Professional Documents

Culture Documents

Mech Easy

Uploaded by

ananda narayananCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mech Easy

Uploaded by

ananda narayananCopyright:

Available Formats

Downloaded From : www.EasyEngineering.

net

ww

w.E

a syE

ngi

nee

rin

g.n

et

**Note: Other Websites/Blogs Owners Please do not Copy (or) Republish

this Materials without Legal Permission of the Publishers.

**Disclimers : EasyEngineering not the original publisher of this Book/Material

on net. This e-book/Material has been collected from other sources of net.

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

SYLLABUS

ME6702- MECHATRONICS

UNIT I INTRODUCTION 12

Introduction to Mechatronics – Systems – Concepts of Mechatronics

approach – Need for Mechatronics – Emerging areas of Mechatronics

ww

– Classification of Mechatronics. Sensors and Transducers: Static and

w.E

dynamic Characteristics of Sensor, Potentiometers – LVDT –

Capacitance Sensors – Strain gauges – Eddy current sensor – Hall

asy

Effect sensor – Temperature sensors – Light Sensors.

En

UNIT II 8085 MICROPROCESSOR AND 8051 MICROCONTROLLER

10

gin

ee

Introduction – Architecture of 8085 – Pin Configuration –

Addressing Modes –Instruction set, Timing Diagram of 8085 –

rin

Concepts of 8051 microcontroller – Block diagram.

g.n

UNIT III PROGRAMMABLE PERIPHERAL INTERFACE

Introduction – Architecture of 8255, Keyboard interfacing, LED

et 8

display –interfacing, ADC and DAC Interface, Temperature Control –

Stepper Motor Control – Traffic Control interface.

UNIT IV PROGRAMMABLE LOGIC CONTROLLER 7

Introduction – Basic structure – Input and output processing –

Programming – Mnemonics – Timers, Counters and internal relays –

Data handling – Selection of PLC.

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

UNIT V ACTUATORS AND MECHATRONIC SYSTEM DESIGN 8

Types of Stepper and Servo motors – Construction – Working

Principle – Advantages and Disadvantages. Design process-stages of

design process – Traditional and Mechatronics design Concepts –

Case studies of Mechatronics systems – Pick and place Robot –

Engine Management System – Automatic car park barrier.

ww TOTAL: 45 PERIODS

w.E

Text Books:

asy

1. Bolton, “Mechatronics”, Printice Hall, 2008

2. Ramesh S Gaonkar, “Microprocessor Architecture, Programming,

En

and Applications with them 8085”, 5th Edition, Prentice Hall, 2008.

gin

REFERENCES:

ee

1. Michael B.Histand and Davis G.Alciatore, “Introduction to

rin

Mechatronics and Measurement systems”, McGraw Hill International

g.n

edition, 2007.

2. Bradley D.A, Dawson D, Buru N.C and Loader A.J, “Mechatronics”,

Chapman and Hall, 1993.

et

3. Smaili.A and Mrad.F , “Mechatronics Integrated Technologies for

Intelligent Machines”, Oxford University Press, 2007.

4. Krishna Kant, “Microprocessors & Microcontrollers”, Prentice Hall

of India, 2007.

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

TABLE OF CONTENTS

PAGE.

S.NO TABLE OF CONTENTS

NO

a. Aim and Objective of the subject 5

b. Detailed Lesson Plan 6-8

wwc. Unit I- Introduction -Part A 9-10

w.E

d. Unit I- Introduction -Part B 10-27

e. asy

Unit II -8085 Microprocessor And 8051 Microcontroller

Part A

En

Unit II -8085Microprocessor And 8051 Microcontroller

28-30

f. Part B

gin 31-54

g.

ee

Unit III- Programmable Peripheral Interface-Part-A

rin 55-56

h. Unit III- Programmable Peripheral Interface-Part-B g.n 57-67

i. Unit IV- Programmable Logic Controller-Part-A et 68-70

J. Unit IV- Programmable Logic Controller-Part-B 70-92

k. Unit V- Actuators And Mechatronic System Design-Part- A 93-95

l. Unit V- Actuators And Mechatronic System Design-Part -B 95-114

115-

m. Model Question Paper 116

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

AIM :

The aim of the program is to equip students with the skills and knowledge

required to function as an effective mechatronic engineer.

This requires studies in the foundations of electrical and mechanical

engineering and the integration of these areas to problem involving the

design of mechatronic system.

This study aims to further develop your understanding of robotic and

ww mechatronic system.

w.E

OBJECTIVE:

asy

Select and apply the knowledge, techniques, skills and modern tools in

En

mechatronics engineering technology.

gin

Apply concepts of circuit analysis, analog and digital electronics, automation

computers to aid inee

and controls, motors, electric drives, power systems, instrumentation, and

the design,

rin

characterization, analysis, and

troubleshooting of mechatronics systems.

g.n

Use advanced principles of statics, dynamics, fluid mechanics, strength of

et

materials, engineering materials, engineering standards, and manufacturing

processes to aid in the design, characterization, analysis, and troubleshooting

of mechatronics systems.

Design a system component or process to meet desired needs within realistic

constraints, such as economic, environmental and/or social.

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

DETAILED LESSON PLAN

Name of the Subject& Code: ME6702 MECHATRONICS

TEXT BOOKS

1. Bolton, “Mechatronics”, Printice Hall, 2008

2. Ramesh S Gaonkar, “Microprocessor Architecture, Programming, and Applications

ww

with the 8085”, 5th Edition, Prentice Hall, 2008.

w.E

REFERENCES

1. Michael B.Histand and Davis G.Alciatore, “Introduction to Mechatronics and

asy

Measurement systems”, McGraw Hill International edition, 2007.

En

2. Bradley D.A, Dawson D, Buru N.C and Loader A.J, “Mechatronics”, Chapman and

Hall, 1993.

gin

ee

3. Smaili.A and Mrad.F , “Mechatronics Integrated Technologies for Intelligent

Machines”, Oxford University Press, 2007.

rin

g.n

4. Devadas Shetty and Richard A. Kolk, “Mechatronics Systems Design”, PWS

publishing company, 2007.

et

5. Krishna Kant, “Microprocessors & Microcontrollers”, Prentice Hall of India, 2007.

6. Clarence W, de Silva, "Mechatronics" CRC Press, First Indian Re-print, 2013

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

NO OF CUMULATIVE BOOKS

S.NO UNIT TOPICS COVERED

HOURS HOURS REFERRED

INTRODUCTION

Introduction to Mechatronics –

Systems – Concepts of

1 3 3 TI, R1

Mechatronics approach – Need

ww for Mechatronics –

Emerging areas of Mechatronics

w.E Classification of Mechatronics.

Sensors and Transducers: Static

1 4 TI, R1

2 1

Sensor,

asy

and dynamic Characteristics of 2 6 T1, R1

En

Potentiometers – LVDT –

3

gin

Capacitance sensors

2 8 T1, R1

4

ee

Strain gauges – Eddy current

sensor – Hall effect sensor –

Temperature sensors – Light

2

rin

10 T1, R1

5

Sensors

2

g.n

12 T1, R1

1

MICROPROCESSOR AND 8051 MICROCONTROLLER

Introduction – Architecture of

8085

2

et

14 T2, R5

Pin Configuration – Addressing

2 2 16 T2, R5

Modes

2 Instruction set, Timing diagram

3 of 8085 2 18 T2, R5

Concepts of 8051

4 4 22 T2, R5

microcontroller – Block diagram

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

PROGRAMMABLE PERIPHERAL INTERFACE

Introduction – Architecture of

1 8255, 2 24 T2, R5

Keyboard interfacing, LED

2 2 26 T2, R5

3 display –interfacing

ADC and DAC interface,

3 2 28 T2, R5

Temperature Control

Stepper Motor Control – Traffic

4 2 30 T2, R5

ww Control interface.

