Professional Documents

Culture Documents

Duplex Stainless Steel Pipe Specification Standards and Tolerances

Uploaded by

iuiuiooiuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Duplex Stainless Steel Pipe Specification Standards and Tolerances

Uploaded by

iuiuiooiuCopyright:

Available Formats

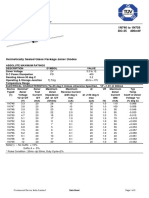

Duplex Stainless Steel Pipe Specification TubingChina.

com

Standard

ASTM A789 ASTM A790 EN 10216-5

Item

1.4301 1.4307 1.4948 1.4315

1.4401 1.4404 1.4571 1.4541

Grade S31803 S32205 S32750 S31803 S32205 S32750

1.4941 1.4845 1.4449 1.4438

1.4550 1.4912 1.4462 1.4410

Yield Strength

≥450;≥485;≥550 ≥450;≥450;≥550 ---

(Mpa)

Tensile Strength

≥620;≥655;≥800 ≥620;≥655;≥800 ---

(Mpa)

Elongation(%) ≥25;≥25;≥15 ≥25;≥25;≥15 ---

The hydrostatic test shall be carried

The Hydrostatic Test shall be in The Hydrostatic Test shall be in out at a test pressure of 7MPa or

accordance with ASTM A1016. accordance with ASTM A999. at a test pressure calculated

Hydrostatic Test

using the following formula

Could be replaced by ECT. Could be replaced by ECT.

P=2St/D S=70%Rp0.2

IC Test Usually use Pitting Corrosion Test. Usually use Pitting Corrosion Test. EN ISO 3651-2 (Optional)

Eddy Current Test Could be replaced by HT. Could be replaced by HT. EN 10246-3

O.D. O.D.Tolerance O.D. O.D.Tolerance O.D. Tolerance Class

D<12.7 +/-0.13 10.3≤D≤48.3 +0.40/-0.80 +/-0.75% or

D3

+/-0.3mm

O.D. Tolerance 12.7≤D<38.1 +/-0.13 48.3<D≤114.3 +0.80/-0.80

whichever is the greater

(mm)

38.1≤D<88.9 +/-0.25 114.3<D≤219.1 +1.60/-0.80 +/-0.5% or

D4

+/-0.1mm

88.9≤D<139.7 +/-0.38 219.1<D≤457.0 +2.40/-0.80

whichever is the greater

O.D. W.T.Tolerance O.D. W.T.Tolerance W.T. Tolerance Class

D<12.7 +/-15% +20.0%/-12.5% +/-10% or

10.3≤D≤73.0 T3

+/-0.2mm

W.T. Tolerance

12.7≤D<38.1 +/-10% whichever is the greater

(mm) 88.9≤D≤457.0 +22.5%/-12.5%

t/D ≤5% +/-7.5% or

38.1≤D<88.9 +/-10% T4

88.9≤D≤457.0 +/-0.15mm

+15.0%/-12.5%

88.9≤D<139.7 +/-10% t/D >5% whichever is the greater

www.TubingChina.com

You might also like

- PENETRANT TEST PROCEDURE (PT Procedure)Document9 pagesPENETRANT TEST PROCEDURE (PT Procedure)Senthil Kumaran100% (1)

- Designation: A 928/A 928M – 04 Standard Specification for Ferritic/Austenitic (Duplex) Stainless Steel PipeDocument6 pagesDesignation: A 928/A 928M – 04 Standard Specification for Ferritic/Austenitic (Duplex) Stainless Steel PipeiuiuiooiuNo ratings yet

- Black Line Breaker ToolsDocument16 pagesBlack Line Breaker ToolsDeno Manuel LudzanNo ratings yet

- Chemical Injection CalcDocument17 pagesChemical Injection CalciuiuiooiuNo ratings yet

- API SizingDocument13 pagesAPI SizingJayesh SanganiNo ratings yet

- Datasheet for Poly and Mono PV Modules up to 280WpDocument5 pagesDatasheet for Poly and Mono PV Modules up to 280WpRafdi Dzulfikar RNo ratings yet

- Crude Oil Processing by Physical Separation: Paulus L GintingDocument20 pagesCrude Oil Processing by Physical Separation: Paulus L Gintingiuiuiooiu100% (1)

- Oil Tan Delta Concepts Standards and Testing en V01Document3 pagesOil Tan Delta Concepts Standards and Testing en V01eng_hmaNo ratings yet

