Professional Documents

Culture Documents

Service Manual PGP/PGM315, 330, 350, 365

Uploaded by

PaulPaucarCamposOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Service Manual PGP/PGM315, 330, 350, 365

Uploaded by

PaulPaucarCamposCopyright:

Available Formats

Service Manual HY09-SM300/US

Service Manual

PGP/PGM315, 330, 350, 365

Effective: April 15, 2002

Supersedes: July 1, 1998

PGP/PGM 300 Series

PGP/PGM 300 Series

Service Manual HY09-SM300/US

Cast Iron

Housings

Case Hardened Gears SAE 2- or 4-Bolt

Mountings

Single Pump

Split-flange or ODT

Ports

High Temperature

Seals

Low-friction

Bushing Coating

One-piece Drive Balanced Thrust Plates

Shaft & Gear Minimize Friction and Leakage

Long Shaft Journals Superior

Bearing Surface

Internal Passage Constantly

Multiple Pump Lubricates Bushings

Large Passages for

Better Pump Feed

Extended Studs

Available for Mounting

Support

Use Genuine Parker Replacement parts

Legal Notification

WARNING

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS AND/OR SYSTEMS DESCRIBED HEREIN OR RELATED ITEMS CAN CAUSE DEATH, PERSONAL

INJURY AND PROPERTY DAMAGE.

This document and other information from Parker Hannifin Corporation, its subsidiaries and authorized distributors provide product and/or system options for further investigation by users

having technical expertise. It is important that you analyze all aspects of your application and review the information concerning the product or system in the current product catalog. Due

to the variety of operating conditions and applications for these products or systems, the user, through its own analysis and testing, is solely responsible for making the final selection of

the products and systems and assuring that all performance, safety and warning requirements of the application are met.

The products described herein, including without limitation, product features, specifications, designs, availability and pricing, are subject to change by Parker Hannifin Corporation and its

subsidiaries at any time without notice.

Offer of Sale

The items described in this document are hereby offered for sale by Parker Hannifin Corporation, its subsidiaries or its authorized distributors. This offer and its acceptance are governed

by the provisions stated in the “Offer of Sale”.

© Copyright 2002, Parker Hannifin Corporation, All Rights Reserved.

2 Parker Hannifin Corporation

Gear Pump Division

Youngstown, OH

PGP/PGM 300 Series

Service Manual HY09-SM300/US

315/330/350/365

Service Manual

General Instructions

These service instructions will familiarize you with

Parker's single and multiple pumps

• their component parts

• the relative position of each part

• proper methods for assembly or disassembly of

the units

To facilitate the repair of these units and before any

work is done, we suggest that you first read all of the

steps used in disassembly and assembly.

Dirt is the enemy of any hydraulic system. The first

requirement for good maintenance of hydraulic

equipment is cleanliness. MAKE SURE YOU

DISASSEMBLE AND ASSEMBLE YOUR

HYDRAULIC EQUIPMENT IN A CLEAN AREA.

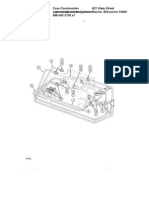

The pictures show Model PGP365. Notes in the

text cover variations between this unit and the

other models.

It is important to airblast all parts and wipe them with

a clean, lintless cloth before assembly. Items shaded apply to

multiple assemblies only.

USE CAUTION IN GRIPPING ALL PARTS

IN THE VISE TO AVOID DAMAGING NOTE:

MACHINED SURFACES. For PGP315 and PGP330 ONLY - Plug 5

required in position A and position B.

A pump must be driven in the direction of rotation for

which it was built; otherwise, pressure will blow the For PGP350 and PGP365 ONLY - Plug 5 in

shaft seal. Check the exploded view and notes at right position B gives clockwise rotation. Plug 5 in

for proper direction of rotation. position A gives counterclockwise rotation.

Parker's PARTS LIST

Replacement Parts 1. Snap Ring

11. Dowel Pins (Solid for

PGP/PGM 315, 330 and

2. Outboard Bearing

Parker's replacement parts are of original equipment 350. Hollow for PGP/PGM

3. Seal

standards. For assured quality of material and work- 365 ONLY.)

4. Shaft End Cover

manship, and for compatibility in assembly, USE 12. Gear Housing

5. Plug

ONLY GENUINE PARTS. 13. Bearing Carrier

6. Bushings

14. Connecting Shaft

Check all replacement parts before installing them to 7. Channel Seal

15. Matched Gear Set

be certain that they were not damaged in shipment. 8. Thrust Plates

16. Gear Housing

9. Integral Drive Shaft

17. Port End Cover

and Gear Set

18. Studs or Cap Screws

10. Gasket Seal

19. Washers

20. Nuts

3 Parker Hannifin Corporation

Gear Pump Division

Youngstown, OH

PGP/PGM 300 Series

Service Manual HY09-SM300/US

Tool List Bushing Puller: The bushings in PGP/PGM315, 330, 350 and 365

pumps may be removed from their bores, using blind hole collet-type

• Arbor press bushing pullers similar to those manufactured by Owatonna Tool Co.

• Awl The table below illustrates the modifications necessary to adapt the

• 1 1/2" Dia. steel ball OTC collets to this task. Equivalent pullers from other suppliers may

• Bearing puller (Owatonna Tool Co. be modified in similar fashion.

M D - 956 or equivalent)

• Bushing remover tool (See A)

• Clean, lintless cloths

• Deburring tool (an old file with

cutting teeth ground off) A

• Machinist's hammer

• Soft hammer PGP/PGM

• Permatex Aviation Form-A-GasketTM 315

PGP/PGM

No. 3 non-hardening sealant or equivalent 330

• Medium grit carborundurn stone PGP/PGM

350

• Seal removal tool (See B)

• Oil and grease

• Snap ring pliers

• Prick punch

• Bushing installation tool (See C)

• Scale ( 1/32" or 1/64" graduations)

• Small screw driver

• Torque wrench

• Vise with 6" minimum opening.

• Bar for lip seal installation

Note: For PGP/PGM315 use 1 5/8" dia. x 2" bar.

For PGP/PGM330 use 1 3/4" dia. x 2" bar. B C

For PGP/PGM350 use 2 1/2" dia. x 2" bar

For PGP/PGM365 use 2 1/2" dia. x 2" bar.

• Special steel sleeve ( see sketch )

Seal Removal Tool PGP/PGM

315

Easily made from an

old screw driver. Heat PGP/PGM

330

the tip and bend as

shown. Grind the tip PGP/PGM

350

to fit the notch behind

PGP/PGM

the shaft seal. 365

Special Steel Sleeve

The special steel sleeve is

used to insert the drive shaft

through the lip seal without

damage and can be made

from bar stock: For the PGP/ PGP/PGM

315

PGM315 use a 1 " dia. x 3-1/

8" bar; for the PGP/PGM330

PGP/PGM

use a 1-1/8" or 1-1/4" dia. x 330

4- 5/8" bar; for the PGP/

PGM350 use a 1-3/8" dia. x PGP/PGM

350

4-5/8" bar; for the PGP/

PGM365 use a 1- 1 /2" dia. x PGP/PGM

4-5/8" bar. The drawing and 365

chart give details for making

this special tool.

