, 1995.

Program Outcome as given by NBA:

PROGRAM OUTCOMES (POs) Engineering Graduates will be able to:

PO1. Engineering knowledge: Apply the knowledge of mathematics, science, engineering fundamentals,

and an engineering specialization to the solution of complex engineering problems.

PO2. Problem analysis: Identify, formulate, review research literature, and analyze complex engineering

problems reaching substantiated conclusions using first principles of mathematics, natural sciences, and

engineering sciences.

PO3. Design/development of solutions: Design solutions for complex engineering problems and design

system components or processes that meet the specified needs with appropriate consideration for the

public health and safety, and the cultural, societal, and environmental considerations.

PO4. Conduct investigations of complex problems: Use research-based knowledge and research

methods including design of experiments, analysis and interpretation of data, and synthesis of the

information to provide valid conclusions.

PO5. Modern tool usage: Create, select, and apply appropriate techniques, resources, and modern

engineering and IT tools including prediction and modeling to complex engineering activities with an

understanding of the limitations.

PO6. The engineer and society: Apply reasoning informed by the contextual knowledge to assess

societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to the

professional engineering practice.

PO7. Environment and sustainability: Understand the impact of the professional engineering solutions

in societal and environmental contexts, and demonstrate the knowledge of, and need for sustainable

development.

PO8. Ethics: Apply ethical principles and commit to professional ethics and responsibilities and norms of

the engineering practice.

PO9. Individual and team work: Function effectively as an individual, and as a member or leader in

diverse teams, and in multidisciplinary settings.

PO10. Communication: Communicate effectively on complex engineering activities with the engineering

community and with society at large, such as, being able to comprehend and write effective reports and

design documentation, make effective presentations, and give and receive clear instructions.

PO11. Project management and finance: Demonstrate knowledge and understanding of the engineering

and management principles and apply these to one’s own work, as a member and leader in a team, to

manage projects and in multidisciplinary environments.

PO12. Life-long learning: Recognize the need for, and have the preparation and ability to engage in

independent and life-long learning in the broadest context of technological change.

SRMTRPEC/ IQAC/ OBE Template/ May 2019 Page 2 of 13

DEPARTMENT/ PROGRAM EDUCATIONAL OBJECTIVES

Basic and strong fundamental knowledge in mathematics, science and engineering to have a

PEO 1

successful career in mechanical and interdisciplinary domain (Preparation).

Core competency to ensure sustainable development and meet the diversified needs of the

PEO 2

society. (Core competency).

Ability to strengthen their knowledge and skill to provide solutions to real time problems

PEO 3 with an understanding of its impact on economical, environmental, ethical and social

consideration (Breadth).

Effective communication skill, self-reliance and multidisciplinary approach to exhibit their

PEO 4

professional and leadership skills with ethical attitude (Professionalism).

Aware of the current trends and carry out research in the frontier areas of mechanical

PEO 5 engineering to serve the society through lifelong learning using modern engineering tools

and techniques (Learning environment).

PROGRAM SPECIFIC OUTCOMES (PSOs)

PSO1 Demonstrate the knowledge attained in mathematics, science and mechanical engineering

necessary to achieve excellence in solving and analyzing various engineering problems

PSO2 Apply modern computational tools to interpret data, design and develop solutions to complex

mechanical engineering issues employing ethical principles and professional engineering practices.

Course Outcomes (COs)

CO1 Acquire the knowledge of potential benefits and applications of a CAD system, importance of

CAD/CAM interface.

CO2 Develop automated process plans using variant and generative approaches and study about

computer aided process planning, material requirement planning (MRP)Enterprise resource

planning (ERP).

CO3 Implement group technology concepts in production to facilitate cellular manufacturing and

production flow analysis.

CO4 Design automated material handling and storage systems for a typical production.

CO5 Acquire knowledge in artificial intelligence and its applications in various fields and exposed to

robotic programming techniques.

CO6 Understand the use of computers in process planning and use of FMS and Robotics in CIM.

