Professional Documents

Culture Documents

Routine Pile Load Test 225 A-2 Design R-0

Uploaded by

Kishore KumarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Routine Pile Load Test 225 A-2 Design R-0

Uploaded by

Kishore KumarCopyright:

Available Formats

OWNER

ENGINEER PMC-2R /OCG-OCI-NK-NKI-RITES

CONTRACTOR TATA PROJECTS-IRCON-MITUSUI & CO JV

Anindya Infratech Pvt. Ltd

TESTING AGENCY www.aipltech.com an ISO-9001-2015 company

Head Office: 38C/28, A.N.Jha Marg

George Town,Allahabad -211002, U.P

DEDICATED FREIGHT CORRIDOR WESTERN CORRIDOR (SACHIN to VADODRA) EXPRESS FREIGHT

PROJECT

CONSORTIUM CONTRACT PACKAGE - 13

TITLE ROUTINE VERTICAL PILE LOAD TEST of Major Bridge-225 Km 16+664.719 (Abutment A-2)

STRUCTURE NO Major Bridge Br-225 Test Pile Location (Pile Group A-2)

Reference Drg No 13/MB/DG/5042/B

REV MODIFICATIONS/

DATE PREPARED CHECKED APPROVED

NO. PURPOSE OF ISSUE

7-Apr-21 R-0 For Review & Approval RJ MK NKS

Signature

Date Document No

AIPL TPL RITES

AIPL/DFCCIL/TPL-IRCON-MITSUI/BR-225/PKG-13/RLT(A-

7-Apr-21

1)/02

Revision-R-0 1 of 7 Design Doc.

Anindya Infratech Pvt. Ltd

www.aipltech.com an ISO-9001-2015 company

Control Doc.No AIPL/DFCCIL/TPL-IRCON-MITSUI/BR-225/PKG-13/RLT(A-1)/02

DEDICATED FREIGHT CORRIDOR WESTERN CORRIDOR (SACHIN to VADODRA) EXPRESS

PROJECT : Document No DATE

FREIGHT CONSORTIUM CONTRACT PACKAGE - 13

AIPL/DFCCIL/TPL-IRCON-MITSUI/BR-

225/PKG-13/RLT(A-1)/02 7-Apr-21

TITLE : ROUTINE VERTICAL PILE LOAD TEST of Major Bridge-225 Km 16+664.719 (Abutment A-2)

Design Checked SHEET

MH NKS 1

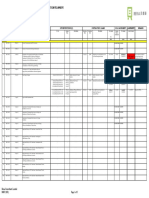

Test Pile Detail A-1 Pile Group

Grade of Concrete = M-35

TMT STEEL = Fe-500

Length of Test Pile from CoF = 18.00 m COL: '+' 15.544 m

Dia of test pile = 1,200.00 mm TRL : '-' 2.456

SAFE LOAD = 265.02 MT Note Refer Drg 5040 B

TEST LOAD AS PER 2911 (Initial) [S.F X 1.5] = 397.53 MT

** Design has been adopted for greater Test load

REACTION PILE

Available Reaction capacity is

Nos of REACTION PILE = 2.00 Nos 591.01 MT as below i.e 297 %

Dia of Reaction Pile = 1200 mm w.r.t 198.765 MT , Refer

Clause 7.1.3.1 of IS 2911 Part4

Required Uplift /Pull Load Per Reaction [ T.L/2] = 198.765 MT : 2013, higer than 25 %

Design Load per Reaction [ Req Uplift of Working Pile] = Required , Hence OK

[25% Extra as per IS 2911 ]

Length of Reaction Pile as per app drawing = 18.00 m

Nos of Reaction Proposed = 2.00 Nos

CHECK FOR TMT STEEL OF WORKING PILE

TMT dia in Reaction/Working Pile = 25.00 mm Drg No 5042B

Nos of Bar in working pile as per approved drg = 22.00 Nos Drg No 5042B

Nominal x-section area = 490.87 Sqmm

Yield Stress of TMT Fe-500 = 500.00 N/Sqmm

Permi. Stress [ 87% of 500 N/Sqmm] = 435.00 N/Sqmm

Breaking load in KN 25 mm dia bar = 213.53 kN

Breaking load in MT [ BL ] = 21.79 MT/No

Min Required Uplift Load per Reaction [ Uplift ] = 248.46 MT 25% added in required load

Nos of bar Required [DL/BL] Theoretical = 11.40 Nos

Nos of Bar Available in working pile as per app drg = 22.000 Nos Drg No 5043 B

Prposed To use for Anchoring = 14.000 Nos

Thus Load imposed on each bar = 17.747 MT

Thus 81.45%

17.75 MT < 21.79 MT

Hence Safe

CHECK FOR UPLIFT OF REACTION /WORKING PILE Refer Drawing 13/MB/DG/5415/C dt 10.09.18

Required Uplift for working pile to be used as a reaction pile = 198.765 MT

Skin friction Calculation as per Sub Clause 6.3.2 = 591.09 MT 297%

Uplift Capacity The uplift capacity of a pile is given by sum of the frictional resistance

and the weight of the pile (buoyant or total as relevant). The recommended factor of

safety is 3.0 in the absence of any pullout test results and 2.0 with pullout test results. As per IS 2911

