Professional Documents

Culture Documents

Rocky Mountain Safety Procedures

Uploaded by

SAMUEL POBREOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rocky Mountain Safety Procedures

Uploaded by

SAMUEL POBRECopyright:

Available Formats

This document is part of the Safety Toolbox on http://www.wilderness.

net/safety/

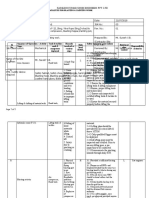

ROCKY MOUNTAIN NATIONAL PARK PAGE 1 OF 3

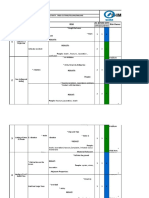

JOB HAZARD ANALYSIS (JHA)

1. WORK PROJECT OR ACTIVITY: 2. DATE: NEW

Lifting/Moving Heavy Loads REVISED

3. LOCATION OF JOB: 4. DIVISION: 5. BRANCH:

Rocky Mountain National Park Facility Management

6. NAME OF EMPLOYEE(S) INVOLVED IN ANALYSIS: 7. SUPERVISOR: 8. DIVISION CHIEF:

9. REQUIRED PERSONAL PROTECTIVE EQUIPMENT:

Gloves, Safety Toe Shoes/Boots

10. REQUIRED TOOLS AND EQUIPMENT:

11. APPLICABLE STANDARDS:

12. TRAINING REQUIREMENTS:

13. SEQUENCE OF JOB STEPS 14. POTENTIAL HAZARD 15. HAZARD CONTROL

Check the intended route and point of placement Slips, Trips & Falls Inspect the area immediately around the load and

Crush Injury the route for clearance and tripping hazards.

Clear movable objects from the route. Check for

uneven terrain. Clean up spills that could affect

foot traction.

Fatigue If the load must be carried for a long distance,

find location(s) load can be placed to allow for a

rest break. If possible, keep load elevated to

avoid lifting the object to resume moving it.

Evaluate the Load Lacerations, Splinters Examine object for snags, burrs, splinters, sharp

edges, nails. Remove objects prior to lift and/or

wear gloves for hand protection.

Crush Injury Check object for greasy/slippery surfaces.

Remove grease prior to lifting. Wear gloves to

improve grip. Wear safety toe shoes/boots.

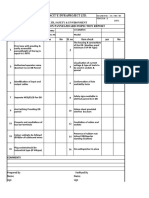

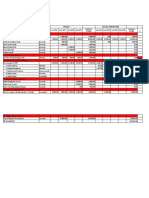

JOB HAZARD ANALYSIS (JHA) CONTINUATION SHEET PAGE 2 OF 3

1. WORK PROJECT OR ACTIVITY:

Lifting/Moving Heavy Loads

13. SEQUENCE OF JOB STEPS 14. POTENTIAL HAZARD 15. HAZARD CONTROL

Back Injury Size up the load before you lift. If load is too

big or awkward:

Divide load up

Ask for help

Use mechanical assist device such as a

hand truck or dolly

Trips, Falls If load will block your vision, get help.

Performing the Lift Crush Injury Grip the object firmly. Do not pinch object

between your thumb and forefinger. Wear

gloves to improve grip.

Back Injury Stand close to object, with feet solid and

shoulder-width apart. Do not reach over an

obstacle to lift the load. Move whatever is in

your way.

Squat down, bending your knees. Keep your

back straight and upright.

Grip the object firmly and pull it close to

you.

Tighten your abdomen.

Lift with your legs in a gradual and smooth

movement. Keep your back straight. Keep

the load close to your body.

Do not twist your body while lifting.

Do not lift objects over your head.

Moving the Load Back Injury Do not twist. Use your feet to turn your

body.

Carry the load as close to your body as

possible.

Keep your back straight.

Crush Injury Take precautions to prevent bruising or crushing

hands or arms in narrow passage ways.