SRMTRPEC/ IQAC/ OBE Template/ May 2019 Page 3 of 13

CO – PO Matrix – Mapping of COs with POs

PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12

CO1 2 0 0 0 3 0 0 0 0 0 0 0

CO2 0 0 2 0 2 0 0 0 2 0 0 0

CO3 3 0 2 0 1 0 0 0 0 0 0 0

CO4 3 2 2 0 2 0 0 0 0 0 0 0

CO5 2 0 2 0 0 0 0 0 0 0 0 0

CO6 3 2 0 0 3 0 0 0 1 0 0 0

CO-PSO Matrix – Mapping of COs with PSOs

PSO1 PSO2

CO1 0 2

CO2 0 2

CO3 0 2

CO4 0 2

CO5 0 2

CO6 0 2

CO Attainment Assessment Matrix (methods to check whether CO has been attained by the students)

Class Assignment CIA Mini- University Open book Technology

test/ quiz tests projects# exam test* Review paper#

CO1 X X X X

CO2 X X X X X

CO3 X X X X

CO4 X X X X X

CO5 X X X X

CO6 X X

*To be conducted in class for lengthy design problems for any 2 COs, # details given under

Attainment plan for CO6

CO – Syllabus Unit Matrix

Unit 1 Unit 2 Unit 3 Unit 4 Unit 5 Mini-project &

paper

CO1 X

CO2 X

CO3 X

CO4 X

CO5 X

CO6 X

SRMTRPEC/ IQAC/ OBE Template/ May 2019 Page 4 of 13

CO Attained and Targeted Levels for this Course

CO CO1 CO2 CO3 CO4 CO5 CO6

CO attainment levels for previous year*

CO attainment targets for this year#

*To be taken from CO attainment calculation of previous year for this course

# targets to be set higher than previous attainment levels

Attainment levels – High (Level 3 - 80% students scoring more than 60% marks): Medium (Level 2 - 70% students

scoring more than 60% marks); Low (Level 1 - 60% students scoring more than 60% marks); Not Attained (Level <1

- less than or equal to 60% students scoring 60% Marks)

CO Attainment Plan

CO1: Acquire the knowledge of potential benefits and applications of a CAD system, importance of

CAD/CAM interface.

CO1 will be attained through the following exercises:

1. Classroom Lecture : Kindly fill-up Annexure-1 (lesson Plan)

2. Assignments (assignment/ exercise given to enable student to attain CO1 shall be listed below. Care shall

be taken to choose assignment in order to cover all Bloom’s Taxonomy Levels (BTL): L1RE- Remember,

L2UN-Understand, L3AP- Apply, L4AN-Analyze, L5EV – Evaluate, L6CR – Create. Also kindly refer to

Annexure -2.)

Sl. No. Assignment problem/ Exercise BTL

1 Production Performance metrics L4AN

2 Concurrent Engineering. L3AP

3 levels of automation L5EV

3. CIA Tests : Question Bank for Unit-1 for Slow learners

Sl. No. Questions/ Problems Marks BTL

1 What are the types of production systems? 2 L1RE

2 What are the basic elements of automated system? 2 L2UN

3 Explain Lean Production and Just-In-Time production system. 13 L4AN

4 What are the levels of automation and explain it in detail? 13 L5EV

5 Write in detail about the Production Performance metrics 13 L3AP

4. Any other activity planned for the attainment of CO1/ COs

CO2: Develop automated process plans using variant and generative approaches and study about

computer aided process planning, material requirement planning (MRP)

Enterprise resource planning (ERP).

SRMTRPEC/ IQAC/ OBE Template/ May 2019 Page 5 of 13

CO2 will be attained through the following exercises:

1. Classroom Lecture : Kindly fill-up Annexure-1 (lesson Plan)

2. Assignments (assignment/ exercise given to enable student to attain CO2 shall be listed below)

Sl. No. Assignment problem/ Exercise BTL

1 various approaches of CAPP L6CR

2 phases of Shop Floor Control L3AP

3 Aggregate Production Planning L6CR

3. CIA Tests : Question Bank for Unit-2 for Slow learners

Sl. No. Questions/ Problems Marks BTL

1 Explain Capacity planning and MRP-II. 2 L1RE

2 What is MRP and list out the inputs of MRP? 2 L2UN

3 Briefly explain the approaches of CAPP. 13 L5EV

4 Briefly explain the activities in a PPC system. 13 L4AN

5 Explain EOQ in detail? 13 L6CR

CO3: Implement group technology concepts in production to facilitate cellular manufacturing and

production flow analysis.

