Professional Documents

Culture Documents

Lab Safety Checklist for Chemicals

Uploaded by

1a2s3d4f5g6h7jOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lab Safety Checklist for Chemicals

Uploaded by

1a2s3d4f5g6h7jCopyright:

Available Formats

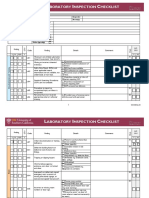

Laboratory Safety Checklist

Chemical

Building: Room Number: Date:

Area Supervisor: Area Use: Phone:

General Laboratory Safety

Facility

1. Does the area conform to the definition of a laboratory? Yes No N/A

2. Does the area have at least two exits? Yes No N/A

3. Are exits clearly marked and unobstructed? Yes No N/A

4. Are the appropriate warning signs posted near the lab entrance(s)? Yes No N/A

5. Are emergency procedures and phone numbers clearly posted? Yes No N/A

6. Are aisles unobstructed and maintained at least 36 inches wide throughout? Yes No N/A

7. Are lab benches and work area free of clutter? Yes No N/A

8. Are shelves and cabinets in good condition? Yes No N/A

9. Do shelves have seismic restraints (e.g., lips or wires)? Yes No N/A

10. Are shelves and cabinets secured to the walls? Yes No N/A

11. Is storage above eye level minimized and the items restrained from falling? Yes No N/A

12. Are first aid materials readily available? Yes No N/A

13. Are fire extinguishers readily available? Yes No N/A

14. Are safety showers/eye wash stations accessible within 10 seconds via an

Yes No N/A

unobstructed route (e.g., no closed doors)?

15. Has the safety shower been tested and documented within the past year? Yes No N/A

16. Has the eye wash station been tested, flushed, and documented at least

Yes No N/A

monthly?

17. Are smoking, eating, and drinking prohibited in the lab? Yes No N/A

18. Are refrigerators and freezers clearly labeled “Not for Storage of Food for

Yes No N/A

Human Consumption?”

19. Are refrigerators with flammables an approved type for flammables? Yes No N/A

Right-to-Know

20. Is the Hazardous Chemical Right-to-Know Poster prominently displayed in the

Yes No N/A

building?

21. Is the Hazardous Chemical Right-to-Know Notebook accessible to employees? Yes No N/A

22. Has an up-to-date inventory been maintained for all hazardous materials? Yes No N/A

23. Are SDSs maintained and readily available at all times employees are present? Yes No N/A

24. Are employees familiar with the Chemical Hygiene Plan? Yes No N/A

25. Do employees know the location of the chemical inventory, SDSs, and related

Yes No N/A

reference material?

26. Are employees currently trained in accordance with RTK and Laboratory

Yes No N/A

Standard regulations and documented?

27. Are employees familiar with the information and training requirements of

Yes No N/A

RTK?

28. Are employees familiar with the physical and health hazards of chemicals in

Yes No N/A

the work area?

Page 1 of 3 Updated May 2016

Laboratory Safety Checklist

Chemical

29. Are employees able to describe how to detect the presence or release of

Yes No N/A

hazardous materials?

30. Do employees know how to protect themselves and others from the effects of

Yes No N/A

hazardous materials?

31. Are all storage containers clearly labeled in English with chemical names, CAS

Yes No N/A

Numbers, percent composition (for mixtures), and hazard warnings?

Personal Protection

32. Has a workplace hazard assessment and certification been completed? Yes No N/A

33. Is a fume hood available? Yes No N/A

34. Is the fume hood free of clutter? Yes No N/A

35. Has the fume hood been inspected within the last 12 months and capable of

Yes No N/A

drawing at least 100 LFPM (or more if appropriate)?

36. Are fume hoods equipped with air flow indicators? Yes No N/A

37. Are fume hoods labeled “Not for Perchloric Acid” unless designed as a

Yes No N/A

dedicated perchloric acid hood?

38. Are the appropriate type goggles and face shields worn? Yes No N/A

39. Are lab coats of appropriate material available and worn? Yes No N/A

40. Are appropriate gloves available and worn? Yes No N/A

41. Is appropriate respiratory protection available? Yes No N/A

42. Are respirators cleaned, stored, and inspected regularly? Yes No N/A

43. Is respirator training done and documented along with fit test and medical

Yes No N/A

evaluation of employees?