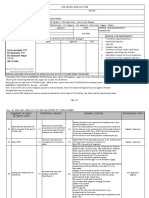

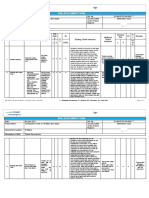

JOB HAZARD ANALYSIS (JHA) CONTINUATION SHEET PAGE 3 OF 3

2. WORK PROJECT OR ACTIVITY:

Lifting/Moving Heavy Loads

13. SEQUENCE OF JOB STEPS 14. POTENTIAL HAZARD 15. HAZARD CONTROL

Lowering the Load Back Injury Keep your back straight.

Tighten your abdomen.

Bend at the knees.

Keep the load close to your body.

Crush Injury Protect your fingers and hands from

pinching and scraping.

In tight places, set the load down close

to the final location and slide it into

place.

Multiple Lifting/Moving Heavy Loads Fatigue Pace yourself. Take breaks

Repetitive Motion Injury Perform a reverse stretch. That means stretch in

the opposite direction of the work you are

doing. Reverse stretches help the body to return

to neutral posture.

Emergency Evacuation Instructions

Work supervisors and crew members are responsible for developing and discussing field emergency evacuation procedures (EEP) and alternatives in the event a person(s)

become seriously ill or injured at the worksite.

Be prepared to provide the following information:

a. Nature of the accident or injury (avoid using the victim’s name).

b. Type of assistance needed, if any (ground, air, or water).

c. Location of accident or injury, best access route into the worksite (road name/number), identifiable ground/air landmarks.

d. Radio frequency(s).

e. Contact Person.

f. Local hazards to ground vehicles or aviation.

g. Weather conditions (wind speed and direction, visibility, temperature).

h. Topography.

i. Number of individuals to be transported.

j. Estimated weight of individuals for air/water evacuation.

The items listed above serve only as guidelines for the development of emergency evacuation procedures.

JHA and Emergency Evacuation Procedures Acknowledgement

We, the undersigned Supervisor and employees, acknowledge participation in the development of this JHA and accompanying emergency evacuation procedures. We have

thoroughly discussed and understand the provisions of each of these documents.

SUPERVISOR’S SIGNATURE DATE:

EMPLOYEE SIGNATURE EMPLOYEE SIGNATURE

EMPLOYEE SIGNATURE EMPLOYEE SIGNATURE

EMPLOYEE SIGNATURE EMPLOYEE SIGNATURE

EMPLOYEE SIGNATURE EMPLOYEE SIGNATURE

EMPLOYEE SIGNATURE EMPLOYEE SIGNATURE

EMPLOYEE SIGNATURE EMPLOYEE SIGNATURE

DIVISION CHIEF’S SIGNATURE DATE:

JHA Instructions Block 14: Identify all known or suspect hazards associated with each respective

task/procedure listed in block 13. For example:

The JHA shall identify the date(s) the JHA was written, the location of the work project a. Research past accidents/incidents

or activity, the Division and Branch writing the JHA, the name of the employee(s) b. Research appropriate literature

writing the JHA, the name of the employee(s)’s supervisor approving the JHA, and the c. Discuss the work project/activity with participants

name of the Division Chief approving the JHA. The Supervisor acknowledges that d. Observe the work project/activity

employees have read and understand the contents, have received the required training, e. A combination of the above

and are qualified to perform the work project or activity.

Block 15: Identify appropriate actions to reduce or eliminate the hazards identified in

Blocks 1, 2, 3, 4, 5: Self explanatory block 14. Abatement measures listed below are the order of the preferred abatement

method:

Block 6: Name of employee(s) writing the JHA a. Engineering Controls: The most desirable method of abatement.

Examples: Ergonomically designed tools, equipment, and furniture

Block 7: Name of employee(s)’s supervisor approving the JHA b. Substitution: Example: Switching to high flash point, non-toxic solvents

c. Administrative Controls: Example: Limiting exposure by reducing the

Block 8: Name of the Division Chief approving the JHA work schedule

d. Personal Protective Equipment (PPE): The least desirable method of

Block 9: List all required Personal Protective Equipment (PPE) identified in Hazard abatement. Example: Hearing protection when working with or close to

Control section of the JHA. portable machines (chainsaws, rock drills, and portable water pumps)

e. A combination of above

Block 10: List all the tools and equipment required to perform the work project or

activity.