CO3 will be attained through the following exercises:

1. Classroom Lecture : Kindly fill-up Annexure-1 (lesson Plan)

2. Assignments (assignment/ exercise given to enable student to attain CO3 shall be listed below)

Sl. No. Assignment problem/ Exercise BTL

1 coding systems L3AP

2 Production flow analysis. L3AP

3 Cellular Manufacturing L2UN

3. CIA Tests : Question Bank for Unit-3 for Slow learners

Sl. No. Questions/ Problems Marks BTL

1 What is a part family? 2 L2UN

2 What is cellular manufacturing? 2 L1RE

3 Explain Optiz part parts classification and coding system. 13 L3AP

4 Explain the steps involved in Production flow analysis. 13 L4AN

5 Explain (i) Cellular Manufacturing (ii) Composite part concept. 13 L3AP

SRMTRPEC/ IQAC/ OBE Template/ May 2019 Page 6 of 13

CO4: Design automated material handling and storage systems for a typical production.

CO4 will be attained through the following exercises:

1. Classroom Lecture : Kindly fill-up Annexure-1 (lesson Plan)

2. Assignments (assignment/ exercise given to enable student to attain CO4 shall be listed below)

Sl. No. Assignment problem/ Exercise BTL

1 Vehicle Guidance technology L3AP

2 Vehicle Management & Safety L3AP

3 FMS L1RE

3. CIA Tests : Question Bank for Unit-4 for Slow learners

Sl. No. Questions/ Problems Marks BTL

1 What is a FMS? 2 L2UN

2 What is a AGVS? 2 L1RE

3 Explain any two Vehicle guidance technology of AGV. 13 L4AN

4 Explain Vehicle management & safety 13 L5EV

5 List out the various functions that are performed by the FMS 13 L4AN

computer control system.

CO5: Acquire knowledge in artificial intelligence and its applications in various fields and exposed to

robotic programming techniques.

CO5 will be attained through the following exercises:

1. Classroom Lecture : Kindly fill-up Annexure-1 (lesson Plan)

2. Assignments (assignment/ exercise given to enable student to attain CO5 shall be listed below)

Sl. No. Assignment problem/ Exercise BTL

1 robot control systems. L3AP

2 Robot Anatomy L3AP

3. CIA Tests : Question Bank for Unit-5 for Slow learners

Sl. No. Questions/ Problems Marks BTL

1 List out the various types of grippers. 2 L1RE

2 Classify the robots based on Body-and-Arm configurations 2 L2UN

3 Explain the various robotic applications. 13 L5EV

4 Explain the types of robot control systems. 13 L6CR

5 Explain Robot Anatomy and related attributes. 13 L4AN

SRMTRPEC/ IQAC/ OBE Template/ May 2019 Page 7 of 13

CO6: Understand the use of computers in process planning and use of FMS and Robotics in CIM.

CO6 will be attained through the following exercises:

1. Mini Projects (mini-projects can be any exercise apart from assignments from the syllabus: it can

be a design, survey in the field about usage of technology, current problems, any activity which

will enable the student to gain practical knowledge, etc.)

Sl. No. Mini-project Batch No. BTL

& Roll Nos

1

2

3

4

5

6

Add as many rows as required

2. Review paper on recent Journal/e-magazine publications on a particular technology (Journals

shall be from SCI List and e-magazines shall of reputed international level, ex. Techcrunch, wired,

gizmodo, popular mechanics, GE, Electronics weekly, concretecentre, etc.)

Sl. Technology to be Journal / e-magazine name Batch No. BTL

No. reviewed & Roll

Nos

1 automation History and future of human-automation interaction L3AP

2 Enterprise Resource Integration of Business Intelligence and Enterprise Resource L2UN

Planning Planning within Organizations

3 Cellular Evaluation of the Human Error Probability in Cellular L5EV

Manufacturing Manufacturing

4 Automated Guided Implementation of Automated Guided Vehicle System in L3AP

Vehicle System Healthcare Facility

5 Robot Control Developing and modeling of voice control system for L2UN

systems prosthetic robot arm in medical systems

SRMTRPEC/ IQAC/ OBE Template/ May 2019 Page 8 of 13

3. Details of related courses (similar to this course/subject) available in NPTEL & other MOOCs

Sl. Related Course URL Title of Course Faculty Name Institute

No MOOC (web address)

.

