Professional Documents

Culture Documents

Insulation Bricks

Uploaded by

Pranabesh MallickCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Insulation Bricks

Uploaded by

Pranabesh MallickCopyright:

Available Formats

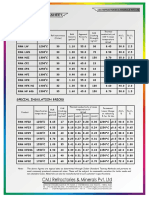

INSULATION BRICKS

Thermal

Cold

Bulk Apparent conductivity at

Service Refractoriness Crushing Al2O3 Fe2O3

Product Density Porosity 600 °C mean

Temp. (Orton) Strength % %

gm/cm3 % temperature

kg/cm2

W/mK

RRM LW 12000C 30 1.10 55.0 30 0.45 30.0 2.5

RRM LWS 12000C 30 1.30 50.0 70 0.58 30.0 2.5

RRM HSI 13000C 31 1.60 45.0 150 0.70 35.0 2.5

RRM CFI 12500C 30 0.80 65.0 15 0.35 30.0 2.5

RRM CFS 12500C 30 0.65 70.0 10 0.23 30.0 2.5

RRM HFI 13000C 30 0.90 60.0 20 0.40 30.0 2.5

RRM HFK 14000C 32 1.10 55.0 40 0.50 40.0 2.5

RRM HFK HS 14000C 32 1.30 50.0 100 0.60 40.0 2.0

RRM HF 60S 15000C 35 1.60 45.0 150 0.70 58.0 1.5

SPECIAL INSULATION BRICKS

Thermal conductivity at mean

Cold Permanent

Bulk temperature of

Classification Crushing Linear Change Al2O3 Fe2O3

Product Density W/mK

temperature Strength on reheating % %

gm/cm3

kg/cm2 400 C 600 C 8000C 10000C

0 0

% for 24 Hrs

RRM HF22 12500C 0.65 17 0.24 0.27 0.28 0.30 1200°C ±0.5 40.0 0.70

RRM HF23 13000C 0.55 10 0.18 0.20 0.22 0.24 1250°C ±0.6 42.0 0.65

RRM HF25 14000C 0.80 40 0.32 0.36 0.40 0.45 1350°C ±1.5 38.0 0.80

RRM HF26 14500C 0.70 16 0.25 0.27 0.29 0.31 1350°C ±0.5 58.0 0.70

RRM HF28 15500C 1.00 35 0.41 0.43 0.44 0.45 1450°C ±0.7 60.0 1.00

RRM HF28S 15500C 0.90 40 0.39 0.41 0.47 0.43 1450°C ±0.5 62.0 0.80

RRM HF30 16500C 1.10 40 0.46 0.51 0.56 0.60 1550°C ±0.5 72.0 0.80

RRM HF32 17000C 1.30 60 0.58 0.63 0.67 0.70 1600°C ±0.5 72.0 0.60

Note: The above figures are typical data as determined through Indian Standard Testing Methods and pertains to

most commonly produced commercial sizes. These will be subject to reasonable variation for tailor made and

non-standard sizes. Materials can also be manufactured to suit customer's specifications.

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

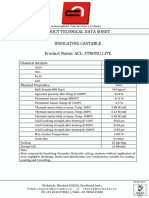

- Refractory CastableDocument1 pageRefractory CastablePranabesh MallickNo ratings yet

- Refractory CastableDocument1 pageRefractory CastablePranabesh MallickNo ratings yet

- Mullite BrickDocument1 pageMullite BrickPranabesh MallickNo ratings yet

- 0007Document1 page0007Pranabesh MallickNo ratings yet

- Insulating Castable (Vermiculite Based)Document1 pageInsulating Castable (Vermiculite Based)Pranabesh MallickNo ratings yet

- Mill Test Certificate: Type of Test Conducted Unit Typical Value Sample Average Value Obtained No-1 No. 2 No.3 No.4Document1 pageMill Test Certificate: Type of Test Conducted Unit Typical Value Sample Average Value Obtained No-1 No. 2 No.3 No.4Pranabesh MallickNo ratings yet

- Importers Saudi ArabiaDocument34 pagesImporters Saudi ArabiaPranabesh Mallick100% (1)

- Insulation Bricks PDFDocument1 pageInsulation Bricks PDFPranabesh MallickNo ratings yet

- High Alumina BrickDocument1 pageHigh Alumina BrickPranabesh MallickNo ratings yet

- Profile Fasteners PDFDocument20 pagesProfile Fasteners PDFPranabesh MallickNo ratings yet

- Basic Monolithics Sintering Application MgO SiO2 Cr2O3 Grading TemperatureDocument1 pageBasic Monolithics Sintering Application MgO SiO2 Cr2O3 Grading TemperaturePranabesh MallickNo ratings yet

- ADHESIET 180 P Dry Air Setting Refractory MortarDocument1 pageADHESIET 180 P Dry Air Setting Refractory MortarPranabesh MallickNo ratings yet

- Draft Mou CMJ and FciDocument4 pagesDraft Mou CMJ and FciPranabesh MallickNo ratings yet

- Sabic DirectoryDocument9 pagesSabic DirectoryPranabesh MallickNo ratings yet

- Firelite 2600 Li Metric Data SheetDocument1 pageFirelite 2600 Li Metric Data SheetPranabesh MallickNo ratings yet

- Engineering ConsultantDocument17 pagesEngineering ConsultantPranabesh Mallick100% (1)

- KolkataDocument18 pagesKolkataPranabesh MallickNo ratings yet

- Method Statement: Departmental Representative Contractors RepresentativeDocument1 pageMethod Statement: Departmental Representative Contractors RepresentativePranabesh MallickNo ratings yet

- HSE ManualDocument22 pagesHSE ManualPranabesh Mallick100% (1)

