Professional Documents

Culture Documents

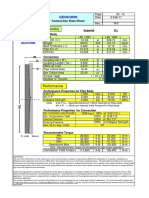

Flushmax-II - TBG 4.5 11.6# N80

Uploaded by

Hiro Garces-SimonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flushmax-II - TBG 4.5 11.6# N80

Uploaded by

Hiro Garces-SimonCopyright:

Available Formats

Metal One Corp.

Page 22-N

FLUSHMAX-II Date 25-Jan-17

Connection Data Sheet Rev. N-1

Geometry Imperial S.I.

Pipe Body

Grade L80 / N80 L80 / N80

Pipe OD ( D ) 4 1/2 in 114.30 mm

FLUSHMAX-II Weight 11.60 lb/ft 17.26 kg/m

Actual weight 11.35 lb/ft 16.89 kg/m

Wall Thickness ( t ) 0.250 in 6.35 mm

Pipe ID ( d ) 4.000 in 101.60 mm

2 2

Pipe body cross section 3.336 in 2,152 mm

Drift Dia. 3.875 in 98.43 mm

Connection

Box OD ( D ) 4.500 in 114.30 mm

PIN ID 4.000 in 101.60 mm

Make up Loss 2.352 in 59.74 mm

Box Critical Area 1.737 in2 1,121 mm2

Box

Joint load efficiency 60 % 60 %

critical Thread Taper 1 / 16 ( 3/4" per ft )

area Number of Threads 8 TPI

Make

d

Performance

up

loss Performance Properties for Pipe Body

S.M.Y.S. 267 kips 1,187 kN

Pin

M.I.Y.P. 7,780 psi 53.66 MPa

critical Collapse Strength 6,350 psi 43.79 MPa

area Note S.M.Y.S.= Specified Minimum YIELD Strength of Pipe body

M.I.Y.P. = Minimum Internal Yield Pressure of Pipe body

Performance Properties for Connection

Tensile Yield load 160 kips ( 60% of S.M.Y.S. )

Min. Compression Yield 160 kips ( 60% of S.M.Y.S. )

Internal Pressure 6,220 psi ( 80% of M.I.Y.P. )

D External Pressure 100% of Collapse Strength

Max. DLS ( deg. /100ft) 25

Recommended Torque

Min. 2,700 ft-lb 3,600 N-m

Opti. 3,200 ft-lb 4,300 N-m

Max. 3,700 ft-lb 5,000 N-m

Operational Max. 3,700 ft-lb 5,000 N-m

Note : Operational Max. torque can be applied for high torque application

Legal Notice

The use of this information is at the reader/user’s risk and no warranty is implied or expressed by Metal One Corporation or its parents, subsidiaries or

affiliates (herein collectively referred to as “Metal One”) with respect to the use of information contained herein. The information provided on this Connection

Data Sheet is for informational purposes only, and was prepared by reference to engineering information that is specific to the subject products, without regard

to safety-related factors, all of which are the sole responsibility of the operators and users of the subject connectors. Metal One assumes no responsibility for

any errors with respect to this information.

Statements regarding the suitability of products for certain types of applications are based on Metal One’s knowledge of typical requirements that are often

placed on Metal One products in standard well configurations. Such statements are not binding statements about the suitability of products for a particular

application. It is the customer’s responsibility to validate that a particular product with the properties described in the product specification is suitable for use in

a particular application

The products described in this Connection Data Sheet are not recommended for use in deep water offshore applications. For more information, please refer

to http://www.mtlo.co.jp/mo-con/_images/top/WebsiteTerms_Active_20333287_1.pdf the contents of which are incorporated by reference into this Connection

Data Sheet.

You might also like

- Cameron - Type U BOPDocument38 pagesCameron - Type U BOPJohn Alexander Bonilla AngelNo ratings yet

- Drilling Rig Inspection ChecklistDocument33 pagesDrilling Rig Inspection Checklistmr_heera75% (4)

- Diaphragm Wall PresentationDocument52 pagesDiaphragm Wall PresentationGagan Goswami100% (11)

- XQ28-2 6Y英文说明书Document26 pagesXQ28-2 6Y英文说明书ADM MTCNo ratings yet

- CALCULATE TRADE AND CASH DISCOUNTSDocument13 pagesCALCULATE TRADE AND CASH DISCOUNTSrommel legaspi71% (7)

- Capital Today FINAL PPMDocument77 pagesCapital Today FINAL PPMAshish AgrawalNo ratings yet