4 Parker Hannifin Corporation

Gear Pump Division

Youngstown, OH

PGP/PGM 300 Series

Service Manual HY09-SM300/US

Start Disassembly Here

CAUTION:

1. If prying off sections becomes necessary, take extreme care not to mar or damage machined surfaces. Excessive force while prying

can result in misalignment and seriously damage parts.

2. If parts are difficult to fit during assembly, tap gently with a soft hammer (never use an iron hammer).

3. Gears are closely matched, therefore they must be kept together as sets when removed from a unit. Handle with care to avoid

damage to the journals or teeth. Avoid touching gear journals.

4. Never hammer bushings into bores; use an arbor press.

1) Place the pump in a 2) Use a socket wrench

vise with the drive shaft to remove the 4 cap

pointIng down. Caution: screws on single units or

DO NOT GRIP ON OR the 4 hex nuts, studs

NEAR ANY MACHINED and washers of multiple

SURFACES DURING units.

ASSEMBLY OR

DISASSEMBLY.

Match-mark all sections.

Be sure to align these

marks when

reassembling.

3) Lift off the port end 4) Remove the thrust

cover. If prying is plate. Examine and

necessary, be careful not replace if necessary.

to damage the machined See wear guide page 10.

surfaces. Dowel pins will

remain in either the port

end cover or the gear

housing.

5) Carefully remove the 6) Lift the gear housing

drive and driven gears. from the bearing carrier.

Avoid tapping the gear teeth If prying is necessary,

together or against other take care not to damage

hardened surfaces. Keep machined surfaces.

these gears together Examine and replace

because they are a matched if necessary.

set. Examine and replace if (See page 10)

necessary. (See page 10). For multiple assemblies

Remove the thrust plate only

from the bearing carrier.

Examine and replace if

necessary.

For multiple assemblies only

5 Parker Hannifin Corporation

Gear Pump Division

Youngstown, OH

PGP/PGM 300 Series

Service Manual HY09-SM300/US

7) Carefully lift or pry off 8) Remove the

the bearing carrier to connecting shaft.

prevent damage to Remove the thrust plate.

contact face and edges. Examine and replace if

Dowel pins will remain in necessary. (See page

either the bearing carrier 10). Remove the driven

or the gear housing. gear and the integral gear

DO NOT REMOVE THEM. and drive shaft. Keep

For multiple assemblies only these together as they

are a matched set.

Examine and replace if

necessary. (*See page

10). Be careful not to

damage the machined

surfaces of the gears.

9) Lift or pry off the first 10) Inspect all bushings

section gear housing. Be for scoring or

careful not to damage discoloration and

machined surfaces. replace if necessary.

Examine and replace if Use a bushing puller as

necessary (see page 10). shown in the tool list to

remove bushings (see

page 4).

11) If the pump is 12) Use a bearing puller

equipped with an to remove the outboard

outboard bearing, place bearing.

the shaft end cover in

the vise with the

mounting face up.

Remove the snap ring

with snap ring pliers. If a

unit is equipped with a

spiral-lock retaining ring,

remove with a small

screwdriver or awl.

13) Grip the shaft end

cover in a vise with the

mounting face down.

Remove double lip seal

by inserting the special

seal removal tool (see

Tool List) into the notch

between the double lip

seal and the shaft end

cover. Tap the seal out

and discard.

Remove and discard all

rubber and polymer seals.

6 Parker Hannifin Corporation

Gear Pump Division

Youngstown, OH

PGP/PGM 300 Series

Service Manual HY09-SM300/US

Start Assembly Here

1) Stone all machined 2) If the bushings have

surfaces with a medium been removed, deburr

grit carborundurn stone. the bushing bores with an

emery cloth. Rinse parts

in a solvent. Air blast all

the parts and wipe with

a clean, lintless cloth

before starting assembly.

3) Grip shaft end cover in 4) New plugs should be

vise with mounting face screwed in tightly. Stake

down. Examine plug or the plug with a prick

plugs* to be sure they're punch at both ends of the

tightly in place. screwdriver slot and

Replacement is necessary around edges. Peen the

only if parts are damaged. edge of the hole 1/32" to

Remove with screwdriver. 1/16" with a1-1/2"

*PGP/PGM315 and 330 diameter steel ball.

have two plugs in both the NOTE: If new plug or

shaft end and port end plugs are being installed,

covers. PGP/PGM350 and coat threads with

365 have one plug on the LoctiteTM thread sealant.

outlet side of their shaft end

and port end covers.

5) Note: Assembly steps 5, 6, 7 & 8 6) Bushings should be

apply to shaft end cover, bearing pressed into the bores,

carrier and portend cover. one at a time, using the

Any bushings removed from the special installation tool

shaft end cover, portend cover and an arbor press. Be

or bearing carrier should be sure the that the grooves

assembled in the drive bores with (or seams) are positioned

the groove to the top of unit (12 as stated in Step #5. The

o'clock). Assemble the bushings in bushings must be pressed

the driven bores with the groove to into the bores flush with

the bottom of the unit (6 o'clock). the casting face. Be sure

The PGP/PGM315 does not have to support the castings

grooved bushings, therefore the so that they are square

bushing seams should be placed and level.

at the 12 and 6 o'clock positions.

7) Repeat Steps 1 and 2, 8) See that dowel pins

stone and rinse parts. are in place in any new

castings. Examine all of

the dowels. Before

inserting, make certain

that the hole is clean and

free from burrs. Gently

start the pin straight into

the hole and tap lightly

with a soft hammer.

7 Parker Hannifin Corporation

Gear Pump Division

Youngstown, OH

PGP/PGM 300 Series

Service Manual HY09-SM300/US

9) Before inserting a new lip 10) If the unit is equipped

seal in the shaft end cover, with an outboard bearing,

coat the outer edge of the guide the bearing into its

lip seal and its recess with recess in the shaft end

Permatex Aviation cover. This is a light

Form-A-Gasket™ No. 3 press fit. It may be

non-hardening sealant or necessary to lightly tap

equivalent. With the metal the bearing into the

side of the lip seal up, press bore.

it into the mounting flange

side of the shaft end cover

with an arbor press and bar

(see Tool List on page 4).

Be careful not to damage

the lip of the seal. Press in

until flush with the recess.

Wipe off excess sealant.

11) Install the snap ring in 12) Grease the new gasket

the groove to retain the seals and insert them into

outboard bearing. the grooves in both sides of

all gear housings. Position

the first gear housing over

the shaft end cover and

dowels. Tap it with a soft

hammer until it rests tightly

against the shaft end cover.

Be careful not to pinch the

gasket seal. Also be sure

that the large rounded core

is on the inlet side.

13) Assemble the channel 14) Gently slip the thrust

seals into the grooves in plate through the gear

the thrust plates with the housing and into place on

flat side of the seal facing the shaft end cover. The

away from the thrust plate channel seal from Step

as shown below. #13 should face the shaft

end cover. The relief

groove in the plate should

face the outlet side of the

Flat Side Thrust pump.

of Seal Plate

15) Slide the driven gear 16) Slip the thrust plate

through the housing and into with the seal over the gear

the bushing in the shaft end journals and into the

cover. Coat the steel sleeve housing bore. The flat side

tool with grease. Place the of the seal should face up

lightly-greased drive shaft with the relief groove

inside the sleeve and slide facing the outlet side. (For

both through the shaft end single pump assemblies

cover with a twisting motion, go directly to Step #21).

until the integral gear rests

against the thrust plate.

