Professional Documents

Culture Documents

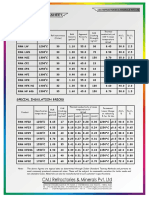

Basic Monolithics Sintering Application MgO SiO2 Cr2O3 Grading Temperature

Uploaded by

Pranabesh MallickOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Basic Monolithics Sintering Application MgO SiO2 Cr2O3 Grading Temperature

Uploaded by

Pranabesh MallickCopyright:

Available Formats

Basic Monolithics

Sintering Application

MgO SiO2 Cr2O3 Grading temperature temperature

Product % % % Setting mm °C °C Application Area

RRM MGM 85 - - Ceramic 0-0.5 1600

Mortar for

RRM MCM 55 - 12 Ceramic 0-1 1650 general

application

RRM CMM 30 - 18 Ceramic 0-1 1650

RRM PATCH MCX 75 - 8 Ceramic 0-2 800 1750

Masses for

Induction

Furnace

RRM RAM MCX 75 - 8 Ceramic 0-5 800 1750

RRM RAM 84 84 - - Ceramic 0-5 1550 1750

RRM FET 84 84 - - Ceramic 0-5 1500 1750

Ramming Masses

RRM GUN 85 85 6.5 - Chemical/Ceramic 0-4 1500 1750 for EAF,EOF &

LD

RRM RAM 86 86 - - Ceramic 0-5 1550 1750

RRM RAM 90 90 5 - Ceramic 0-5 1550 1750

RRM RAM 95 95 5 - Ceramic 0-5 1550 1750

RRM GUN 88 88 - - Ceramic 0-3 1550 1750

Gunning Masses

for EAF, EOF

and LD Converter

RRM GUN 92 92 5 - Ceramic 0-3 1550 1750

RRM GUN 95 94 2.5 - Ceramic 0-3 1550 1750

Hot patching

RRM HOT PATCH MIX 88 2 - Ceramic 0-4 1550 1750 mass for LRF &

BOF

Note: The above figures are typical data as determined through Indian Standard Testing Methods.

Materials can also be manufactured to suit customer's specifications.

You might also like

- Alumina SilicaDocument15 pagesAlumina Silicabhujakhia_748657110No ratings yet

- SA 387 Grade 91 Class 2Document4 pagesSA 387 Grade 91 Class 2briang-2No ratings yet

- Special steels - American standards ASTM A193 B7 and B7MDocument1 pageSpecial steels - American standards ASTM A193 B7 and B7MNarimane BentyNo ratings yet

- Automig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalsDocument1 pageAutomig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalssatnamNo ratings yet

- Metco105TechnicalBulletin PDFDocument8 pagesMetco105TechnicalBulletin PDF張政雄100% (1)

- Ordering from Kemet Materials GuideDocument24 pagesOrdering from Kemet Materials Guidevantuan17792No ratings yet

- International Standard: Cu-ETP - CW004ADocument2 pagesInternational Standard: Cu-ETP - CW004AgnanasekarNo ratings yet

- CWC-BookletF1 17Document1 pageCWC-BookletF1 17satnamNo ratings yet

- Mixed Ms 120Document42 pagesMixed Ms 120Fernando OrtizNo ratings yet

- Roll Grade PDFDocument1 pageRoll Grade PDFVicente GarcíaNo ratings yet

- Grade multi-binder and single-binder chemical and physical propertiesDocument1 pageGrade multi-binder and single-binder chemical and physical propertiesVicente GarcíaNo ratings yet

- Weartech SHS 9290P: Severe Abrasion, (PAW) Weld PowerDocument2 pagesWeartech SHS 9290P: Severe Abrasion, (PAW) Weld PowerKara WhiteNo ratings yet

- NiCu-7 solid wire for welding nickel-copper alloysDocument1 pageNiCu-7 solid wire for welding nickel-copper alloyssatnamNo ratings yet