- Tools-Components Stimgun PDFDocument4 pagesTools-Components Stimgun PDFLuis Alfonso EstebanNo ratings yet

- Retrievble Packer System - BakerDocument60 pagesRetrievble Packer System - BakerLAGRAA Med Bechikh KheiraNo ratings yet

- 14P220 Triplex Mud Pump Spec SheetDocument1 page14P220 Triplex Mud Pump Spec SheetWHWENNo ratings yet

- 2006 International Sucker Rod Pumping WorkshopDocument33 pages2006 International Sucker Rod Pumping WorkshopRodrigo DacolNo ratings yet

- Kunkletabla Seleccion PSVDocument12 pagesKunkletabla Seleccion PSVedwinmenaNo ratings yet

- Swaco' Style Drilling Choke PartsDocument1 pageSwaco' Style Drilling Choke PartsBodega 3001No ratings yet

- Financial Statements of An Entity That Have Been Reviewed by An AccountantDocument3 pagesFinancial Statements of An Entity That Have Been Reviewed by An AccountantQueen ValleNo ratings yet

- Metal One Corp. Connection Data SheetDocument1 pageMetal One Corp. Connection Data SheetBalkis FatihaNo ratings yet

- Drill Pipe Make/Break Machines and Spinners by Hawk IndustriesDocument3 pagesDrill Pipe Make/Break Machines and Spinners by Hawk IndustriesShandiPrasetyoNo ratings yet

- Lot Pit CSG TestDocument18 pagesLot Pit CSG TestsrikantaLeeNo ratings yet

- Microeconomics Lecture - Profit Maximization and Competitive SupplyDocument48 pagesMicroeconomics Lecture - Profit Maximization and Competitive Supplybigjanet100% (1)

- Blowout Preventer - Wikipedia PDFDocument70 pagesBlowout Preventer - Wikipedia PDFEndhy Wisnu Novindra100% (1)

- xg01 Koso Kent Introl PDFDocument22 pagesxg01 Koso Kent Introl PDFhaidinuNo ratings yet

- Araña BJ 350 Ton 13 3-8Document60 pagesAraña BJ 350 Ton 13 3-8ceciliachableNo ratings yet

- AB-09-01 Drawworks Auxiliary BrakeDocument2 pagesAB-09-01 Drawworks Auxiliary BrakeAgohuvNo ratings yet

- Safety Budget PlannerDocument12 pagesSafety Budget Plannersidhant nayakNo ratings yet

- Drilling Workshop BHADocument39 pagesDrilling Workshop BHAOnmmmmNo ratings yet

- Drill Collar Performance SheetDocument1 pageDrill Collar Performance SheetИнженер Луис А. ГарсиаNo ratings yet

- Manual RAMSDocument80 pagesManual RAMSPalomaWilson100% (1)

- Specification:: Hammer UnionsDocument5 pagesSpecification:: Hammer Unionscmpuck100% (1)

- Student Report Card ManagementDocument38 pagesStudent Report Card ManagementKannan Thangaraju41% (17)

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance SheetGarcia C L AlbertoNo ratings yet

- Hydraulic Power Tong Parts ManualDocument25 pagesHydraulic Power Tong Parts Manualsebastián BohórquezNo ratings yet

- NitrogenoDocument139 pagesNitrogenoEmanuelLopezNo ratings yet

- Hammer Unions and Swivel Joints GuideDocument16 pagesHammer Unions and Swivel Joints GuideFabricio100% (1)

- A Intro To Fracturing SmallDocument18 pagesA Intro To Fracturing SmallMahmoud HamdyNo ratings yet

- Overshot overview guide for fishing toolsDocument1 pageOvershot overview guide for fishing toolsShazly Sayed AhmedNo ratings yet

- Llave de Tuberia FosterDocument17 pagesLlave de Tuberia FosterjuansinopecNo ratings yet

- Mud/Gas Separator Sizing and Evaluation: G.R. MacdougallDocument6 pagesMud/Gas Separator Sizing and Evaluation: G.R. MacdougallDiego AraqueNo ratings yet

- Man TC 032 PDFDocument10 pagesMan TC 032 PDFVendro MunajadNo ratings yet

- ESQUEMA MULTIBOWL - Cabezal de ProducciónDocument1 pageESQUEMA MULTIBOWL - Cabezal de ProducciónJulianNo ratings yet

- Surface BOP Kill Sheet - Vertical Well (Metric/BarDocument2 pagesSurface BOP Kill Sheet - Vertical Well (Metric/BarMelnapsterDsouzaNo ratings yet