- Standard Item ASTM A789 ASTM A790 EN 10216-5Document1 pageStandard Item ASTM A789 ASTM A790 EN 10216-5iuiuiooiuNo ratings yet

- Mechanical Tubes Nou Rev1 UpdatatDocument13 pagesMechanical Tubes Nou Rev1 UpdatatGoran DjuricNo ratings yet

- NIC Components NSTLW SeriesDocument2 pagesNIC Components NSTLW SeriesNICCompNo ratings yet

- Pipe TolerancesDocument1 pagePipe TolerancesKotu KotNo ratings yet

- NIC Components NRE-HW SeriesDocument6 pagesNIC Components NRE-HW SeriesNICCompNo ratings yet

- NIC Components NRE-HDocument6 pagesNIC Components NRE-HNICCompNo ratings yet

- EPEVER DataSheet IP Plus 100 110 120VACDocument4 pagesEPEVER DataSheet IP Plus 100 110 120VACulisesrpcNo ratings yet

- ASTM and ISO pipe tolerance standardsDocument1 pageASTM and ISO pipe tolerance standardsgame freakaNo ratings yet

- NIC Components NEXT SeriesDocument1 pageNIC Components NEXT SeriesNICCompNo ratings yet

- 1N5344B - 1N5388B: 5W Zener DiodeDocument4 pages1N5344B - 1N5388B: 5W Zener DiodeNana CianchettaNo ratings yet

- ETCR-2000C+ Earth Resistance MeterDocument2 pagesETCR-2000C+ Earth Resistance Meteranggi tri wibowoNo ratings yet

- SM Series: Aluminium Electrolytic CapacitorDocument2 pagesSM Series: Aluminium Electrolytic CapacitorStuxnetNo ratings yet

- CKH Cke-2944644Document4 pagesCKH Cke-2944644ChrisNo ratings yet

- C3 Catalog CE Miniatura ElraDocument3 pagesC3 Catalog CE Miniatura ElraSneezy DwarfNo ratings yet

- Capacitor HF B41858 TDKDocument33 pagesCapacitor HF B41858 TDKb_dupNo ratings yet

- NIC Components NRE-LW SeriesDocument5 pagesNIC Components NRE-LW SeriesNICCompNo ratings yet

- Varistor PDFDocument9 pagesVaristor PDFcarlosNo ratings yet

- NIC Components NCF SeriesDocument3 pagesNIC Components NCF SeriesNICCompNo ratings yet

- Precision Milliohm MeterDocument1 pagePrecision Milliohm MeterAdam SonenshineNo ratings yet

- NIC Components NSTL SeriesDocument2 pagesNIC Components NSTL SeriesNICCompNo ratings yet

- Capsun (Radial Thru-Hole) SWB SeriesDocument2 pagesCapsun (Radial Thru-Hole) SWB Serieshes545No ratings yet

- NIC Components NSWC SeriesDocument4 pagesNIC Components NSWC SeriesNICCompNo ratings yet

- Acon (Radial Thru-Hole) GFW SeriesDocument3 pagesAcon (Radial Thru-Hole) GFW Seriesxyz99No ratings yet

- Tta 2944741 PDFDocument4 pagesTta 2944741 PDFDhaval PatelNo ratings yet

- Capa Panasonic Low EsrDocument5 pagesCapa Panasonic Low EsrClovis APOVONo ratings yet

- 8081 Extended SpecificationsDocument10 pages8081 Extended SpecificationsAldrin HernandezNo ratings yet

- Aluminum electrolytic capacitors withdrawal noticeDocument29 pagesAluminum electrolytic capacitors withdrawal noticeb_dupNo ratings yet

- Capacitor PanasonicDocument6 pagesCapacitor PanasonicdenisharkNo ratings yet

- NIC Components NSR SeriesDocument5 pagesNIC Components NSR SeriesNICCompNo ratings yet

- Capxon (Polymer) 2011 PH SeriesDocument2 pagesCapxon (Polymer) 2011 PH Serieshes545No ratings yet

- High Efficiency, Multicrystalline PV Modules: The Sealite AdvantageDocument1 pageHigh Efficiency, Multicrystalline PV Modules: The Sealite AdvantagedevarajuNo ratings yet

- E ZLHDocument3 pagesE ZLHJoe CrabshawNo ratings yet

- TMG PC Strands, Wire & BarDocument10 pagesTMG PC Strands, Wire & BarHenrique Braglia PachecoNo ratings yet