- CWC-BookletF1 15Document1 pageCWC-BookletF1 15satnamNo ratings yet

- Material Product Data Sheet Copper & Copper Alloy (Brass, Bronze) Thermal Spray WiresDocument4 pagesMaterial Product Data Sheet Copper & Copper Alloy (Brass, Bronze) Thermal Spray WiresSerkan ÖzcanNo ratings yet

- TMT RebarsDocument15 pagesTMT RebarsMohan Dakshina0% (1)

- Alloy Steel Plates TdsDocument6 pagesAlloy Steel Plates TdsSrikanth SrikantiNo ratings yet

- Poweroil: Power Gem Ep00, Ep0, Ep1 & Ep2 Extreme Pressure GreasesDocument1 pagePoweroil: Power Gem Ep00, Ep0, Ep1 & Ep2 Extreme Pressure GreasesTechnicians SIMNo ratings yet

- Merkel Omegat OMK-MR 01Document13 pagesMerkel Omegat OMK-MR 01Ana Tereza Holzhausen GrönerNo ratings yet

- LM25 Aluminium Casting Alloy (Al Ð Si7Mg) : Chemical CompositionDocument3 pagesLM25 Aluminium Casting Alloy (Al Ð Si7Mg) : Chemical Compositionsankar4582No ratings yet

- Predict Amine20 OverviewDocument23 pagesPredict Amine20 Overviewqueno1No ratings yet

- Technical Datasheet: High Purity Solder AlloyDocument6 pagesTechnical Datasheet: High Purity Solder Alloyاوس محمد رؤوف لؤيNo ratings yet

- lecture 11(mems) thermal sensorsDocument3 pageslecture 11(mems) thermal sensorsMANUDEYNo ratings yet

- Metco 54NS-1 (Aluminum Seal Coat) PDFDocument3 pagesMetco 54NS-1 (Aluminum Seal Coat) PDFJ. BangjakNo ratings yet

- Technological & Safety Aspects of BOF & CCPDocument69 pagesTechnological & Safety Aspects of BOF & CCPSANTOSH KUMAR100% (2)

- Tool Steel MMDocument3 pagesTool Steel MMBhushan UNo ratings yet

- Hostaperm Red Violet ERX A High Purity SS-Quinacridone Pigment With Outstanding PropertiesDocument2 pagesHostaperm Red Violet ERX A High Purity SS-Quinacridone Pigment With Outstanding PropertiesMaximiliano MackeviciusNo ratings yet

- en 197 1 2011 SR PDFDocument1 pageen 197 1 2011 SR PDFUdari LiyanageNo ratings yet

- 1.4401 1.4404 316 316L X2Crnimo17-12-2 S31603: en Designation Astm DesignationDocument2 pages1.4401 1.4404 316 316L X2Crnimo17-12-2 S31603: en Designation Astm Designation池边树No ratings yet

- ARCAP - Grades and PropertiesDocument7 pagesARCAP - Grades and PropertiesEminent RishNo ratings yet

- Tungsten Carbide Mill Rolls and Guide RollersDocument2 pagesTungsten Carbide Mill Rolls and Guide RollersQuy SopNo ratings yet

- E 9018-B9 Product-SheetDocument1 pageE 9018-B9 Product-SheetjuanNo ratings yet

- AAMRADocument50 pagesAAMRARona Khairol Pratama100% (1)

- Ams 5391 HDocument9 pagesAms 5391 HEhab HarbNo ratings yet

- The Aluminium Evolution: Continuous Casting Aluminium AlloysDocument2 pagesThe Aluminium Evolution: Continuous Casting Aluminium AlloysHareth MRAIDINo ratings yet

- Scule de Abkant Promecam Amada Scara 1:1Document81 pagesScule de Abkant Promecam Amada Scara 1:1SM TECH SRLNo ratings yet

- Motor Design Basic TutorialDocument38 pagesMotor Design Basic TutorialDHRUV UPADHAYANo ratings yet

- Surda Mine Report Details Post Pillar Mining and Froth Flotation ProcessesDocument20 pagesSurda Mine Report Details Post Pillar Mining and Froth Flotation Processesvictory shahbazNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Jonathan Getial CruzNo ratings yet