Avoid damaging the double

lip seal. Remove the steel

sleeve. Squirt clean oil over

the gears.

8 Parker Hannifin Corporation

Gear Pump Division

Youngstown, OH

PGP/PGM 300 Series

Service Manual HY09-SM300/US

17) Place the bearing 18) Insert the connecting

carrier onto the journals shaft into the spline of

of the drive and driven the drive gear. Position

gears. Be sure to line up and place the second

the dowel holes over the gear housing on the

dowel pins. When the bearing carrier as

parts are parallel, outlined in Step #12.

squeeze them together For multiple assemblies

or alternately tap over only

each dowel until the

parts are together.

19) Place the thrust plate 20) Check the plug or

in the gear housing per plugs in the port end

Step #14. Insert the drive cover to be sure that

and driven gears of the they are tight. Follow the

second section in their procedure outlined in

respective bearings. Make Step #4 for new plugs.

certain the gears are in For multiple assemblies

contact with the thrust only

plate face. Place the port

end cover plate in the

housing per Step #16.

For multiple assemblies

only

21) Place the port end 22) Thread the fasteners

cover over the gear into the shaft end cover

journals. Align the dowels and tighten alternately or

with the holes in the cross corner. Rotate the

mating casting. Being drive shaft with a 6"

careful not to pinch the wrench to check for

gasket-seal, tap the port binding. If there is no

end cover lightly in the internal binding, torque

center between bearing diagonally opposed

bores to engage the fasteners to 200 ft. lbs.

dowels and to move parts (2400 in. lbs.); 141 ft. lbs.

together in the final (1700 in. lbs.) for PGP/

seating. PGM315 models; 450 ft.

lbs. (5400 in lbs.) for PGP/

PGM365.

9 Parker Hannifin Corporation

Gear Pump Division

Youngstown, OH

PGP/PGM 300 Series

Service Manual HY09-SM300/US

Guideline for acceptable wear

Gear Housings Dowel Pins

Wear in excess of .007" cut-out necessitates If either the dowel or dowel hole is damaged,

replacement of the gear housing. Place a straight-edge the dowel or machined casting, or both, must

across bore. If you can slip a .007 feeler gage under be replaced.

the straight-edge in the cut-out area, replace

the gear housing. If more than reasonable force is required to

seat dowels, the cause may be poorly deburred

Pressure pushes the gears against the or dirty parts; cocking of the dowel in the hole or

housing on the low pressure side. As the improper pin-to-hole fit.

hubs and bushings wear, the cut-out

becomes more pronounced. Excessive Bushings

cut-out in a short period of time indicates excessive If gears are replaced, bushings must be

pressure or oil contamination. If the relief valve settings replaced. Bushings should fit into the bore with

are within prescribed limits, check for shock pressures a heavy press fit.

or tampering.

When the cut-out is moderate, 007" or less, the gear Seals and Gaskets

housing is in good condition and may be reused. Replace all rubber and polymer seals,

including all "0" rings, thrust plate channel

Gears seals, shaft seal and gasket seals.

Any scoring on gear hubs necessitates

replacement. Scoring, grooving, or Plugs

burring of the outside diameter of the Examine the plugs in the shaft end and port

teeth requires replacement. Nicking, end cover to make sure that they are in the

grooving, or fretting of teeth surfaces also proper position and tight. The PGP/PGM315 and

necessitates replacement. PGP/PGM330 should have two plugs in both the

shaft end and port end in tandem units only. The

Drive Shafts PGP/PGM350 and PGP/PGM365 have one plug in

Replace if there is any wear their shaft and port ends high pressure side only.

detectable by touch in the seal

area or at the drive coupling. The

maximum allowable wear is .002".

Wear in the shaft seal area indicates oil

contamination. Wear or damage to splines, keys,

or keyways necessitates replacement.

Thrust Plates

The thrust plates seal the gear section at

the sides of the gears. Wear here will allow

internal slippage, that is, oil will bypass

within the pump.

A maximum of .002" wear is allowable. Replace

thrust plates if they are scored, eroded or pitted.

Check center of thrust plates where the gears mesh.

Erosion here indicates oil contamination.

Pitted thrust plates indicate cavitation or oil aeration.

Discolored thrust plates indicate overheating, likely due

to insufficient oil.

10 Parker Hannifin Corporation

Gear Pump Division

Youngstown, OH

PGP/PGM 300 Series

Service Manual HY09-SM300/US

Lubrication and Oil

Recommendations

All parts, with the exception of the outboard bearing, General Recommendations:

are lubricated by the hydraulic oil in the circuit. A good-quality hydraulic oil conforming to the

Particular attention must be paid to keep clean oil in characteristics listed above is essential to the

the circuit system. Whenever there is a pump or satisfactory performance and long life of any

motor failure, and there is reason to feel that metal hydraulic system.

particles may be in the system, the oil must be

drained, the entire system flushed clean and any The oil should be changed on regular schedules in

filter screens thoroughly cleaned or replaced. New oil accordance with the manufacturer's recommendations,

should be supplied for the entire system. Oil suitable and the system periodically flushed.

and recommended for use in circuits involving

Parker's pumps and motors should meet the following The oil temperature in the reservoir must not exceed

specifications: 200° F., (93.3° C.) with a maximum temperature of

180° F. (82.2° C.) recommended. Higher temperatures

Viscosity: will result in rapid oil deterioration.

• 50 SSU minimum @ operating temperature

7500 SSU maximum @ starting temperature Reservoir capacity should equal in gallons the pump

output in gpm or the total gpm of all pumps, where

• 150 to 225 SSU @ 100° F. (37.8°C.) (generally) there is more than one in the system.

44 to 48 SSU @ 210° F. (98.9° C.) (generally)

Oil poured into the reservoir should pass through a

100-mesh screen. Pour only clean oil from clean

Approximate SSU @ containers into the reservoir. A 100-mesh screen may

be used in the suction line leading to the pump. A

suction filter should be of sufficient size to handle

twice the pump capacity. It must be cleaned and

checked regularly to avoid damage due to

contamination and cavitation.

Viscosity Index: 90 minimum Normal Temperatures:

O° F. (-1 8° C.) to 100° F. (37.8° C.) Ambient 100° F.

Aniline Point: 175 minimum (37.8° C.) to 180° F. (82.2° C.) System. Be sure your

oil is recommended for the temperatures you expect to

Recommended Additives: Foam depressant,

encounter.

rust and oxidation inhibitors. Filtration: 10 micron

recommended for maximum pump life. Cold Weather Operation:

Other Desirable Characteristics: Oils for use in cold weather should have a viscosity

not exceeding 7500 SSU at the minimum start-up

• Stability of physical and chemical characteristics. temperature. A pour point of at least 20° F. below

• High demulsibility (low emulsibility) for separation start-up temperature is recommended. Start-up

of water, air and contaminants. procedures should allow for a gradual warm-up until

the oil reaches a reasonably fluid state.