1 NPTEL https://nptel.ac.in/c Advanced Dr. A. K. Sharma Mechanical

ourses/112107078/ Manufacturing ,IIT Roorkee Engineering ,IIT

Processes Roorkee

2 NPTEL https://nptel.ac.in/c Advanced Dr. Shantanu Mechanical

ourses/112104162/ manufacturing Bhattacharya Engineering ,IIT

process for micro ,IIT Kanpur Kanpur

system fabrication

3 MITOC https://ocw.mit.edu Control of Prof. David Defense

W /courses/mechanical Manufacturing Hardt Acquisition

-engineering/2-830j- Processes University

Prof. Duane

control-of- Boning

manufacturing-

processes-sma-

6303-spring-2008/

4 EdX https://www.edx.or Manufacturing David Hardt Professor of

g/course/manufactu Process Control I Ralph E. and Mechanical

ring-process-control- Evelyn F. Cross EngineeringMas

i sachusetts

Institute of

Technology

5 COURSE https://www.course CAD and Digital

RA ra.org/specialization Manufacturing

s/cad-design-digital- Specialization

manufacturing?#inst

ructors

SRMTRPEC/ IQAC/ OBE Template/ May 2019 Page 9 of 13

Annexure 1 : Lesson Plan for Class Room Lecture

Mode of Lecture: Black Board (BB), Power point Projection (PPT), OHP, any other, etc.

Lecture Plann Topic Pert Mode Page No. of

No. ed ainin of prescribed

Date g to Lecture text book

CO

No.

Unit - 1 INTRODUCTION

1 Brief introduction to CAD and CAM – Manufacturing CO 1 BB/PPT TB1,CH23,Pg-

Planning, Manufacturing control 701-713

2 CO 1 BB/PPT TB1,CH23,Pg-

Introduction to CAD/CAM – Concurrent Engineering-

701-713, 728-

CIM concepts

729

3 CO 1 BB/PPT TB1,CH4, Pg-

Computerised elements of CIM system

94

4 CO 1 BB/PPT TB1,CH2,Pg-

Types of production

48-54

5 CO 1 BB/PPT TB1,CH3,Pg.6

Manufacturing models and Metrics

2-82

6 CO 1 BB/PPT TB1,CH3,Pg.6

Mathematical models of Production Performance

2-82

7 CO 1 BB/PPT TB1,CH3,Pg.6

Simple problems

2-82

8 Basic Elements of an Automated system – Levels of CO 1 BB/PPT TB1,CH4,Pg-

Automation 91-107

9 CO 1 BB/PPT TB1,CH26,Pg-

Lean Production

767

10 CO 1 BB/PPT TB1,CH26,Pg-

Just-In-Time Production.

771-782

Unit - 2 PRODUCTION PLANNING AND CONTROL AND

COMPUTERISED PROCESS PLANNING

11 CO 2 BB/PPT TB1,CH24,

Process planning

Pg-719-720

12 CO 2 BB/PPT TB1,CH24,

Computer Aided Process Planning (CAPP)

Pg-725

13 CO 2 BB/PPT TB1,CH24,

Logical steps in Computer Aided Process Planning

Pg-725

14 CO 2 BB/PPT TB1,CH25,

Aggregate Production Planning

Pg-739

15 CO 2 BB/PPT TB1,CH25,

Master Production Schedule

Pg-739

16 CO 2 BB/PPT TB1,CH24,

Material Requirement planning

Pg-741

17 CO 2 BB/PPT TB1,CH24,

Control Systems-Shop Floor Control

Pg-749

18 CO 2 BB/PPT TB1,CH24,

Capacity Planning- Inventory Control

Pg-747

19 CO 2 BB/PPT TB1,CH24,

Brief on Manufacturing Resource Planning-II (MRP-II)

Pg-759

SRMTRPEC/ IQAC/ OBE Template/ May 2019 Page 10 of 13

20 CO 2 BB/PPT TB1,CH24,

Enterprise Resource Planning (ERP) - Simple Problems

Pg-760

Unit-3 CELLULAR MANUFACTURING

21 CO 3 BB/PPT TB1,CH18,

Group Technology(GT)

