Professional Documents

Culture Documents

Carbon Film Fixed Resistors (Rohs Compliant) CF-RC Series: 2 9 1 1 0 K R E E L - R C

Uploaded by

willian GaldinoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Carbon Film Fixed Resistors (Rohs Compliant) CF-RC Series: 2 9 1 1 0 K R E E L - R C

Uploaded by

willian GaldinoCopyright:

Available Formats

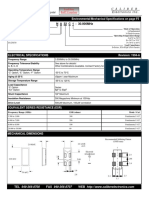

Carbon Film Fixed Resistors (RoHS Compliant) CF-RC Series

FEATURES

• Temperature Range -55°C ~ +155°C

• ±5% tolerance

• High quality performance at economical prices

• Compatible with automatic insertion equipment

• Flame retardant type available

• Tin coated annealed copper wire

• Values below 1Ω or above 10MΩ are available by special request, please ask for details

DERATING CURVE CURRENT NOISE TEMPERATURE COEFFICIENT

db ppm/°C

100 0 μV/v 0

Percent Rated Load (%)

80 -10 0.32 -200

-400

-20 0.1

-600

40 -30 0.03

-800

20 -40 0.01

-1000

0 0-5 0.003

20 40 70 100 120 155 100 1K 10K 100K 1M 10 100 1K 10K 100K 1M

Ambient Temperature (°C) Normal Resistance (Ω) Normal Resistance (Ω)

PART NUMBERING SYSTEM

2 9 1 1 0 K R E E L - R C

Series Ohms Package Code Suffix (RoHS Compliant)

SERIES, WATTAGE, SIZE, VOLTAGE, DIMENSIONS, AND AVAILABLE PACKAGING

d

+.02 -.05 Code: Package:

Bulk

/REEL Tape and Reel

H ±3 L H ±3 D /AP Ammo Pack

Voltage (max.) Dimensions (mm) Standard Quantities Available

Series Watts Size

W.V. O.V. L max. D max. H d Bulk Tape and Reel Ammo Pack

294 1W Small 500 1,000 12 5.0 28 0.7 1,000 3,000 1,000

299 1/8W Standard 200 400 3.5 1.85 28 0.45 1,000 5,000 2,000

291 1/4W Standard 250 500 6.8 2.5 28 0.54 1,000 5,000 1,000

293 1/2W Standard 350 700 10 3.5 28 0.54 1,000 3,000 1,000

STANDARD VALUES (Ω)

0.5 2.0 4.3 9.1 20 43 91 200 430 910 2K 3.9K 8.2K 18K 39K 82K 180K 390K 820K 1.8M 3.9M 8.2M

1.0 2.2 4.7 10 22 47 100 220 470 1K 2.2K 4.3K 9.1K 20K 43K 91K 200K 430K 910K 2M 4.3M 9.1M

1.1 2.4 5.1 11 24 51 110 240 510 1.1K 2.4K 4.7K 10K 22K 47K 100K 220K 470K 1M 2.2M 4.7M 10M

1.2 2.7 5.6 12 27 56 120 270 560 1.2K 2.7K 5.1K 11K 24 K 51K 110K 240K 510K 1.1M 2.4M 5.1M 15M

1.3 3.0 6.2 13 30 62 130 300 620 1.3K 3K 5.6K 12K 27K 56K 120K 270K 560K 1.2M 2.7M 5.6M 22M

1.5 3.3 6.8 15 33 68 150 330 680 1.5K 3.2K 6.2K 13K 30K 62K 130K 300K 620K 1.3M 3M 6.2M

1.6 3.6 7.5 16 36 75 160 360 750 1.6K 3.3K 6.8K 15K 33K 68K 150K 330K 680K 1.5M 3.3M 6.8M

1.8 3.9 8.2 18 39 82 180 390 820 1.8K 3.6K 7.5K 16K 36K 75K 160K 360K 750K 1.6M 3.6M 7.5M

XICON PASSIVE COMPONENTS • ARLINGTON, TX 76003 • www.xicon-passive.com • (800) 628-0544