Block 11: List all applicable standards associated with the completion of the work

project or activity. (Example: OSHA 1910.134 Respiratory Protection)

Block 12: List specific employee training required to perform the work project or

activity.

Block 13: Identify all tasks and procedures associated with the work project or activity

that have potential to cause injury or illness to personnel and damage to property or

material. Include emergency evacuation procedures (EEP).

You might also like

- JSA Crack Injection at Scruber Basin Unit 3Document6 pagesJSA Crack Injection at Scruber Basin Unit 3MarhendraNo ratings yet

- JHA Maintenance Tech HVACDocument2 pagesJHA Maintenance Tech HVACMdavaNo ratings yet

- JSA Formet New Blasting & PaintingDocument5 pagesJSA Formet New Blasting & Paintingsakthi venkatNo ratings yet

- Contractor Ehs Risk Assessment For NDT TestingDocument6 pagesContractor Ehs Risk Assessment For NDT TestingBernard PenuliarNo ratings yet

- Tool Box Talk - Working in Hot WeatherDocument1 pageTool Box Talk - Working in Hot WeatherMobashir MahmoodNo ratings yet

- Job HazardDocument2 pagesJob HazardBre WirabumiNo ratings yet

- Demolition: Hazards & Control MeasuresDocument9 pagesDemolition: Hazards & Control MeasuresSAMUEL POBRENo ratings yet

- Beauty Assessment Booklet - SHBXWHS001 - Apply Safe Hygiene Health and Work Practices - BookletDocument18 pagesBeauty Assessment Booklet - SHBXWHS001 - Apply Safe Hygiene Health and Work Practices - BookletXantia AmoreNo ratings yet

- TowingSailaway Transportation and Installation PlanDocument27 pagesTowingSailaway Transportation and Installation PlaneNo ratings yet

- John Deere 328 Skid Steer Service Repair Manual (TM2192)Document14 pagesJohn Deere 328 Skid Steer Service Repair Manual (TM2192)laopaodunNo ratings yet

- JSA Forklift PDFDocument2 pagesJSA Forklift PDFfauziNo ratings yet

- AEG - JSA - 107 - Oxygen Acetylene Torch PDFDocument2 pagesAEG - JSA - 107 - Oxygen Acetylene Torch PDFanon_421433640No ratings yet

- Qatar Liquefied Gas Company Limited JSA for Cutting, Grinding and WeldingDocument5 pagesQatar Liquefied Gas Company Limited JSA for Cutting, Grinding and WeldingMohammad Fazal KhanNo ratings yet

- All ChecklistsDocument0 pagesAll Checklistsmalika_00No ratings yet

- NASDA WIND POWER SUB-STATION EXCAVATION SAFETYDocument2 pagesNASDA WIND POWER SUB-STATION EXCAVATION SAFETYRaza Muhammad SoomroNo ratings yet

- Pha ExcavationDocument13 pagesPha ExcavationirshadNo ratings yet

- Building De-Dusting JSADocument3 pagesBuilding De-Dusting JSAJayesh J PillaiNo ratings yet

- Job Safety Analysis Sheet: Activity Potential Hazard Likely Causes Control MeasureDocument2 pagesJob Safety Analysis Sheet: Activity Potential Hazard Likely Causes Control MeasureM Waqas HabibNo ratings yet

- JHA-Mechanical Lifting1Document2 pagesJHA-Mechanical Lifting1john jaycoh veranoNo ratings yet

- Workplace Hazards in ConstructionDocument2 pagesWorkplace Hazards in ConstructionDWi Uwee DejHeNo ratings yet

- Jsa For Site EstablishmentDocument8 pagesJsa For Site EstablishmentBenasher IbrahimNo ratings yet

- Jsa For The Installation of I EamDocument5 pagesJsa For The Installation of I EamMohammed MinhajNo ratings yet

