Professional Documents

Culture Documents

Cummins ISX CM570 Fuel - English (Auto-Generated)

Uploaded by

abotaleb0 ratings0% found this document useful (0 votes)

410 views3 pagesCummins cm570

Original Title

Cummins ISX CM570 Fuel - English (Auto-generated) (1)

Copyright

© © All Rights Reserved

Available Formats

TXT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCummins cm570

Copyright:

© All Rights Reserved

Available Formats

Download as TXT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

410 views3 pagesCummins ISX CM570 Fuel - English (Auto-Generated)

Uploaded by

abotalebCummins cm570

Copyright:

© All Rights Reserved

Available Formats

Download as TXT, PDF, TXT or read online from Scribd

You are on page 1of 3

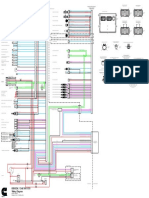

to fill the system with fuel and purge

air from the IFS M the ECM at Keyon

turns on the priming pump for 2 minutes

during this 2-minute period the priming

pump draws fuel from the tank to the IFS

M Inlet and Inlet screen this 140 micron

mesh screen prevents debris from

entering the lift pump

the fuel from the inlet screen flows

through the priming pump and fills the

suction side fuel filter fuel enters the

top of the filter and flows down the

sides of the filter before moving up the

center of the filter and flowing through

the anti drain back valve at the top of

the filter outlet

the fuel then flows up the right side of

the eye FSM to the gear pump Inlet

any air that was trapped in the

low-pressure side of the I FSM is

rounded from the top of the I FSM

through a passage in the I FSM mounting

gasket to the air bleed check valve and

on to the I FSM drain

the priming pump will shut down after

the two-minute period has passed the

engine is now ready to be started during

normal operation the gear pump pulls the

fuel from the tank through the inlet

screen in the inlet check valve that

bypasses the priming pump

the fuel then flows up the right side of

the eye FSM to the gear pump and enters

the top of the gears all the fuel at

this point is under a vacuum

the fuel travels around the gears and

the gear pump and is forced out of the

gears at the bottom is the gear teeth

mesh pressure begins to develop in the

system this pressure continues to

increase with engine speed

as the fuel moves out of the gear pump

it passes the 320 psi regulator this

regulator dumps to drain when excessive

pressure is developed in the system

fuel from the outlet of the gear pump is

routed down and over to the center of

the I FSM to the fuel shutoff valve when

energized by the ECM the shutoff valve

opens and fuel flows through the valve

to the actuator feed rail

the fuel out of the shut-off valve flows

into the center of the actuator feed

rail and splits to flow to the front and

rear banks of timing and metering

actuators

the 250 psi regulator is located below

the shutoff valve and regulates the

actuator feed rail pressure when the

rail pressure in the system exceeds 250

psi the regulator dumps the fuel back to

the inlet of the gear pump

any air trapped in the rail pressure

side of the system is routed with the

actuator feed rail decay flow through

the 8,000 inch orifice and to drain

You might also like

- QSM11 Engine Fault Code GuideDocument5 pagesQSM11 Engine Fault Code GuideTaha RdmanNo ratings yet

- MJB639 L4aDocument4 pagesMJB639 L4aAshfaq Ahmed Khawer bhattiNo ratings yet

- TP 6437Document34 pagesTP 6437Roberto Sanchez ZapataNo ratings yet

- C11 C13 WiringDocument14 pagesC11 C13 Wiringbenge henriqueNo ratings yet

- Diagnostic Trouble Codes (DTC) : DTC P0712 Transmission Fluid Temperature Sensor Circuit Low Input (High Temperature)Document4 pagesDiagnostic Trouble Codes (DTC) : DTC P0712 Transmission Fluid Temperature Sensor Circuit Low Input (High Temperature)luis eduardo corzo enriquezNo ratings yet

- Emcp Ii - O&mDocument12 pagesEmcp Ii - O&mJorge Luis Tanaka ConchaNo ratings yet