44. Is mechanical pipetting used – no mouth suction? Yes No N/A

45. Do personnel wear shoes that fully cover feet and full length trousers to

Yes No N/A

protect legs?

46. Is long hair confined and inappropriate jewelry removed? Yes No N/A

Compressed Gases

47. Are cylinders stored upright and properly secured at all times? Yes No N/A

48. Is the storage area dry, cool, and well ventilated? Yes No N/A

49. Are caps properly secured when cylinders are not in use? Yes No N/A

50. Are proper regulators for type gas ALWAYS used and pressure bled when not

Yes No N/A

in use?

51. Are cylinders in good condition and clearly marked? Yes No N/A

52. Are flammables stored separately from oxidizers, and are toxics in a secure

Yes No N/A

area?

53. Are cylinders of flammable gases stored in ventilated enclosures? Yes No N/A

54. Are cylinders moved on cylinder trucks with regulators removed and caps

Yes No N/A

secured?

55. Are cylinders of gases with NFPA health hazard 3 or 4 stored in continuously

Yes No N/A

ventilated enclosures?

56. Are cylinders of gases with NFPA health hazard 2 with no physiological

Yes No N/A

warning properties stored in continuously ventilated enclosures?

Page 2 of 3 Updated May 2016

Laboratory Safety Checklist

Chemical

Chemicals

57. Are flammable liquids stored in OSHA/NFPA approved cabinets if more than 10

gallons without approved safety containers? Yes No N/A

58. Are ignition sources avoided when using/storing flammables? Yes No N/A

59. Are containers segregated by hazard class – flammables away from oxidizers,

acids separate from bases, incompatible acids separated (e.g., nitric acid not

with sulfuric or acetic acid), etc.? Yes No N/A

60. Are corrosives stored in acid cabinets or other appropriate cabinets? Yes No N/A

61. Are chemicals stored at eye level and below? Yes No N/A

62. Are chemicals stored away from light and heat sources? Yes No N/A

63. Are chemical containers in good condition, with labels intact (e.g., metal cans

free of rust)? Yes No N/A

64. Are containers labeled with receipt date and date opened? Yes No N/A

65. Are containers closed unless actively adding/removing contents? Yes No N/A

66. Are peroxide formers properly labeled and inventory tracked? Yes No N/A

67. Is picric acid sufficiently wet? Yes No N/A

68. Are large containers (4L or greater) stored near the floor? Yes No N/A

69. Are bottle carriers utilized when transporting hazardous chemicals between

work areas? Yes No N/A

70. Are proper signs placed to delineate designated areas where HTOX, REP, and

CAR chemicals are used? Yes No N/A

71. Are designated areas properly cleaned and decontaminated? Yes No N/A

72. Is the spill procedure prominently posted and information filled in by laboratory

personnel? Yes No N/A

73. Are spill control materials readily available and personnel familiar with how to

use them? Yes No N/A

Waste Management

74. Is hazardous waste properly labeled with the words “Hazardous Waste,” a list

of contents, and accumulation start date? Yes No N/A

75. Is departmental hazardous waste coordinator informed of waste for disposal? Yes No N/A

76. Is the departmental waste reduction plan adopted and in effect? Yes No N/A

77. Is a chemical inventory management/ordering system in place and checked

before ordering new chemicals? Yes No N/A

78. Does the department have a system to determine hazardous waste generation

rate and quantity accumulated on site? Yes No N/A

79. Is a system in place to notify EH&S of acute hazardous waste (“P listed” waste)? Yes No N/A

80. Is a satellite accumulation area near the point of generation? Yes No N/A

81. Are waste containers tightly closed unless actively adding or removing waste? Yes No N/A

82. Does the waste storage area have communication equipment readily available? Yes No N/A

83. Are waste containers inspected weekly and an inspection log maintained? Yes No N/A

Page 3 of 3 Updated May 2016

You might also like

- Risk Assessment for Human Metal Exposures: Mode of Action and Kinetic ApproachesFrom EverandRisk Assessment for Human Metal Exposures: Mode of Action and Kinetic ApproachesNo ratings yet

- Weekly Hazardous Waste ChecklistDocument1 pageWeekly Hazardous Waste ChecklistOM SUTARNo ratings yet