- Toolbox Talks Forklift Safety EnglishDocument1 pageToolbox Talks Forklift Safety EnglishBayu Mandala PratamaNo ratings yet

- Warehouse Job Hazard AssessmentDocument2 pagesWarehouse Job Hazard AssessmentAnonymous cuHV7lTNo ratings yet

- RoutineJobHazardAnalysis 000Document2 pagesRoutineJobHazardAnalysis 000sugiyanto100% (1)

- For Electrical PannelDocument2 pagesFor Electrical Panneljithin shankarNo ratings yet

- QUSAHWIRA FIELD DEVELOPMENTDocument1 pageQUSAHWIRA FIELD DEVELOPMENTJayaprakasan Koyadan KorothNo ratings yet

- JSEA FOR DISMNTLING OF MACHINES (Central Work Shop)Document16 pagesJSEA FOR DISMNTLING OF MACHINES (Central Work Shop)B&R HSE BALCO SEP SiteNo ratings yet

- Heavy Loads ChecklistDocument2 pagesHeavy Loads ChecklistSubzone ThreeNo ratings yet

- EEEPL - JSA Unloading MaterialsDocument3 pagesEEEPL - JSA Unloading MaterialsnishanthNo ratings yet

- Safe Work Procedure: Overhead CraneDocument2 pagesSafe Work Procedure: Overhead CraneNos GoteNo ratings yet

- Al-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetDocument3 pagesAl-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetMustafa hse JafferNo ratings yet

- Machine excavation hazard analysisDocument7 pagesMachine excavation hazard analysisVenkadesh Periathambi100% (1)

- Jobs Safety Analysis: Start DateDocument2 pagesJobs Safety Analysis: Start Dater afriantoNo ratings yet

- 5 First Aid Box Inventory (Old) 2018Document1 page5 First Aid Box Inventory (Old) 2018lez2100% (1)

- Corporate Safety - Template: Job Safety & Environmental Analysis (JSEA) / Safe Work Method Statement (SWMS)Document6 pagesCorporate Safety - Template: Job Safety & Environmental Analysis (JSEA) / Safe Work Method Statement (SWMS)yyyyyuil100% (1)

- Job Hazard Analysis Worksheet: Page 1 of 2Document2 pagesJob Hazard Analysis Worksheet: Page 1 of 2Lourdes Marianne MenesesNo ratings yet

- JSA For Work at HeightDocument3 pagesJSA For Work at Heightbagas prakoso100% (1)

- JSA Pressure TestingDocument1 pageJSA Pressure TestingScott Mills100% (1)

- FR - HSE - 061 - en Permit To Work Audit ChecklistDocument2 pagesFR - HSE - 061 - en Permit To Work Audit ChecklistNibu P ShajiNo ratings yet

- Safe Working PracticesDocument7 pagesSafe Working PracticesDiana ParkerNo ratings yet

- Ocp BatchingDocument1 pageOcp BatchingAarya Mishra TiwariNo ratings yet

- DOD-MST-AKG-2-E-012 (Rev-A) Installation of TransformerDocument4 pagesDOD-MST-AKG-2-E-012 (Rev-A) Installation of TransformerProfessional TrustNo ratings yet

- F-Sp-Hse06-01 Rev 03 Hira NewDocument14 pagesF-Sp-Hse06-01 Rev 03 Hira Newvishal bailurNo ratings yet

- F HSE 008 Job Safety AnalysisDocument27 pagesF HSE 008 Job Safety AnalysisBoy100% (1)

- HIRAC B224 Najarul On ConcreteDocument9 pagesHIRAC B224 Najarul On ConcreteSurendra JangidNo ratings yet

- Akk Jha Installation of Diesel TankDocument3 pagesAkk Jha Installation of Diesel TankDouglas Delly0% (1)

- TSTI FormDocument2 pagesTSTI FormJinu ThomasNo ratings yet

- Incident Reporting Form (Ir 01) : Fatality Lti I RWC Accident NEAR MissDocument1 pageIncident Reporting Form (Ir 01) : Fatality Lti I RWC Accident NEAR Missmuhammadumar412296No ratings yet

