Professional Documents

Culture Documents

Compliance of lateral pile load test procedure

Uploaded by

Kishore Kumar0 ratings0% found this document useful (0 votes)

6 views6 pagesCompliance

Original Title

Compliance_work Procedure for Lateral Pile Load Test-18.09.19

Copyright

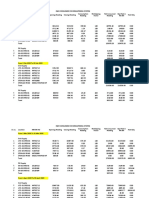

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCompliance

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views6 pagesCompliance of lateral pile load test procedure

Uploaded by

Kishore KumarCompliance

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 6

Compliance of Comments on work procedure for lateral pile load test

DOCUMENT NO. : GHAVP/2019/N12TPLCM100.6

DOCUMENT TITLE:Work procedure for lateral pile load test

S.No. NPCIL Comments TPL- Comments TPL-Compliance on

Compliance 18/09/2019

on

05/09/2019

1. Section 4, point Corrected

number 5: Correct

abbreviation LVDT is

linear variable

differential

transducers. The same

is to be corrected in the

report

2. Page no 4 of 10_Figure- Removed

1b: Arrangement type

B of instruments are

not used in the latera

pile as per drawing

(GHAVP-

1&2/21210/2001/DD)

and delete the figure.

3. Section 6: Anchor pile Corrected

numbering system

shall be ascending

order to avoid

confusion of

numbering system of

anchor pile.

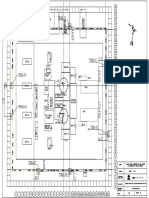

4. Page-5 of 10_Figure-3: Sketch

Projected length of the modified as

test pile above the per the

ground level is 600mm. details.

Width of girder

(vertical dimension)

shall be restricted to

maximum 750mm to

avoid eccentricity in

load transfer

arrangement.

5. Figure-3: Suitable Will be

sketches shall be complied

included showing the after getting

location of supports for the vendor

datum bars for dial details.

gauges and LVDTs for

lateral load test.

6. Include in Cl No-7.2: Added Criteria of 45 Noted.

degrees should be

Datum bars shall be

follow as per

placed with its sketch.(given in

code)

supports placed at 3D

(D- diameter of pile)

away from the edge of

test pile on either side.

7. One dial gauge or LVDT Noted and Couldn’t find at any Noted and Added.

shall be suitably placed corrected. clause?

on each reaction pile to

measure the

displacement of

reaction pile as per IS

code.

8. Please add in Sec -7.2 Added

that readings of the

strain gauges shall be

recorded just

before start of test, just

after and 12hrs after

completion of test in

addition to the

readings during the

test at all load steps.

9. Cl No-7.3: The Load Steps Mention the time Noted and added.

percentage of lateral &Un- and load steps in

load incremental steps Loading the unloading step.

(loading & unloading Steps

steps) shall be same as attached in Include

per validation pile procedure in load/unload step

tests. The loading steps line with in the form of table

should be attached in load steps along with

the procedure. delete for 1200mm percentage of

Cl No-7.3: Bullet no- dia pile. estimated ultimate

1(a) load as per

validation pile load

test and not as per

1200 mm dia piles.

Review Cl 7.3 as per

above

observations.

10. Cl No-7.3: Bullet No-2: Noted and Please clarify the Please refer IS 2911 part-

Give the distance corrected. no. of dial gauge 4 (2013) of Clause 8.3 for

between two dial and LVDT. As per the details of dial gauges.

gauges, which are kept code min 2 dial

horizontally one above gauge if the dial

the other on the test gauge are not in the

pile. axis of jack. And

same shall be

verified by LVDT.

11. Indicate Noted and incorporated.

locations/positions

of LVDTs and dial

gauges at the back

of test pile in

figure-4.

12. At CL 9.0 : Noted and added.

Update the

relevant paragraph

as follows:

“LVDTs and load

cell data shall be

stored/recorded at

5 min interval. Dial

gauge and pressure

gauge data shall be

recorded at 15 min

interval.”

13. Dial gauge is not Noted and incorporated.

mention in the

plant and

equipments

section.