• Resistant to the formation of gums, sludges, acids,

tars and varnishes.

• High lubricity and film strength.

Continued on the following page.

11 Parker Hannifin Corporation

Gear Pump Division

Youngstown, OH

PGP/PGM 300 Series

Service Manual HY09-SM300/US

Continued from the previous page Recommended Start-up

Procedure For New or

Rebuilt Pump

The Use of Other Fluids: Before installing a new or rebuilt pump, back off

• Automatic Transmission Fluid (ATF): In general, ATF the main relief valve until the spring tension on the

performance is satisfactory; however these fluids are adjusting screw is relieved. This will avoid the

sometimes too expensive for normal use in hydraulic possibility of immediate damage to the replacement

systems. unit in the event that the relief valve setting had

been increased beyond the recommended operating

• Diesel Fuel or Kerosene (Coal Oil): Though pressure, prior to removing the old unit.

sometimes used as dilutants for cold weather

operations, they are not recommended, as they Before connecting any lines to the pump, fill all ports

are not sufficiently refined. with clean oil to provide initial lubrication. This is

particularly important if the unit is located above the

• Fire Resistant Fluids: DO NOT USE ANY FIRE

oil reservoir.

RESISTANT FLUIDS OR NON-PETROLEUM OILS

WITHOUT CONSULTING OUR TECHNICAL SERVICE After connecting the lines and mounting the

DEPARTMENT. replacement unit, operate the pump at least two

• These suggestions are intended as a guide only. minutes at no load and at low rpm (400 min.) During

OBTAIN YOUR FINAL FLUID RECOMMENDATIONS this break-in period, the unit should run free and not

FROM YOUR FLUID SUPPLIER. develop an excessive amount of heat. If the unit

operates properly, speed and pressure can then be

increased to normal operating settings.

Reset the main relief valve to its proper setting while

the pump is running at maximum operating engine

(motor) speed for the vehicle.

ALWAYS USE AN ACCURATE GAUGE

WHEN ADJUSTING THE RELIEF VALVE

PRESSURE SETTING.

12 Parker Hannifin Corporation

Gear Pump Division

Youngstown, OH

PGP/PGM 300 Series

Service Manual HY09-SM300/US

Recommended

Test Procedure

Make certain that there is an adequate supply of oil for Many repairmen measure the output at normal

the pump; at least one gallon of oiI for each gpm of operating speed and at zero pressure, then again at

pump capacity. 1000 psi (or the operating pressure of the equipment)

and allow a volume decrease approximating the listing

If one section of a tandem pump is being tested, below. It is a suggested reference only which makes

make sure that all other sections not being tested allowance for reused parts.

are adequately supplied with oil. If any of the other

sections run dry, or if plugs are left in ports, serious At test speeds other than 1800 rpm, gpm delivery will

and permanent damage will result. vary almost proportionately, but the same (drop-off)

figures should be used.

The oil should be a good quality hydraulic oil rated at

150 SSU at 100° F., with the oil temperature held at Be sure to run the pump in the direction for which it

120° F. plus or minus 50° F. (Test procedures are was designed and built. Driving the pump in the wrong

described in detail in SAE handbooks; see Hydraulic direction will build up pressure behind the shaft seal,

Power Pump Test Procedure, SAE J745c.) damaging it and necessitating replacement.

The feed line must be of adequate size with no more After completing testing procedures, the pump is

than 5" mercury vacuum adjacent to the pump inlet. As ready for installation and immediate duty operation

a rule, the feed line must provide a feed flow velocity on equipment. Again, it must be remembered that

not in excess of 8 feet per second. to prevent seizure, hot oil must not be fed into a

cold pump.

Feeding hot oil into a cold pump may cause the pump

to seize. Jog the pump by momentarily starting and

stopping repeatedly the driving engine or motor to

gradually equalize pump and oil temperatures.

Run the pump at least two minutes at no load and

moderate speed (not over 1500 rpm). If the pump

becomes excessively hot, shut down immediately and

locate the problem source.

Gradually increase pressure on pump, in 500 psi

increments until the desired test pressure has been

reached. This should take about five minutes.

Delivery should run close to rated catalog performance

figures, which are averaged from testing several

pumps. A 5% lower reading may be used as a rated

minimum if new or relatively new parts have been

used. When rebuilding the pump with parts from the

original pump, which, while worn, appear satisfactory

for reuse, a 10% or 15% lower reading may be

permitted, depending on the performance expected

from the equipment. One's own experience will prove

the best guide here.

13 Parker Hannifin Corporation

Gear Pump Division

Youngstown, OH

PGP/PGM 300 Series

Service Manual HY09-SM300/US

Offer of Sale

The items described in this document and other documents or descriptions provided by Parker Hannifin Corporation, its subsidiaries and its authorized

distributors are hereby offered for sale at prices to be established by Parker Hannifin Corporation, its subsidiaries and its authorized distributors. This offer and

its acceptance by any customer ("Buyer") shall be governed by all of the following Terms and Conditions. Buyer’s order for any such items, when communicated

to Parker Hannifin Corporation, its subsidiary or an authorized distributor ("Seller") verbally or in writing, shall constitute acceptance of this offer.

1. Terms and Conditions of Sale: All descriptions, quotations, propos- items sold hereunder, even if such apparatus has been specially con-

als, offers, acknowledgments, acceptances and sales of Seller’s products verted or adapted for such manufacture and notwithstanding any charges

are subject to and shall be governed exclusively by the terms and paid by Buyer. Unless otherwise agreed, Seller shall have the right to alter,

conditions stated herein. Buyer’s acceptance of any offer to sell is limited discard or otherwise dispose of any special tooling or other property in its

to these terms and conditions. Any terms or conditions in addition to, or sole discretion at any time.

inconsistent with those stated herein, proposed by Buyer in any accep- 8. Buyer’s Property: Any designs, tools, patterns, materials, drawings,

tance of an offer by Seller, are hereby objected to. No such additional, confidential information or equipment furnished by Buyer or any other

different or inconsistent terms and conditions shall become part of the items which become Buyer’s property, may be considered obsolete and

contract between Buyer and Seller unless expressly accepted in writing may be destroyed by Seller after two (2) consecutive years have elapsed

by Seller. Seller’s acceptance of any offer to purchase by Buyer is without Buyer placing an order for the items which are manufactured using

expressly conditional upon Buyer’s assent to all the terms and conditions such property, Seller shall not be responsible for any loss or damage to

stated herein, including any terms in addition to, or inconsistent with those such property while it is in Seller’s possession or control.

contained in Buyer’s offer, Acceptance of Seller’s products shall in all 9. Taxes: Unless otherwise indicated on the face hereof, all prices and

events constitute such assent. charges are exclusive of excise, sales, use, property, occupational or like

2. Payment: Payment shall be made by Buyer net 30 days from the date taxes which may be imposed by any taxing authority upon the manufac-

of delivery of the items purchased hereunder. Amounts not timely paid ture, sale or delivery of the items sold hereunder. If any such taxes must

shall bear interest at the maximum rate permitted by law for each month be paid by Seller or if Seller is liable for the collection of such tax, the

or portion thereof that the Buyer is late in making payment. Any claims by amount thereof shall be in addition to the amounts for the items sold. Buyer