- Creep behaviourDocument1 pageCreep behaviourSagarika AdityaNo ratings yet

- 11⁄4Cr-1⁄2Mo Steel Welding Electrodes Data SheetDocument7 pages11⁄4Cr-1⁄2Mo Steel Welding Electrodes Data Sheetanon_928750560No ratings yet

- Engineering 1 RevDocument1 pageEngineering 1 Revapi-492336633No ratings yet

- LM4 Aluminium Casting Alloy (Al - Si5Cu3) : Chemical CompositionDocument3 pagesLM4 Aluminium Casting Alloy (Al - Si5Cu3) : Chemical Compositiona.suleimanNo ratings yet

- Welding ProcessesDocument28 pagesWelding ProcessesAnaswarpsNo ratings yet

- Steel Making Overview (MR Amit Sarkar)Document52 pagesSteel Making Overview (MR Amit Sarkar)Murali Krishna ENo ratings yet

- Man New Piston RingsDocument3 pagesMan New Piston RingsMario AndrewNo ratings yet

- Midalloy-ER410Document2 pagesMidalloy-ER410Alessandro sergio de souzaNo ratings yet

- Automig 100S-G / Tigfil 100S-G: AWS A/SFA 5.28Document1 pageAutomig 100S-G / Tigfil 100S-G: AWS A/SFA 5.28Jagannath SahuNo ratings yet

- Aerospace Material Specification: AMS5709 REV. HDocument6 pagesAerospace Material Specification: AMS5709 REV. Hfelipe jurema100% (1)

- Hostaperm Red P2GL-WD A New High Performance Pigment For Water-Based CoatingsDocument2 pagesHostaperm Red P2GL-WD A New High Performance Pigment For Water-Based CoatingsMaximiliano MackeviciusNo ratings yet

- MAN SL2018-659 - JAP (2018.03) - Cerment-Coated Piston Rings For Low-Sulphur Fuels (0.5% or Lower)Document9 pagesMAN SL2018-659 - JAP (2018.03) - Cerment-Coated Piston Rings For Low-Sulphur Fuels (0.5% or Lower)GrandpaNo ratings yet

- Macam Macam Aplikasi Perancangan GeneratorDocument4 pagesMacam Macam Aplikasi Perancangan GeneratorwikoNo ratings yet

- LM25 Aluminium Casting Alloy PropertiesDocument3 pagesLM25 Aluminium Casting Alloy Propertiesdaniel_sasikumarNo ratings yet

- A834Document4 pagesA834mithileshNo ratings yet

- Etm Api 600 Trim Material PDFDocument1 pageEtm Api 600 Trim Material PDFbenabdallah131No ratings yet

- API 600 Trim Materials Disc Wedge Seat RDocument1 pageAPI 600 Trim Materials Disc Wedge Seat RManan DesaiNo ratings yet

- Metco 16C 10-040Document8 pagesMetco 16C 10-040JSH100No ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

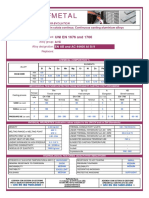

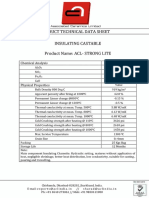

- Refractory CastableDocument1 pageRefractory CastablePranabesh MallickNo ratings yet

- Refractory CastableDocument1 pageRefractory CastablePranabesh MallickNo ratings yet

- Mullite BrickDocument1 pageMullite BrickPranabesh MallickNo ratings yet

- 0007Document1 page0007Pranabesh MallickNo ratings yet

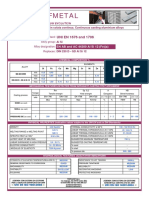

- Insulating Castable (Vermiculite Based)Document1 pageInsulating Castable (Vermiculite Based)Pranabesh MallickNo ratings yet