Pg-513

22 CO 3 BB/PPT TB1,CH18,

Parts Classification and coding

Pg-518

23 CO 3 BB/PPT TB1,CH18,

Simple Problems in OPITZ Part Coding system

Pg-544

24 CO 3 BB/PPT TB1,CH18,

Production flow Analysis

Pg-520-522

25 CO 3 BB/PPT TB1,CH18,

Cellular Manufacturing

Pg-522

26 CO 3 BB/PPT TB1,CH18,

Composite part concept– Machine cell design and layout

Pg-523

27 CO 3 BB/PPT TB1,CH18,

Quantitative analysis in Cellular Manufacturing

Pg-529-531

28 CO 3 BB/PPT TB1,CH18,

Rank Order Clustering Method

Pg-529-531

29 Arranging Machines in a GT cell – Hollier Method – CO 3 BB/PPT TB1,CH18,

Simple Problems. Pg-532-534

Unit-4 FLEXIBLE MANUFACTURING SYSTEM (FMS) AND

AUTOMATED GUIDED VEHICLE SYSTEM (AGVS)

30 CO 4 BB/PPT TB1,CH19,

Types of Flexibility - FMS – FMS Components

Pg-547-554

31 CO 4 BB/PPT TB1,CH19,

FMS Application & Benefits Pg-561,564-

565

32 CO 4 BB/PPT TB1,CH19,

FMS Planning and Control

Pg-562-564

33 CO 4 BB/PPT TB1,CH19,

Quantitative analysis in FMS

Pg-565-576

34 CO 4 BB/PPT TB1,CH19,

Simple Problems

Pg-570-571

35 CO 4 BB/PPT TB1,CH10,

Automated Guided Vehicle System (AGVS)

Pg-294-295

36 CO 4 BB/PPT TB1,CH10,

Vehicle Guidance technology

Pg-296-298

37 CO 4 BB/PPT TB1,CH10,

Vehicle Management & Safety

Pg-298-300

Unit-5 INDUSTRIAL ROBOTICS

38 Robot Anatomy and Related Attributes – Classification of CO 5 BB/PPT TB1,CH8, Pg-

Robots 220-230

39 CO 5 BB/PPT TB1,CH8, Pg-

Robot Control systems

230-231

40 End Effectors – Sensors in Robotics – Robot Accuracy CO 5 BB/PPT TB1,CH8, Pg-

and Repeatability 232

41 CO 5 BB/PPT TB1,CH8, Pg-

Robot Part Programming

242

42 CO 5 BB/PPT TB1,CH8, Pg-

Robot Accuracy and Repeatability

250

SRMTRPEC/ IQAC/ OBE Template/ May 2019 Page 11 of 13

43 CO 5 BB/PPT TB1,CH8, Pg-

Industrial Robot Applications

233

44 CO 5 BB/PPT TB1,CH8, Pg-

Robot Accuracy and Repeatability

250

45 CO 5 BB/PPT TB1,CH8, Pg-

Simple Problems.

251&241

Text books referred for preparation of notes:

1. Mikell.P.Groover “Automation, Production Systems and Computer Integrated Manufacturing”, Prentice Hall

of India, 2008.

2. Radhakrishnan P, Subramanyan S.and Raju V., “CAD/CAM/CIM”, 2nd Edition, New AgeInternational (P)

Ltd, New Delhi, 2000.

Prepared By: Approved By: Approved By:

Faculty/ Course In-charge HOD Principal

Name:

Date:

SRMTRPEC/ IQAC/ OBE Template/ May 2019 Page 12 of 13

Annexure – 2.

SRMTRPEC/ IQAC/ OBE Template/ May 2019 Page 13 of 13

You might also like

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Faculty Python Lab ManualDocument33 pagesFaculty Python Lab ManualJitendra Kumar Chauhan100% (1)

- Digital Approaches To Art History and Cultural Heritage: Thursday, March 4th, 2021Document26 pagesDigital Approaches To Art History and Cultural Heritage: Thursday, March 4th, 2021Aytaç YürükçüNo ratings yet

- Discussion Forum Unit 5Document2 pagesDiscussion Forum Unit 5studyjunkyNo ratings yet

- COMPUTER-NETWORKS-CourseFile 28 11 2022Document10 pagesCOMPUTER-NETWORKS-CourseFile 28 11 2022pvssivaprasadcseNo ratings yet

- Production Technology Lab ManualDocument59 pagesProduction Technology Lab Manualuma deviNo ratings yet