14. For the rate of Noted and mentioned in

deflection, mention point-5 of section-9

the time interval in

which

displacement is

measured. Every

10min or 15 min

and what is min.

time for one load

steps

15. Movement of Noted and added in the

Anchor pile during section-11

the testing shall be

measured by

coordinate if

required by total

station

16. Clarify the Loading and unloading

unloading same as table added in this

loading revised report

You might also like

- DWG Ti 2198 A - 008 - 01Document52 pagesDWG Ti 2198 A - 008 - 01fadilNo ratings yet

- Power Systems-On-Chip: Practical Aspects of DesignFrom EverandPower Systems-On-Chip: Practical Aspects of DesignBruno AllardNo ratings yet

- Fluke 77Document24 pagesFluke 77Jon LewisNo ratings yet

- Embedding DeembeddingDocument16 pagesEmbedding DeembeddingManeesh PandeyNo ratings yet

- Pressure ProcedureDocument4 pagesPressure ProcedureCitco IdfcNo ratings yet

- CNS Ground Locator Procedure SummaryDocument9 pagesCNS Ground Locator Procedure Summaryalonnsoo01No ratings yet

- Brookfield Manual PDFDocument36 pagesBrookfield Manual PDFAnonymous T32l1RNo ratings yet

- WI-NG-6460-002-102 Post Energization In-Service Test Rev01Document12 pagesWI-NG-6460-002-102 Post Energization In-Service Test Rev01Mohamed NasrNo ratings yet

- TB 9-5210-207-24 - Micrometer ISDocument16 pagesTB 9-5210-207-24 - Micrometer ISJose Hernandez DiazNo ratings yet

- TR Differential Ret670Document19 pagesTR Differential Ret670Mahdi AlamriNo ratings yet

- TR Differential Ret670 Y YDocument19 pagesTR Differential Ret670 Y Ym khNo ratings yet

- Locomotive: Service Manu AlDocument17 pagesLocomotive: Service Manu AlVictor Raul Tobosque Muñoz100% (1)

- Comissioning Guide RISONIC Modular Clamp-OnDocument12 pagesComissioning Guide RISONIC Modular Clamp-OnManuel TrujilloNo ratings yet

- Transformer Differential TestingDocument39 pagesTransformer Differential Testingerbvp22No ratings yet

- sd45 sms13Document16 pagessd45 sms13GabrielaNo ratings yet

- Transformer DifferentialDocument39 pagesTransformer DifferentialcskathirsNo ratings yet

- MettlerDocument5 pagesMettlernimeshjolly20028579No ratings yet

- TB 9-4935-251-50-7Document9 pagesTB 9-4935-251-50-7enticoNo ratings yet

- Laboratory For Analog VoltmeterDocument7 pagesLaboratory For Analog VoltmeterzakikarimNo ratings yet

- Power Grid-India-Annexure-II-Specific-Requirement - Rev-05 - With-Annexures-1-11Document11 pagesPower Grid-India-Annexure-II-Specific-Requirement - Rev-05 - With-Annexures-1-11Jose ValdiviesoNo ratings yet

- FI 01 - PAil Filling Line E&I Works - REIDocument11 pagesFI 01 - PAil Filling Line E&I Works - REISolarajan SudhakarNo ratings yet

- Observations and Actions from Quality Inspection RecordsDocument10 pagesObservations and Actions from Quality Inspection RecordsAkash ChaudharyNo ratings yet

- calibracion de gobernador 320CDocument9 pagescalibracion de gobernador 320CymaqservicesNo ratings yet

- DS85 002Document21 pagesDS85 002Patrick ByronNo ratings yet

- 7ut - Transformer Diff Relay TestDocument25 pages7ut - Transformer Diff Relay TestAnoss Olier100% (2)

- Polling Loop TroubleshootingDocument14 pagesPolling Loop TroubleshootingMagda Sánchez HerreraNo ratings yet

- Transformer Comment Sheet - 20.11.2020Document3 pagesTransformer Comment Sheet - 20.11.2020Mani SNo ratings yet

- Mc31a Rev5Document33 pagesMc31a Rev5sanju939No ratings yet

- Ring Bus Reclosing 20121217112215906Document133 pagesRing Bus Reclosing 20121217112215906Rick JordanNo ratings yet

- AWS G2.1.tmpDocument12 pagesAWS G2.1.tmpgazaliNo ratings yet

- Guide EN13155 A1 Rev0Document18 pagesGuide EN13155 A1 Rev0EdivaldoNo ratings yet

- 05103Document32 pages05103m89624888No ratings yet

- CommissioningDocument8 pagesCommissioningHeri MunirNo ratings yet

- 7ss - Busbar Low Imp Relay Test-1Document17 pages7ss - Busbar Low Imp Relay Test-1Ravi100% (3)