Buyer for omissions or shortages in a shipment shall be waived unless agrees to pay all such taxes or to reimburse Seller therefore upon receipt

Seller receives notice thereof within 30 days after Buyer’s receipt of the of its invoice. If Buyer claims exemption from any sales, use or other tax

shipment. imposed by any taxing authority, Buyer shall save Seller harmless from

3. Delivery: Unless otherwise provided on the face hereof, delivery shall and against any such tax, together with any interest or penalties thereon

be made F.O.B. Seller’s plant. Regardless of the method of delivery, which may be assessed if the items are held to be taxable.

however, risk of loss shall pass to Buyer upon Seller’s delivery to a carrier. 10. Indemnity For Infringement of Intellectual Property Rights: Seller

Any delivery dates shown are approximate only and Seller shall have no shall have no liability for infringement of any patents, trademarks, copy-

liability for any delays in delivery. rights, trade dress, trade secrets or similar rights except as provided in this

4. Warranty: Seller warrants that the items sold hereunder shall be free Part 10. Seller will defend and indemnify Buyer against allegations of

from defects in material or workmanship for a period of 18 months from infringement of U.S. Patents, U.S. Trademarks, copyrights, trade dress

date of shipment from Parker Hannifin Corporation. THIS WARRANTY and trade secrets (hereinafter ‘Intellectual Property Rights’). Seller will

COMPRISES THE SOLE AND ENTIRE WARRANTY PERTAINING TO defend at its expense and will pay the cost of any settlement or damages

ITEMS PROVIDED HEREUNDER. SELLER MAKES NO OTHER WAR- awarded in an action brought against Buyer based on an allegation that an

RANTY, GUARANTEE, OR REPRESENTATION OF ANY KIND WHAT- item sold pursuant to this contract infringes the Intellectual Property Rights

SOEVER. ALL OTHER WARRANTIES, INCLUDING BUT NOT LIM- of a third party. Seller’s obligation to defend and indemnify Buyer is

ITED TO, MERCHANTABILITY AND FITNESS FOR PURPOSE, contingent on Buyer notifying Seller within ten (10) days after Buyer

WHETHER EXPRESS, IMPLIED, OR ARISING BY OPERATION OF becomes aware of such allegations of infringement, and Seller having sole

LAW, TRADE USAGE, OR COURSE OF DEALING ARE HEREBY control over the defense of any allegations or actions including all

DISCLAIMED. NOTWITHSTANDING THE FOREGOING, THERE negotiations for settlement or compromise. If an item sold hereunder is

ARE NO WARRANTIES WHATSOEVER ON ITEMS BUILT OR AC- subject to a claim that it infringes the Intellectual Property Rights of a third

QUIRED WHOLLY OR PARTIALLY, TO BUYER’S DESIGNS OR party, Seller may, at its sole expense and option, procure for Buyer the right

SPECIFICATIONS. to continue using said item, replace or modify said item so as to make it

5. Limitation Of Remedy: SELLER’S LIABILITY ARISING FROM OR IN noninfringing, or offer to accept return of said item and return the purchase

ANY WAY CONNECTED WITH THE ITEMS SOLD OR THIS CON- price less a reasonable allowance for depreciation. Notwithstanding the

TRACT SHALL BE LIMITED EXCLUSIVELY TO REPAIR OR RE- foregoing, Seller shall have no liability for claims of infringement based on

PLACEMENT OF THE ITEMS SOLD OR REFUND OF THE PURCHASE information provided by Buyer, or directed to items delivered hereunder for

PRICE PAID BY BUYER, AT SELLER’S SOLE OPTION. IN NO EVENT which the designs are specified in whole or part by Buyer, or infringements

SHALL SELLER BE LIABLE FOR ANY INCIDENTAL, CONSEQUEN- resulting from the modification, combination or use in a system of any item

TIAL OR SPECIAL DAMAGES OF ANY KIND OR NATURE WHATSO- sold hereunder. The foregoing provisions of this Part 10 shall constitute

EVER, INCLUDING BUT NOT LIMITED TO LOST PROFITS ARISING Seller’s sole and exclusive liability and Buyer’s sole and exclusive remedy

FROM OR IN ANY WAY CONNECTED WITH THIS AGREEMENT OR for infringement of Intellectual Property Rights.

ITEMS SOLD HEREUNDER, WHETHER ALLEGED TO ARISE FROM If a claim is based on information provided by Buyer or if the design for an

BREACH OF CONTRACT, EXPRESS OR IMPLIED WARRANTY, OR IN item delivered hereunder is specified in whole or in part by Buyer, Buyer

TORT, INCLUDING WITHOUT LIMITATION, NEGLIGENCE, FAILURE shall defend and indemnify Seller for all costs, expenses or judgments

TO WARN OR STRICT LIABILITY. resulting from any claim that such item infringes any patent, trademark,

6. Changes, Reschedules and Cancellations: Buyer may request to copyright, trade dress, trade secret or any similar right.

modify the designs or specifications for the items sold hereunder as well 11. Force Majeure: Seller does not assume the risk of and shall not be

as the quantities and delivery dates thereof, or may request to cancel all liable for delay or failure to perform any of Seller’s obligations by reason

or part of this order, however, no such requested modification or cancel- of circumstances beyond the reasonable control of Seller (hereinafter

lation shall become part of the contract between Buyer and Seller unless ‘Events of Force Majeure’). Events of Force Majeure shall include without

accepted by Seller in a written amendment to this Agreement. Acceptance limitation, accidents, acts of God, strikes or labor disputes, acts, laws, rules

of any such requested modification or cancellation shall be at Seller’s or regulations of any government or government agency, fires, floods,

discretion, and shall be upon such terms and conditions as Seller may delays or failures in delivery of carriers or suppliers, shortages of materials

require. and any other cause beyond Seller’s control.

7. Special Tooling: A tooling charge may be imposed for any special 12. Entire Agreement/Governing Law: The terms and conditions set

tooling, including without limitation, dies, fixtures, molds and patterns, forth herein, together with any amendments, modifications and any

acquired to manufacture items sold pursuant to this contract. Such special different terms or conditions expressly accepted by Seller in writing, shall

tooling shall be and remain Seller’s property notwithstanding payment of constitute the entire Agreement concerning the items sold, and there are

any charges by Buyer. In no event will Buyer acquire any interest in no oral or other representations or agreements which pertain thereto. This

apparatus belonging to Seller which is utilized in the manufacture of the Agreement shall be governed in all respects by the law of the State of Ohio.

No actions arising out of the sale of the items sold hereunder or this

Agreement may be brought by either party more than two (2) years after

the cause of action accrues.