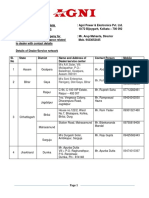

- M/s A.K.Solar, Vill: Moilapathar, P.O.: Baladmari, Goalpara, Assam-783101 Mr. Abdul KaderDocument3 pagesM/s A.K.Solar, Vill: Moilapathar, P.O.: Baladmari, Goalpara, Assam-783101 Mr. Abdul KaderPranabesh MallickNo ratings yet

- Profile Fasteners PDFDocument20 pagesProfile Fasteners PDFPranabesh MallickNo ratings yet

- Manpower CV Insulation JobsDocument1 pageManpower CV Insulation JobsPranabesh MallickNo ratings yet

- Refractory & Mechanical ProfileDocument17 pagesRefractory & Mechanical ProfilePranabesh MallickNo ratings yet

- Demand Draft Application FormDocument1 pageDemand Draft Application FormPranabesh MallickNo ratings yet

- Site: Page 1 of 6 Client Enquiry No Type of Job Dated CountryDocument6 pagesSite: Page 1 of 6 Client Enquiry No Type of Job Dated CountryPranabesh MallickNo ratings yet

- Demand Draft Application FormDocument1 pageDemand Draft Application FormPranabesh MallickNo ratings yet

- Solar Power Plant DomesticDocument11 pagesSolar Power Plant DomesticPranabesh MallickNo ratings yet

- CCCL High Alumina BricksDocument2 pagesCCCL High Alumina BricksPranabesh MallickNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- hlL3 - SSHT II 201213Document30 pageshlL3 - SSHT II 201213Will Morgan-EvansNo ratings yet

- Design and Fabrication of Spiral Coiled Heat ExchangerDocument20 pagesDesign and Fabrication of Spiral Coiled Heat ExchangerHem KumarNo ratings yet

- Recap ThermalDocument8 pagesRecap ThermalGunnerZedNo ratings yet

- HSE Specification - Ionising Radiation SP 1237Document42 pagesHSE Specification - Ionising Radiation SP 1237mac1677No ratings yet

- SDip - ME102 - Coord - 2015a - Rev - 25 - May - 2015 (ACMV)Document37 pagesSDip - ME102 - Coord - 2015a - Rev - 25 - May - 2015 (ACMV)zaw100% (1)

- Thermo 2 Final Exam Study Guide (Answered)Document13 pagesThermo 2 Final Exam Study Guide (Answered)Stefan JobeNo ratings yet

- Tutorial Heat ExchangerDocument2 pagesTutorial Heat ExchangerAhmad Nor Fahmi WalidNo ratings yet

- KOBE's BAHX Experience ListDocument67 pagesKOBE's BAHX Experience Listlutfi_ismailNo ratings yet

- Electrical Load CalculationsDocument10 pagesElectrical Load CalculationsajaynmenonNo ratings yet

- Transient Conduction in Semi-Infinite Slab CDeep PDFDocument3 pagesTransient Conduction in Semi-Infinite Slab CDeep PDFpraveen4ubvsNo ratings yet

- IMG - 0177 PSME Code 2008 167Document1 pageIMG - 0177 PSME Code 2008 167let ramNo ratings yet

- Yasmine City Mess HallDocument1 pageYasmine City Mess HallDeepak JoyNo ratings yet

- Topic 7 Cascade Refrigeration SystemsDocument6 pagesTopic 7 Cascade Refrigeration SystemsJanelle D. Puti-anNo ratings yet

- How Window Air Conditioners WorkDocument11 pagesHow Window Air Conditioners WorkSAATVIK JAINNo ratings yet

- Heat Transfer: Mechanical EngineeringDocument10 pagesHeat Transfer: Mechanical EngineeringVenkatasairamreddy KandulaNo ratings yet

- EC1Document1 pageEC1sam9montgomeryNo ratings yet

- Ch-4 Transient HMTDocument27 pagesCh-4 Transient HMTrana abdul waasayNo ratings yet

- Essential 2013072502 Screen 0 PDFDocument5 pagesEssential 2013072502 Screen 0 PDFzrno5No ratings yet

- MODES OF HEAT TRANSFER - Docx FinDocument6 pagesMODES OF HEAT TRANSFER - Docx FinJerome MosadaNo ratings yet

- Heat Transfer BasicsDocument20 pagesHeat Transfer BasicshellboytonmoyNo ratings yet

- Objectives: Heat TransferDocument75 pagesObjectives: Heat TransferTarikuNo ratings yet

- Slides Lec 9 HVAC and Refrigeration System PDFDocument28 pagesSlides Lec 9 HVAC and Refrigeration System PDFAhmed JavedNo ratings yet

- Lecture - 3 Dosimetric Quantities and Biological EffectsDocument33 pagesLecture - 3 Dosimetric Quantities and Biological Effectsmz2v8rs7srNo ratings yet

- Glass Data - v4 Low ResDocument15 pagesGlass Data - v4 Low ResPatrick SyNo ratings yet

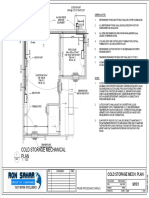

- M101 - Cold Storage Mech - PlanDocument1 pageM101 - Cold Storage Mech - PlanLiaqatSrakNo ratings yet

- Library 1 PDFDocument7 pagesLibrary 1 PDFUpendarNo ratings yet

- Second Law of ThermodynamicsDocument32 pagesSecond Law of ThermodynamicsLyndsay Jazmhere Madrilejos50% (2)

- What Are Air Handlers or AHUDocument24 pagesWhat Are Air Handlers or AHUTushar PatilNo ratings yet