- Deltacal Manual 2.0.0Document25 pagesDeltacal Manual 2.0.0Camilo RamirezNo ratings yet

- Engineering Specification for Seamless Coolant Hose PortDocument5 pagesEngineering Specification for Seamless Coolant Hose Portjavier ortizNo ratings yet

- Calibrating BFP Turbine Expansion SensorsDocument9 pagesCalibrating BFP Turbine Expansion Sensorsnaresh977977No ratings yet

- Manual SupplementDocument4 pagesManual Supplementmkashkooli_scribdNo ratings yet

- CMC Calculations For Force Measurements Rev6Document40 pagesCMC Calculations For Force Measurements Rev6Naim AburayyamNo ratings yet

- CMC Calculations For Force MeasurementsDocument40 pagesCMC Calculations For Force MeasurementsNaim AburayyamNo ratings yet

- PM Is-13779Document8 pagesPM Is-13779dduraisamymanikandanNo ratings yet

- Calibration Procedure For Tpi Model 275 Digital Amp Meter - Tb-9-6625-2400-24Document17 pagesCalibration Procedure For Tpi Model 275 Digital Amp Meter - Tb-9-6625-2400-24luroguitaNo ratings yet

- Pole Discrepancy Panel Testing ProceduresDocument9 pagesPole Discrepancy Panel Testing Proceduresessam khalilNo ratings yet

- Nozzle CheckDocument11 pagesNozzle CheckincaurcoNo ratings yet

- Additional Information For Technical Specifications Under DDUGJY/IPDS SchemesDocument220 pagesAdditional Information For Technical Specifications Under DDUGJY/IPDS SchemesAmit Kumar SinghNo ratings yet

- Checklist For AMR-AMI T&C Rev00Document4 pagesChecklist For AMR-AMI T&C Rev00Santhosh Kumar VinayagamNo ratings yet

- SB 1364A - Fuel Quantity Capacitance Probe Check 2021-04-14 NA by SNDocument4 pagesSB 1364A - Fuel Quantity Capacitance Probe Check 2021-04-14 NA by SNAlexander GraytrousesNo ratings yet

- P544 (87LB 21BU 50BU) Test Report Rev 3Document21 pagesP544 (87LB 21BU 50BU) Test Report Rev 3samiahmedmansourNo ratings yet

- Calibration Procedure For Oscilloscope, Agilent Models Dso3062a and Dso3202a - Tb-9-6625-2409-24Document17 pagesCalibration Procedure For Oscilloscope, Agilent Models Dso3062a and Dso3202a - Tb-9-6625-2409-24luroguitaNo ratings yet

- Line Diff - p546Document9 pagesLine Diff - p546shanthikumaravel100% (1)

- T-33B/C/D: Air Transponder Ramp Test SetDocument90 pagesT-33B/C/D: Air Transponder Ramp Test SetJuan Garcia SanchezNo ratings yet

- Calibrate Falling Weight DeflectometersDocument16 pagesCalibrate Falling Weight Deflectometersvncs08No ratings yet

- Restricted Earth Fault Protection Stability & Sensitivity Test Rev01Document9 pagesRestricted Earth Fault Protection Stability & Sensitivity Test Rev01Mohamed EldinNo ratings yet

- Digital Low Resistance OhmmeterDocument68 pagesDigital Low Resistance OhmmeterPaul TuctoNo ratings yet

- Dimension 1200 and 1200es BST/SST Troubleshooting GuideDocument30 pagesDimension 1200 and 1200es BST/SST Troubleshooting GuidekornjudisticNo ratings yet

- Apm ServicemanualDocument40 pagesApm ServicemanualmichigatoNo ratings yet

- Receiver SpecDocument29 pagesReceiver SpecSreeja SujithNo ratings yet

- Validation of Welding MachineDocument7 pagesValidation of Welding MachineManivasagan Vasu100% (2)

- RabighDocument7 pagesRabigharsathmd08No ratings yet

- A1 Open Foundation With SlopeDocument1 pageA1 Open Foundation With SlopeKishore KumarNo ratings yet

- Rapport 2013-04 SoA II 2011 - Earthquake Design IssuesDocument21 pagesRapport 2013-04 SoA II 2011 - Earthquake Design IssuesOanh PhanNo ratings yet