Layer-1 From 15.544 m To 8.04 m Side Resistance = 156.90 MT

in MT

Layer-2 From 8.04 m To 0.04 m Side Resistance = 343.57 MT

in MT

Layer-3 From 0.04 m To -2.51 m Side Resistance = 90.61 MT

in MT

Factor of Safety in absence of Pull out test = 3.0

Thus Safe Uplift Capacity as per 6.3.2 [Sum of Friction Resistance /3.0] = 197.03 MT

[777.93/3]

Add Weight of Pile [ Length x 1.13 x 2.5 ] = 50.85 MT

Thus Total Uplift Capcity of Pile as per IS 2911 Part1/Sec-2 [ Ulift / Cal ] = 247.88 MT

Required Uplift Capacity [ Ulift / Req ] = 198.765 MT

Hence 247.88 MT > 198.765 MT Hence working Pile may be safe for using as reaction pile

Revision-R-0 2 of 7 Design Doc.

Anindya Infratech Pvt. Ltd

www.aipltech.com an ISO-9001-2015 company

Control Doc.No 0

PROJECT : DEDICATED FREIGHT CORRIDOR WESTERN CORRIDOR (SACHIN to VADODRA) EXPRESS FREIGHT CONSORTIUM CONTRACT PACKAGE - 13 Document No DATE

AIPL/DFCCIL/TPL-IRCON-MITSUI/BR-

7-Apr-21

225/PKG-13/RLT(A-1)/02

TITLE : ROUTINE VERTICAL PILE LOAD TEST of Major Bridge-225 Km 16+664.719 (Abutment A-2) Design Checked SHEET

MH NKS 2

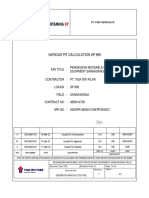

COMPUTATION OF UPLIFT CAPACITY OF ROUTIEN PILE

R-1

Layer 1 From 15.544 m To 8.04 m SIDE RESISTANCE gw= 1 g/cc

7.504 m LOAD CARRYING CAPACITY-STATIC FORMULA (Qu= K x Pdi x tan d x Asi + a x C x As) G= 2.59

1 D Stem Dia in cms 120.000 g dry = 1.92 g/cc

2 L Total Length of Pile in cms Calculation of Submerged density

750.400

Note :- 1mt depth considered as cutoff level gb = (e S + G) x gw

3 Ap c/s Area in cm2 [3.14 x D x D /4] 11,309.734 (1+ e )

4 K Coe. Of Earth Press. 1.500

Top Overburder pressure - field Dry density

5 Pdi Bottom Overburder pressure 0.88449 S= 0

Eff. Overburden pressure for ith layer (Pdi) in kg/cm2. Avg of Top Over Press & Bottom 0.44224 therefore,

6 g Unit weight (Submerged) In kg/cc gsub = gsat - gw 0.001 e= 0.348958333 [G x γw /γdry]-1

7 a Reduction Factor as per IS 2911 Part-1 Appendix-A 1.000 S= 1

8 C Avg. Cohesion kg/cm2 0.300 gsat = (e + G) x gw

9 Φ Angle Of Inter.Friction, degree 21.000 (1+ e )

10 As Surface Area in cm2 [3.14 x D x L ] 282,894.135 = 2.178687259

11 Qu Ultimate Bearing Capacity

12 Friction Capacity, kg As*Pdi*TAN(RADIANS(Φ))*K+a*C*As 156,904.980 gsub = gsat -gw

Factor of Safety 1.000 = 1.178687 g/cc

13 Qu Side Resistance in MT 156.905 0.001178687 kg/cc

Layer 2 From 8.04 m To 0.04 m SIDE RESISTANCE gw= 1 g/cc

8.000 m LOAD CARRYING CAPACITY-STATIC FORMULA (Qu= K x Pdi x tan d x Asi + a x C x As) G= 2.56

1 D Stem Dia in cms 120.000 g dry = 1.72 g/cc

2 L Total Length of Pile in cms Calculation of Submerged density

800.000

Note :- 1mt depth considered as cutoff level gb = (e S + G) x gw

3 Ap c/s Area in cm2 [3.14 x D x D /4] 11,309.734 (1+ e )

4 K Coe. Of Earth Press. 1.500

Top Overburder pressure 0.884 field Dry density

5 Pdi Bottom Overburder pressure 0.83850 S= 0

Eff. Overburden pressure for ith layer (Pdi) in kg/cm2. Avg of Top Over Press & Bottom 0.86149 therefore,

6 g Unit weight (Submerged) In kg/cc gsub = gsat - gw 0.001 e= 0.488372093 [G x γw /γdry]-1

7 a Reduction Factor as per IS 2911 Part-1 Appendix-A 1.000 S= 1

8 C Avg. Cohesion kg/cm2 0.300 gsat = (e + G) x gw

9 Φ Angle Of Inter.Friction, degree 33.000 (1+ e )