PROGRAMMABLE LOGIC CONTROLLER

1

w.E Introduction – Basic structure 2 32 T1

2

asy

Input and output processing –

Programming

2 34 T1

4

En

Data handling -Selection of PLC.

3

gin 1 35 T1

4

and internal relaysee

Mnemonics – Timers, counters

2

rin

37 T1

ACTUATORS AND MECHATRONIC SYSTEM DESIGN

Types of Stepper and Servo g.n

1

motors – Construction –

Working Principle – Advantages

and Disadvantages.

2 et

39 T1

Design process-stages of design

2 process – Traditional and 2 41 T1,R4

5 Mechatronics design concepts

Case studies of Mechatronics

3 2 43 T1,R4

systems – Pick and place Robot

Engine Management system –

4 Automatic car park barrier. 2 45 T1, R4

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

UNIT-I

INTRODUCTION

PART A

1) Define mechatronics?

Mechatronics brings together the areas of technology involving sensors and

measurement system, drive and actuation system, analysis of behavior of the

system, control system and microprocessor system.

ww

2) What is meant by system in mechatronics?

The system is a group of physical component combined to perform a specific

w.E

function. Any mechatronics devices consist of system.

3) What are the main applications of mechatronics?

asy

Washing machines, dish washers, micro ovens, cameras, atm and camcorders.

En

4) What are the types of control systems?

a) Closed loop system

b) Open loop system gin

ee

5) Obtain the basic function of control system?

rin

a) To minimize the error between the actual and desired output

b) To minimize the time response to load changes in the system.

g.n

6) Name elements of feedback system?

et

a) Forward path

b) Feedback path

c) Error detecting device

d) Amplifier

e) Compensating network

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

7) What is a sensor?

A sensor is an element in measurement system that acquires a physical parameter

and changes it into signal.

8) What is hysteresis?

Hysteresis is defined as the difference in the output for a given input when this

value is approached from the opposite direction.

9) State the dynamic characteristics of simplified measuring system?

1) Speed of response

2) Lag

ww

3) Fidelity

w.E

4) Dynamic error

10) Name few materials used in binding of strain gauge?

a) Ceramic cement asy

b) Epoxy

En

c) Nitrocellulose

gin

ee PART B

1. What are the basic elements of a closed loop control system?

rin

g.n

If there is feedback device to compare the actual value with desired one, then

the system is called closed loop control system.

et

10

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

Elements of Closed Loop System:

The elements of closed loop control system are Comparison Unit, Control

Unit, Correction Unit, Process Unit, Measurement Device

i. Comparision element

This element compares the required or reference value of the variable condition

being controlled with the measured value and produces an error signal.

Error signal = reference value-measured value

ww

ii. Control element

w.E This element decides the corrective action to be taken when an error signal is

received by it.

iii.

asy

Correction element

En

gin

Correction element is an actuator that produces a change in a process to correct

or change the controller condition.

iv. Process element ee rin

An element that controls the process is known as process element.

g.n

v.

Eg. Room temperature of a house is being controlled

Measurement element

et

The measurement element produces a signal related to the variable condition of

the process that is being controlled.

2. Explain the static and dynamic characteristic of a sensor?

Range and Span:

The range of a transducer defines the limits between which the input can

vary.

11

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

The difference between the limits (maximum value - minimum value) is

known as span.

For example a load cell is used to measure force. An input force can vary from

20 to 100 N. Then the range of load cell is 20 to 100 N. And the span of load

cell is 80 N (i.e., 100-20)

Error:

The algebraic difference between the indicated value and the true value of the

measured parameter is termed as the error of the device.

Error = Indicated value — true value

ww For example, if the transducer gives a temperature reading of 30°C when the

w.Eactual temperature is 29° C, then the error is + 1°C. If the actual temperature

is 3 1° C, then the error is — 1°C.

Accuracy:

asy

En

Accuracy is defined as the ability of the instrument to respond to the true

value of the measure variable under the reference conditions.

gin

For example, a thermocouple has an accuracy of ± 1° C. This means that

1°C of the true value.

ee

reading given by the thermocouple can be expected to lie within + 1°C (or) —

rin

g.n

Accuracy is also expressed as a percentage of the full range output (or) full

scale deflection.

et

For example, a thermocouple can be specified as having an accuracy of ±4 %

of full range output. Hence if the range of the thermocouple is 0 to 200°C, then

the reading given can be expected to be within + 8°C (or) — 8°C of the true

reading.

Sensitivity:

The sensitivity is the relationship showing how much output we can get per

unit input.

Sensitivity = Output / Input

12

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

Precision:

It is defined as the degree of exactness for which the instrument is intended

to perform.

Hysteresis error:

When a device is used to measure any parameter plot the graph of output Vs

value of measured quantity.

First for increasing values of the measured quantity and then for decreasing

values of the measured quantity.

The two output readings obtained usually differ from each other.

ww

w.E

asy

En

gin

Repeatability: ee rin

The repeatability and reproducibility of a transducer are its ability to give the

same output for repeated applications of the same input value. g.n

Reliability:

et

The reliability of a system is defined as the possibility that it will perform its

assigned functions for a specific period of time under given conditions.

Stability:

The stability of a transducer is its ability to give the same output when used

to measure a constant input over a period of time.

Drift:

The term drift is the change in output that occurs over time.

13

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

Dead band:

There will be no output for certain range of input values. This is known as dead

band. There will be no output until the input has reached a particular value.

Dead time:

It is the time required by a transducer to begin to respond to a change in

input value.

Resolution:

Resolution is defined as the smallest increment in the measured value that

can be detected. The resolution is the smallest change in the input value

ww which will produce an observable change in the input.

w.E

Backlash:

asy

Backlash is defined as the maximum distance (or) angle through which any

part of a mechanical system can be moved in one direction without causing

En

any motion of the attached part.

gin

Backlash is an undesirable phenomenon and is important in the precision

design of gear trains.

Dynamic characteristics ee rin

Response time:

g.n

This is the time which elapses after a constant input is applied to the

transducer up to the point at which the transducer gives an output

et

corresponding to some specified percentage, e.g.95%, of the value of the

input.

Time constant:

This is the 63.2% response time. The time constant is a measure of the inertia

of the sensor and so how fast it will react to changes in its input. The bigger

the time constant, the slower the reaction to a changing input signal.

14

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

Rise time:

This is the time for the output to rise to some specified percentage of the

steady state output. Often the rise time refers to the time taken for the output

to rise from 10% of the steady state value to 90 or 95% of the steady state

value.