- Mill Test Certificate: Type of Test Conducted Unit Typical Value Sample Average Value Obtained No-1 No. 2 No.3 No.4Document1 pageMill Test Certificate: Type of Test Conducted Unit Typical Value Sample Average Value Obtained No-1 No. 2 No.3 No.4Pranabesh MallickNo ratings yet

- Importers Saudi ArabiaDocument34 pagesImporters Saudi ArabiaPranabesh Mallick100% (1)

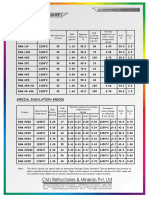

- Insulation BricksDocument1 pageInsulation BricksPranabesh MallickNo ratings yet

- High Alumina BrickDocument1 pageHigh Alumina BrickPranabesh MallickNo ratings yet

- Profile Fasteners PDFDocument20 pagesProfile Fasteners PDFPranabesh MallickNo ratings yet

- Insulation Bricks PDFDocument1 pageInsulation Bricks PDFPranabesh MallickNo ratings yet

- ADHESIET 180 P Dry Air Setting Refractory MortarDocument1 pageADHESIET 180 P Dry Air Setting Refractory MortarPranabesh MallickNo ratings yet

- Draft Mou CMJ and FciDocument4 pagesDraft Mou CMJ and FciPranabesh MallickNo ratings yet

- Sabic DirectoryDocument9 pagesSabic DirectoryPranabesh MallickNo ratings yet

- Firelite 2600 Li Metric Data SheetDocument1 pageFirelite 2600 Li Metric Data SheetPranabesh MallickNo ratings yet

- Engineering ConsultantDocument17 pagesEngineering ConsultantPranabesh Mallick100% (1)

- KolkataDocument18 pagesKolkataPranabesh MallickNo ratings yet

- Method Statement: Departmental Representative Contractors RepresentativeDocument1 pageMethod Statement: Departmental Representative Contractors RepresentativePranabesh MallickNo ratings yet

- HSE ManualDocument22 pagesHSE ManualPranabesh Mallick100% (1)

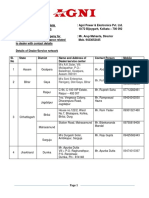

- M/s A.K.Solar, Vill: Moilapathar, P.O.: Baladmari, Goalpara, Assam-783101 Mr. Abdul KaderDocument3 pagesM/s A.K.Solar, Vill: Moilapathar, P.O.: Baladmari, Goalpara, Assam-783101 Mr. Abdul KaderPranabesh MallickNo ratings yet

- Profile Fasteners PDFDocument20 pagesProfile Fasteners PDFPranabesh MallickNo ratings yet

- Manpower CV Insulation JobsDocument1 pageManpower CV Insulation JobsPranabesh MallickNo ratings yet

- Refractory & Mechanical ProfileDocument17 pagesRefractory & Mechanical ProfilePranabesh MallickNo ratings yet

- Demand Draft Application FormDocument1 pageDemand Draft Application FormPranabesh MallickNo ratings yet

- Site: Page 1 of 6 Client Enquiry No Type of Job Dated CountryDocument6 pagesSite: Page 1 of 6 Client Enquiry No Type of Job Dated CountryPranabesh MallickNo ratings yet

- Demand Draft Application FormDocument1 pageDemand Draft Application FormPranabesh MallickNo ratings yet

- Solar Power Plant DomesticDocument11 pagesSolar Power Plant DomesticPranabesh MallickNo ratings yet

- CCCL High Alumina BricksDocument2 pagesCCCL High Alumina BricksPranabesh MallickNo ratings yet

- HPMDocument8 pagesHPMRicardo SerranoNo ratings yet

- Honors Pre Cal Chapter 13 NotesDocument16 pagesHonors Pre Cal Chapter 13 NotesKent MillerNo ratings yet

- RTU Syllabus Robotics& FEMDocument2 pagesRTU Syllabus Robotics& FEMshailendra_236No ratings yet

- CPDA The Specification Design and Construction of Drainage and Sewerage Systems Using Vitrified Clay PipesDocument55 pagesCPDA The Specification Design and Construction of Drainage and Sewerage Systems Using Vitrified Clay PipesfaisaltmNo ratings yet