10 As Surface Area in cm2 [3.14 x D x L ] 301,592.895 = 2.048125

11 Qu Ultimate Bearing Capacity

12 Friction Capacity, kg As*Pdi*TAN(RADIANS(Φ))*K+a*C*As 343,571.788 gsub = gsat -gw

Factor of Safety 1.000 = 1.048125 g/cc

13 Qu Side Resistance in MT 343.572 0.001048125 kg/cc

Side Resistance in MT/Sqm

Adopted for designing of Pile anchor pile [MT/Sqm]

Revision-R-0 3 of 7 Design Doc. Reaction PileReaction Pile Uplift

Layer 3 From 0.04 m To -2.51 m SIDE RESISTANCE gw= 1 g/cc

2.550 m LOAD CARRYING CAPACITY-STATIC FORMULA (Qu= K x Pdi x tan d x Asi + a x C x As) G= 2.56

1 D Stem Dia in cms 120.000 g dry = 1.72 g/cc

2 L Total Length of Pile in cms Calculation of Submerged density

255.000

Note :- 1mt depth considered as cutoff level gb = (e S + G) x gw

3 Ap c/s Area in cm2 [3.14 x D x D /4] 11,309.734 (1+ e )

4 K Coe. Of Earth Press. 1.500

Top Overburder pressure 0.839 field Dry density

5 Pdi Bottom Overburder pressure 0.26727 S= 0

Eff. Overburden pressure for ith layer (Pdi) in kg/cm2. Avg of Top Over Press & Bottom 0.55289 therefore,

6 g Unit weight (Submerged) In kg/cc gsub = gsat - gw 0.001 e= 0.488372093 [G x γw /γdry]-1

7 a Reduction Factor as per IS 2911 Part-1 Appendix-A 1.000 S= 1

8 C Avg. Cohesion kg/cm2 0.340 gsat = (e + G) x gw

9 Φ Angle Of Inter.Friction, degree 36.000 (1+ e )

10 As Surface Area in cm2 [3.14 x D x L ] 96,132.735 = 2.048125

11 Qu Ultimate Bearing Capacity

12 Friction Capacity, kg As*Pdi*TAN(RADIANS(Φ))*K+a*C*As 90,609.210 gsub = gsat -gw

Factor of Safety 1.000 = 1.048125 g/cc

13 Qu Side Resistance in MT 90.609 0.001048125 kg/cc

Revision-R-0 4 of 7 Design Doc. Reaction PileReaction Pile Uplift

Anindya Infratech Pvt. Ltd

www.aipltech.com an ISO-9001-2015 company

DEDICATED FREIGHT CORRIDOR WESTERN CORRIDOR (SACHIN to VADODRA) EXPRESS FREIGHT

PROJECT : Document No DATE

CONSORTIUM CONTRACT PACKAGE - 13

AIPL/DFCCIL/TPL-IRCON-MITSUI/BR-225/PKG-

13/RLT(A-1)/02

7-Apr-21

TITLE : ROUTINE VERTICAL PILE LOAD TEST of Major Bridge-225 Km 16+664.719 (Abutment A-2)

Design Checked SHEET

MH NKS 3

[a] Desing Calculation for Pile Capacity as per Soil Data for Respective location

Basic Detial of Pile and location

Pile Diameter D = 1.20 m

Area of Pile {X-Sec} Ap = 1.13 m2

Ground Water Table = 10.00 m

Existing Ground RL EGL = 18.08 m

High Flood RL HGL = 0.00 m Drg 5042 B

Cut-off level of pile = 15.54 m

Critical Depth for 15D = -2.46 m

5/4/2021

Ultimate Capacity for Piles in Cohesionless soil Qu = Ap ( 0.5 Dy Ny + Pd Nq ) + ∑ Ki Pdi tan Ai Asi

Ultimate Capacity for Pile in Cohesive Soil - Qu = Ap Nc Cp + ∑ ai Ci Asi

Ultimate Load Capacity of Pile KN = Qu

Area of Pile {X-Sec} 2 Ap

m =

Pile Diameter m = D

Effective Unit Weight at Pile Tip kN/m³ = γ

Bearing Capacity Factors depends on Ø of soil as per IS: 6403 = Ny

Effective overburden pressure at pile tip in kN/m² kN/m2 = Pd

Bearing Capacity Factors depends on Ø of soil as per Fig 1 of IS 2911 Part 1 sec 2 = Nq

Coefficient of earth pressure applicable for the ith Layer = Ki

Effective overburden pressure for the ith layer in kN/m² kN/m2 = PDi

Angle of wall friction between pile and soil for the ith layer = δi

Surface area of Pile in ith layer m2 = Asi

Average Cohesion at Pile Tip kN/m2 = Cp

Adhesion factor for the ith layer depending on the consistency of soil = αi

Average Cohesion for ith layer kN/m2 = Ci

Soil Data

Depth Effective Side Resistance

Layer Soil Tpye N Ncr γ c Ø K

in MT

BGEL depth

m m m

Nos. kN/m³ kN/m2 Degree

3.000 0.000

Layer 1 15.544 8.04 Silty Clay/HP 27 25 21.50 30 21 1.5 156.905 MT

Layer 2 8.040 0.04 Clay Sand 73 43 21.50 30 33 1.5 343.572 MT

Layer 3 0.040 -2.51 Silty Clay/IP 100 43 21.50 34 36 1.5 90.609 MT

Total Side Resistance 591.086 MT

Ref Geotechnical Report -BH-03 (pg 15)

Revision-R-0 5 of 7 Design Doc. Reaction PileSoil Data.