- DC13072ADocument5 pagesDC13072AEdsonNo ratings yet

- Engine Control (MR) - Information Exchange With Drive Control (FR)Document5 pagesEngine Control (MR) - Information Exchange With Drive Control (FR)Bogar PinedaNo ratings yet

- Cat c15 Cylinder Head InstallationDocument7 pagesCat c15 Cylinder Head InstallationMUHSIN MTNo ratings yet

- Engine Fault Code GuideDocument20 pagesEngine Fault Code GuideEldin RizvićNo ratings yet

- ECU List 7 9 0 New Features ListDocument66 pagesECU List 7 9 0 New Features ListDavoud AlmasiNo ratings yet

- 1300 Series User HandbookDocument44 pages1300 Series User Handbookmohammed mostafaNo ratings yet

- بعض رموز الفولفوDocument26 pagesبعض رموز الفولفومحمد يونس100% (3)

- Manual: For Diesel EngineDocument112 pagesManual: For Diesel EngineMarinel ILIE0% (1)

- Fpt-Cr16-Te1w MGFPT001Document3 pagesFpt-Cr16-Te1w MGFPT001Marcos Vinicio StizzioliNo ratings yet

- EDC7 MAN Fault Codes List PDFDocument19 pagesEDC7 MAN Fault Codes List PDFДмитрий АндрущенкоNo ratings yet

- Manual Partes Onan10hdkcgDocument67 pagesManual Partes Onan10hdkcgjhayber100% (1)

- Cummins: Fault Code: 376 PID: P1691Document2 pagesCummins: Fault Code: 376 PID: P1691Enrrique LaraNo ratings yet

- General: Technical Data TAD721GEDocument8 pagesGeneral: Technical Data TAD721GEbaljeetjatNo ratings yet

- Egcp 1Document4 pagesEgcp 1JorgeNo ratings yet

- Codigo 73 S227 Fmi2Document14 pagesCodigo 73 S227 Fmi2WalterNo ratings yet

- Timing Calibration Harness AssemblyDocument5 pagesTiming Calibration Harness Assemblyflordeliz jimenez rodriguezNo ratings yet

- Cummins Confidential: This Document (And The Information Shown Thereon) Is CONFIDENTIAL AND PROPRIETARYDocument1 pageCummins Confidential: This Document (And The Information Shown Thereon) Is CONFIDENTIAL AND PROPRIETARYJulio LeijaNo ratings yet

- Bosch Edc17cv54 Irom Tc1767 AllbrandDocument5 pagesBosch Edc17cv54 Irom Tc1767 Allbrandsharya775No ratings yet

- Fault Code: 143 Oil Pressure - Engine Protection: Codes Reason EffectDocument3 pagesFault Code: 143 Oil Pressure - Engine Protection: Codes Reason EffectDung PhamNo ratings yet

- R448 Manual From Macfarlane GeneratorsDocument14 pagesR448 Manual From Macfarlane Generatorsabuzer1981No ratings yet

- QSK19 CM850 MCRS Wiring DiagramDocument11 pagesQSK19 CM850 MCRS Wiring DiagramMussardNo ratings yet

- EDC MS5 For Injection Pump: Issue 3Document17 pagesEDC MS5 For Injection Pump: Issue 3Musharraf KhanNo ratings yet

- FAULT CODE 559 - Injector Metering Rail 1 Pressure - Data Valid But Below Normal Operating Range - Moderately Severe LevelDocument8 pagesFAULT CODE 559 - Injector Metering Rail 1 Pressure - Data Valid But Below Normal Operating Range - Moderately Severe LevelDylan tejadaNo ratings yet

- Field Service Tips: Fault tracing on D6B enginesDocument3 pagesField Service Tips: Fault tracing on D6B enginesyazeed naibanNo ratings yet

- 8.edc 17 9 Aug 2016Document34 pages8.edc 17 9 Aug 2016iqbal husseinNo ratings yet

- GPM 22Document2 pagesGPM 22Khalid SaddikNo ratings yet

- Connecting an engine control moduleDocument1 pageConnecting an engine control moduleOmar Hernández100% (1)