Settling time:

This is the time for the output to settle to within some percentage, example

2% of the steady state value.

ww

3. Explain the construction and working of potentiometer sensor and LVDT

sensor.

w.E

Potentiometer

Principle:

asy

It works on variable resistance transduction principle Linear or Rotary

En

potentiometer is a variable resistance displacement transducer which uses the

gin

variable resistance transduction principle in which the displacement or rotation is

converted into a potential difference due to the movement of sliding contact over a

resistive element ee rin

g.n

et

Construction & working:

A resistor with three terminals.

Two end terminal & one middle terminal (wiper)

Two end terminal are connected to external input voltage

One middle and one end terminal as output voltage

15

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

The slider determines the magnitude of the potential difference developed

Characteristics:

Resistance element = Precision Drawn wire with a diameter of about 25 to 50

microns, and wad over a cylindrical or a flat mandrel of ceramic, glass or

Anodized Aluminium. 2mm to 500 mm in case of linear pot.

Wipers (Sliders) = Tempered phosphor bronze, beryllium copper or other

precious alloys.

Wire Material = Strong, ductile and protected from surface corrosion by

enamelling or oxidation. Materials &e alloys of copper nickel, Nickel

ww chromium, and silver palladium.

w.E

Resistance range = 20Ω to 200KΩ and for plastic 500Ω to 80KΩ

Accuracy = Higher temperature coefficient of resistance than the wire and so

asy

temperature changes have a greater effect Accuracy.

En

Linear variable differential transformer:

It consists of three symmetrically spaced coils.

gin

The centre coil is primary coil and other two are secondary coil

ee rin

Secondary coils are connected in series opposition and equally positioned

with respect to primary coil

g.n

et

The output voltage is proportional to the displacement of the core from null

position

16

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

4. Explain the construction and working of eddy current and Hall Effect

sensor.

Principle:

When a current carrying semiconductor plate is placed in a transverse

magnetic field, it experiences a force (Lorentz force). Due to this action a beam of

charged particles are forced to get displaced from its straight path. This is known as

Hall Effect.

A current flowing in a semiconductor plate is like a beam of moving charged

particles and thus can be deflected by a magnetic field. The side towards which the

ww

moving electron deflected becomes negatively charged and the other side of the

w.E

plate becomes positively charged or the electrons moving away from it.

This charge separation produces an electrical voltage which continues until

asy

the Lorentz force on the charged particles from the electric field balances the forces

En

produced by the magnetic field. The result is a traverse potential difference known

as Hall voltage.

gin

ee rin

g.n

et

Current is passed through leads 1 and 2 of the semiconductor plate and the output

leads are connected to the element faces 3 and 4.

17

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

These output faces are at same potential when there is no transverse

magnetic field passing through the element and voltage known as Hall

voltage appears when a transverse magnetic field is passing through the

element.

This voltage is proportional to the current and the magnetic field.

The direction of deflection depends on the direction of applied current and

the direction of magnetic field

Eddy current proximity sensor:

Principle:

ww When a coil is supplied with alternating current, an alternating magnetic field

w.E

is produced which induces an EMF on it. If there is a metal near to this alternating

magnetic field, on EMF is induced in it. The EMF cause current to flow. This current

flow is eddy current.

asy

En

gin

ee rin

g.n

et

Construction & working:

It has two identical coils.

One reference coil & another sensing coil which senses the magnetic current

in the object.

Eddy current start to flow due to AC(conducting object) close to sensor

18

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

Eddy current produce a magnetic field to oppose the magnetic field generated

by sensing coil.

Due to this opposition reduction flux is created. To detect 0.001mm

5. Explain the construction and working of capacitive and strain gauge sensor.

Capacitive Sensors:

It is used for measuring, displacement, velocity, force etc.

Principle:

It is passive type sensors in which equal and opposite charges are generated

ww

on the plates due to voltage applied across the plate which is separated by dielectric

w.E

material.

Formula:

asy

En

gin

ee rin

g.n

By Changing the Distance between Two Plates:

The displacement is measured due to the change in capacitance

et

19

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

By Varying the Area of Overlap:

The displacement causes the area of overlap to vary

The capacitance is directly proportional to the area of the plates and varies

linearly with changes in the displacement between the plates

ww

w.E

By Varying the Dielectric Constant:

The change in capacitance can be measured due to change in dielectric

asy

constant as a result of displacement.

When the dielectric material is moved due to the displacement, the material

En

causes the dielectric constant to vary in the region where the two electrodes

gin

are separated that results in a charge in capacitance

ee rin

g.n

Push Pull Sensor:

et

Push pull displacement sensor is used to overcome the non-linearity error.

The sensor consists of three plates with the upper pair forming one capacitor

and the lower pair forming another capacitor.

The displacement moves central plate between the two other plates.

If the central plate moves downwards.

The plate separation of the upper capacitor increases and the separation of

the lower one decreases.

20

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

Strain gauge:

Strain gauges are passive type resistance sensor whose electrical resistance

change when it is stretched or compressed (mechanically strained) under the

ww application of force.

w.E

The electrical resistance is changed due to the change in length (increases)

and cross sectional area (decreases) of the strain gauge.

asy

This change in resistance is then usually converted into voltage by connecting

one, two or four similar gauges as an arm of a Wheatstone bridge (known as

En

Strain Gauge Bridge) and applying excitation to the bridge. The bridge output

gin

voltage is then a measure of strain, sensed by each strain gauge.

Unbonded Type Strain Gauges:

ee rin

In unbonded type, fine wire filaments (resistance wires) are stretched around

rigid and electrically insulated pins on two frames.

One frame is fixed and the other is movable. g.n

The frames are held close with a spring loaded mechanism. et

Due to the relative motion between two frames, the resistance wires are

strained.

This strain is then can be detected through measurement of the change in

electrical resistance since they are not cemented with the surfaces, they can

be detached and reused.

Bonded Type Strain Gauges:

Bonded type strain gauges consists of resistance elements arranged in the

form of a grid of fine wire, which is cemented to a thin paper sheet or very

21

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

thin Bakelite sheet, and covered with a protective sheet of paper or thin

Bakelite.

The paper sheet is then bonded to the surface to be strained. The gauges have

a bonding material which acts an adhesive material during bonding process

of a surface with the gauge element.

Classification of Bonded Type Strain Gauges:

Fine wire gauges

Metal foil gauges

Semiconductor filament type

ww

Fine Wire Gauges:

w.E

Wire of 3 to 25 microns diameter is arranged in the form of grid consisting of

parallel loops

asy

En

gin

Metal Foil Gauges:

ee rin

g.n

A thin foil of metal, deposited as a grid pattern onto a plastic backing material

using polyimide

Foil pattern is terminated at both ends with large metallic pads

et

Entire gauge size 5- 15mm

22

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

ww

Semiconductor Filament Type:

The gauges are produced in wafers from silicon or germanium crystals

w.E

Special impurities such as boron is added

It is mounted on an epoxy resin backing with copper on nickel leads

asy

Filament about 0.05mm thick 0.25mm wide and 1.25 to 12mm length

En

gin

ee rin

g.n

6. Explain any four temperature sensors.

Bimetallic Strips:

et

A Bimetallic thermostat consists of two different metal strips bounded

together and they cannot move relative to each other.

These metals have different coefficients of expansion and when the

temperature changes the composite strips bends into a curved strip, with the

higher coefficient metal on the outside of the curve.

The basic principle in this is all metals try to change their physical dimensions

at different rates when subjected to same change in temperature.