Anindya Infratech Pvt. Ltd

www.aipltech.com an ISO-9001-2015 company

DEDICATED FREIGHT CORRIDOR WESTERN CORRIDOR (SACHIN to VADODRA) EXPRESS

PROJECT : Document No DATE

FREIGHT CONSORTIUM CONTRACT PACKAGE - 13

AIPL/DFCCIL/TPL-IRCON-MITSUI/BR-225/PKG-13/RLT(A-

1)/02

7-Apr-21

TITLE : ROUTINE VERTICAL PILE LOAD TEST of Major Bridge-225 Km 16+664.719 (Abutment A-2)

Design Checked SHEET

MH NKS 5

[1] DESIGN WITH TMT FE-500 in place of HTS strand

Design Load per Reaction = 248.46 MT [25 % Added ]

TMT dia = 25.00 mm

Nominal x-section area = 490.87 Sqmm

Yield Stress of TMT Fe-500 = 500.00 N/Sqmm

Permissible Stress of Rft [ 87% 0f 500] = 435.00 N/Sqmm

Load Carrying Capacity of each bar = 21.79 MT

[435 x 3.14 x 25 x 25 x 0.25 /9.8 x 1000]

Nos of TMT Proposed For Review & Approval = 11.400 Nos

Theoretical Load imposed [437.5 / 24.0 Nos] = 14.000 Nos

5/4/2021 Required load /per bar = 17.747 MT

Hence Hence Safe

17.7 MT < 21.8 MT

[2] DESIGN OF WELDING OF ANCHORS AS PER I.S. 816

Assume Size of weld = 12.5 mm

for lap welding (Both face)

Permissible stress of weld = 86.30 N/mm2

1100*0.8*98066.5/10^6 Refer IS 816

As per IS 816 Sub Clause 7.0 Per. Stress is 1100 Kgf/SqCm

, as it is site weld 80% will be considered sub-clause

7.3 = 1100 Kgf/SqCm x 0.8 = 880 Kgf/Sqcm x 98066.5 N/Sqm

Strength of Weld per mm length = 755.11 N/mm

Strength of Weld per mm length = K (0.7) x Size of Weld x

permissible stress [0.7 x 86.4 x 12.5 = 756 N/mm]

Thus length of weld required = 230.00 mm

[Load on each rod x9.8 x1000/756

[= 25.391 MT x 9.8 x1000/756]

Provided at both face = 2 x 250 mm

= 500.000 mm Welding to be done on both faces of bar

500.00 > 230.00 Hence Safe

It is designed to provide 250 mm long welding of 12.5 mm size at both side of TMT bar considering extra care while using reaction. Girder will be

supported over the sand bags to be provided at site

Revision-R-0Date-05.05.20 6 of 7 Design Doc.

Anindya Infratech Pvt. Ltd

38C/28 A.J. Marg, George Town

Allahabad-211002

Email:- anindyainfratech@gmail.com SHEET

09415239428,8756829428 6

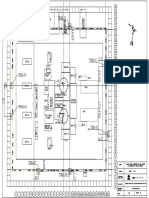

Major Bridge Br-225 Test Pile Location (Pile Group A-2)

Main Girder 1.2 m 3600.00

Main Girder

## As suitable

1400 mm 3600 mm 3600 mm 1400 mm

10.00 m

Legend Datum Bar

Test Pile 1200 m dia

Reactin Pile 1200 m dia

All Dimension in m

S.N Particular Qty (P-1) Remarks

1 Main Girder ~ 10 m long 1.00 Nos

1 Cross Girder ~ 5 m long 0.00 Nos

2 Nos of Reaction Pile 2.00 Nos

DEDICATED FREIGHT CORRIDOR WESTERN CORRIDOR (SACHIN to VADODRA) EXPRESS FREIGHT CONSORTIUM

3 Length of Reaction Pile 18.00 m CONTRACT PACKAGE - 13

3 Chipping off Cut-Off

4 Dia of Reaction Pile 1200.00 mm Doc.No AIPL/DFCCIL/TPL-IRCON-MITSUI/BR-225/PKG-13/RLT(A-1)/02

5 Dia of Bar in Reaction Pile 25.00 mm Revision Date Prep.By Approved by

5 Nos of Bars in Anchor 0.00 Nos

R-0 7-Apr-21 MH NKS

Revision-R-0 7 of 7 Design Doc.