- Soil Nails As Per RDSO-204-212Document9 pagesSoil Nails As Per RDSO-204-212Kishore KumarNo ratings yet

- Ijser: Design of Well FoundationDocument6 pagesIjser: Design of Well FoundationKARAN SINGLA 15BCL0073No ratings yet

- CMRL P2C401 Final Report 1-319-338Document20 pagesCMRL P2C401 Final Report 1-319-338Kishore KumarNo ratings yet

- Pile 17 ProcessedDocument6 pagesPile 17 ProcessedKishore KumarNo ratings yet

- Capacity Based On Shear Parameters As Per IS 6403: C C C C W Q Q Q Q F y y y yDocument5 pagesCapacity Based On Shear Parameters As Per IS 6403: C C C C W Q Q Q Q F y y y yKishore KumarNo ratings yet

- Capacity Based On Shear Parameters As Per IS 6403: C C C C W Q Q Q Q F y y y yDocument5 pagesCapacity Based On Shear Parameters As Per IS 6403: C C C C W Q Q Q Q F y y y yKishore KumarNo ratings yet

- A1 Open Foundation With SlopeDocument1 pageA1 Open Foundation With SlopeKishore KumarNo ratings yet

- Abstract Sheet For Dewatering Power ConsumtionDocument5 pagesAbstract Sheet For Dewatering Power ConsumtionKishore KumarNo ratings yet

- Ulr - TC752121000004643FDocument16 pagesUlr - TC752121000004643FKishore KumarNo ratings yet

- Routine Pile Load Test 225 A-2 Design R-0Document7 pagesRoutine Pile Load Test 225 A-2 Design R-0Kishore KumarNo ratings yet

- Routine Pile Load Test 225 A-2 Design R-0Document7 pagesRoutine Pile Load Test 225 A-2 Design R-0Kishore KumarNo ratings yet

- DFCC Western Corridor GIR for Minor RUBs Ch 60-79 kmDocument32 pagesDFCC Western Corridor GIR for Minor RUBs Ch 60-79 kmKishore KumarNo ratings yet

- Tata Projects Limited Ghavp - Npcil Gorakhpur HaryanaDocument3 pagesTata Projects Limited Ghavp - Npcil Gorakhpur HaryanaKishore KumarNo ratings yet

- MN RUB 69 - SBC - Minor RUB - 60-79 KM (Part 1) - Rev IDocument70 pagesMN RUB 69 - SBC - Minor RUB - 60-79 KM (Part 1) - Rev IKishore KumarNo ratings yet

- Abstract Sheet For Dewatering Power ConsumtionDocument5 pagesAbstract Sheet For Dewatering Power ConsumtionKishore KumarNo ratings yet

- Replacement Page 1Document1 pageReplacement Page 1Kishore KumarNo ratings yet

- B.M Cordinate-Model PDFDocument1 pageB.M Cordinate-Model PDFKishore KumarNo ratings yet

- Design of 750mm Diameter Test PilesDocument35 pagesDesign of 750mm Diameter Test PilesKishore KumarNo ratings yet

- Nuclear Power Corporation of India Limited (A Govt. of India Enterprise)Document4 pagesNuclear Power Corporation of India Limited (A Govt. of India Enterprise)Kishore KumarNo ratings yet

- Joining Report PDFDocument1 pageJoining Report PDFKishore KumarNo ratings yet

- Replacement Page 1Document1 pageReplacement Page 1Kishore KumarNo ratings yet

- Geotechnical Investigation of Proposed Nuclear Power ProjectDocument11 pagesGeotechnical Investigation of Proposed Nuclear Power ProjectKishore KumarNo ratings yet

- Girder Drawing-For 8 & 16 AnchorDocument2 pagesGirder Drawing-For 8 & 16 AnchorKishore KumarNo ratings yet

- Observations On Work Procedure of ExcavationDocument5 pagesObservations On Work Procedure of ExcavationKishore KumarNo ratings yet

- Scour Depth RefDocument5 pagesScour Depth RefKishore KumarNo ratings yet

- IGC 2018 BrochureDocument2 pagesIGC 2018 BrochureKishore KumarNo ratings yet

- Is 15026 2002 PDFDocument32 pagesIs 15026 2002 PDFKishore KumarNo ratings yet

- Splunk Ot Security Solution Technical Guide and DocumentationDocument101 pagesSplunk Ot Security Solution Technical Guide and DocumentationDr. Sanaz TehraniNo ratings yet