23

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

This deformation may be used as a temperature- controlled switch, as in the

simple thermostat.

ww

w.E

asy

Resistance Temperature Detectors (RTDs):

En

The materials used for RTDs are Nickel, Iron, Platinum, Copper, Lead,

gin

Tungsten, Mercury, Silver, etc.

ee

The resistance of most metals increases over a limited temperature range and

rin

the relationship between Resistance and Temperature is shown below.

g.n

et

The Resistance temperature detectors are simple and resistive elements in

the form of coils of wire

The equation which is used to find the linear relationship in RTD is

24

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

Constructional Details of RTDs:

The platinum, nickel and copper in the form wire are the most commonly

used materials in the RTDs.

Thin film platinum elements are often made by depositing the metal on a

suitable substrate wire- wound elements involving a platinum wire held by a

high temperature glass adhesive inside a ceramic tube.

ww

w.E

Thermistors:

Thermistor is a semiconductor device that has a negative temperature

asy

coefficient of resistance in contrast to positive coefficient displayed by most

metals.

En

gin

Thermistors are small pieces of material made from mixtures of metal oxides,

such as Iron, cobalt, chromium, Nickel, and Manganese.

ee

The shape of the materials is in terms of discs, beads and rods.

rin

The thermistor is an extremely sensitive device because its resistance

changes rapidly with temperature. g.n

et

The resistance of conventional metal-oxide thermistors decreases in a very

non-linear manner with an increase in temperature.

The change in resistance per degree change in temperature is considerably

larger than that which occurs with metals.

25

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

The resistance-temperature relationship for a thermistor can be described by

an equation of the form

Rt = Keβ/t

Where Rt, is the resistance at temperature t, with K and β being constant.

Thermistors have many advantages when compared with other temperature

sensors.

ww

w.E

asy

En

The simple series circuit for measurement of temperature using a thermistor

gin

and the variation of resistance with temperature for a typical thermistor.

ee rin

g.n

et

The thermistor is an extremely sensitive device because its resistance

changes rapidly with temperature.

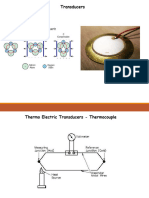

Thermocouples:

Thermocouples are based on the See back Effect.

The thermocouple temperature measurement is based on a creation of an

electromotive force (emf).

26

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

"When two dissimilar metals are joined together an e.m.f will exist between

ww the two points A and B, which is primarily a function of the junction

temperature. The above said to be principle is See back effect..

w.E

The thermocouple consist of one hot junction and one cold junction

asy

Hot junction is inserted where temperature is measured

Cold junction is maintained at a constant reference temperature.

En

gin

ee rin

g.n

et

27

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

UNIT II

8085 MICROPROCESSOR AND 8051 MICROCONTROLLER

PART – A

1. What is stack and what is the use of stack pointer?

The stack is a reserved area of the memory in the RAM where temporary

information may be stored. A 16-bit stack pointer is used to hold the address of the

most recent stack entry.

2. Mention the use of ALE.

The ALE signal is used to demultiplex (separate) AD0 – AD7 lines to A0 – A7 (address

ww

lines) and D0 – D7 (data lines). The separation of address lines and data lines is

w.E

achieved by connecting a external latch to AD0 – AD7 lines and enabling the latch

when signal is active.

3.

asy

List the 8085 flags.

Various flags are: S (Sign flag), Z (Zero flag), AC (Auxiliary carry flag), P (Parity

flag), CY (Carry flag). En

4. gin

What is the function of program counter in 8085 microprocessor?

used as pointer to the instruction.

ee

Program counter stores the address of the next instruction to be fetched. Thus it is

rin

5. What is trap interrupt and its significance?

g.n

This interrupt is a non-maskable interrupt. It is unaffected by any mask or

et

interrupt enable. TRAP has the highest priority. TRAP interrupt is edge and level

triggered. This means that the TRAP must go high and remain high until it is

acknowledged. This avoids false triggering caused by noise and transients.

6. List the control and status signals of 8085 and mention its need.

ALE (Address Latch Enable)

̅̅̅̅

RD and ̅̅̅̅̅

WR (Read and Write)

̅ , S0 S1

IO/M

READY

28

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

7. Define the function of parity flag and zero flag in 8085.

Parity is defined by the number of one’s present in the accumulator. After an

arithmetic or logical operation if the result has an even number of ones, i.e., even

parity, the flag is set. If the parity is odd, flag is reset. Zero flag – the zero flag sets if

the result of operation in ALU is zero and flag resets if result is non zero. The zero

flag is also is also set if certain register content becomes zero following an

increment or decrement operation of that register.

8. List the five interrupts pins available in the 8085.

ww

The five interrupt pins are : TRAP RST 7.5, RST 6.5, RST 5.5, and INTR.

9.

w.E What is interrupt?

Interrupt is an external signal that causes a microprocessor to jump to a specific

subroutine.

10.

asy

What is Microcontroller?

En

A device which contains the microprocessor with integrated peripherals like

gin

memory, serial ports, parallel ports, timer/counter, interrupt controller, data

11. What are the

ee

acquisition interfaces like ADC, DAC is called microcontroller.

differences between a

rin

Microcontroller and

Microprocessor?

Microprocessor g.n

Microcontroller

It is termed as general purpose

digital computer.

et

It is termed as special purpose

digital Controller.

It contains the CPU, memory, It possesses all features of

addressing circuits and interrupt microprocessor and additionally it

handling circuit. includes timers, parallel and serial

I/O and the internal RAM and ROM.

It has one or two types of bit It has many bit handling instructions.

handling Instructions.

Memory and I/O access time is large Memory and I/O access time is less.

29

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

12. What are the various types of 8085 instructions?

Data transfer group – MOV A,B

Arithmetic group – ADD B

Logical group- ANA B

Branch group – JMP LABEL

Stack I/O and Machine Control group – PUSH, POP, HLT.

13. What are the different types of addressing modes?

The addressing modes specify the location of the operand (data). The different types

are as follows

ww

Immediate addressing

w.E

Register addressing

Direct addressing

Indirect addressing

Implicit addressing

asy

14. En

Define stack and stack related instructions?

gin

The stack is a group of memory locations in the R/W memory that is used for the

ee

temporary storage of binary information during the execution of the program. The

stack related instructions are PUSH and POP

rin

15. What is subroutine?

g.n

Subroutine is group of instructions stored as a separate program in memory and it

is called from the main program whenever required. et

30

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

PART – B

1.Draw and explain the architecture of 8085.

ww

w.E

asy

En

gin

ee rin

g.n

et

It consists of various functional blocks.

Registers

Arithmetic and logic unit

Instruction decoder and machine cycle encoder

Address buffer

Address/Data buffer

Increment / Decrement address latch

Interrupt control

31

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

Serial control

Serial I/O control

Timing and control circuitry

Registers

It has eight addressable 8-bit registers A,B,C,D,E,H,L,F and two 16-bit

registers PC and SP

These register can be classified as,

1. General purpose registers

2. Temporary registers

ww (a) Temporary data register (b) W and Z registers

w.E 3. Special purpose registers

(a) Accumulator (b) Flag registers (c) Instruction registers

asy

4. 16-bit registers

(a) Program counter (PC) (b) Stack pointer (SP)

General purpose registers:En

gin

B,C,D,E,H,L are 8-bit general purpose registers can be used as a separate (or)

ee

as 16-bit register pairs BC, DE, HL.

rin

When used in register pair mode the higher order byte resides in the first

register and the low order byte in the second.

g.n

HL pair also functions as a data pointer (or) memory pointer. These are also

called scratched registers as user can store data in them. et

To store and read data from these registers bus access is not required, it is an

internal operation.