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 4Document6 pagesThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 4Nitesh KumarNo ratings yet

- Petrochina International Jabung LTD.: Job Safety AnalysisDocument4 pagesPetrochina International Jabung LTD.: Job Safety AnalysisYosua SitumorangNo ratings yet

- Procedure For OffloadingDocument10 pagesProcedure For OffloadingStansilous Tatenda Nyagomo100% (1)

- Safe Lifting Procedure 2Document6 pagesSafe Lifting Procedure 2angelaNo ratings yet

- Jsa Fan Coil Unites MaintenanceDocument5 pagesJsa Fan Coil Unites MaintenanceASLAM MULANINo ratings yet

- Permanent Facilities Storage ProtectionDocument2 pagesPermanent Facilities Storage ProtectionMOHAMMED RIYAN TNo ratings yet

- Lifting Tools & Tackle RegisterDocument1 pageLifting Tools & Tackle RegisterDth InfraNo ratings yet

- Job Safety Analysis: JSA Basic DataDocument5 pagesJob Safety Analysis: JSA Basic DataPrabhu DivakaranNo ratings yet

- Manual Handling Safety TipsDocument1 pageManual Handling Safety TipsNishadh NishNo ratings yet

- JSA For Pressure Test 2ND REVISIONDocument10 pagesJSA For Pressure Test 2ND REVISIONMuthu AlaguRaj100% (1)

- Job Hazard AnalysisDocument3 pagesJob Hazard AnalysisBrain Dee Tech LtdNo ratings yet

- Jha Region7 GeoprobeDocument10 pagesJha Region7 Geoprobewasif ahmedNo ratings yet

- JSA-03 Shed DismantlingDocument3 pagesJSA-03 Shed DismantlingSwaroop Cherry0% (1)

- Jacks and Vehicle Stands PDFDocument1 pageJacks and Vehicle Stands PDFcityofdarwingisNo ratings yet

- Control of Substances Hazardous To Health - Epoxy PrimerDocument4 pagesControl of Substances Hazardous To Health - Epoxy PrimerSAMUEL POBRENo ratings yet

- LRT1 Admin BLDG Daily BA SheetDocument2 pagesLRT1 Admin BLDG Daily BA SheetSAMUEL POBRENo ratings yet

- 1label For Project Binder - SITE LAYOUTDocument1 page1label For Project Binder - SITE LAYOUTSAMUEL POBRENo ratings yet

- Hazid Baclaran DepotDocument16 pagesHazid Baclaran DepotSAMUEL POBRENo ratings yet

- 1label For Project Binder - Baclaran Depot-Esh Program & ProcessesDocument1 page1label For Project Binder - Baclaran Depot-Esh Program & ProcessesSAMUEL POBRENo ratings yet

- 1label For Project Binder - Legal & Other RequirmentsDocument1 page1label For Project Binder - Legal & Other RequirmentsSAMUEL POBRENo ratings yet

- 001-Jsa Survey & TopographyDocument3 pages001-Jsa Survey & Topographynasution220% (1)

- Hazard Identification and Risk Assessment Control - Tree Cutting & Earth BallingDocument11 pagesHazard Identification and Risk Assessment Control - Tree Cutting & Earth BallingSAMUEL POBRENo ratings yet

- HAZARD IDENTIFICATION AND RISK ASSESSMENT FOR TREE CUTTING AND REMOVAL AT BAC DEPOT EXPANSIONDocument9 pagesHAZARD IDENTIFICATION AND RISK ASSESSMENT FOR TREE CUTTING AND REMOVAL AT BAC DEPOT EXPANSIONSAMUEL POBRENo ratings yet

- HAZARD IDENTIFICATION AND RISK ASSESSMENT FOR TREE CUTTING AND REMOVAL AT BAC DEPOT EXPANSIONDocument9 pagesHAZARD IDENTIFICATION AND RISK ASSESSMENT FOR TREE CUTTING AND REMOVAL AT BAC DEPOT EXPANSIONSAMUEL POBRENo ratings yet