- GH 1C 12LDocument2 pagesGH 1C 12LRoberto MendesNo ratings yet

- Acon (Radial Thru-Hole) DM SeriesDocument2 pagesAcon (Radial Thru-Hole) DM Seriesxyz99No ratings yet

- MF72-NTC-ThermistorDocument8 pagesMF72-NTC-ThermistorReviewNo ratings yet

- Insulation Tester - HT7051 - EN1-01Document3 pagesInsulation Tester - HT7051 - EN1-01Muaf FaizudeenNo ratings yet

- Harmonics According To IEC61000-3-12: Limit OK N/A (Rule) Limit Over N/A Limit OK N/A (Rule) Limit Over N/ADocument3 pagesHarmonics According To IEC61000-3-12: Limit OK N/A (Rule) Limit Over N/A Limit OK N/A (Rule) Limit Over N/AHLGerardNo ratings yet

- Manual Amperimetro Ad-7000Document17 pagesManual Amperimetro Ad-7000maurilioctbaNo ratings yet

- SERIES - Lead Terminal: FeaturesDocument4 pagesSERIES - Lead Terminal: FeaturesVenu Gopal Rao AggressNo ratings yet

- Capsun (Radial Thru-Hole) SWM SeriesDocument2 pagesCapsun (Radial Thru-Hole) SWM Serieshes545No ratings yet

- ISO 9001 Certified Zener Diodes 1N746 to 1N759 400mW 3.3V to 12VDocument1 pageISO 9001 Certified Zener Diodes 1N746 to 1N759 400mW 3.3V to 12VAlejandro G SantosNo ratings yet

- JRG CapacitorsDocument2 pagesJRG Capacitorsmarina anastasovaNo ratings yet

- Capxon (Radial) 2011 GS (GR) SeriesDocument4 pagesCapxon (Radial) 2011 GS (GR) Serieshes545No ratings yet

- NIC Components NNR SeriesDocument5 pagesNIC Components NNR SeriesNICCompNo ratings yet

- NIC Components NRE-L SeriesDocument5 pagesNIC Components NRE-L SeriesNICCompNo ratings yet

- Topstek Current Transducers TD25A-400A Specs, Features & ApplicationsDocument2 pagesTopstek Current Transducers TD25A-400A Specs, Features & Applicationsдмитрий рещиковNo ratings yet

- Aluminum Electrolytic CapacitorsDocument27 pagesAluminum Electrolytic Capacitorsb_dupNo ratings yet

- Test Certificate for 3G4mm2 H07RN-F CableDocument1 pageTest Certificate for 3G4mm2 H07RN-F CableSoha ElsamraNo ratings yet

- Series: Absolute Rotary Encoder (Contactless)Document2 pagesSeries: Absolute Rotary Encoder (Contactless)Jason LambrechtNo ratings yet

- Beryl (Radial Thru-Hole) TC SeriesDocument2 pagesBeryl (Radial Thru-Hole) TC Seriesester853No ratings yet

- Acon (Radial Thru-Hole) DKL SerieDocument2 pagesAcon (Radial Thru-Hole) DKL Seriexyz99No ratings yet

- Deutsche Akkreditierungsstelle GMBH: Gigahertz Optik GMBH An Der Kälberweide 12, 82299 TürkenfeldDocument5 pagesDeutsche Akkreditierungsstelle GMBH: Gigahertz Optik GMBH An Der Kälberweide 12, 82299 TürkenfeldMauroNo ratings yet

- Acon (Radial Thru-Hole) NK SeriesDocument2 pagesAcon (Radial Thru-Hole) NK Seriesser4595No ratings yet

- NIC Components NSRZ SeriesDocument4 pagesNIC Components NSRZ SeriesNICCompNo ratings yet

- Co. Material Samp. Batch No. Sample Id T (°C) G*/Sin (Δ) (Kpa 2.442 G* (Kpa) Δ (°) Η* (Mpa S) Ω (Rad/S) Γ* (%) Σ* (Kpa) G (Mm) Τ (N M) Ts (S) Texp (S) Dplate Notes Tcontroller Op. ResultDocument1 pageCo. Material Samp. Batch No. Sample Id T (°C) G*/Sin (Δ) (Kpa 2.442 G* (Kpa) Δ (°) Η* (Mpa S) Ω (Rad/S) Γ* (%) Σ* (Kpa) G (Mm) Τ (N M) Ts (S) Texp (S) Dplate Notes Tcontroller Op. ResultNaveen SinghNo ratings yet