Used to store intermediate results and use them when required.

Temporary registers:

(a) Temporary data register:

The ALU has two inputs

One input is supplied by the accumulator and other from temporary data

register.

32

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

The programmer cannot access this temporary data.

(b) W and Z registers:

W and Z registers are temporary registers.

These registers are used to hold 8-bit data during execution of some

instructions.

These registers are not available for programmer since 8085 uses them

internally.

Special purpose registers:

(a) Register A (Accumulator)

ww It is a tri state 8-bit register.

w.E

It is extensively used in arithmetic, logic, load and store operations as well as

input/output (I/O) operations.

asy

Most of the times the result of arithmetic and logical operations is stored in

the register A.

(b) En

Flag register:

gin

It is an 8-bit register in which five of the bits carry significant information in

the form of flags.

ee rin

S – Sign flag; Z – Zero flag; AC – Auxiliary carry flag; P – Parity flag; CY – carry

flag.

S- Sign flag: g.n

et

After the execution of arithmetic (or) logical operations if bit D7 of the result

is 1, the sign flag is set.

In a given byte if D7 is 1, the number will be viewed as negative number.

If D7 is 0, the number will be considered as positive number.

Z – Zero flag:

The zero flag sets if the result of operation is ALU is zero and flag resets if

result is non zero.

The zero flag is also set if certain register content becomes zero following as

increment (or) decrement operation of that register.

33

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

AC – Auxiliary carry register:

This flag is set if there is an overflow out of bit 3 i.e., carry from lower nibble

to higher nibble (D3 bit to D4 bit).

This flag is used for BCD operations and it is not available for the

programmer.

P – Parity flag:

Parity flag is defined as the number of one’s present in the accumulator.

CY – carry flag:

This flag is set if there is an overflow out of bit 7.

ww The carry flag also serves as a borrow flag for subtraction.

w.E

© Instruction registers:

In a typical processor operation the processor first fetches the opcode of

asy

instruction from memory.

The CPU stores this opcode in a register called the instruction register.

En

This opcode is further sent to the instruction decoder to select one of the 256

alternatives. gin

16-bit registers:

(a) Program counter (PC):

ee rin

Program counter is sequence of instructions

g.n

The PC is a special purpose register which at a given time stores the address

of the next instruction to be fetched.

Program counter acts as a pointer to the next instruction.

et

The Pc increments depends upon the nature of the instruction, for one byte

instruction it increments program counter by one, for two byte instruction it

increments PC by two and so on.

(b) Stack pointer (SP):

The stack pointer is a reserved area of the memory in the RAM where

temporary information may be stored.

34

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

A 16-bit stack pointer is used to hold the address of the most recent stack

entry.

Arithmetic logic unit (ALU):

The 8085’s ALU performs arithmetic and logical functions on 8-bit variables.

The arithmetic unit performs addition and subtraction.

The logic unit perform logical operations such as complement, AND, OR, EX-

OR, rotate, clear etc.,

The ALU also looks after the branching decisions.

Instruction decoder:

ww The processor first fetches the opcode of instructions from memory and

w.E stores this opcode in the instruction register.

It is then send to the instruction decoder.

asy

The instruction decoder decodes it and accordingly gives the timing and

control signals which control the register, the data buffers, ALU etc.,

En

The 8085 executes seven different types of machine cycles

gin

It gives the information about which machine cycle is currently executing in

ee ̅ lines

the encoded from on the S0, S1 and IO/𝑀

This task is done by machine cycle encoder.

rin

Address buffer:

This is an 8-bit unidirectional buffer. g.n

It is used to drive external high order address bus (A15 – A8). et

It is also used to tri-state the high order address bus under certain conditions

such as reset, hold, halt, and when address lines are not in use.

Address/Data buffer:

This is an 8-bit bi-directional buffer.

It is used to drive multiplexed address/data bus ie, lower order address bus

(A7-A0) abd data bus (D7-D0).

It is also used to tri-state the high order address bus under certain conditions

such as reset, hold, halt, and when address lines are not in use.

35

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

The address and data buffers are used to drive external address and data

buses respectively.

Due to these buffers the address and data buses can be tri-stated when they

are not in use.

Increment/Decrement address latch:

This 16-bit register is used to increment (or) decrement the contents of PC

(or) AP as a part of execution of instruction related to them.

Interrupt control:

The processor fetches, decodes and execute instructions in a sequence.

ww

Serial I/O control:

w.E

In serial communication one bit is transferred at a time over a single line.

The 8085 serial I/O control provides two lines, SOD and SID for serial

communication.

asy

The serial output data (SOD) line is used to send data serially and serial input

En

data (SID) line is used to receive data serially.

Timing and control circuitry: gin

operations.

ee

The control circuitry in the processor 8085 is responsible for all the

rin

g.n

The control circuitry and operations in 8085 are synchronized with the help

of clock signal.

et

Control circuitry also generates signals required to interface external devices

to the processor 8085.

36

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

2. Draw and explain the timing diagram of memory read and write

operation.

ww

w.E

Memory read cycle:

asy

The 8085 executes the memory read cycle to read the contents of R/W

memory or ROM. En

gin

The length of this machine cycle is 3T-states(T1-T3)

ee

In this machine cycle processor places the address on the address lines from

rin

the stack pointer, general purpose register pair or program counter and

g.n

through the read process, reads the data from the addressed memory

location.

Memory read cycle is similar to the opcode fetch machine cycle. et ̅ =0,

However they use only states T1 to T3 and the status signal values (IO/𝑀

S1=1, S0=0) appropriate for memory read machine cycle are issued in T1.

The following section describes the memory read machine cycle in step by step

manner.

Step 1: (State T1)

In T1 state, microprocessor places the address on the address lines from the

stack pointer, general purpose register pair or program counter and activates

ALE signal in order to latch low-order byte of address.

37

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

During T1, 8085 sends status signal: IO/M=0, S1=1, S0=0 for memory read

machine cycle.

Step 2: (State T2)

In T2, 8085 sends RD signal low to enable the addressed memory location.

The memory device then places the contents of addressed memory location of

the data bus (AD0-AD7).

Step 3: (State T3)

During T3, 8085 loads the data from the data bus into specified register (F, A, B, C, D,

E, H and L) and raises RD to high which disables the memory device.

ww

Memory write cycle:

w.E

asy

En

gin

ee rin

g.n

et

The 8085 executes the memory write cycle to store the data into data

memory or stack memory.

The length of this machine cycle is 3T-states(T1-T3)

38

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

In this machine cycle processor places the address on the address lines from

the stack pointer general purpose register pair and through the write process,

stores the data into the addressed memory location.

The memory write timing diagram is similar to the memory read timing

diagram, except the instead of RD, WR signal goes low during T2 and T3.

̅ =0, S1=0, S0=1. The

The status signals for memory write cycle are: IO/𝑀

following section describes the memory write machine cycle in step by step

manner.