- 043 Man TruckDocument4 pages043 Man TruckFilipposNo ratings yet

- EAM127-24 - Interface Com S6 Scania PDFDocument2 pagesEAM127-24 - Interface Com S6 Scania PDFthyagoenergNo ratings yet

- 06-fc1682 Aftertreatment Diesel Exhaust Fluid Dosing Control Unit Input Lines - Condition Exists PDFDocument4 pages06-fc1682 Aftertreatment Diesel Exhaust Fluid Dosing Control Unit Input Lines - Condition Exists PDFSuryadiNo ratings yet

- Codigos Celec PlusDocument3 pagesCodigos Celec PlusChester PalermoNo ratings yet

- Perkins 2306c-E14tag1Document2 pagesPerkins 2306c-E14tag1Patricia J Ángeles100% (2)

- 682-fc 2639Document3 pages682-fc 2639Otniel BetancoNo ratings yet

- TDC - EDC 7" FaultcodesDocument268 pagesTDC - EDC 7" FaultcodesJason KozminskaNo ratings yet

- Fault Code: 2771 - SPN: 3226 - FMI: 9: ISX15 CM2250Document16 pagesFault Code: 2771 - SPN: 3226 - FMI: 9: ISX15 CM2250EnriqueNo ratings yet

- 3000 and 4000 Product Families Troubleshooting Manual-Allison 4 Generation ControlsDocument6 pages3000 and 4000 Product Families Troubleshooting Manual-Allison 4 Generation ControlsElectroventica ElectroventicaNo ratings yet

- Tad 1641 GeDocument2 pagesTad 1641 GeGiangDoNo ratings yet

- EPM72 Engine Protection ModuleDocument8 pagesEPM72 Engine Protection Moduleandy habibiNo ratings yet

- Service Mode: Operação Dos SistemasDocument4 pagesService Mode: Operação Dos Sistemaswagner_guimarães_1No ratings yet

- Ajuste Valvula 3176CDocument3 pagesAjuste Valvula 3176CAdelio RamirezNo ratings yet

- Actros .Rve..Alternatorinstallation Instructions 18siDocument2 pagesActros .Rve..Alternatorinstallation Instructions 18siVasile SilvioNo ratings yet

- Perkins Service Letter SL001E1Document4 pagesPerkins Service Letter SL001E1Jacques Van NiekerkNo ratings yet

- ADocument17 pagesAWillian CristianoNo ratings yet

- Coduri Man TGXDocument31 pagesCoduri Man TGXMocanu LaurentiuNo ratings yet

- Project: Place of InstallationDocument34 pagesProject: Place of InstallationDaniel MuratallaNo ratings yet

- List of Parts and Connectors for Industrial VehicleDocument11 pagesList of Parts and Connectors for Industrial VehicleonrabiNo ratings yet

- Delphi IMVDocument1 pageDelphi IMVmdataguy100% (1)

- S08210Document610 pagesS08210jorgeeduardo1000100% (1)

- Complete List of Cummins Celect Fault CodesDocument3 pagesComplete List of Cummins Celect Fault CodesEduardo TorresNo ratings yet

- Accelerator Pedal Position Sensor/IVS Switch (APS/IVS)Document2 pagesAccelerator Pedal Position Sensor/IVS Switch (APS/IVS)Franz JW MontezaNo ratings yet

- Below Is An Overview of The Fuel System Intake OperationDocument8 pagesBelow Is An Overview of The Fuel System Intake OperationchigauNo ratings yet

- DieselDocument9 pagesDieselvandanaharikumar100% (1)

- Komat'Su - HPI Fuel SystemDocument76 pagesKomat'Su - HPI Fuel SystemKarthik Rao100% (2)

- MODERN FUEL SUPPLY SYSTEMS IN PETROL ENGINES (Original)Document52 pagesMODERN FUEL SUPPLY SYSTEMS IN PETROL ENGINES (Original)Balaji Auto garageNo ratings yet

- Dse7310/20 MKII: Auto Start & Auto Mains Failure Control ModulesDocument2 pagesDse7310/20 MKII: Auto Start & Auto Mains Failure Control ModulesSulaiman HasanNo ratings yet