- Hazardous Material Weekly InspectionDocument1 pageHazardous Material Weekly InspectionYexiong YIALENGNo ratings yet

- Lab Self Inspection Checklist PDFDocument11 pagesLab Self Inspection Checklist PDFarif_fatur324872No ratings yet

- Laboratory Inspection Checklist Form Hsse World: SN Observations Recommendation (S) By: StatusDocument4 pagesLaboratory Inspection Checklist Form Hsse World: SN Observations Recommendation (S) By: StatusMyolwinooNo ratings yet

- Hazardouas Chemicals Safe Work InstructionDocument3 pagesHazardouas Chemicals Safe Work Instructiontelteguh01No ratings yet

- SECTION A: DESCRIPTION OF PROBLEM (To Be Completed by Initiator)Document4 pagesSECTION A: DESCRIPTION OF PROBLEM (To Be Completed by Initiator)Koshal RaiNo ratings yet

- Assessment Checklist EnvironmentalDocument3 pagesAssessment Checklist EnvironmentalSanket Patil100% (1)

- GAS-HSE-GEN-002 Rev 0 Fire Drill Checklist RecordDocument2 pagesGAS-HSE-GEN-002 Rev 0 Fire Drill Checklist RecordRafeeq Ur RahmanNo ratings yet

- Lab Safety Inspection Checklist GuideDocument5 pagesLab Safety Inspection Checklist GuideRichard.nlNo ratings yet

- Plant Checklist PDFDocument2 pagesPlant Checklist PDFmj santosNo ratings yet

- Hazard Communication Program 1Document4 pagesHazard Communication Program 1myo lwinNo ratings yet

- Occupational Health and Safety Management System (OSHAS 18001)Document8 pagesOccupational Health and Safety Management System (OSHAS 18001)rslapena100% (1)

- Compressed Gases ChecklistDocument3 pagesCompressed Gases ChecklistImam FirdausNo ratings yet

- F.e.& Scba InspectionDocument5 pagesF.e.& Scba InspectionAviects Avie JaroNo ratings yet

- Chemical Storeroom ChecklistDocument5 pagesChemical Storeroom ChecklistEamonn Mc Conway100% (1)

- Color CodingDocument3 pagesColor CodingIwan SetiawanNo ratings yet

- Chemical Storage Color CodesDocument6 pagesChemical Storage Color CodesMohan PrasadNo ratings yet

- GPCB SOP For De-Contamination FacilityDocument9 pagesGPCB SOP For De-Contamination FacilityEHS HalolNo ratings yet

- Laboratory Emergency PlanDocument35 pagesLaboratory Emergency PlanMß WæžəəřNo ratings yet

- Utico FZC Work Instruction Manual Drilling MachineDocument2 pagesUtico FZC Work Instruction Manual Drilling MachineNAVANEETHNo ratings yet

- Lead Awareness Toolbox TalkDocument2 pagesLead Awareness Toolbox Talkarunengg100% (1)

- HSE MS Training Feb 2019Document17 pagesHSE MS Training Feb 2019Musalim Shaikh100% (1)

- 4 First Aid Box Inventory (White) 2020Document1 page4 First Aid Box Inventory (White) 2020lez2No ratings yet

- Machinery Safety CheckDocument3 pagesMachinery Safety CheckYuva samaj sewa TrustNo ratings yet

- Req Trial Audit WW 2009 PDFDocument1 pageReq Trial Audit WW 2009 PDFZedNo ratings yet

- How To Conduct An Incident InvestigationDocument4 pagesHow To Conduct An Incident Investigationkenoly123No ratings yet

- Safety Behavior and Safety at Work Program DaraDocument3 pagesSafety Behavior and Safety at Work Program DaraSayed Saad ShehataNo ratings yet

- Chemical Storage Checklist: Risk, Labels, ControlsDocument4 pagesChemical Storage Checklist: Risk, Labels, Controlsterzici13No ratings yet

- Checklist Biosafety Level - 2Document5 pagesChecklist Biosafety Level - 2Vincent Reyes100% (1)

- Hazardous Materials and Chemicals: Standard Operating ProceduresDocument11 pagesHazardous Materials and Chemicals: Standard Operating ProceduresLuis Adrián ElguézabalNo ratings yet