Step 1: (State T1)

ww In T1-state, the 8085 places the address on the address lines from stack

w.E pointer or general purpose register pair and activates ALE signal in order to

latch low-order byte of address.

asy ̅ = 0, S1=0, S0=1 for memory write

During T1, 8085 sends status signals: IO/𝑀

machine cycle.

Step 2: (State T2) En

gin

In T2, 8085 places data on the data bus and sends WR signal low for writing

Step 3: (State T3)

ee

into the addressed memory location.

rin

g.n

During T3, WR signal goes high, which disables the memory device and

terminates the write operation.

et

3. What are the different addressing modes in 8085 microprocessor? Explain

it with an example?

Addressing mode specifies the location of operand (data). Every instruction of

a program has to operate on a data. The method of specifying the data to be

operated by the instruction is called Addressing. The 8085 has the following 5

different types of addressing.

a. Immediate Addressing

b. Direct Addressing

c. Register Addressing

39

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

d. Register Indirect Addressing

e. Implied Addressing

a. Immediate Addressing:

In immediate addressing mode, the data is specified in the instruction itself.

The data will be a part of the program instruction. All instructions that have ‘I’ in

their mnemonics are of immediate addressing type.

Example: MVI A, 01H- Move the data 01H given in the instruction to A register.

b. Direct Addressing:

In direct addressing mode, the address of the data is specified in the

ww

instruction. The data will be in memory. In this addressing mode, the program

w.E

instructions and data can be stored indifferent memory blocks. This type of

addressing can be identified by 16-bit address present in the instruction.

asy

Example:LDA 4500H- Load the data available in memory location 4500H in A

register.

c. Register Addressing: En

gin

In register addressing mode, the instruction specifies the name of the register

names in the instruction.

ee

in which the data is available. This type of addressing can be identified by register

rin

Example: MOV A, B -Move the content of B register to A register.

d. Register Indirect Addressing: g.n

et

In register indirect addressing mode, the instruction specifies the name of the

register in which the address of the data is available. The data will be in memory

and the address will be in the register pair. This type of addressing can be identified

by letter ‘M’ present in the instruction.

Example: MOV A, M - The content of memory (data) addressed by HL pair is moved

to A register.

40

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

e. Implied Addressing:

In implied addressing mode, the instruction itself specifies the type of operation and

location of data to be operated. This type of instruction does not have any address,

register name, immediate data specified along with it.

Example: CMA - Complement the content of accumulator

4. Explain the different types of instruction in 8085.

An instruction is a command given to the microprocessor to perform

specified operation on a given data. The instruction set of a microprocessor is the

ww

collection of instructions that the microprocessor is designed to execute. It is

w.E

classified into

i. Data Transfer Instructions.

asy

ii.

iii.

Arithmetic Instructions.

Logical Instructions.

iv. En

Branching / Control Transfer Instructions.

v. gin

Stack & I/O Machine Control Instructions.

i. Data transfer instructions:

ee rin

The data transfer instructions move the data between registers or between

g.n

registers and memory. It copies the data from source location to destination

location. No flags will be affected.

Move instruction:

MOV Rd, Rs

et

MOV M, Rs

MOV Rd, M

This instruction copies the contents of the source register into the destination

register. The contents of the source register are not altered. If one of the operands is

a memory location, its location is specified by the contents of the HL registers.

Example: MOV B, C - This instruction move the content of C register to B register.

41

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

MOV B, M -This instruction move the content of memory location pointed

by HL register to B register.

Move immediate 8-bit:

MVI Rd, data

MVI M, data

The 8-bit data is stored in the destination register or memory. If the operand

is a memory location, its location is specified by the contents of the HL registers.

Example: MVI A, 01 - The data 01 will move to A register.

MVI M, 01 – The data 01 will move to the memory location pointed by HL

ww registers.

w.E

Load accumulator:

LDA 16-bit address

asy

The contents of a memory location, specified by a16-bit address in the

operand, are copied to the accumulator. The contents of the source are not altered.

En

This is a 3-byte instruction, the second byte specifies the low-order address and the

gin

third byte specifies the high-order address.

Store accumulator:

ee

Example: LDA 4000 –The content of memory location 4000 is loaded into A register.

rin

STA 16-bit address

g.n

The contents of the accumulator are copied into the memory location

et

specified by the operand. This is a 3-byte instruction, the second byte specifies the

low-order address and the third byte specifies the high-order address.

Example: STA 4500–The content of A register is loaded into memory location 4500.

Exchange:

XCHG

The contents of register H are exchanged with the contents of register D, and

the contents of register L are exchanged with the contents of register E.

Example: XCHG: This instruction exchange the content of H and L with D and E

42

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

ii. Arithmetic instructions:

The arithmetic instructions include addition, subtraction, increment and

decrement operations.

Addition:

ADD REGISTER OR MEMORY TO ACCUMULATOR

ADD Rs

ADD M

The contents of the operand (register or memory) are added to the contents

of the accumulator and the result is stored in the accumulator. If the operand is a

ww

memory location, its locations specified by the contents of the HL registers. All flags

w.E

are modified to reflect the result of the addition.

Example: ADD B – The content of A register is added with the content of B register

asy

and the result is stored in A register.

ADD M -The content of A register is added with the content of memory

En

Location pointed by HL register and the result is stored in A register.

gin

Add register to accumulator with carry:

ADC R

ADC M

ee rin

g.n

The contents of the operand (register or memory) and the Carry flag are

added to the contents of the accumulator and the result is stored in the accumulator.

et

If the operand is a memory location, its location is specified by the contents of the

HLregisters. All flags are modified to reflect the result of the addition.

Example: ADC B -The content of A register is added with the content of B register

and also Carry and the result is stored in A register.

ADD IMMEDIATE TO ACCUMULATOR

ADI 8-bit data

The 8-bit data (operand) is added to the contents of the accumulator and the result

is stored in the accumulator. All flags are modified to reflect the result of the

addition.

43

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

Example: ADI 45 – The data 45H is immediately added with the content of A register

and result Is stored in A register.

Subtraction:

SUBTRACT REGISTER OR MEMORY FROM ACCUMULATOR

SUBRs

SUB M

The contents of the operand (register or memory) are subtracted from the contents

of the accumulator and the result is stored in the accumulator. If the operand is a

memory location, its locations specified by the contents of the HL registers. All flags

ww

are modified to reflect the result of the subtraction.

w.E

Example: SUB B – The content of A register is subtracted with the content of B

register and the result is stored in A register. SUB M -The content of A register is

asy

subtracted with the content of memory location pointed by HL register and the

result is stored in A register.

En

SUBTRACT SOURCE AND BORROW FROM ACCUMULATOR:

SBB R gin

SBB M

ee rin

The contents of the operand (register or memory) and the Borrow flag are

g.n

subtracted from the contents of the accumulator and the result is placed in the

accumulator. If the operand is a memory location, its location is specified by the

contents of the HL registers.

All flags are modified to reflect the result in accumulator.

et

Example: SBB B - The content of A register is subtracted with the content of B

register and also Borrow flag and the result is stored in A register. SBB M- The

content of A register is subtracted with the content of memory location pointed by

HL register and also Borrow and the result is stored in A register.