XC-600035 Date Revised: 6/9/09

Carbon Film Fixed Resistors (RoHS Compliant) CF-RC Series

CHARACTERISTICS

Characteristics Limits Test Methods ( JIS C 5201-1 )

Must be within the specified 5.1 The limit of error of measuring apparatus

DC. Resistance tolerance. shall not exceed allowable range or 5% of

resistance tolerance

Resist. Range T.C.R. (PPM / °C) 5.2 Natural resistance change per temp.

degree centigrade.

Temperature < 10 Ω 0 ~ ±350 R2-R1

coefficient 11Ω ~ 99K 0 ~ -450 x106 (PPM/°C)

100K ~ 1M 0 ~ -700 R1(t2-t1)

1.1M ~ 10M 0 ~ -1500 R1: Resistance value at room temperature (t1)

R2: Resistance value at room temp.plus 100°C (t2)

Resistance change rate is 5.5 Permanent resistance change after the

Short time ± (1 % + 0.05Ω) Max. with no application of a potential of 2.5 times RCWV

overload evidence of mechanical damage for 5 seconds.

5.6 Resistors shall be clamped in the trough of

Insulation Insulation resistance is a 90° metallic V-block and shall be tested at

Resistance 10,000 MΩ Min DC potential respectively specified in the

above list for 60 +10/ -0 seconds.

Dielectric No evidence of flashover 5.7 Resistors shall be clamped in the trough

withstanding mechanical damage,arcing or of a 90° metallic V-block and shall be tested

voltage insulation break down. at AC potential respectively specified in the

table 1 for 60 + 10/-0 seconds.

6.1 Direct load

Resistance to a 2.5 kgs direct load for 10 secs.

in the direction of the longitudinal axis of the terminal leads.

Terminal No evidence of mechanical Twist test :

strength damage. Terminal leads shall be bent through 90° at a point of about

6mm from the body of the resistor and shall be rotated through 360°

about the original axis of the bent terminal in alternating direction

for a total of 3 rotations.

Resistance to Resistance change rate is 6.4 Permanent resistance change when leads

soldering heat ± (1% + 0.05Ω) Max. with no immersed to 3.2 to 4.8 mm from the body in

evidence of mechanical damage. 350 °C ± 10°C solder for 3 ± 0.5 seconds

6.5 The area covered with a new , smooth

clean , shiny and continuous surface free

Solderability 95 % coverage Min. from concentrated pinholes.

Test temp. of solder : 245°C ± 3°C

Dwell time in solder : 2 ~ 3 seconds

7.4 Resistance change after continuous

5 cycles for duty shown below:

Temperature Resistance change rate is Step Temperature Time

cycling ± (1% + 0.05Ω) Max. with no 1 -55°C ±3°C 30 mins

evidence of mechanical damage. 2 Room temp. 10~15 mins

3 +155°C ±2°C 30 mins

4 Room temp. 10~15 mins

Resistance value ΔR/R 7.9 Resistance change after 1,000 hours

Load life in operating at RCWV with duty cycle of

humidity Normal Type < than 100KΩ ±3% (1.5 hours "on", 0.5 hour "off") in a humidity

>100KΩ ±5% test chamber controlled at 40°C ± 2°C

and 90 to 95 % relative humidity

Resistance value ΔR/R 7.10 Permanent resistance change after

Load life 1,000 hours operating at RCWV with duty

Normal Type < than 56KΩ ±2% cycle of ( 1.5 hours "on", 0.5 hour "off" ) at

> 56KΩ ±3% 70°C ± 2°C ambient

XICON PASSIVE COMPONENTS • ARLINGTON, TX 76003 • www.xicon-passive.com • (800) 628-0544