- Accurate Doppler Current Sensor for Measuring Sea Current Speed and DirectionDocument4 pagesAccurate Doppler Current Sensor for Measuring Sea Current Speed and DirectionKiran VepanjeriNo ratings yet

- SRD 1813576Document7 pagesSRD 1813576Sazzad Reza Durlov 1813576630No ratings yet

- Lord Immanuel Institute Foundation, Inc.: First Periodical Test in Mathematics 9Document5 pagesLord Immanuel Institute Foundation, Inc.: First Periodical Test in Mathematics 9Cee Jay AbanillaNo ratings yet

- Fujitsu LMCE - Technical ManualDocument56 pagesFujitsu LMCE - Technical ManualKornelije KovacNo ratings yet

- Tahir Iqbal CVDocument4 pagesTahir Iqbal CVAnonymous bCFC8fjLVNo ratings yet

- Actualpdf: Unlimited Lifetime Access To 5000+ Certification Actual Exams PDFDocument8 pagesActualpdf: Unlimited Lifetime Access To 5000+ Certification Actual Exams PDFMohamed Hussein EidNo ratings yet

- Northwestern Visayan Colleges: Subject SyllabusDocument4 pagesNorthwestern Visayan Colleges: Subject SyllabusMa. Gladys Mae PanadoNo ratings yet

- QP ManualDocument1,897 pagesQP ManualMarvinNo ratings yet

- ThermodynamicsDocument9 pagesThermodynamicssamir boseNo ratings yet

- Basis Set OptimizationDocument16 pagesBasis Set OptimizationNdhoz Los GandhozNo ratings yet

- Structural Stability and Design Course OverviewDocument16 pagesStructural Stability and Design Course OverviewMarinos GiannoukakisNo ratings yet

- Practice 2.8 A: Sketch The Graph of Each Linear InequalityDocument4 pagesPractice 2.8 A: Sketch The Graph of Each Linear InequalityKadi SantanaNo ratings yet

- Calculation Formula For The CapacitorDocument9 pagesCalculation Formula For The CapacitorMedyouNo ratings yet

- Learning From DataDocument402 pagesLearning From DataAnuvrat TikuNo ratings yet

- 3.01.01 - Acetaldehyde Determination by Enzymatic AnalysisDocument9 pages3.01.01 - Acetaldehyde Determination by Enzymatic AnalysisRiyanNo ratings yet

- Biological Catalysts: IGCSE Biology (Cambridge)Document40 pagesBiological Catalysts: IGCSE Biology (Cambridge)송준혁No ratings yet

- 3d AutoCad Test 11 (06-03-2020)Document9 pages3d AutoCad Test 11 (06-03-2020)nadirNo ratings yet

- How To Explort Gerber Files From KicadDocument10 pagesHow To Explort Gerber Files From KicadjackNo ratings yet

- Injection Pump Test SpecificationsDocument2 pagesInjection Pump Test SpecificationsKevin TtitoNo ratings yet

- Programs and ExamplesDocument346 pagesPrograms and Examplesali yousifzaiNo ratings yet

- Effects of High Chlorine in Biomass FuelDocument16 pagesEffects of High Chlorine in Biomass FuelJaideepMannNo ratings yet

- ALEJDocument6 pagesALEJAlejandro OdinNo ratings yet

- Chapter 5Document37 pagesChapter 5Yasser ElshaerNo ratings yet

- 5 - Lab5 - Permanganate and Dichromate TitrationDocument5 pages5 - Lab5 - Permanganate and Dichromate TitrationHoang Thao0% (1)

- Motion Assignment Class 9Document73 pagesMotion Assignment Class 9Monica SreeNo ratings yet

- Final BFK40303 2018 2019 Sem 2Document6 pagesFinal BFK40303 2018 2019 Sem 2EJ KooNo ratings yet

- 20a Solar Power Controller ManualDocument8 pages20a Solar Power Controller ManualVeilleur De ConscienceNo ratings yet

- ATFJ ReleaseDocument10 pagesATFJ ReleaseLeandroValdezJaénNo ratings yet

- Needle Roller Bearing Combined TypeDocument5 pagesNeedle Roller Bearing Combined TypeNemish KanwarNo ratings yet