You might also like

- Steel Design LSMDocument65 pagesSteel Design LSMStructural SpreadsheetsNo ratings yet

- Token Ring Technology ReportFrom EverandToken Ring Technology ReportNo ratings yet

- Expansion Tank (Et) : Rabigh II Project Interconnecting Package (UO1)Document14 pagesExpansion Tank (Et) : Rabigh II Project Interconnecting Package (UO1)dodonggNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Datahseet For Strainer With Air EliminatorDocument4 pagesDatahseet For Strainer With Air Eliminatorvinoj chandranNo ratings yet

- KG98 2 ONT OMF in 7861 DS 152 R4 Differential Pressure Transmitter Datasheet (Code 1)Document7 pagesKG98 2 ONT OMF in 7861 DS 152 R4 Differential Pressure Transmitter Datasheet (Code 1)Madheswaran DharmapuriNo ratings yet

- Approved ITP - RTN - VS215B-101-A-PLN-7001 - 05 - Code ADocument131 pagesApproved ITP - RTN - VS215B-101-A-PLN-7001 - 05 - Code ALionell Logesh0% (1)

- Inspection Test and Plan For Storage Tank For Material Carbon SteelDocument5 pagesInspection Test and Plan For Storage Tank For Material Carbon SteelPLTU SULUT QC PASTINo ratings yet

- MD1-0-T-030-05-00370-A - ITP For CFBC Boiler InstallationDocument30 pagesMD1-0-T-030-05-00370-A - ITP For CFBC Boiler InstallationTran KhuynhNo ratings yet

- TBL-31-E-GMA - ED80-DL-113-EN-1-Wiring and Interconnection Diagram-Waste Water Central Monitoring BasinDocument6 pagesTBL-31-E-GMA - ED80-DL-113-EN-1-Wiring and Interconnection Diagram-Waste Water Central Monitoring BasinAjeng InsaniNo ratings yet

- Analysis & Design of Pump-Turbine Foundation for Cirebon Power PlantDocument24 pagesAnalysis & Design of Pump-Turbine Foundation for Cirebon Power PlantJohn Rosero100% (1)

- RFA & RFI For 400KV Gantry Verticality CheckingDocument3 pagesRFA & RFI For 400KV Gantry Verticality Checkingsathya2040No ratings yet

- Structcon Designs PVT LTD.: National Highways Authority of IndiaDocument88 pagesStructcon Designs PVT LTD.: National Highways Authority of IndiakaushikNo ratings yet

- Vedanta Limited Cairn Oil & Gas: Foundation Design Calculations For EXPORT GAS COMPRESSOR-1 (Temporary)Document44 pagesVedanta Limited Cairn Oil & Gas: Foundation Design Calculations For EXPORT GAS COMPRESSOR-1 (Temporary)SHAJINo ratings yet

- Pumpturbine Foundation Design Spreadsheet - CompressDocument26 pagesPumpturbine Foundation Design Spreadsheet - CompressHussain AliNo ratings yet

- Railway Project Cofferdam DesignDocument39 pagesRailway Project Cofferdam DesignFilipus Ivan DenataNo ratings yet

- Construction Steel Erection PlansDocument10 pagesConstruction Steel Erection PlansTran KhuynhNo ratings yet

- Request For Inspection: Tripatra-Samsung ConsortiumDocument12 pagesRequest For Inspection: Tripatra-Samsung Consortiumcrys suryo pNo ratings yet

- T-25-2018-00-Pe-Das-1048 - Rev-2 - Datasheet For Sight GlassDocument3 pagesT-25-2018-00-Pe-Das-1048 - Rev-2 - Datasheet For Sight Glassvinoj chandranNo ratings yet

- 4467 - Comment Management Sheet (CMS) P-A Ramp A & C - P07 - P13 - 20181001Document2 pages4467 - Comment Management Sheet (CMS) P-A Ramp A & C - P07 - P13 - 20181001Amila SampathNo ratings yet

- 2020 PTJ en TR 348Document1 page2020 PTJ en TR 348hamada2006oilNo ratings yet

- 65 Titik 1.5-2 LC Gempa BumiDocument28 pages65 Titik 1.5-2 LC Gempa BumidenyNo ratings yet

- Client Calculation of Pipe Rack Structur PDFDocument179 pagesClient Calculation of Pipe Rack Structur PDFMegha Lakhani100% (1)

- Request Section: Site Inspection Request Date 1 November 2021 Ref No. KVLRT3-GSTSB-GS04-EC-SIR-C&S-101007Document16 pagesRequest Section: Site Inspection Request Date 1 November 2021 Ref No. KVLRT3-GSTSB-GS04-EC-SIR-C&S-101007nidduzziNo ratings yet

- Tower FDNDocument8 pagesTower FDNSohan Lal JainNo ratings yet

- Itp ElectricalDocument31 pagesItp ElectricalAnonymous e8rOBLYx0100% (3)

- DPR - 18-06-2023Document1 pageDPR - 18-06-2023Muhammad AftabNo ratings yet

- Fencing and GateDocument16 pagesFencing and Gatemustika05No ratings yet

- B224 Cdu TPL 000 MP Ga PR0013 0002 0 - 2Document4 pagesB224 Cdu TPL 000 MP Ga PR0013 0002 0 - 2PRASHANTNo ratings yet