XC-600035 Date Revised: 9/28/05

You might also like

- Evidence-Based Eating GuideDocument11 pagesEvidence-Based Eating GuideDarioNo ratings yet

- Kasco Safety Manual CurrentDocument171 pagesKasco Safety Manual CurrentLea Santos CidNo ratings yet

- Reshaping Herbal Medicine - Knowledge, Education and Professional Culture (2005) PDFDocument200 pagesReshaping Herbal Medicine - Knowledge, Education and Professional Culture (2005) PDFLuiz FelipeNo ratings yet

- MateriaMedica DunhamDocument436 pagesMateriaMedica Dunhamphani_bNo ratings yet

- HANGCHA Spec 5324518cc81da1141Document99 pagesHANGCHA Spec 5324518cc81da1141greek_tester100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- EmpilhamaxDocument653 pagesEmpilhamaxwillian GaldinoNo ratings yet

- Thuja's Effectiveness Against SmallpoxDocument361 pagesThuja's Effectiveness Against SmallpoxFrank NavaNo ratings yet

- AMAZEN Manual ForWebONLY 2 5 19 PDFDocument13 pagesAMAZEN Manual ForWebONLY 2 5 19 PDFkg27r-scribd9325100% (1)

- XC 600035Document2 pagesXC 600035sheyla veronica martinez ruizNo ratings yet

- 18 Ohm ResistorDocument2 pages18 Ohm ResistorVlatko AtanasovNo ratings yet

- Surface Mount 2920L SeriesDocument6 pagesSurface Mount 2920L SeriesAfonso MoutinhoNo ratings yet

- Celula de Carga HBM S40-700-100Document2 pagesCelula de Carga HBM S40-700-100Eletrolm Materiais EletricosNo ratings yet

- Metal Film Fixed Resistors (Rohs Compliant) MF-RC SeriesDocument4 pagesMetal Film Fixed Resistors (Rohs Compliant) MF-RC SeriesPablo ElíasNo ratings yet

- Utp PDFDocument1 pageUtp PDFEduardo UnadmxNo ratings yet

- Model 240 Model 240: Tedea-HuntleighDocument3 pagesModel 240 Model 240: Tedea-HuntleighJuan Carlos BallinariNo ratings yet

- Xicon - XC 600046 1218702Document4 pagesXicon - XC 600046 1218702Damián PastreNo ratings yet

- CT 200 DatasheetDocument2 pagesCT 200 Datasheetjeffv65No ratings yet

- MMBTA44-G: General Purpose TransistorDocument6 pagesMMBTA44-G: General Purpose Transistorwds657No ratings yet

- ZX10-2-20-S+ Mini - CircuitsDocument1 pageZX10-2-20-S+ Mini - CircuitsCADTDDNo ratings yet

- BCH Mini Limit SwitchDocument6 pagesBCH Mini Limit SwitchJayesh MewadaNo ratings yet

- Film Resistors MR Series: Metal Film: FeaturesDocument1 pageFilm Resistors MR Series: Metal Film: FeaturesGeorge Ribeiro Lucas GeorgeNo ratings yet

- Tension Compression Load Cell Tension Compression Load Cell: Model 614Document3 pagesTension Compression Load Cell Tension Compression Load Cell: Model 614Juan Carlos BallinariNo ratings yet

- Band Pass Filter: FP-E80-OD01, FP-E80D-OD01Document3 pagesBand Pass Filter: FP-E80-OD01, FP-E80D-OD01Muh IkramNo ratings yet

- DC Blocker BLK 89+Document1 pageDC Blocker BLK 89+CristianNo ratings yet

- ResistorDocument9 pagesResistordennis0611237No ratings yet

- ResistorDocument9 pagesResistorSakahi SharmaNo ratings yet

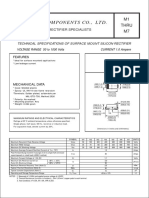

- DC Components Co., LTD.: M1 Thru M7Document2 pagesDC Components Co., LTD.: M1 Thru M7PVALVERDEANo ratings yet