- Course Information Sheet: Smart ManufacturingDocument4 pagesCourse Information Sheet: Smart ManufacturingRanjan KumarNo ratings yet

- PYTHON PROGRAMMING-CourseFile 05 09 2022Document11 pagesPYTHON PROGRAMMING-CourseFile 05 09 2022pvssivaprasadcseNo ratings yet

- Technical Skilling-3 (18TS403)Document13 pagesTechnical Skilling-3 (18TS403)Harish DharavathNo ratings yet

- It WorkshopDocument51 pagesIt WorkshopSarthak DugarNo ratings yet

- UID-LABDocument2 pagesUID-LABsrustishree sahuNo ratings yet

- Technical Skilling-3Document11 pagesTechnical Skilling-3Go StargNo ratings yet

- 2018 7TH Sem Elective Stream 1Document11 pages2018 7TH Sem Elective Stream 1Aman SinghNo ratings yet

- 6 (L: 0 T: 0 P:6) - Sem 6: 90 (Sem 6)Document2 pages6 (L: 0 T: 0 P:6) - Sem 6: 90 (Sem 6)adomax2003No ratings yet

- DBMS LabDocument58 pagesDBMS Labmahedi.hassanNo ratings yet

- Oops Manual - Final - 1Document58 pagesOops Manual - Final - 1R.J.K100% (1)

- Machine Design - I COPODocument5 pagesMachine Design - I COPOrajdecoratorsNo ratings yet

- Daa 2019 SyllabusDocument3 pagesDaa 2019 Syllabusmemoriesbringback121No ratings yet

- r14r WSN Fcar Final With Po Attainment 7oct 2018 KMR FelDocument11 pagesr14r WSN Fcar Final With Po Attainment 7oct 2018 KMR FelKommisetty MurthyrajuNo ratings yet

- Mec481 PDFDocument9 pagesMec481 PDFpoomarimuthukumarNo ratings yet

- MTech SMFE Rev12032019Document78 pagesMTech SMFE Rev12032019Mr.Bhaskar WabhitkarNo ratings yet

- Ce3511 Highway Engineering Lab Manual 2021Document64 pagesCe3511 Highway Engineering Lab Manual 2021Baskar Singh GNo ratings yet

- HPC Revised SyllabusDocument4 pagesHPC Revised SyllabusPratiksha BhapkarNo ratings yet

- Department of Computer Science & Engineering: Course FileDocument11 pagesDepartment of Computer Science & Engineering: Course FilePathivadaSantoshNaiduNo ratings yet

- CN Manual 2022Document80 pagesCN Manual 2022Harris AhmedNo ratings yet

- Graduate Attributes and Program OutcomesDocument4 pagesGraduate Attributes and Program OutcomesBelagaviNo ratings yet

- Course Objective(s) :: Major ElectiveDocument2 pagesCourse Objective(s) :: Major ElectiveKKNo ratings yet

- IT Curriculum - SEM4Document13 pagesIT Curriculum - SEM4vidihac283No ratings yet

- 20AIL58A (Lab Manual Final) - 1Document47 pages20AIL58A (Lab Manual Final) - 1adarshramesh2002No ratings yet

- 2.6.1 Programme and Course Outcomes CIVIL Dept.Document76 pages2.6.1 Programme and Course Outcomes CIVIL Dept.PrashanthNo ratings yet

- IOT Lab ManualDocument35 pagesIOT Lab ManualRaghawendra SinghNo ratings yet

- Design and Analysis of Algorithm Lab (BSCS2351) Lab ManualDocument46 pagesDesign and Analysis of Algorithm Lab (BSCS2351) Lab ManualvintNo ratings yet

- CH - CSE2014 - Software Engineering - As Per NAACDocument10 pagesCH - CSE2014 - Software Engineering - As Per NAACNuman ManiyarNo ratings yet

- DAA Manual (2021-2022)Document66 pagesDAA Manual (2021-2022)Aditya Aryan100% (1)

- CS3491AI & ML Lab ManualDocument105 pagesCS3491AI & ML Lab Manualsspradeepa44No ratings yet

- CS Lab Manual FinalDocument40 pagesCS Lab Manual FinalYashwin.v YashuNo ratings yet