Subtract immediate from accumulator:

SUI 8-bit data

44

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

The 8-bit data (operand) is subtracted from the contents of the accumulator and the

result is stored in the accumulator. All flags are modified to reflect the result of the

subtraction.

Example: SUI 45 -The data 45H is immediately subtracted with the content of A

register and Result is stored in A register.

Increment register or memory

INR R

INR M

The content of the designated (register or memory) are incremented by 1 and the

ww

result is stored in the same place. If the operand is a memory location, its location is

w.E

specified by the contents of the HL registers.

Example: INR B – The content of B register is incremented by 1. INR M – The content

asy

of memory location pointed by HL register is incremented by 1.

INCREMENT REGISTER PAIR:

INX R En

gin

The contents of the designated register pair are incremented by1 and the result is

stored in the same place.

ee rin

Example: INX H – The HL register pair is incremented by 1 and showing the next

memory location.

Decrement register or memory g.n

DCR R

DCR M

et

The contents of the designated (register or memory) are decremented by 1 and the

result is stored in the same place. If the operand is a memory location, its location is

specified by the contents of the HL registers.

Example: DCR B – The content of B register is decremented by 1.

DCR M –The content of memory location pointed by HL register is

decremented by 1.

45

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

Decrement register pair:

DCX R

The contents of the designated register pair are decremented by1 and the result is

stored in the same place.

Example: DCX H – The HL register pair is decremented by 1 and showing the

previous Memory location.

iii. Logicalinstructions:

The logical instructions includes AND, OR, XOR, Complement operations.

Logical AND:

ww

Logical AND register or memory with accumulator

w.E ANA R

ANA M

asy

The contents of the accumulator are logically AND with the contents of the operand

(register or memory), and the result is placed in the accumulator. If the operand is a

En

memory location, its address is specified by the contents of HL registers, Z, P are

gin

modified to reflect the result of the operation. CY is reset. AC is set.

ee

Example: ANA B - The content of A register is AND with the content of B register and

rin

the result is stored in A register. ANA M - The content of A register is AND with the

g.n

content of memory location pointed by HL register and the result is stored A

register.

Logical and immediate with accumulator

ANI 8-bit data

et

The contents of the accumulator are logically AND with the 8-bit data (operand) and

the result is placed in the accumulator. S, Z, P are modified to reflect the result of the

operation. CY is reset. AC is set.

Example: ANI 45 -The data 45H is immediately ANDed with the content of A register

and result is stored in A register.

46

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

Exclusive or register or memory with accumulator

XRA R

XRA M

The contents of the accumulator are Exclusive OR with the contents of the operand

(register or memory), and the result is placed in the accumulator. If the operand is a

memory location, its address is specified by the contents of HL registers.S, Z, P are

modified to reflect the result of the operation. CY and AC are reset.

Example: XRA B -The content of A register is XOR with the content of B register and

the result is stored in A register. XRA M -The content of A register is XOR with the

ww

content of memory location pointed by HL register and the result is stored A

w.E

register.

Exclusive or immediate with accumulator

asy

XRI 8-bit data

The contents of the accumulator are Exclusive OR with the8-bit data (operand) and

En

the result is placed in the accumulator.S, Z, P are modified to reflect the result of the

gin

operation. CY and AC are reset.

ee

Example: XRI 45 -The data 45H is immediately XOR with the content of A register

and result is stored in A register.

rin

LOGICAL OR REGISTER OR MEMORY WITH ACCUMULATOR

ORA R g.n

ORA M et

The contents of the accumulator are logically OR with the contents of the operand

(register/memory), and the Result is placed in the accumulator. If the operand is a

memory location, its address is specified by the contents of HL registers.S, Z, P are

modified to reflect the result of the operation. CY and AC are reset.

Example: ORA B -The content of A register is OR with the content of B register and

the result is stored in A register. ORA M- The content of A register is OR with the

content of memory location pointed by HL register and the result is stored A

register.

47

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

Logical or immediate with accumulator:

ORI 8-bit data

The contents of the accumulator are logically OR with the8-bit data (operand) and

the result is placed in the accumulator. S, Z, P are modified to reflect the result of the

operation. CY and AC are reset.

Example: ORI 45 - The data 45H is immediately OR with the content of A register

and result is stored in A register.

Complement accumulator:

CMA

ww

The contents of the accumulator are complemented. No flags are affected.

w.E

iv. Branching (control transfer)instructions :

The branching instructions are used to change the execution order. They are divided

asy

into conditional jump/call or unconditional jump/call.

JUMP UNCONDITIONALLY

En

JMP 16-bit address

gin

The program sequence is transferred to the memory location specified by the 16-bit

address given in the operand.

Example: JMP 4000

ee rin

JUMP CONDITIONALLY

g.n

The program sequence is transferred to the memory location specified by the 16- bit

address given in the operand based on the specified flag of the PSW.

Example:

et

OPCODE DESCRIPTION FLAG STATUS

JC Jump on Carry CY = 1

JNC Jump on no Carry CY = 0

48

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

JP Jump on Positive S=0

JM Jump on Minus S=1

JZ Jump on Zero Z =1

JNZ Jump on no Zero Z=0

JPE Jump on parity even P = 1

JPO Jump on parity odd P=0

ww

w.E

Unconditional subroutine call :

CALL 16-bit address

asy

The program sequence is transferred to the memory location specified by the 16-bit

address given in the operand. Before the transfer, the address of the next

En

instruction after CALL the contents of the program counter is pushed onto the stack.

Example: CALL 4000 gin

CONDITIONAL SUBROUTINECALL:

ee rin

The program sequence is transferred to the memory location specified by the 16-bit

g.n

address given in the operand based on specified flag of the PSW. Before the

transfer, the address of the next instruction after the call the contents of the

program counter is pushed onto the stack.

Unconditional return from subroutine:

et

RET

The program sequence is transferred from the subroutine to the calling program.

The two bytes from the top of the stack are copied into the program counter, and

program execution begins at the new address.

Example: RET

CONDITIONAL RETURN FROM SUBROUTINE:

49

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

The program sequence is transferred from the subroutine to the calling program

based on the specified flag of the PSW. The two bytes from the top of the stack are

copied into the program counter, and program execution

begins at the new address.

Example: RZ

OPCODE DESCRIPTION FLAG STATUS

ww RC Return on Carry CY = 1

w.E RNC Return on no Carry CY = 0

RP

asy Return on Positive S=0

RM

En Return on Minus S=1

RZ

gin

Return on Zero Z =1

RNZ

RPE

ee

Return on no Zero

Return on parity even P = 1

Z=0

rin

RPO Return on parity odd P=0 g.n

v. Stack i/o,machine control instructions:

et

These instructions are used to manipulate the stack to perform the input /output

and to alter the internal control flags. Unless specified the flags are not affected.

Stack instruction:

PUSH :

Example: PUSH PSW

The contents of register A and the contents of condition flags which form the PSW

are pushed onto the stack.

50

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

Pop instruction:

Example: POP PSW The contents of register A and the contents of condition flags

which form the PSW are restored from the stack.

I/O instruction :

IN port

The data placed on the 8 bit bidirectional data bus by the specified port is moved to

register A.

OUT port

The contents of register A are placed on the 8 bit data bus is transferred to the

ww

specified port.

w.E

Machine control instruction:

EI

asy

The interrupt system is enabled.