- CDBC520-G Thru936922. CDBC5100-G RevC-268425Document5 pagesCDBC520-G Thru936922. CDBC5100-G RevC-268425georgerouseNo ratings yet

- NIC Components NMC NPO SeriesDocument3 pagesNIC Components NMC NPO SeriesNICCompNo ratings yet

- Avx F98 DTSH 08 16-1158749Document4 pagesAvx F98 DTSH 08 16-1158749Deepak D PillaiNo ratings yet

- WH/WN Series: Miniature Molded WirewoundDocument2 pagesWH/WN Series: Miniature Molded WirewoundVebry AndrianNo ratings yet

- NIC Components NRC-HDocument4 pagesNIC Components NRC-HNICCompNo ratings yet

- Resistencia 220 Ohm 5 W PDFDocument2 pagesResistencia 220 Ohm 5 W PDFAndrés JassoNo ratings yet

- NDK Nx5032ga 16MHZ STD Csu 2 - C485370Document1 pageNDK Nx5032ga 16MHZ STD Csu 2 - C485370Hamid ValinejadNo ratings yet

- Model 1022 Model 1022: Tedea-HuntleighDocument2 pagesModel 1022 Model 1022: Tedea-HuntleighMartin GandaraNo ratings yet

- RL70510-30 t/RL80453-100,000 LB: Interchangeable Products 70510 80453 SpecificationsDocument1 pageRL70510-30 t/RL80453-100,000 LB: Interchangeable Products 70510 80453 SpecificationsEMILIANO RETANANo ratings yet

- G3SBA RECTIFIERDocument2 pagesG3SBA RECTIFIERCarlosNo ratings yet

- 2EZ3 6D5-FormosaMSDocument6 pages2EZ3 6D5-FormosaMSLeonel cadenas hernandezNo ratings yet

- TLN Series: Tantalum Solid Electrolytic Chip Capacitors - Undertab SeriesDocument4 pagesTLN Series: Tantalum Solid Electrolytic Chip Capacitors - Undertab SeriesNorman Emmanuel CordovaNo ratings yet

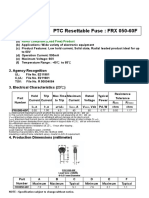

- Radial Leaded 3PTC Resettable Fuse: FRX 050-60F: 1. SummaryDocument7 pagesRadial Leaded 3PTC Resettable Fuse: FRX 050-60F: 1. SummaryАнатолий ДонецкNo ratings yet

- Large Aluminum Electrolytic Capacitors: Snap-In Terminal Type, SeriesDocument3 pagesLarge Aluminum Electrolytic Capacitors: Snap-In Terminal Type, SeriesMohamed HassanNo ratings yet

- Capacitor Tipo DPFFDocument4 pagesCapacitor Tipo DPFFgrasia77No ratings yet

- CJ3401-HF RevB289632Document5 pagesCJ3401-HF RevB289632alteromr mrNo ratings yet

- Bi-Directional Diac DB3 & DB4 Series: SpecificationsDocument1 pageBi-Directional Diac DB3 & DB4 Series: SpecificationsfsadvscNo ratings yet

- DataDocument1 pageDataStuxnetNo ratings yet

- Tai Tech HCB4532KF 800T90 - C357029Document21 pagesTai Tech HCB4532KF 800T90 - C357029otiapleNo ratings yet

- TEDEA HUNTLEIGH Model 4158Document3 pagesTEDEA HUNTLEIGH Model 4158Manoj DoshiNo ratings yet

- 10/100 PC Card LAN Magnetic Modules: MechanicalsDocument2 pages10/100 PC Card LAN Magnetic Modules: MechanicalsAbdelrhman ElsayedNo ratings yet