- Annexure-1 RFIs - Sept 2nd WeekDocument4 pagesAnnexure-1 RFIs - Sept 2nd WeekAbhinandan MazumderNo ratings yet

- ACFrOgDV - 7kt04AxDyGcNL79lC HfjgmZ6EO0SqXVcl2uZ5cAPbhNyMY4 LmmxCpo4Xo2Uo5GezhPw4E543REYaq9k2iN JkFqjIIYkAU9U4nEi16BAkFxkRK2pbvbEDocument5 pagesACFrOgDV - 7kt04AxDyGcNL79lC HfjgmZ6EO0SqXVcl2uZ5cAPbhNyMY4 LmmxCpo4Xo2Uo5GezhPw4E543REYaq9k2iN JkFqjIIYkAU9U4nEi16BAkFxkRK2pbvbEwlv hugoNo ratings yet

- Boq 1Document37 pagesBoq 1nafrisqsNo ratings yet

- UPD-KM-G8-VL-LT-2002 - Spare Part List For Commissioningstart Up Rev.0Document4 pagesUPD-KM-G8-VL-LT-2002 - Spare Part List For Commissioningstart Up Rev.0Sudar MyshaNo ratings yet

- NG50!3!200-EnG-RP-AB-00-2235 Spools & Jumpers Basis of DesignDocument67 pagesNG50!3!200-EnG-RP-AB-00-2235 Spools & Jumpers Basis of DesignsurNo ratings yet

- Summary ReportDocument24 pagesSummary ReportRonniNo ratings yet

- Calculation Sheet For Gantry CPF & Cluster Rev.0 (8015-0151-82-Po-45-0009-9784-S03-12054)Document36 pagesCalculation Sheet For Gantry CPF & Cluster Rev.0 (8015-0151-82-Po-45-0009-9784-S03-12054)tanujaayerNo ratings yet

- V-31e0-001-A-700 - 2 Method Statement For Scaffolding WorkDocument22 pagesV-31e0-001-A-700 - 2 Method Statement For Scaffolding WorkWidya PrasetyaNo ratings yet

- PT Truba Jaya Engineering Field Inspection PlanDocument7 pagesPT Truba Jaya Engineering Field Inspection PlanbernardNo ratings yet

- PT. PLN Powerhouse Structure CalculationDocument67 pagesPT. PLN Powerhouse Structure Calculationmustika05No ratings yet

- Ga 33 KV Truss Beam (Bm-2a) 10.5m For Approval - Rev-1 - 08.11.2023Document2 pagesGa 33 KV Truss Beam (Bm-2a) 10.5m For Approval - Rev-1 - 08.11.2023Sinden AyuNo ratings yet

- Flexible Roads and Paving SpecificationDocument33 pagesFlexible Roads and Paving Specificationrasnowmah2012No ratings yet

- 1922A691OO ANG 52 CI CCS 1002 - VariousPitCalculationSP998 - Rev0Document90 pages1922A691OO ANG 52 CI CCS 1002 - VariousPitCalculationSP998 - Rev0Didi Hadi RiantoNo ratings yet

- I RM 3010.2G 5425 947 Kes 001 - 0Document11 pagesI RM 3010.2G 5425 947 Kes 001 - 0Choong K WNo ratings yet

- AK2 - RevADocument13 pagesAK2 - RevAChirag ShahNo ratings yet

- Contractor instrument pressure piping hook-up documentDocument35 pagesContractor instrument pressure piping hook-up documentTahir100% (1)

- MK-S4437-I-01-01 Service Water Tank DesignDocument55 pagesMK-S4437-I-01-01 Service Water Tank DesignRanu JanuarNo ratings yet

- MR For Pipeline Bulk Materials, Rev.ADocument31 pagesMR For Pipeline Bulk Materials, Rev.ASandeepNBabuNo ratings yet

- 4442 16 MS 0015 - 2Document42 pages4442 16 MS 0015 - 2Vasu SNo ratings yet

- 2023-OS-0007-BCP-0003 Tank Inspection Test Plan (ITP) Rev.02Document7 pages2023-OS-0007-BCP-0003 Tank Inspection Test Plan (ITP) Rev.02teethai2524No ratings yet

- MPS 3lpeDocument11 pagesMPS 3lpeabhishek_me03No ratings yet

- 10624-Master Index For Pipe SupportsDocument36 pages10624-Master Index For Pipe SupportsSARFRASNo ratings yet

- Inspection and Test Plan: Enclosed Ground Flare (EGF)Document17 pagesInspection and Test Plan: Enclosed Ground Flare (EGF)vincent100% (1)

- Work Inspection Request (Wir) : North-South Commuter Railway Extension ProjectDocument4 pagesWork Inspection Request (Wir) : North-South Commuter Railway Extension ProjectResearcherNo ratings yet

- Upper Zakum 750 Islands Surface Facilities Project - EPC2 PROJECT No. P7512Document15 pagesUpper Zakum 750 Islands Surface Facilities Project - EPC2 PROJECT No. P7512Anonymous xyZH2OaUVNo ratings yet