- Dynamic VSST method measures drilling fluid sagDocument3 pagesDynamic VSST method measures drilling fluid sagLMP2 Mud EngineerNo ratings yet

- QCI P3 BrochureDocument2 pagesQCI P3 BrochureiswantmachooNo ratings yet

- 20-1701 Slips DCSDocument7 pages20-1701 Slips DCSRahul M.RNo ratings yet

- 00-24 Proper Clamps Mud HoseDocument2 pages00-24 Proper Clamps Mud Hoseforajistu100% (1)

- NutsDocument8 pagesNutsGerry Dan ChanliongcoNo ratings yet

- Dump Bailer CapacitiesDocument1 pageDump Bailer CapacitiesJulio GuzmánNo ratings yet

- Formation strength data and surface BOP kill sheetDocument0 pagesFormation strength data and surface BOP kill sheetjosesito_amoroso2005No ratings yet

- Equipment Information Sheet: Conventional Coring - Safety JointDocument10 pagesEquipment Information Sheet: Conventional Coring - Safety JointMiguel Chavez Coca100% (1)

- Standard Releasing Spear: Manual B215Document36 pagesStandard Releasing Spear: Manual B215IgorCencičNo ratings yet

- Xyq2 6Document26 pagesXyq2 6Jesús MéndezNo ratings yet

- VAM FJL Torque TableDocument17 pagesVAM FJL Torque TableKhaledFekairNo ratings yet

- Performance Criteria: Work Force 360 Mud PumpDocument1 pagePerformance Criteria: Work Force 360 Mud PumpMIGUEL ANGEL100% (1)

- 575 Venturi Jet Basket Mini Tech Brief Ver 3 PDFDocument8 pages575 Venturi Jet Basket Mini Tech Brief Ver 3 PDFJhonathan MirandaNo ratings yet

- Pipe Data Sheet with Dimensions and SpecificationsDocument1 pagePipe Data Sheet with Dimensions and Specifications087825550697No ratings yet

- Mug Pump Technical InfoDocument5 pagesMug Pump Technical InfoEmmanuel Soberano HernandezNo ratings yet

- Texas Oil Tools: Packer Inserts & EnergizersDocument12 pagesTexas Oil Tools: Packer Inserts & Energizersshahrol effendy rodziNo ratings yet

- Wireline Anchor Weight Indicator Systems Illustrated Parts BreakdownDocument118 pagesWireline Anchor Weight Indicator Systems Illustrated Parts BreakdownLuis AlbarracinNo ratings yet

- Arrow Set Ficha TecnicaDocument3 pagesArrow Set Ficha TecnicaOscar GuaricalloNo ratings yet

- Cup Type TesterDocument1 pageCup Type TesterJohnsNo ratings yet

- SuckerRods Torque Limits V02ii PDFDocument1 pageSuckerRods Torque Limits V02ii PDFsong LiNo ratings yet

- 00087167Document11 pages00087167JohnSmith100% (1)

- Blind Back Off Tubing, Drill PipeDocument1 pageBlind Back Off Tubing, Drill PipeReda BoualiNo ratings yet

- 1 - Drill String & BHA Components - Review - D1 - D2Document27 pages1 - Drill String & BHA Components - Review - D1 - D2علي سعيد سعودNo ratings yet

- C 06.C Wellhead DesignDocument6 pagesC 06.C Wellhead DesignJose David Hernandez OteroNo ratings yet

- Technical Manual Mecanical Bumper SubDocument6 pagesTechnical Manual Mecanical Bumper SubYeisson Rubio100% (1)

- Drilling Rig Components: Crown Block and Water TableDocument8 pagesDrilling Rig Components: Crown Block and Water TableShoq AlahbabNo ratings yet

- Introducción A Las Conexiones Roscadas y Sus Prestaciones PDFDocument51 pagesIntroducción A Las Conexiones Roscadas y Sus Prestaciones PDFRicardo Yashin Tavara La ChiraNo ratings yet

- Tubing Sand Bailer - Titus ToolsDocument3 pagesTubing Sand Bailer - Titus ToolsJeisson E Ruiz DNo ratings yet

- Cavins Double Action Tubing Pump Cleans Out Sand, Scale and Debris in Low Fluid Level WellsDocument2 pagesCavins Double Action Tubing Pump Cleans Out Sand, Scale and Debris in Low Fluid Level WellsHassan KhalidNo ratings yet