- SX34FDocument5 pagesSX34FHSA ComputerNo ratings yet

- E2SB Series 2.5 2.0 Seam Sealing CrystalDocument1 pageE2SB Series 2.5 2.0 Seam Sealing CrystalMaksimUSNo ratings yet

- CEP6000Document6 pagesCEP6000flavio torresNo ratings yet

- 2955 - 12317 KOSD 40 Draft1Document4 pages2955 - 12317 KOSD 40 Draft1Khan Tayabur Rahman MoniNo ratings yet

- High-Temp Stainless ElectrodeDocument1 pageHigh-Temp Stainless Electroderusf123No ratings yet

- NIC Components NMC X8S SeriesDocument2 pagesNIC Components NMC X8S SeriesNICCompNo ratings yet

- PTD90 Series - 9 MM Multi-Ganged Potentiometer: FeaturesDocument3 pagesPTD90 Series - 9 MM Multi-Ganged Potentiometer: FeaturesДмитрийNo ratings yet

- Low Profile Bending Beam Low Profile Bending Beam: Model 60040Document3 pagesLow Profile Bending Beam Low Profile Bending Beam: Model 60040Alec Hernandez GomezNo ratings yet

- Asco Series 44 Pressure Sensor CatalogDocument2 pagesAsco Series 44 Pressure Sensor CatalogAnonymous uXxyCieO3100% (1)

- HUBER 2bSUHNER RG 213 U DataSheet-1489695Document3 pagesHUBER 2bSUHNER RG 213 U DataSheet-1489695Gigi PlesoianuNo ratings yet

- Bzx84C2V4-Au Series: Surface Mount Silicon Zener DiodesDocument7 pagesBzx84C2V4-Au Series: Surface Mount Silicon Zener DiodesErasmo Franco SNo ratings yet

- sb8 Datasheet enDocument3 pagessb8 Datasheet ensrinivas raghavanNo ratings yet

- SEWHA - SB210 - (WWW - Towzin-Meter - Ir)Document1 pageSEWHA - SB210 - (WWW - Towzin-Meter - Ir)Professional TrustNo ratings yet

- DOC000758182Document2 pagesDOC000758182Oleg ShevchenkoNo ratings yet

- PHLAudio - Bass 20cm-8inchDocument1 pagePHLAudio - Bass 20cm-8inchRoberto richardsenNo ratings yet

- Lau enDocument2 pagesLau enAmer CajdricNo ratings yet

- Low-Cost Environmental Relay SpecificationsDocument2 pagesLow-Cost Environmental Relay SpecificationsNestor Dino DominiciNo ratings yet

- Metal Film Precision MELF Resistor AEC-Q200 Qualified for AutomotiveDocument13 pagesMetal Film Precision MELF Resistor AEC-Q200 Qualified for AutomotivecutoNo ratings yet

- CZRV3 55C27 GDocument3 pagesCZRV3 55C27 Gabner kaiberNo ratings yet

- Ysl R596CR3G4B5C C10 PDFDocument4 pagesYsl R596CR3G4B5C C10 PDFCesar VilledaNo ratings yet

- Capacitors: High QualityDocument220 pagesCapacitors: High Qualitywillian GaldinoNo ratings yet

- TL284xB, TL384xB High-Performance Current-Mode PWM ControllersDocument26 pagesTL284xB, TL384xB High-Performance Current-Mode PWM Controllerswillian GaldinoNo ratings yet

- Data PDFDocument10 pagesData PDFwillian GaldinoNo ratings yet

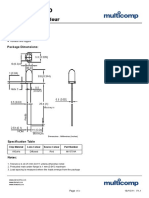

- T-1 3/4 (5Mm) Full Color Led Lamp: AttentionDocument9 pagesT-1 3/4 (5Mm) Full Color Led Lamp: AttentionAdindanvrynNo ratings yet