- For Approval: Refractory Installation ProcedureDocument16 pagesFor Approval: Refractory Installation ProcedureLuis EscobedoNo ratings yet

- KG98 2 ONT OMF in 7861 DS 151 R4 Pressure Transmitter Datasheet (Code 1)Document9 pagesKG98 2 ONT OMF in 7861 DS 151 R4 Pressure Transmitter Datasheet (Code 1)Madheswaran DharmapuriNo ratings yet

- ACC Cube Test Report PDFDocument1 pageACC Cube Test Report PDFsyed sulemanNo ratings yet

- A1 Open Foundation With SlopeDocument1 pageA1 Open Foundation With SlopeKishore KumarNo ratings yet

- Rapport 2013-04 SoA II 2011 - Earthquake Design IssuesDocument21 pagesRapport 2013-04 SoA II 2011 - Earthquake Design IssuesOanh PhanNo ratings yet

- Soil Nails As Per RDSO-204-212Document9 pagesSoil Nails As Per RDSO-204-212Kishore KumarNo ratings yet

- Ijser: Design of Well FoundationDocument6 pagesIjser: Design of Well FoundationKARAN SINGLA 15BCL0073No ratings yet

- CMRL P2C401 Final Report 1-319-338Document20 pagesCMRL P2C401 Final Report 1-319-338Kishore KumarNo ratings yet

- Pile 17 ProcessedDocument6 pagesPile 17 ProcessedKishore KumarNo ratings yet

- Capacity Based On Shear Parameters As Per IS 6403: C C C C W Q Q Q Q F y y y yDocument5 pagesCapacity Based On Shear Parameters As Per IS 6403: C C C C W Q Q Q Q F y y y yKishore KumarNo ratings yet

- Capacity Based On Shear Parameters As Per IS 6403: C C C C W Q Q Q Q F y y y yDocument5 pagesCapacity Based On Shear Parameters As Per IS 6403: C C C C W Q Q Q Q F y y y yKishore KumarNo ratings yet

- A1 Open Foundation With SlopeDocument1 pageA1 Open Foundation With SlopeKishore KumarNo ratings yet

- B.M Cordinate-Model PDFDocument1 pageB.M Cordinate-Model PDFKishore KumarNo ratings yet

- Ulr - TC752121000004643FDocument16 pagesUlr - TC752121000004643FKishore KumarNo ratings yet

- Routine Pile Load Test 225 A-2 Design R-0Document7 pagesRoutine Pile Load Test 225 A-2 Design R-0Kishore KumarNo ratings yet

- DFCC Western Corridor GIR for Minor RUBs Ch 60-79 kmDocument32 pagesDFCC Western Corridor GIR for Minor RUBs Ch 60-79 kmKishore KumarNo ratings yet

- MN RUB 69 - SBC - Minor RUB - 60-79 KM (Part 1) - Rev IDocument70 pagesMN RUB 69 - SBC - Minor RUB - 60-79 KM (Part 1) - Rev IKishore KumarNo ratings yet

- Abstract Sheet For Dewatering Power ConsumtionDocument5 pagesAbstract Sheet For Dewatering Power ConsumtionKishore KumarNo ratings yet

- Tata Projects Limited Ghavp - Npcil Gorakhpur HaryanaDocument3 pagesTata Projects Limited Ghavp - Npcil Gorakhpur HaryanaKishore KumarNo ratings yet

- Abstract Sheet For Dewatering Power ConsumtionDocument5 pagesAbstract Sheet For Dewatering Power ConsumtionKishore KumarNo ratings yet

- Replacement Page 1Document1 pageReplacement Page 1Kishore KumarNo ratings yet

- Joining Report PDFDocument1 pageJoining Report PDFKishore KumarNo ratings yet

- Geotechnical Investigation of Proposed Nuclear Power ProjectDocument11 pagesGeotechnical Investigation of Proposed Nuclear Power ProjectKishore KumarNo ratings yet

- Design of 750mm Diameter Test PilesDocument35 pagesDesign of 750mm Diameter Test PilesKishore KumarNo ratings yet

- Nuclear Power Corporation of India Limited (A Govt. of India Enterprise)Document4 pagesNuclear Power Corporation of India Limited (A Govt. of India Enterprise)Kishore KumarNo ratings yet

- Replacement Page 1Document1 pageReplacement Page 1Kishore KumarNo ratings yet

- Observations On Work Procedure of ExcavationDocument5 pagesObservations On Work Procedure of ExcavationKishore KumarNo ratings yet

- Girder Drawing-For 8 & 16 AnchorDocument2 pagesGirder Drawing-For 8 & 16 AnchorKishore KumarNo ratings yet

- Compliance of lateral pile load test procedureDocument6 pagesCompliance of lateral pile load test procedureKishore KumarNo ratings yet