- ADS Lecture Plan 2022 23 ODDDocument6 pagesADS Lecture Plan 2022 23 ODD1SI20CS116 - Sunil Kumar B ANo ratings yet

- Distributed Systems - Final MaterialsDocument181 pagesDistributed Systems - Final MaterialsGaneshNo ratings yet

- Computer Networks Lab Manual - 21cs52Document56 pagesComputer Networks Lab Manual - 21cs52NIKHIL N KUMARNo ratings yet

- Sem Vi Csdlo6023 Erp Lessonplan 2018-2019Document13 pagesSem Vi Csdlo6023 Erp Lessonplan 2018-2019Asep JoniNo ratings yet

- Erts Course Plan 2020Document13 pagesErts Course Plan 2020Ashok KumarNo ratings yet

- Cybersecurity Lab MaualDocument66 pagesCybersecurity Lab Maualmoubiswas232003No ratings yet

- CC Lab ManualDocument67 pagesCC Lab ManualCoderarmy OfficialNo ratings yet

- 21CS52Document42 pages21CS52Sidharth PremdasNo ratings yet

- Bcse2370 DCN LabDocument27 pagesBcse2370 DCN LabJATIN KUMAR SHARMA 22SCSE1012203No ratings yet

- 21CSL35-OOPS LAB - Lab Manual 21CSL35-OOPS LAB - Lab ManualDocument88 pages21CSL35-OOPS LAB - Lab Manual 21CSL35-OOPS LAB - Lab ManualKavi ShettyNo ratings yet

- Co-Creation & Interpersonal AbilitiesDocument5 pagesCo-Creation & Interpersonal Abilitiesrashmin tannaNo ratings yet

- Programming in PythonDocument12 pagesProgramming in PythonThomas JerardNo ratings yet

- CBCS - MTech - Design of Mechanical Equipments - Syllabus 271218Document106 pagesCBCS - MTech - Design of Mechanical Equipments - Syllabus 271218Ranjan KumarNo ratings yet

- Course Delivery Plan for Numerical MethodsDocument9 pagesCourse Delivery Plan for Numerical MethodsG S HARSHA STUDENT - AERONo ratings yet

- Department of Mechanical Engineering Mtech-Course Plan - 2021-22 Odd A. Course DetailsDocument12 pagesDepartment of Mechanical Engineering Mtech-Course Plan - 2021-22 Odd A. Course DetailsSudipta MaityNo ratings yet

- CCS356 OOSE LAB MANUALDocument16 pagesCCS356 OOSE LAB MANUALMakendran CSENo ratings yet

- Mad Manual 2020-21 230331 142034Document67 pagesMad Manual 2020-21 230331 142034ShrutiNo ratings yet

- Unit1 TAFLDocument159 pagesUnit1 TAFLKanika RajputNo ratings yet

- Modified DSP Course File (2018-19)Document30 pagesModified DSP Course File (2018-19)annam karthikNo ratings yet

- Automobile Engineering CO-PO-PSO MatrixDocument12 pagesAutomobile Engineering CO-PO-PSO MatrixpriyankaNo ratings yet

- SWPD - 4311603 - CO-PO-PSO Mapping With Justification Format For ComplianceDocument7 pagesSWPD - 4311603 - CO-PO-PSO Mapping With Justification Format For ComplianceNilay PatelNo ratings yet

- BS-CSBS Course FileDocument16 pagesBS-CSBS Course FileDr.Ebenezer Abishek.B Assoc Professor ECENo ratings yet

- MR 431 Mechatronics Lab - 1Document61 pagesMR 431 Mechatronics Lab - 1OptimMart InternationaleNo ratings yet

- CIM Syllabus 2nd SemeterDocument65 pagesCIM Syllabus 2nd Semetercdaz897No ratings yet

- Machine Drawing Manual Using AutocadDocument103 pagesMachine Drawing Manual Using AutocadAVINASHNo ratings yet

- Using Artificial Neural Networks for Analog Integrated Circuit Design AutomationFrom EverandUsing Artificial Neural Networks for Analog Integrated Circuit Design AutomationNo ratings yet

- Fall 2022 - CS607 - 2Document2 pagesFall 2022 - CS607 - 2Husnain IqbalNo ratings yet

- Random Forest for Air Quality PredictionDocument28 pagesRandom Forest for Air Quality PredictionzalakthakkarNo ratings yet