- Respirator Inspection ChecklistDocument1 pageRespirator Inspection ChecklistLalit TomarNo ratings yet

- Waste Segregation and ManagementDocument6 pagesWaste Segregation and ManagementJeswinNo ratings yet

- WINEWISE-Water Management ChecklistDocument3 pagesWINEWISE-Water Management ChecklistCCRNo ratings yet

- QEHS ManualDocument100 pagesQEHS ManualRob WillestoneNo ratings yet

- VINDAIR Construction Safety CHECK LISTDocument3 pagesVINDAIR Construction Safety CHECK LISTRamakrishna AgumbeNo ratings yet

- Example-Self Safety Inspection Checklist - QADocument3 pagesExample-Self Safety Inspection Checklist - QAHehok Hehe100% (1)

- 01 Chemical Handling Procedure PDFDocument6 pages01 Chemical Handling Procedure PDFAmol Kashid100% (1)

- Laboratory Safety ChecklistDocument11 pagesLaboratory Safety Checklistarif_fatur324872100% (1)

- MG-HSEQ-Q-P-0268 Rev A1 Corporate Procedure For Visual InspectionDocument11 pagesMG-HSEQ-Q-P-0268 Rev A1 Corporate Procedure For Visual InspectionAbdelrahman Hosny100% (1)

- Lightning Brochure18Document2 pagesLightning Brochure18Matt GunnNo ratings yet

- Radiator Cleaning of Instrument Air Compressor-3: Lock Out Tagout OrderDocument1 pageRadiator Cleaning of Instrument Air Compressor-3: Lock Out Tagout OrderZeeshan RehmanNo ratings yet

- NS Toolbox Sdftalk 006 Welding Consumable Control and TracebilityDocument1 pageNS Toolbox Sdftalk 006 Welding Consumable Control and TracebilityNeil SoansNo ratings yet

- Tube Filling and Bottle Filling Inspection ChecklistDocument25 pagesTube Filling and Bottle Filling Inspection ChecklistSudhakar JainNo ratings yet

- Lab Audit FormDocument6 pagesLab Audit Formmahesh90600No ratings yet

- Cutting Machine Check Sheet: Machine Set No.: Department: Contractor Name: Last Inspection Date: Inspection DateDocument1 pageCutting Machine Check Sheet: Machine Set No.: Department: Contractor Name: Last Inspection Date: Inspection Datepartha100% (1)

- Questions 2377 Inspection and Testing of Electrical Equipment Examination 1Document5 pagesQuestions 2377 Inspection and Testing of Electrical Equipment Examination 1Faisal NaseemNo ratings yet

- General Lab Inspection Checklist 2016Document10 pagesGeneral Lab Inspection Checklist 2016Tanveer AzizNo ratings yet

- QuickLabel GHS Labeling White PaperDocument15 pagesQuickLabel GHS Labeling White Papermyxomatosis33No ratings yet

- Tank Cleaning RequirementsDocument9 pagesTank Cleaning RequirementsRuddy GunawanNo ratings yet

- HSE Training ProgramDocument5 pagesHSE Training Programbotahra0% (1)

- Waste Monitoring Flow Chart PicDocument1 pageWaste Monitoring Flow Chart PicDilip Kumar KNo ratings yet

- Unitech Metro - SAFE WORK METHOD STATEMENT - PAINTINGDocument4 pagesUnitech Metro - SAFE WORK METHOD STATEMENT - PAINTING'David TeeNo ratings yet

- Safety Data SheetDocument6 pagesSafety Data SheetWici WiciNo ratings yet

- Chemical Management ProcedureDocument9 pagesChemical Management ProcedureCyril AngkiNo ratings yet

- Compressed Gas Cylinder SafetyDocument36 pagesCompressed Gas Cylinder Safetyelvis hidalgoNo ratings yet

- 1-Mock Drill Report of Aegis Gas On 16-01-2018Document3 pages1-Mock Drill Report of Aegis Gas On 16-01-2018Parth PatelNo ratings yet

- Humade Msds MaDocument5 pagesHumade Msds MadchyNo ratings yet

- Daily Observation SheetDocument2 pagesDaily Observation Sheetarun100% (2)

- Health, Environment and Safety HandbookDocument50 pagesHealth, Environment and Safety HandbooklordlucasenNo ratings yet