9/91-P

14 Parker Hannifin Corporation

Gear Pump Division

Youngstown, OH

PGP/PGM 300 Series

Service Manual HY09-SM300/US

Parker Hannifin Corporation

About Parker Hannifin Corporation Parker’s Charter

Parker Hannifin is a leading global motion-control To be a leading worldwide manufacturer of components

company dedicated to delivering premier customer and systems for the builders and users of durable

service. A Fortune 500 corporation listed on the goods. More specifically, we will design, market and

New York Stock Exchange (PH), our components manufacture products controlling motion, flow and

and systems comprise over 1,400 product lines that pressure. We will achieve profitable growth through

control motion in some 1,000 industrial and premier customer service.

aerospace markets. Parker is the only

manufacturer to offer its customers a choice of Product Information

hydraulic, pneumatic, and electromechanical North American customers seeking product information,

motion-control solutions. Our the location of a nearby distributor, or repair services

Company has the largest distribution network in its will receive prompt attention by calling the Parker

field, with over 7,500 distributors serving more Product Information Center at our toll-free number:

than 350,000 customers worldwide. 1-800-C-PARKER (1-800-272-7537). In the UK, a similar

service is available by calling 0500-103-203.

The Aerospace Group The Climate & Industrial

is a leader in the development, Controls Group

design, manufacture and designs, manufactures and

servicing of control systems markets system-control and

and components for aerospace fluid-handling components

and related high-technology and systems to refrigeration,

markets, while achieving air-conditioning and industrial

growth through premier customers worldwide.

customer service.

The Fluid Connectors The Seal Group designs,

Group designs, manufactures manufactures and distributes

and markets rigid and flexible industrial and commercial

connectors, and associated sealing devices and related

products used in pneumatic products by providing

and fluid systems. superior quality and

total customer satisfaction.

The Hydraulics Group The Filtration Group

designs, produces and designs, manufactures and

markets a full spectrum markets quality filtration

of hydraulic components and clarification products,

and systems to builders providing customers with

and users of industrial the best value, quality,

and mobile machinery technical support, and

and equipment. global availability.

The Automation Group The Instrumentation

is a leading supplier of Group is a global leader

pneumatic and electro- in the design, manufacture

mechanical components and distribution of high-

and systems to automation quality critical flow

customers worldwide. components for worldwide

process instrumentation,

ultra-high-purity, medical

and analytical applications.

15 Parker Hannifin Corporation

Gear Pump Division

Youngstown, OH

Parker Hannifin Corporation Service Manual HY09-SM300/US

Gear Pump Division 04/02 T&M 2.5M

1775 Logan Avenue

Youngstown, OH 44501 USA

Tel: (330) 746-8011

Fax: (330) 746-1148

www.parker.com

You might also like

- DISOCONT® Tersus Weighfeeder Instruction Manual bvh2407gbDocument338 pagesDISOCONT® Tersus Weighfeeder Instruction Manual bvh2407gbMizi KoNo ratings yet

- V51065 Clark 19D AxleDocument117 pagesV51065 Clark 19D AxlePaulPaucarCamposNo ratings yet

- Roto-Xtend Duty Fluid: Safety Data SheetDocument7 pagesRoto-Xtend Duty Fluid: Safety Data SheetPEDRO PABLO DUQUENo ratings yet

- V61167 Commercial VA20 35 VG20 35 DCVDocument31 pagesV61167 Commercial VA20 35 VG20 35 DCVPaulPaucarCampos100% (1)

- Sally JamesonDocument3 pagesSally JamesonMithun Sridharan100% (2)

- p1 PD XL Service Lte 00062 3 C 0707 075 100 140Document42 pagesp1 PD XL Service Lte 00062 3 C 0707 075 100 140Bernardo Orozco LariosNo ratings yet

- HALLITEDocument318 pagesHALLITERubensNo ratings yet

- 1630002Document16 pages1630002Israel RamoneNo ratings yet

- Yuken DSHGDocument28 pagesYuken DSHGDian PramadiNo ratings yet

- Traction Module (Flow Divider) RTM: RE 64592/05.2015, Bosch Rexroth AGDocument20 pagesTraction Module (Flow Divider) RTM: RE 64592/05.2015, Bosch Rexroth AGZu PiNo ratings yet

- Denison GOLD CUP Product Catalog Piston Pumps & Motors: For Open & Closed CircuitsDocument88 pagesDenison GOLD CUP Product Catalog Piston Pumps & Motors: For Open & Closed CircuitsUsama PopatiaNo ratings yet

- 10 01 Breather Filters GBDocument8 pages10 01 Breather Filters GBosuengNo ratings yet

- Aa2fm Model CodeDocument27 pagesAa2fm Model CodeCristianNo ratings yet

- Accumulator Charging Valves: Single Charging Valves, Dual Charging Valves, and Load Sensing Charging ValvesDocument27 pagesAccumulator Charging Valves: Single Charging Valves, Dual Charging Valves, and Load Sensing Charging ValvesPedro MendozaNo ratings yet

- VAG HYsec Hydraulic Brake and Lift UnitDocument3 pagesVAG HYsec Hydraulic Brake and Lift UnitLuka Borna100% (1)

- Relief Cartridge ValvesDocument16 pagesRelief Cartridge Valvesvivek_11111987No ratings yet

- High Torque Radial Piston Motors MR Type: Fixed Displacement (Up To 9000 CM /rev - 550 in /rev)Document56 pagesHigh Torque Radial Piston Motors MR Type: Fixed Displacement (Up To 9000 CM /rev - 550 in /rev)Edwin Mamani DiazNo ratings yet

- 2011 AC & DC Hydraulic Power Packs CompactDocument97 pages2011 AC & DC Hydraulic Power Packs CompactNicolae MogosNo ratings yet

- The Staffa Motor For PDFDocument134 pagesThe Staffa Motor For PDFOMP Hydraulics O Meara PartsNo ratings yet

- Pilot Oil Supply: Type: MHSTE5G L1X/350 MHSTE5G L1X/100Document9 pagesPilot Oil Supply: Type: MHSTE5G L1X/350 MHSTE5G L1X/100anandsubbiahNo ratings yet

- Gearbox-Mounted Power Take Off: General InstructionsDocument4 pagesGearbox-Mounted Power Take Off: General InstructionsChimuonechi NyirendaNo ratings yet

- TD8600005733 03e PDFDocument93 pagesTD8600005733 03e PDFshahnamNo ratings yet

- Cat. Hy15-3502-R PDFDocument659 pagesCat. Hy15-3502-R PDFRuddy Ral100% (1)

- EH DX300LC DemolitioNDocument12 pagesEH DX300LC DemolitioNCopemaq CopemaqNo ratings yet

- Pressure relief and anti-cavitation valves for mobile applicationsDocument12 pagesPressure relief and anti-cavitation valves for mobile applicationsOleg080No ratings yet

- PM - Clinic D375A-5Document6 pagesPM - Clinic D375A-5Lucio ValderramaNo ratings yet

- 15 05 025 - Modification and Refurbishment ReportDocument9 pages15 05 025 - Modification and Refurbishment ReportEngineersEDGE CoimbatoreNo ratings yet

- Link-Belt t004 - r00431 - v0Document16 pagesLink-Belt t004 - r00431 - v0macsosaNo ratings yet

- 4 X 5 and 5 X 6 Parts & Service Manual TUL-C-600 - A PDFDocument47 pages4 X 5 and 5 X 6 Parts & Service Manual TUL-C-600 - A PDFzachNo ratings yet