- DSFfilmDocument4 pagesDSFfilmGagandeep BhatiaNo ratings yet

- Experimental Study of Bell-Mouth Intakes On Discharge CoefficientDocument5 pagesExperimental Study of Bell-Mouth Intakes On Discharge CoefficientiuiuiooiuNo ratings yet

- 94020O Open Pressure / Vacuum Vent Websize Rev. 0.1.007: 2021-09-09 04:44:55 Page 1/1Document1 page94020O Open Pressure / Vacuum Vent Websize Rev. 0.1.007: 2021-09-09 04:44:55 Page 1/1iuiuiooiuNo ratings yet

- 94020O Open Pressure / Vacuum Vent Websize Rev. 0.1.007: 2021-09-09 04:44:55 Page 1/1Document1 page94020O Open Pressure / Vacuum Vent Websize Rev. 0.1.007: 2021-09-09 04:44:55 Page 1/1iuiuiooiuNo ratings yet

- 7 Flow Patterns ExplainedDocument33 pages7 Flow Patterns ExplainedSyazreen AminNo ratings yet

- 300 W - 320 W Poly-Crystalline Solar Module: SEP 300W/305W/310W/315W/320WDocument2 pages300 W - 320 W Poly-Crystalline Solar Module: SEP 300W/305W/310W/315W/320WMahmoud EL-SayedNo ratings yet

- Storage Tank Safety, A PROTEGO® Webinar: Click Here To RegisterDocument3 pagesStorage Tank Safety, A PROTEGO® Webinar: Click Here To RegisteriuiuiooiuNo ratings yet

- Selecting Fluid PackageDocument13 pagesSelecting Fluid PackageWassili KorobitsynNo ratings yet

- ALOHA ExamplesDocument53 pagesALOHA ExamplesOrkun KabaşNo ratings yet

- Option 1 Froude No. 0.3: V Velocity of Liquid, Fps G Gravitational Constant, 32.2 Ft/sec D Diameter of Pipe, FTDocument5 pagesOption 1 Froude No. 0.3: V Velocity of Liquid, Fps G Gravitational Constant, 32.2 Ft/sec D Diameter of Pipe, FTiuiuiooiuNo ratings yet

- The New Normal Is Not New For AUDIENCEDocument30 pagesThe New Normal Is Not New For AUDIENCEiuiuiooiuNo ratings yet

- Gas-Liquid Separator Sizing CalculationsDocument12 pagesGas-Liquid Separator Sizing CalculationsiuiuiooiuNo ratings yet

- Guideline - PDF Clouds Online Utilization Rev2Document6 pagesGuideline - PDF Clouds Online Utilization Rev2iuiuiooiuNo ratings yet

- Fun Learning MatDocument17 pagesFun Learning MatiuiuiooiuNo ratings yet

- PT Pertamina (Persero) : Safety Data SheetDocument10 pagesPT Pertamina (Persero) : Safety Data SheetFaizal HidayatNo ratings yet

- 2.3.8.a ResidentialWaterSupplyDocument30 pages2.3.8.a ResidentialWaterSupplyiuiuiooiuNo ratings yet

- 2.3.8.a ResidentialWaterSupplyDocument30 pages2.3.8.a ResidentialWaterSupplyiuiuiooiuNo ratings yet

- Darcy Weisbach FormulaDocument3 pagesDarcy Weisbach Formulasairam2234No ratings yet

- Absolute Roughness of Pipe MaterialDocument3 pagesAbsolute Roughness of Pipe MaterialiuiuiooiuNo ratings yet

- Compute Time To Drain or Empty A Tank Pond or Reservoir PDFDocument5 pagesCompute Time To Drain or Empty A Tank Pond or Reservoir PDFiuiuiooiuNo ratings yet

- 154 Bettis Cba-Series CatalogDocument16 pages154 Bettis Cba-Series CatalogsebastianNo ratings yet

- Instal AspenTechDocument1 pageInstal AspenTechiuiuiooiuNo ratings yet

- Get StartDocument116 pagesGet StartiuiuiooiuNo ratings yet

- Liquefaction Technology - Technology - CHIYODA CORPORATIONDocument2 pagesLiquefaction Technology - Technology - CHIYODA CORPORATIONiuiuiooiuNo ratings yet

- Pipe Flow Head Losses: Major and Minor Pressure DropsDocument35 pagesPipe Flow Head Losses: Major and Minor Pressure DropsJohn Ceasar PascoNo ratings yet

- 2003 Reliability of Fiber-Reinforced Composite Laminate PlatesDocument19 pages2003 Reliability of Fiber-Reinforced Composite Laminate Platesdhiraj.biswasNo ratings yet