- PPE Guide to Gloves, Gowns, Goggles & MoreDocument25 pagesPPE Guide to Gloves, Gowns, Goggles & MoreElvira ManeteNo ratings yet

- MX 4 Material Safety Data Sheet MsdsDocument7 pagesMX 4 Material Safety Data Sheet MsdsDragos TracheNo ratings yet

- 2020-12-03 St. Mary's County TimesDocument32 pages2020-12-03 St. Mary's County TimesSouthern Maryland OnlineNo ratings yet

- Safety Data Sheet for EP Gear OilDocument11 pagesSafety Data Sheet for EP Gear Oilseguridad mdhNo ratings yet

- Portland Cement: Safety Data SheetDocument11 pagesPortland Cement: Safety Data Sheetanon_381289007No ratings yet

- Polyether Polyol MsdsDocument6 pagesPolyether Polyol MsdsMyo SeinNo ratings yet

- Msds HeptadecaneDocument5 pagesMsds Heptadecanenirmal_subudhiNo ratings yet

- Emergency Response Plan of Chlorine Gas For Process Plants in TaiwanDocument7 pagesEmergency Response Plan of Chlorine Gas For Process Plants in TaiwanRavi Mohan Sharma100% (1)

- New Employee OrientationDocument42 pagesNew Employee OrientationGilbert GillNo ratings yet

- X.9.1.a - Light Framed Steel Framing AHA - AnswerDocument7 pagesX.9.1.a - Light Framed Steel Framing AHA - AnswerBunyamin SelimogluNo ratings yet

- Cooling Tower TNCDocument6 pagesCooling Tower TNCAarol Hatta100% (1)

- Safety Data Sheet for VIDAS FT3 - STR (X9Document14 pagesSafety Data Sheet for VIDAS FT3 - STR (X9Kadek Ayang Cendana PrahayuNo ratings yet

- Inox DMDocument6 pagesInox DMZoran DanilovNo ratings yet

- IIP Program For Low-Hazard Industry EmployersDocument58 pagesIIP Program For Low-Hazard Industry EmployersJoseph DeMaria, Ph.D.No ratings yet

- Afag 310Document4 pagesAfag 310egyinspectoryahooNo ratings yet

- MSDS Liquid Tape Electrical SPDocument14 pagesMSDS Liquid Tape Electrical SPSupervisor ElectricoEECNo ratings yet

- Material Safety AvaenionDocument4 pagesMaterial Safety Avaenionfs1640No ratings yet

- JHEA Loading and Offloading FENCEDocument13 pagesJHEA Loading and Offloading FENCEStansilous Tatenda NyagomoNo ratings yet

- Product Name: Ferric Chloride: Material Safety Data SheetDocument4 pagesProduct Name: Ferric Chloride: Material Safety Data SheetocalensNo ratings yet

- ASHP 2022 AccomplishmentDocument4 pagesASHP 2022 AccomplishmentJoseph EncaboNo ratings yet

- Hydranal Composite 5Document5 pagesHydranal Composite 5doraclopesNo ratings yet

- Risk Assessment Form: Contracting W.L.LDocument7 pagesRisk Assessment Form: Contracting W.L.Lbelhareth seifeddineNo ratings yet

- Safety Data Sheet: Part 1 Chemicals and Corporate LogoDocument5 pagesSafety Data Sheet: Part 1 Chemicals and Corporate LogoGhazanfar GulNo ratings yet

- Checklist Roof Access PolicyDocument1 pageChecklist Roof Access PolicyMarcelo CostaNo ratings yet

- List of PPE Is StandardsDocument2 pagesList of PPE Is StandardstpchowoNo ratings yet

- Safety Data Sheet: 1. IdentificationDocument10 pagesSafety Data Sheet: 1. Identificationnorfatin fadzlinda nordinNo ratings yet

- LFJ FormatDocument3 pagesLFJ Formatdennise reyesNo ratings yet