- Front Mount HF TechdataDocument14 pagesFront Mount HF TechdataAlexandru NicuNo ratings yet

- Motores HagglundsDocument8 pagesMotores HagglundsThiago SilvaNo ratings yet

- PCT 1174326Document36 pagesPCT 1174326Andy HaywardNo ratings yet

- SPRAGUE J Pump BrochureDocument8 pagesSPRAGUE J Pump BrochurechauduonguyenNo ratings yet

- L20 Series: Service and Repair ManualDocument28 pagesL20 Series: Service and Repair ManualJoe CorreaNo ratings yet

- P2 Series InstallationlManualDocument6 pagesP2 Series InstallationlManualxxshNo ratings yet

- Full Line Brochure 7-2021Document32 pagesFull Line Brochure 7-2021PrudzNo ratings yet

- D155axi-8 Sen06521-02 Circuit DiagramDocument29 pagesD155axi-8 Sen06521-02 Circuit Diagramhaimay118No ratings yet

- Eaton Closed and Open Loop Hydraulic Motor Duraforce™ HMV / HMR / HMF / HmaDocument52 pagesEaton Closed and Open Loop Hydraulic Motor Duraforce™ HMV / HMR / HMF / Hmaeaglego00No ratings yet

- PVG32 Каталог SAE Версия HK.57.B1.22 PDFDocument44 pagesPVG32 Каталог SAE Версия HK.57.B1.22 PDFDeutsch themeNo ratings yet

- Slewing Units - en-US - 20140701 - 121105Document74 pagesSlewing Units - en-US - 20140701 - 121105Putut SuprihartonoNo ratings yet

- POCLAINDocument3 pagesPOCLAINthierrylindoNo ratings yet

- CH165A-AB: 13,700 LB First Layer Line PullDocument2 pagesCH165A-AB: 13,700 LB First Layer Line Pulliyan supriadiNo ratings yet

- Stick Cylinder - Pala Hidraulica 6040FSDocument9 pagesStick Cylinder - Pala Hidraulica 6040FSAbel Jairo Santos CabelloNo ratings yet

- E-OLSS: Electronic ControlDocument12 pagesE-OLSS: Electronic ControlSamidiNo ratings yet

- Manual Programacion AndroidDocument108 pagesManual Programacion AndroidFranz JW MontezaNo ratings yet

- Installation and Maintenance Guide for Compact CB MotorsDocument34 pagesInstallation and Maintenance Guide for Compact CB MotorsBibhudutta JethyNo ratings yet

- Fixed Displacement Pump Technical SpecsDocument20 pagesFixed Displacement Pump Technical SpecsTaz Juan GNo ratings yet

- General, Steering ComponentsDocument60 pagesGeneral, Steering ComponentsIndra H BasriNo ratings yet

- ICVD 01 GB 0319 - WebDocument20 pagesICVD 01 GB 0319 - WebintecelNo ratings yet

- OMH - RI - Repair InstructionsDocument16 pagesOMH - RI - Repair Instructionsjose manuel barroso pantoja100% (1)

- Owner GuideDocument741 pagesOwner Guidealfatih1407497100% (1)

- Service Parts Manual: Series 40 M25 Axial Piston Tandem PumpDocument40 pagesService Parts Manual: Series 40 M25 Axial Piston Tandem Pumpjose manuel barroso pantojaNo ratings yet

- 45 Series G Frame 74cc and 90cc Parts Manual (520L0582 REV AA Dec 2007)Document56 pages45 Series G Frame 74cc and 90cc Parts Manual (520L0582 REV AA Dec 2007)Sasko Dimitrov100% (2)

- A2vk PDFDocument10 pagesA2vk PDFMohar SinghNo ratings yet

- Industrial Apron FeedersDocument5 pagesIndustrial Apron FeederstonyNo ratings yet

- SB Series: Specification SheetDocument18 pagesSB Series: Specification Sheet'X-fuera' Orchid PhiencNo ratings yet

- Tomar - Industrial Signalling CatalogDocument82 pagesTomar - Industrial Signalling CatalogPrejit RadhakrishnaNo ratings yet

- Denison Calzoni Type MRT Mrte MRTFDocument24 pagesDenison Calzoni Type MRT Mrte MRTFSilvio RomanNo ratings yet

- PGP/PGM600: Service ManualDocument20 pagesPGP/PGM600: Service ManualARTMehr Eng. GroupNo ratings yet

- Hy13 PMD300 SM - UsDocument32 pagesHy13 PMD300 SM - UsJared VegaNo ratings yet

- P2 P3 Series Piston Pumps Variable Displacement HY28 1559 01 PTDocument64 pagesP2 P3 Series Piston Pumps Variable Displacement HY28 1559 01 PTphuocloi82No ratings yet

- Pump & Motor Division Pump & Motor Division: Vocational Truck Pump Program Catalog PGP/PGM 600 Series Service ManualDocument32 pagesPump & Motor Division Pump & Motor Division: Vocational Truck Pump Program Catalog PGP/PGM 600 Series Service Manualรัตนชัย บัวจํารัสNo ratings yet

- V80839 Mesabi Internal Cleaning Service Bulletin 112Document1 pageV80839 Mesabi Internal Cleaning Service Bulletin 112PaulPaucarCamposNo ratings yet

- V80838 Murphy PowerView Wiring DiagramsDocument2 pagesV80838 Murphy PowerView Wiring DiagramsPaulPaucarCampos100% (1)

- V80763 IL2 RF2 CF2 Low Pressure FiltersDocument14 pagesV80763 IL2 RF2 CF2 Low Pressure FiltersPaulPaucarCamposNo ratings yet

- V301092 Donaldson Air Restriction EffectsDocument8 pagesV301092 Donaldson Air Restriction EffectsPaulPaucarCamposNo ratings yet

- Murphy CodigoDocument4 pagesMurphy CodigoGonzalo VillarroelNo ratings yet

- V80768 Donaldson Radial Seal InstructionsDocument1 pageV80768 Donaldson Radial Seal InstructionsPaulPaucarCamposNo ratings yet

- V80696 MSDS Hall Chem Antifreeze Super DieselDocument4 pagesV80696 MSDS Hall Chem Antifreeze Super DieselPaulPaucarCamposNo ratings yet

- V61342 Parker Piston AccumulatorsDocument24 pagesV61342 Parker Piston AccumulatorsPaulPaucarCamposNo ratings yet

- V80832 MSDS Petro Canada DuronE Engine Oil SAE 15W-40Document5 pagesV80832 MSDS Petro Canada DuronE Engine Oil SAE 15W-40PaulPaucarCamposNo ratings yet

- V80541 Lincoln Chassis Lube Electric Grease Pump ADocument4 pagesV80541 Lincoln Chassis Lube Electric Grease Pump APaulPaucarCamposNo ratings yet

- V80827 Lincoln Chassis Lube UV Divider ValvesDocument4 pagesV80827 Lincoln Chassis Lube UV Divider ValvesPaulPaucarCamposNo ratings yet

- V80814 Parker in-AGB Series Hydraulic Filter InsertsDocument10 pagesV80814 Parker in-AGB Series Hydraulic Filter InsertsPaulPaucarCamposNo ratings yet