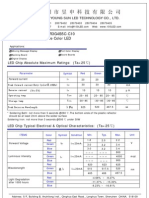

- Standard LED: Red Emitting ColourDocument3 pagesStandard LED: Red Emitting Colourwillian GaldinoNo ratings yet

- 2N3906 General Purpose Transistors: PNP SiliconDocument7 pages2N3906 General Purpose Transistors: PNP SiliconJose G. Cantillo L.No ratings yet

- BC337, BC337-25, BC337-40 Amplifier Transistors: NPN SiliconDocument5 pagesBC337, BC337-25, BC337-40 Amplifier Transistors: NPN Siliconban4444No ratings yet

- C503B Bas Ban BCS BCN Gas Gan GCS GCN 1094 PDFDocument10 pagesC503B Bas Ban BCS BCN Gas Gan GCS GCN 1094 PDFwillian GaldinoNo ratings yet

- Diodos LedDocument4 pagesDiodos LedHector Jose Murillo CordobaNo ratings yet

- File T Technion - Israel HardwarespecsResistors PDFDocument2 pagesFile T Technion - Israel HardwarespecsResistors PDFwillian GaldinoNo ratings yet

- Standard LED: Red Emitting ColourDocument3 pagesStandard LED: Red Emitting Colourwillian GaldinoNo ratings yet

- Data Sheet: General Purpose Chip ResistorsDocument9 pagesData Sheet: General Purpose Chip Resistorswillian Galdino100% (1)

- Resistors PDFDocument1 pageResistors PDFwillian GaldinoNo ratings yet

- Tabela ResistoreDocument13 pagesTabela Resistorewillian GaldinoNo ratings yet

- 91070Document9 pages91070atomdNo ratings yet

- Dy Py: Minibridge 10 Amperes - High SurgeDocument2 pagesDy Py: Minibridge 10 Amperes - High Surgewillian GaldinoNo ratings yet

- MCF 0.5W 1M MCF 0.5W 470K MCF 0.5W 820R MCF 1W 1R5 MCF 1W 330K MCF 1W 33K MCF 1W 680K MCF 1W 68K MCF 1W 68R MCF 2W 150K MCF 2W 470K MCF 2W 680K 287-11040 287-11050 287-11080Document13 pagesMCF 0.5W 1M MCF 0.5W 470K MCF 0.5W 820R MCF 1W 1R5 MCF 1W 330K MCF 1W 33K MCF 1W 680K MCF 1W 68K MCF 1W 68R MCF 2W 150K MCF 2W 470K MCF 2W 680K 287-11040 287-11050 287-11080willian GaldinoNo ratings yet

- Irf640, Sihf640: Vishay SiliconixDocument8 pagesIrf640, Sihf640: Vishay SiliconixJosephNo ratings yet

- AOD420 N-Channel Enhancement Mode Field Effect Transistor: Features General DescriptionDocument5 pagesAOD420 N-Channel Enhancement Mode Field Effect Transistor: Features General Descriptionwillian GaldinoNo ratings yet

- File T Technion - Israel HardwarespecsResistors PDFDocument2 pagesFile T Technion - Israel HardwarespecsResistors PDFwillian GaldinoNo ratings yet

- Opto Electronics Detectors Product GuideDocument1 pageOpto Electronics Detectors Product Guidewillian GaldinoNo ratings yet

- Tabela de Diodos Zener PDFDocument2 pagesTabela de Diodos Zener PDFwillian GaldinoNo ratings yet

- 1N4728A To 1N4764A: Vishay SemiconductorsDocument4 pages1N4728A To 1N4764A: Vishay SemiconductorsAbu Bakr M. SaeedNo ratings yet

- Compact diagnostic wiring diagram titleDocument1 pageCompact diagnostic wiring diagram titlewillian GaldinoNo ratings yet

- FR201 - FR207: Z Ibo Seno Electronic Engineering Co., LTDDocument2 pagesFR201 - FR207: Z Ibo Seno Electronic Engineering Co., LTDwillian GaldinoNo ratings yet