DI

En

The interrupt system is disabled.

NOP gin

No Operation is performed.

No flags are affected.

ee rin

HLT

The processor is stopped. g.n

No flags are affected. et

5. Explain with block diagram the architecture of 8051 microcontroller.

a. Memory Organization

Program Memory

Data Memory

b. Program Status Word

The Program Status Word (PSW) contains several status bits that

reflect the current state of the CPU.

51

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

It contains the Carry bit, the Auxiliary Carry (for BCD operations), the

two register bank select bits, the Overflow flag, a parity bit, and two

user-definable status flags.

c. Interrupt Structure

The 8051 provides 4 interrupt sources

Two external interrupts

Two timer interrupts

d. Port Structures

The 8051 contains four I/O ports

ww All four ports are bidirectional

w.E

Each port has SFR (Special Function Registers P0 through P3) which works

like a latch, an output driver and an input buffer

asy

Both output driver and input buffer of Port 0 and output driver of Port 2 are

En

used for accessing external memory

Accessing external memory works like this

gin

Port 0 outputs the low byte of external memory address (which is time-

ee

multiplexed with the byte being written or read)

rin

Port 2 outputs the high byte (only needed when the address is 16 bits

wide)

g.n

Port 3 pins are multifunctional. The alternate functions are activated

with the 1 written in the corresponding bit in the port SFR. et

52

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

ww

w.E

asy

En

gin

ee rin

g.n

et

e. Timer/Counters

The 8051 has two 16-bit Timer/Counter registers

Timer 0

Timer 1

Both can work either as timers or event counters

53

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

Both have four different operating modes from which to select.

Mode 0 (13-bit Timer)

Mode 1 (16-bit Timer)

Mode 2 (8-bit Timer with Auto-Reload)

Mode 3 (Two 8-bit Timers)

6. Explain the interrupt structure of 8051 microcontroller.

8051 provides 4 interrupt sources

o 2 external interrupts

o 2 timer interrupts

ww They are controlled via two SFRs, IE and IP

w.E

Each interrupt source can be individually enabled or disabled by setting or

clearing a bit in IE (Interrupt Enable). IE also exists a global disable bit, which

asy

can be cleared to disable all interrupts at once.

En

Each interrupt source can also be individually set to one of two priority levels

by setting or clearing a bit in IP (Interrupt Priority)

gin

A low-priority interrupt can be interrupted by high-priority interrupt, but not

by another low-priority one

ee rin

A high-priority interrupt can’t be interrupted by any other interrupt source

g.n

If interrupt requests of the same priority level are received simultaneously, an

internal polling sequence determines which request is serviced, so within

each priority lever there is a second priority structure

External Interrupts

et

External interrupts ~INT0 and ~INT1 have two ways of activation

o Level-activated

o Transition-activated

Timer 0 and Timer 1 Interrupts

Timer interrupts are generated by TF0 and TF1 flags in their respective

Timer/Counter registers.

54

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

UNIT – III

PROGRAMMABLE PERIPHERAL INTERFACE

PART – A

1. What is key debouncing?

When a key press is found, the microprocessor waits for at least 10ms before

it accepts the key as input. It is called key debouncing.

2. Name any two types of ADCs.

ww Single Ramp or Single Slope

Dual slope

w.E Successive approximation

Flash

asy

3. What is the bit set Reset mode of 8255 PPI?

En

The individual bits of port C can be set or reset by sending out a single

gin

OUTPUT instruction to the control register. When port C is used for

control/status operation, this feature can be used to set or reset individual

bits. ee rin

4. What are the applications of D/A converter interfacing with 8255?

Temperature control

g.n

Air conditioning control

Washing machine control

et

Traffic light control

5. What is keyboard interfacing?

A keyboard consists of number of key switches used for entering data, event

etc., using this keyboard, the input data is applied to the microprocessor is

known as keyboard interfacing.

55

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

6. State the purpose and importance of NOP instructions.

NOP: Perform NO Operation

This instruction simply used up three clock cycles and

increments the instructions.

Pointer to pointer to the next instruction.

It can also be used to hold a place In a program for instruction

that will be added later.

7. Define PPI.

8255 is widely used, programmable, parallel I/O device. It can be

wwprogrammed to transfer data under various conditions from simple I/O to

w.E

interrupt I/O.

8. Name any two types of ADC.

asy

Successive approximation ADC

En

Dual slope ADC

Flash type ADC

gin

9. Name the modes available in 8255 A Control Word Format.

BSR Mode

I/O Mode

ee rin

o Mode 0: Simple I/O Mode.

o Mode 1: I/O with Handshaking Mode.

g.n

o Mode 2: Bidirectional data transfer mode.

10. Show the control word format of 8255 in BSR mode.

et

56

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

PART - B

1. Draw the functional block diagram of 8255 ppi and explain each block.

ww

w.E

asy

En

It has a 40 pins of 4 groups. gin

1. Data bus buffer ee rin

2. Read Write control logic

g.n

3. Group A and Group B controls

4. Port A, B and C

et

Data bus buffer:

This is a tri state bidirectional buffer used to interface the 8255 to system data bus.

Data is transmitted or received by the buffer on execution of input or output

instruction by the CPU.

• Control word and status information are also transferred through this unit.

57

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

Read/Write control logic

This unit accepts control signals ( RD, WR ) and also inputs from address bus and

issues commands to individual group of control blocks

( Group A, Group B).It has the following pins.

a) CS – Chip select : A low on this PIN enables the communication between CPU and

8255.

b) RD (Read) – A low on this pin enables the CPU to read the data in the ports or the

ww

status word through data bus buffer.

w.E

c) WR (Write ) : A low on this pin, the CPU can write data on to the ports or on to the

control register through

the data bus buffer. asy

En

d) RESET: A high on this pin clears the control register and all ports are set to the

input mode gin

ee

e) A0 and A1 (Address pins): These pins in conjunction with RD and WR pins

control the selection of one of the rin

3 ports. g.n

Group A and Group B controls et

These block receive control from the CPU and issues commands to their respective

ports.

Group A - PA and PCU ( PC7 –PC4)

Group B - PCL ( PC3 – PC0)

• Control word register can only be written into no read operation of the CW

register is allowed.

58

Downloaded From : www.EasyEngineering.net

Downloaded From : www.EasyEngineering.net

PORTS

a) Port A: This has an 8 bit latched/buffered O/P and 8bit input latch. It can be

programmed in 3 modes – mode 0,

mode 1, mode 2.

b) Port B: This has an 8 bit latched / buffered O/P and 8 bit input latch. It can be

programmed in mode 0, mode1.

c) Port C : This has an 8 bit latched input buffer and 8 bit out put latched/buffer.

ww

This port can be divided into two 4

w.E

bit ports and can be used as control signals for port A and port B. it can be

programmed in mode 0.

asy

Modes of Operation of 8255

En

These are two basic modes of operation of 8255. I/O mode and Bit Set-Reset mode

(BSR). gin

ee

• In I/O mode, the 8255 ports work as programmable I/O ports, while in BSR mode

rin

only port C (PC0-PC7) can be used to set or reset its individual port bits.

g.n

• Under the I/O mode of operation, further there are three modes of operation of

et

8255, so as to support different types of applications, mode 0, mode 1 and mode 2.