- Artificial Intelligence in RoboticsDocument11 pagesArtificial Intelligence in RoboticsAbu RayhanNo ratings yet

- 3 DATA SCIENCE COURSE - Machine Learning CourseDocument3 pages3 DATA SCIENCE COURSE - Machine Learning Coursemohammed KhalidNo ratings yet

- CRISP DM Business Understanding CompletedDocument18 pagesCRISP DM Business Understanding CompletedJaya UjayaNo ratings yet

- GANNDocument6 pagesGANNRobert MaximilianNo ratings yet

- Popdx: An Automated Framework For Patient Phenotyping Across 392 246 Individuals in The Uk Biobank StudyDocument11 pagesPopdx: An Automated Framework For Patient Phenotyping Across 392 246 Individuals in The Uk Biobank StudysubaNo ratings yet

- Thesis StatementDocument45 pagesThesis StatementcrenitepkNo ratings yet

- The ADF Could Be Doing Much More With ArDocument3 pagesThe ADF Could Be Doing Much More With Arcolaxo03No ratings yet

- Journal of Business Research: Yash Raj Shrestha, Vaibhav Krishna, Georg Von KroghDocument16 pagesJournal of Business Research: Yash Raj Shrestha, Vaibhav Krishna, Georg Von KroghgereNo ratings yet

- 100 Daily Job 03mar2021Document32 pages100 Daily Job 03mar2021Himanshu VyasNo ratings yet

- Pronóstico de Ropa Infantil O I 24 25 Terrenos Del Futuro EsDocument17 pagesPronóstico de Ropa Infantil O I 24 25 Terrenos Del Futuro EsOmar ChiroqueNo ratings yet

- Applying AI To Biometric Identification For Recognizing Text Using One-Hot Encoding and CNNDocument9 pagesApplying AI To Biometric Identification For Recognizing Text Using One-Hot Encoding and CNNInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Artificial Intelligence in Healthcare - Evaluating Health Care Professionals' Perspectives & Attitudes Towards Artificial IntelligenceDocument36 pagesArtificial Intelligence in Healthcare - Evaluating Health Care Professionals' Perspectives & Attitudes Towards Artificial IntelligenceDhruv MahajanNo ratings yet

- SSRN Id4337484Document20 pagesSSRN Id4337484Aditya Raj SinghNo ratings yet

- Understanding of Convolutional Neural Network (CNN) - Deep LearningDocument7 pagesUnderstanding of Convolutional Neural Network (CNN) - Deep LearningKashaf BakaliNo ratings yet

- Literature SurveyDocument4 pagesLiterature SurveyArunPandiyanNo ratings yet

- A Sollution To Score 8 in IELTS Writing - UnlockedDocument53 pagesA Sollution To Score 8 in IELTS Writing - UnlockedJeffery GulNo ratings yet

- Semester Question Paper ECS607Document2 pagesSemester Question Paper ECS607Randeep Kumar sahu100% (1)

- Design Thinking CreativityCollaboration and CultureDocument253 pagesDesign Thinking CreativityCollaboration and CultureFox San100% (1)

- Unsupervised Feature Learning for Scene Text Detection and RecognitionDocument6 pagesUnsupervised Feature Learning for Scene Text Detection and RecognitionpetersonjrNo ratings yet

- Accident Detection System A Deep Learning Approach To Detect AccidentsDocument4 pagesAccident Detection System A Deep Learning Approach To Detect AccidentsZeenath Jahan BegumNo ratings yet

- 2019 - ITUNews03-En AI For GoodDocument65 pages2019 - ITUNews03-En AI For GoodRonald mukasaNo ratings yet

- The Impact of Digital LendingDocument9 pagesThe Impact of Digital LendingNaufal Ridlo MuttaqiinNo ratings yet

- Face Door Lock System - Full ReportDocument59 pagesFace Door Lock System - Full ReportThe MindNo ratings yet

- DensePose: Estimating Dense Human Pose in the WildDocument10 pagesDensePose: Estimating Dense Human Pose in the WildJelena TrajkovicNo ratings yet

- International Strategy and InfluenceDocument46 pagesInternational Strategy and InfluenceMohamed CoulibalyNo ratings yet

- Roadmap How To Learn AI in 2024Document6 pagesRoadmap How To Learn AI in 2024test.rifaiNo ratings yet