- User Guide PROMARK T-1000 ENGDocument164 pagesUser Guide PROMARK T-1000 ENGabotalebNo ratings yet

- Datasheet PODocument2 pagesDatasheet POabotalebNo ratings yet

- Elemax Sh15D & Sht15D Models SH15D SHT15D SHT17D Type GeneratorDocument2 pagesElemax Sh15D & Sht15D Models SH15D SHT15D SHT17D Type GeneratorabotalebNo ratings yet

- InteliLite AMF25!1!8 0 Global GuideDocument761 pagesInteliLite AMF25!1!8 0 Global GuideGeorge BarsoumNo ratings yet

- ADEC™ - Electronics Documentation For Electronic Engine Control Unit ECU-7 - 2007 - MTU® PDFDocument246 pagesADEC™ - Electronics Documentation For Electronic Engine Control Unit ECU-7 - 2007 - MTU® PDFpevare90% (30)

- Compact NS630b to 1600 A User ManualDocument41 pagesCompact NS630b to 1600 A User ManualMuati Kapata Júnior KaícaNo ratings yet

- 300 DataDocument4 pages300 DataHoang QuanNo ratings yet

- Dkg-547 Automatic Mains Failure Unit With J1939 Interface: DescriptionDocument2 pagesDkg-547 Automatic Mains Failure Unit With J1939 Interface: DescriptionabotalebNo ratings yet

- Compact NS630b to 1600 A User ManualDocument41 pagesCompact NS630b to 1600 A User ManualMuati Kapata Júnior KaícaNo ratings yet

- Option H5, H7, H12 and H13 MTU MDEC, ADEC, J1939 CANbus Engine Interface 4189340674 UK PDFDocument108 pagesOption H5, H7, H12 and H13 MTU MDEC, ADEC, J1939 CANbus Engine Interface 4189340674 UK PDFmahmod alrousanNo ratings yet

- DKG-227 Manual and Remote Start Unit GuideDocument24 pagesDKG-227 Manual and Remote Start Unit GuideabotalebNo ratings yet

- PDFDocument248 pagesPDFAdam SlametNo ratings yet

- Option H5, H7, H12 and H13 MTU MDEC, ADEC, J1939 CANbus Engine Interface 4189340674 UK PDFDocument108 pagesOption H5, H7, H12 and H13 MTU MDEC, ADEC, J1939 CANbus Engine Interface 4189340674 UK PDFmahmod alrousanNo ratings yet

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- Fundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsFrom EverandFundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsNo ratings yet

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- RV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!From EverandRV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!No ratings yet

- Implementing an Integrated Management System (IMS): The strategic approachFrom EverandImplementing an Integrated Management System (IMS): The strategic approachRating: 5 out of 5 stars5/5 (2)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentFrom EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentRating: 4.5 out of 5 stars4.5/5 (21)

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyFrom EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyNo ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Industrial Waste Treatment HandbookFrom EverandIndustrial Waste Treatment HandbookRating: 5 out of 5 stars5/5 (1)

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- Grid-Scale Energy Storage Systems and ApplicationsFrom EverandGrid-Scale Energy Storage Systems and ApplicationsFu-Bao WuNo ratings yet

- The Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeFrom EverandThe Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeRating: 4 out of 5 stars4/5 (130)

- Solar Electricity Basics: Powering Your Home or Office with Solar EnergyFrom EverandSolar Electricity Basics: Powering Your Home or Office with Solar EnergyRating: 5 out of 5 stars5/5 (3)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Handbook on Battery Energy Storage SystemFrom EverandHandbook on Battery Energy Storage SystemRating: 4.5 out of 5 stars4.5/5 (2)

- Power Quality in Power Systems and Electrical MachinesFrom EverandPower Quality in Power Systems and Electrical MachinesRating: 4.5 out of 5 stars4.5/5 (11)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Biogas Production: Pretreatment Methods in Anaerobic DigestionFrom EverandBiogas Production: Pretreatment Methods in Anaerobic DigestionNo ratings yet