- Magnetism Revision Questions FINALDocument5 pagesMagnetism Revision Questions FINALARSHAD JAMIL100% (2)

- Kluber Paraliq Ga 351Document2 pagesKluber Paraliq Ga 351Rolando DaclanNo ratings yet

- G. ACI 360R-06 Brings Slabs On Ground Into The 21st Century - Art McKinney PDFDocument2 pagesG. ACI 360R-06 Brings Slabs On Ground Into The 21st Century - Art McKinney PDFinitbashNo ratings yet

- Itaste vv3 0Document42 pagesItaste vv3 0api-261640667No ratings yet

- A New Handybook For Electrical Contractors From AicoDocument1 pageA New Handybook For Electrical Contractors From AicoSparks Electrical Wholesalers LtdNo ratings yet

- Divided Attention AronsonDocument19 pagesDivided Attention Aronsonepiphani1100% (1)

- Ece 3313 ElectrostaticsDocument59 pagesEce 3313 ElectrostaticszahraNo ratings yet

- ML5352 Unit 3Document58 pagesML5352 Unit 3Sharan AmuramNo ratings yet

- Bhaskara II: Casey GregoryDocument16 pagesBhaskara II: Casey GregoryVinayakaNo ratings yet

- Geotechnical properties of ballast and role of geosyntheticsDocument13 pagesGeotechnical properties of ballast and role of geosyntheticsgiridharrajeshNo ratings yet

- Standard Test Method For High Speed Puncture Properties of Plastics Using Load and Displacement Sensors'Document10 pagesStandard Test Method For High Speed Puncture Properties of Plastics Using Load and Displacement Sensors'Diego CamargoNo ratings yet

- Utm PDFDocument5 pagesUtm PDFFaisal NaeemNo ratings yet

- Relating Seismic Interpretation To Reserve Resource CalculationsDocument10 pagesRelating Seismic Interpretation To Reserve Resource CalculationsYohannes LemmaNo ratings yet

- RAMAN 2024 BroucherDocument2 pagesRAMAN 2024 BroucherKaran RavalNo ratings yet

- Electrical MotorsDocument53 pagesElectrical MotorsSuda KrishnarjunaraoNo ratings yet

- Exponential Shadow Maps: BstractDocument7 pagesExponential Shadow Maps: BstractTed De LeonNo ratings yet

- Rock Failure Criteria and Strength TestsDocument23 pagesRock Failure Criteria and Strength TestsAlex Fuentes MontesinosNo ratings yet

- DRY UNIT WEIGHT - WATER CONTENT RELATIONSHIPDocument17 pagesDRY UNIT WEIGHT - WATER CONTENT RELATIONSHIPmikeNo ratings yet

- Unknown - Numerical Meth Engineering - 2019 - Qinami - Variational EigenerosionDocument22 pagesUnknown - Numerical Meth Engineering - 2019 - Qinami - Variational EigenerosionHeber Jorge ValenzuelaNo ratings yet

- Energy Efficiency in HVAC Systems Through Load CalculationDocument20 pagesEnergy Efficiency in HVAC Systems Through Load Calculationjigs4568No ratings yet

- Schroedingers Killer AppDocument445 pagesSchroedingers Killer AppasfNo ratings yet

- Topik6 MA2271 - SPDLDocument45 pagesTopik6 MA2271 - SPDLFauzia SavitriNo ratings yet

- Lesson Plan ME-102 Thermodynamics (EE)Document3 pagesLesson Plan ME-102 Thermodynamics (EE)fida khanNo ratings yet

- Novel Technology To Influence Hardness of Flexible Pu FoamsDocument16 pagesNovel Technology To Influence Hardness of Flexible Pu FoamsirwanchemNo ratings yet

- Equation of State Development and UseDocument12 pagesEquation of State Development and UseBilal AbdullahNo ratings yet

- ME2351 Notes PDFDocument204 pagesME2351 Notes PDFVenkatesh MohanNo ratings yet