- Scour Depth RefDocument5 pagesScour Depth RefKishore KumarNo ratings yet

- IGC 2018 BrochureDocument2 pagesIGC 2018 BrochureKishore KumarNo ratings yet

- Is 15026 2002 PDFDocument32 pagesIs 15026 2002 PDFKishore KumarNo ratings yet

- WatershedDocument7 pagesWatersheddivyakalpaNo ratings yet

- G7 SoilDocument43 pagesG7 SoilJamika ReyesNo ratings yet

- Performance FactorsDocument10 pagesPerformance FactorsNitish SinghNo ratings yet

- Oddo-Harkins RuleDocument2 pagesOddo-Harkins RuleSHAGUN YADAVNo ratings yet

- Instant Download Ebook PDF Encyclopedia of Ocean Sciences 3rd Edition PDF ScribdDocument29 pagesInstant Download Ebook PDF Encyclopedia of Ocean Sciences 3rd Edition PDF Scribdhoward.linkovich475100% (49)

- Uhv & Pe Unit 1 & 2Document20 pagesUhv & Pe Unit 1 & 2JAGRITI AWASTHINo ratings yet

- Excess Carrier Tuts 2014Document3 pagesExcess Carrier Tuts 2014ESAUNo ratings yet

- Major ProjectDocument80 pagesMajor ProjectAkhilesh UppulaNo ratings yet

- Atomic Radius and Electronegativity - QuestionsDocument4 pagesAtomic Radius and Electronegativity - QuestionsAnonymous Mj0pfScNo ratings yet

- Final Exam GE10 People and Earths Ecosystem by CEAlarbaDocument8 pagesFinal Exam GE10 People and Earths Ecosystem by CEAlarbachris ian100% (1)

- Studied Refrigerants: 7 IIR Gustav Lorentzen Conference On Natural Working Fluids, Trondheim, Norway, May 28-31, 2006Document1 pageStudied Refrigerants: 7 IIR Gustav Lorentzen Conference On Natural Working Fluids, Trondheim, Norway, May 28-31, 2006amogmhetreNo ratings yet

- Duct Burn Upgrade Retrofit PDFDocument2 pagesDuct Burn Upgrade Retrofit PDFKR PANo ratings yet

- Physicpaper3 Binded 230907 081640Document289 pagesPhysicpaper3 Binded 230907 081640terrencendabambiNo ratings yet

- Saad Ayub Jajja AMEC PaperDocument7 pagesSaad Ayub Jajja AMEC PaperSaad Ayub JajjaNo ratings yet

- SCIENCE-6-QUARTER-4-PERIODIC-TESTDocument6 pagesSCIENCE-6-QUARTER-4-PERIODIC-TESTMaestro Sonny TVNo ratings yet

- Name Jemal Kedir I.D No AWR/031/13 Dep't Arebic WeekendDocument5 pagesName Jemal Kedir I.D No AWR/031/13 Dep't Arebic WeekendJemal Kedir UmerNo ratings yet

- The Natural Environment of The TropicsDocument33 pagesThe Natural Environment of The TropicsEloi Carlos GoveNo ratings yet

- Global Warming and Climate ChangeDocument617 pagesGlobal Warming and Climate Changefasolăi100% (6)

- Profil Departemen Geografi UIDocument10 pagesProfil Departemen Geografi UIfachmizainNo ratings yet

- Zainal (2001) - Prediction of Performance of A Downdraft Gasifier Using Equilibrium Modeling For Different Biomass Materials PDFDocument17 pagesZainal (2001) - Prediction of Performance of A Downdraft Gasifier Using Equilibrium Modeling For Different Biomass Materials PDFHotib PerwiraNo ratings yet

- Modern Physics PDFDocument20 pagesModern Physics PDFkaushik247No ratings yet

- Exercise MATTERDocument8 pagesExercise MATTERShu85No ratings yet

- NATIONAL STANDARD EXAMINATION IN PHYSICS 2013-2014Document27 pagesNATIONAL STANDARD EXAMINATION IN PHYSICS 2013-2014S Prasad Shiva PulagamNo ratings yet

- Improvise Air Cooler Saves EnergyDocument21 pagesImprovise Air Cooler Saves EnergyGazelle ValeraNo ratings yet

- RankineCycleOpt NiMechENSEDocument12 pagesRankineCycleOpt NiMechENSEnidhul07No ratings yet

- 6-Overview of Radiation Practices IndusrialDocument59 pages6-Overview of Radiation Practices Indusrialkirandevi1981No ratings yet

- Q4 Module 1 CompressedDocument2 pagesQ4 Module 1 CompressedFELIX ROBERT VALENZUELANo ratings yet

- PE Exam Review - Geotechnical: Demonstration Problem SolutionsDocument34 pagesPE Exam Review - Geotechnical: Demonstration Problem SolutionsShafiullah KhanNo ratings yet

- Grade 10-12 Geography Pamphlet on Solar System, Earth, Latitudes & LongitudesDocument80 pagesGrade 10-12 Geography Pamphlet on Solar System, Earth, Latitudes & LongitudesBøßß PrîñçéNo ratings yet

- Caribbean Coral ReefsDocument21 pagesCaribbean Coral Reefsapi-596903118No ratings yet