- V62139 United Electrics Pressure SwitchDocument4 pagesV62139 United Electrics Pressure SwitchPaulPaucarCamposNo ratings yet

- V80707 Gresen KCL-RPL Relief Valve SpecificationsDocument4 pagesV80707 Gresen KCL-RPL Relief Valve SpecificationsPaulPaucarCamposNo ratings yet

- v80694 Msds Ansul Foray SpanishDocument6 pagesv80694 Msds Ansul Foray SpanishPaulPaucarCamposNo ratings yet

- V80647 Parker Series 15-30P High Pressure FiltersDocument12 pagesV80647 Parker Series 15-30P High Pressure FiltersPaulPaucarCamposNo ratings yet

- V80695 MSDS Petro Canada Diesel FuelDocument5 pagesV80695 MSDS Petro Canada Diesel FuelPaulPaucarCamposNo ratings yet

- Hydraulic Power Brake Valve: Pedal Actuated - Reverse ModulatingDocument4 pagesHydraulic Power Brake Valve: Pedal Actuated - Reverse ModulatingPaulPaucarCampos100% (1)

- V62143 Danfoss Flow Amplifier InstructionsDocument1 pageV62143 Danfoss Flow Amplifier InstructionsPaulPaucarCamposNo ratings yet

- V62126 Danfoss Hydrostatic Steering UnitDocument32 pagesV62126 Danfoss Hydrostatic Steering UnitPaulPaucarCamposNo ratings yet

- V80516 Ansul Fire Supp Owners ManualDocument12 pagesV80516 Ansul Fire Supp Owners ManualPaulPaucarCamposNo ratings yet

- V51069 Universal Joints TroubleshootingDocument9 pagesV51069 Universal Joints TroubleshootingPaulPaucarCamposNo ratings yet

- V62158 Rexroth Accumulator Charge ValveDocument2 pagesV62158 Rexroth Accumulator Charge ValvePaulPaucarCamposNo ratings yet

- V80690 MSDS Petro Canada Multipurpose Grease Lube EP1 EP2Document4 pagesV80690 MSDS Petro Canada Multipurpose Grease Lube EP1 EP2PaulPaucarCamposNo ratings yet

- V62124 Danfoss Flow Amplifier Service ManualDocument43 pagesV62124 Danfoss Flow Amplifier Service ManualPaulPaucarCamposNo ratings yet

- Material Safety Data Sheet: Section 1. Chemical Product and Company IdentificationDocument5 pagesMaterial Safety Data Sheet: Section 1. Chemical Product and Company IdentificationPaulPaucarCamposNo ratings yet

- V80767 Donaldson General Service Tips PDFDocument1 pageV80767 Donaldson General Service Tips PDFPaulPaucarCamposNo ratings yet

- Model Question Paper WeldingDocument4 pagesModel Question Paper Weldingjasminnee100% (1)

- Construction and Building Materials: Weena Lokuge, Aaron Wilson, Chamila Gunasekara, David W. Law, Sujeeva SetungeDocument10 pagesConstruction and Building Materials: Weena Lokuge, Aaron Wilson, Chamila Gunasekara, David W. Law, Sujeeva SetungeAndrew PiNo ratings yet

- AmwayDocument14 pagesAmwayAlpesh GajjarNo ratings yet

- Gas Lift Design With Self-Well GasDocument12 pagesGas Lift Design With Self-Well GasMohanad HussienNo ratings yet

- INMATEH-Agricultural Engineering Vol.42 - 2014Document175 pagesINMATEH-Agricultural Engineering Vol.42 - 2014Popa LucretiaNo ratings yet

- DFT QuestionsDocument8 pagesDFT QuestionsAdhi SuruliNo ratings yet

- Alexandra Elena Plesu (Bonet Ruiz) PHD ThesisDocument278 pagesAlexandra Elena Plesu (Bonet Ruiz) PHD ThesisThắng MinerNo ratings yet

- PHT3D Tutorial: Pyrite Oxidation ModelingDocument32 pagesPHT3D Tutorial: Pyrite Oxidation ModelingluisgeologoNo ratings yet

- Using Manipulatives To Teach DecimalsDocument2 pagesUsing Manipulatives To Teach DecimalsfazamyNo ratings yet

- Fundamentals of Mathematics L-1 To 22Document200 pagesFundamentals of Mathematics L-1 To 22tanmoy bhattacharjeeNo ratings yet

- 고체역학 문제집Document41 pages고체역학 문제집Michael MeashoNo ratings yet

- Shop Inspection and Test Plan for FRP Water TroughDocument29 pagesShop Inspection and Test Plan for FRP Water TroughEljo AndsNo ratings yet

- Chap2 (B) Fits and TolerancesDocument20 pagesChap2 (B) Fits and TolerancesjojoNo ratings yet

- Adventures in Lead Times PDFDocument20 pagesAdventures in Lead Times PDFAvinash RoutrayNo ratings yet

- Soil Mechanics Lab Teaches Engineering ConceptsDocument4 pagesSoil Mechanics Lab Teaches Engineering Conceptskaas1992No ratings yet

- Julien Rico JR On BehanceDocument5 pagesJulien Rico JR On Behancekira distinctNo ratings yet

- Oil Families in Canadian Williston Basin (Southwestern Saskatchewan) - Osadetz, Snowdon, Brooks - (42, 155-177) - (1994) - PAPERDocument24 pagesOil Families in Canadian Williston Basin (Southwestern Saskatchewan) - Osadetz, Snowdon, Brooks - (42, 155-177) - (1994) - PAPERVitor8AzevedoNo ratings yet

- G6 Q3 Week 2 Jan. 15 19 2024 2Document12 pagesG6 Q3 Week 2 Jan. 15 19 2024 2milc.angela.malabananNo ratings yet

- You Can Do The CubeDocument16 pagesYou Can Do The Cubedeborahmorton100% (1)

- Fluid Mechanics: Chapter Three: Fluid StaticsDocument66 pagesFluid Mechanics: Chapter Three: Fluid StaticsHamidNo ratings yet

- CP R77 Gaia AdminGuideDocument230 pagesCP R77 Gaia AdminGuideRamiro BojorquezNo ratings yet

- 〈85〉 Bacterial Endotoxins TestDocument6 pages〈85〉 Bacterial Endotoxins Testahmed sonyNo ratings yet

- A New Fault Location Method For Underground Cables in Distribution SystemsDocument5 pagesA New Fault Location Method For Underground Cables in Distribution SystemsRagil SenpaiNo ratings yet

- 13/15/19-Wire Installation Guide: D2proDocument1 page13/15/19-Wire Installation Guide: D2proerickNo ratings yet

- Excel 2003 Bible PDF RapidshareDocument2 pagesExcel 2003 Bible PDF RapidshareUrsulaNo ratings yet

- Giant Salt Basin in Peru OverlookedDocument18 pagesGiant Salt Basin in Peru OverlookedFred LuqueNo ratings yet

- 1SXP403001B0202 Su200mDocument10 pages1SXP403001B0202 Su200mAkash kumarNo ratings yet

- Controlled Atmosphere StorageDocument9 pagesControlled Atmosphere StorageAnaniah BlessingNo ratings yet