- Update ResumeDocument3 pagesUpdate ResumeSubbareddy NvNo ratings yet

- The Definition of WorkDocument2 pagesThe Definition of WorkCarlton GrantNo ratings yet

- KK 080711 HancockDocument1 pageKK 080711 HancockkatehasablogNo ratings yet

- Model Question Papers SolutionDocument39 pagesModel Question Papers SolutionVinayaka Gombi100% (2)

- Smoothed Bootstrap Nelson-Siegel Revisited June 2010Document38 pagesSmoothed Bootstrap Nelson-Siegel Revisited June 2010Jaime MaihuireNo ratings yet

- Polycab PVCDocument32 pagesPolycab PVCshilpidangiNo ratings yet

- Library ClassificationDocument10 pagesLibrary ClassificationKakeembo NasiifuNo ratings yet

- Industrial Attachment ReportDocument82 pagesIndustrial Attachment ReportNiyibizi Promesse100% (8)

- Weld Cleaning MethodsDocument7 pagesWeld Cleaning MethodsTrần Thùy LinhNo ratings yet

- Isoefficiency Function A Scalability Metric For PaDocument20 pagesIsoefficiency Function A Scalability Metric For PaDasha PoluninaNo ratings yet

- Teltonika Networks CatalogueDocument40 pagesTeltonika Networks CatalogueazizNo ratings yet

- Guide To Low Voltage Busbar Trunking Systems-BeamaDocument20 pagesGuide To Low Voltage Busbar Trunking Systems-BeamaGhayath Omer100% (1)

- Unit 9 The Post Office: Grammar: Omission of Relative PronounsDocument5 pagesUnit 9 The Post Office: Grammar: Omission of Relative PronounsTrung Lê TríNo ratings yet

- Isla, Julie Anne - Midterm Exam - RM (25 April 2021)Document7 pagesIsla, Julie Anne - Midterm Exam - RM (25 April 2021)Julie anne IslaNo ratings yet

- Vitamin D For MS PatientsDocument1 pageVitamin D For MS PatientsDimitrios PapadimitriouNo ratings yet

- A Day With Maria Becerra (1) - 2Document2 pagesA Day With Maria Becerra (1) - 2FelipeNo ratings yet

- Core Java AdvancedDocument103 pagesCore Java AdvancedRavi Chandra Reddy MuliNo ratings yet

- Macquarie Capital Cover LetterDocument1 pageMacquarie Capital Cover LetterDylan AdrianNo ratings yet

- (332-345) IE - ElectiveDocument14 pages(332-345) IE - Electivegangadharan tharumarNo ratings yet

- bài tập ôn MA1Document34 pagesbài tập ôn MA1Thái DươngNo ratings yet

- Behaviour of Rectangular Travelling Wave (Unit Step Function at Transition Points-Typical CasesDocument1 pageBehaviour of Rectangular Travelling Wave (Unit Step Function at Transition Points-Typical CasesAngela VaughnNo ratings yet

- đề 3Document12 pagesđề 3Vi CầmNo ratings yet

- Assessment of Radical Innovation and Significant Relationship of Metromile Car Insurance CompanyDocument10 pagesAssessment of Radical Innovation and Significant Relationship of Metromile Car Insurance CompanyBidisha BhoumickNo ratings yet

- GDRatingDocument13 pagesGDRatingdgzaquinojcNo ratings yet

- Med - Leaf - Full ReportDocument31 pagesMed - Leaf - Full ReportAdithya s kNo ratings yet

- Jig and Fixture Design AnnaDocument22 pagesJig and Fixture Design AnnaZemariyam BizuayehuNo ratings yet

- Dual Band DAB Pocket Radio: User Manual Manuel D'utilisation Manual Del Usuario Benutzerhandbuch GebruikershandleidingDocument21 pagesDual Band DAB Pocket Radio: User Manual Manuel D'utilisation Manual Del Usuario Benutzerhandbuch Gebruikershandleidingminerva_manNo ratings yet

- Investigating and EvaluatingDocument12 pagesInvestigating and EvaluatingMuhammad AsifNo ratings yet

- Vapocresolene Fast FactsDocument2 pagesVapocresolene Fast Factsapi-275817812No ratings yet

- ConnercasememoDocument12 pagesConnercasememoapi-339018690No ratings yet