- Material Science NotesDocument6 pagesMaterial Science Notessandarasolis11No ratings yet

- A Kinetic Study of The Emulsion Polymerization of Vinyl AcetateDocument17 pagesA Kinetic Study of The Emulsion Polymerization of Vinyl AcetateAnyiSakuraNo ratings yet

- Structural Behavior of Weirs With One Bottom Circular OpeningDocument13 pagesStructural Behavior of Weirs With One Bottom Circular Openingayman_awadallahNo ratings yet

- Testing and Modeling of Soil-Structure InterfaceDocument10 pagesTesting and Modeling of Soil-Structure InterfaceANKIT KUMARNo ratings yet

- The Authoritative Dictionary of IEEE Terms ML12089A535Document4 pagesThe Authoritative Dictionary of IEEE Terms ML12089A535sebastiannistorNo ratings yet

- Darmstadt Vlsi Design CourseDocument533 pagesDarmstadt Vlsi Design Courseapi-3722592100% (1)

- OUZENDocument80 pagesOUZENPLATIN DESIGNNo ratings yet

- Introduction-Basic Concepts: Pooja GhodasaraDocument18 pagesIntroduction-Basic Concepts: Pooja GhodasaraPooja GhodasaraNo ratings yet

- Dynamic Behavior of Combined 100 IBR Transmission and Distribution Networks With Grid-Forming and Grid-Following InvertersDocument5 pagesDynamic Behavior of Combined 100 IBR Transmission and Distribution Networks With Grid-Forming and Grid-Following InvertersgayathriNo ratings yet

- Joint Less Pavements For Heavy-Duty Airport Application: The Semi-Flexible Approach Jean Mayer I & Mikael Thau 2Document14 pagesJoint Less Pavements For Heavy-Duty Airport Application: The Semi-Flexible Approach Jean Mayer I & Mikael Thau 2Dr Rajiv KumarNo ratings yet

- Set 3 - Unit 3Document6 pagesSet 3 - Unit 3Tare Er Kshitij100% (3)

- SSAB Domex Tube Structural Hollow Sections EN1993 Handbook PDFDocument690 pagesSSAB Domex Tube Structural Hollow Sections EN1993 Handbook PDFBabu PonnuswamyNo ratings yet

- Interlloy Grade 1045 Carbon Steel BarDocument3 pagesInterlloy Grade 1045 Carbon Steel BarPRASHANT KANTENo ratings yet

- Duratherm XLT-120Document4 pagesDuratherm XLT-120Goh Kok SweeNo ratings yet

- EE311A 2021 AV Slides L20Document12 pagesEE311A 2021 AV Slides L20Ananya AgarwalNo ratings yet

- Chemical Engineering Process Simulator Software TrainingDocument12 pagesChemical Engineering Process Simulator Software TrainingEvangelista LindaNo ratings yet

- Tesis PDFDocument120 pagesTesis PDFdaniel sernaNo ratings yet

- CV-RVT - (June2023)Document6 pagesCV-RVT - (June2023)Ricardo Villagómez TamezNo ratings yet

- EC 308 AWP Ch-10 Lens AntennaDocument11 pagesEC 308 AWP Ch-10 Lens Antennarrajmohan28No ratings yet

- Going The Distance: Primary Sludge PumpingDocument8 pagesGoing The Distance: Primary Sludge Pumpings_samirkumar1008No ratings yet

- Raman InorgDocument3 pagesRaman InorgJAHELNo ratings yet

- ASPHALT CONCRETE Lecture NoteDocument11 pagesASPHALT CONCRETE Lecture Notekalana mihirangaNo ratings yet

- UEE & T Notes (1) (6th Semester Electrical) - MergedDocument199 pagesUEE & T Notes (1) (6th Semester Electrical) - MergedAmit HansdaNo ratings yet

- Solution Manual For Quantum Mechanics An Accessible Introduction by ScherrerDocument6 pagesSolution Manual For Quantum Mechanics An Accessible Introduction by ScherrerDennis Angelo PablicoNo ratings yet

- ADA027952Document64 pagesADA027952UlfrssonNo ratings yet

- Aplikasi Mangan Zeolit Dan Resin Kation Untuk Mengadsorpsi Ion Besi Dan Mangan Pada Air Tanah DangkalDocument11 pagesAplikasi Mangan Zeolit Dan Resin Kation Untuk Mengadsorpsi Ion Besi Dan Mangan Pada Air Tanah Dangkallilla illahiNo ratings yet