- WR Retrieving Tool Product DatasheetDocument2 pagesWR Retrieving Tool Product DatasheetEvolution Oil ToolsNo ratings yet

- Geometry: Geoconn - TsDocument1 pageGeometry: Geoconn - TsPapa AinunNo ratings yet

- TXPButtress Running GuidelinesDocument13 pagesTXPButtress Running Guidelinessmithyry2014No ratings yet

- TenarisXP Buttress BrochureDocument8 pagesTenarisXP Buttress BrochureHitesh YadavNo ratings yet

- Sucker Road CatalogDocument73 pagesSucker Road CatalogHiro Garces-SimonNo ratings yet

- La Luna Resources Block Concessions - v1Document1 pageLa Luna Resources Block Concessions - v1Hiro Garces-SimonNo ratings yet

- Rescursos Hídricos en La Estimulación Hidráulica - Rob JacksonDocument23 pagesRescursos Hídricos en La Estimulación Hidráulica - Rob JacksonHiro Garces-SimonNo ratings yet

- 2 140910004043 Phpapp01Document74 pages2 140910004043 Phpapp01Hamis RamadhaniNo ratings yet

- Rescursos Hídricos en La Estimulación Hidráulica - Rob JacksonDocument23 pagesRescursos Hídricos en La Estimulación Hidráulica - Rob JacksonHiro Garces-SimonNo ratings yet

- Isoefficiency Function A Scalability Metric For PaDocument20 pagesIsoefficiency Function A Scalability Metric For PaDasha PoluninaNo ratings yet

- Digital Marketing - Scope Opportunities and Challenges - IntechOpen PDFDocument31 pagesDigital Marketing - Scope Opportunities and Challenges - IntechOpen PDFPratsNo ratings yet

- MVP Software User Manual: MVP Maestro II - Design Client MVP System Configuration ToolDocument50 pagesMVP Software User Manual: MVP Maestro II - Design Client MVP System Configuration ToolDan CoolNo ratings yet

- Tacana Project (15687597)Document1 pageTacana Project (15687597)jesusNo ratings yet

- Chord MethodDocument17 pagesChord MethodJedielson GirardiNo ratings yet

- Readings in Philippine History: Tanza, Boac, MarinduqueDocument16 pagesReadings in Philippine History: Tanza, Boac, MarinduqueLucy SyNo ratings yet

- How Do I Create An Import DC ApplicationDocument10 pagesHow Do I Create An Import DC ApplicationPeter CheungNo ratings yet

- Manual Panasonic AG-DVC7Document4 pagesManual Panasonic AG-DVC7richercitolector01No ratings yet

- PSC Marpol InspectionDocument1 pagePSC Marpol InspectionΑΝΝΑ ΒΛΑΣΣΟΠΟΥΛΟΥNo ratings yet

- Job DescriptionDocument4 pagesJob Descriptionnafis hasnayenNo ratings yet

- To Gamify or Not To GamifyDocument13 pagesTo Gamify or Not To GamifySedayeBaroonNo ratings yet

- Dryspell+ ManualDocument71 pagesDryspell+ ManualAldo D'AndreaNo ratings yet

- Garmin Etrex 30Document2 pagesGarmin Etrex 30Desli MunarsaNo ratings yet

- Lesson 5Document16 pagesLesson 5DANANo ratings yet

- Content Focus (And Interaction) : Example: Live Lecture (Online or On Campus)Document6 pagesContent Focus (And Interaction) : Example: Live Lecture (Online or On Campus)Dominic LibradillaNo ratings yet

- Analyzing Memory Bus to Meet DDR Specification Using Mixed-Domain Channel ModelingDocument30 pagesAnalyzing Memory Bus to Meet DDR Specification Using Mixed-Domain Channel ModelingVăn CôngNo ratings yet

- Marketing Plan: Walton NextDocument26 pagesMarketing Plan: Walton NextAnthony D SilvaNo ratings yet

- Med - Leaf - Full ReportDocument31 pagesMed - Leaf - Full ReportAdithya s kNo ratings yet

- PK 7Document45 pagesPK 7Hernan MansillaNo ratings yet

- Audprob 9Document2 pagesAudprob 9lovely abinalNo ratings yet

- User's Manual: 2.5" External Hard DriveDocument26 pagesUser's Manual: 2.5" External Hard DriveMathew PhilipNo ratings yet

- Investigating and EvaluatingDocument12 pagesInvestigating and EvaluatingMuhammad AsifNo ratings yet