- Multi MetroDocument41 pagesMulti Metrowillian GaldinoNo ratings yet

- FliesDocument14 pagesFliesaguilarmvzNo ratings yet

- Supply Chain Operations Manager in Indianapolis IN Resume Robert McVeighDocument2 pagesSupply Chain Operations Manager in Indianapolis IN Resume Robert McVeighRobertMcVeighNo ratings yet

- Student Admission FormDocument2 pagesStudent Admission FormOmmsai co2011No ratings yet

- Human Heredity Principles and Issues 10th Edition Michael Cummings Solutions Manual 1Document10 pagesHuman Heredity Principles and Issues 10th Edition Michael Cummings Solutions Manual 1yvette100% (39)

- CHALLENGES - IN - DEVELOPING - MARGINAL - FIELD - COMPLEXITY, - CO MPILATION - & - IMPROVEMENT - NEEDED - Nik - Edit - 3Document22 pagesCHALLENGES - IN - DEVELOPING - MARGINAL - FIELD - COMPLEXITY, - CO MPILATION - & - IMPROVEMENT - NEEDED - Nik - Edit - 3Wan Mohd ShaharizuanNo ratings yet

- HYDRO 2023 International: Nit Warangal, IndiaDocument2 pagesHYDRO 2023 International: Nit Warangal, IndiaBhargava ReddyNo ratings yet

- The Logic of Immunity Deciphering An EnigmaDocument204 pagesThe Logic of Immunity Deciphering An EnigmaSatyabrataSahaNo ratings yet

- Maxiflex Spiral Wound Gaskets Product DocumentDocument5 pagesMaxiflex Spiral Wound Gaskets Product DocumentPham Thien TruongNo ratings yet

- Diabetes PDFDocument5 pagesDiabetes PDFErica MailigNo ratings yet

- Technical Manual: Weighing TerminalDocument122 pagesTechnical Manual: Weighing Terminalalfredo morenoNo ratings yet

- Chapter 1 To 7Document152 pagesChapter 1 To 7Jhane Sager ManahanNo ratings yet

- Aims & ObjectiveDocument80 pagesAims & Objectivevishaldhande007No ratings yet

- Ladipur EVA LiquidDocument2 pagesLadipur EVA LiquidKalki VermaNo ratings yet

- Mak 187 BulDocument4 pagesMak 187 BulxephilimNo ratings yet

- Translation of The Original Operating Manual: Epg-Sprint XeDocument100 pagesTranslation of The Original Operating Manual: Epg-Sprint XePatricio Exequiel Silva ColileoNo ratings yet

- Listado de Precios HADocument6 pagesListado de Precios HAgloria c.fernandezNo ratings yet

- Pre-Job Hazard AnalysisDocument4 pagesPre-Job Hazard AnalysisFiras HamanNo ratings yet

- Radial UnoDocument5 pagesRadial Unobhupi dagarNo ratings yet

- Chapter - 08 Civics Confronting Marginalisation: Invoking Fundamental RightsDocument2 pagesChapter - 08 Civics Confronting Marginalisation: Invoking Fundamental Rightsnbs saraswathiNo ratings yet

- Bukidnon's Top Food, Nature SitesDocument3 pagesBukidnon's Top Food, Nature SitesslumbaNo ratings yet

- Meniere's Disease and Tinnitus in Nursing PractiseDocument5 pagesMeniere's Disease and Tinnitus in Nursing PractiseLizbeth MarinahNo ratings yet

- Fmea - Failure Mode Effect AnalysisDocument23 pagesFmea - Failure Mode Effect AnalysisAsawari JoshiNo ratings yet

- Hardees ReviewDocument17 pagesHardees ReviewFarhan KamalNo ratings yet

- Ecb Recovery PlanningDocument20 pagesEcb Recovery PlanningMohamed MostafaNo ratings yet