Professional Documents

Culture Documents

Sikafloor 263 SL PDF

Uploaded by

tuonghaiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sikafloor 263 SL PDF

Uploaded by

tuonghaiCopyright:

Available Formats

Product Data Sheet

Edition 11 ,200 9

Identifica ti on no . 8.1 .02

Vers ion No. OO

Sik floo r 20 3 SL

Sikafloor® 263 SL

2-part epoxy self-smoothing and broadcast system

Description Sikafloor -2 3 SL is a two part, economi c . multi purpose binder based

on epoxy.

Uses • Self-smoothing and broadcast systems for concrete and cement

screeds with normal up to medium heavy wear e.g . storage and

assembly halls, maintenance workshops , garages, loading ramps etc.

• The broadcast system is recommended for wet process areas , e.g. in

beverage industry, food industry, maintenance hangars etc.

Advantages • Highly fillable

• Good chemical and mechanical resistance

• Easy application

• Economical

• Liquid proof

• Solvent-free

• Gloss finish

• Slip resistant surface possible

Product Data

Appearance I Colours Resin - part A: coloured, liquid

Hardener - part - B: transparent, liquid

5 Standard colour shades RAL 7030, RAL 7032, RAL 7035, RAL 7037 ,

RAL 7040.

Under direct sun light there may be some discolouration and colour varia

tions; this has no influence on the function and performance of the coating.

Packaging PartA: 15.8 kg can

Part B: 4. 2 kg can

PartA+B: 20 kg set (A+B)

Storage

Shelf life 12 months from date of production if stored properly in original, unopened

and undamaged sealed packaging in dry conditions at temperatures

betNeen +18 °C and +30°C.

Technical Data

Chemical Base Epoxy

1 Sikafloor' 263 SL 1/6

Density Part A. - 1.50 kg/l (DIN EN ISO 28 '11-1)

Pa rt 8 : - 1.00 kg!1

Mixerl Resil1: - '1 .43 kg /l

Filled res in 1 . 1. - '1.84 kg/l

All D nsily va lu es at +2 3' C

Solid Content - 100% (by olume ) I - 100% (b y we igh! )

Mechanical! Physical Prope rt ies

Compressive Strength Re sin : - 60 Nl mm' (28 days I +23°C ) (EN 196-1)

Bond Strength > 1,5 N/mm" (failure in concrete) (ISO 4624)

Shore D Hardness 76 (7 days I +23°C) (DIN 53505)

Abrasion Resistance 70 mg (CS 10/1000/1000) (8 days I +23°C) (DIN 53109 (Taber Abrader Test)

Resistance

Chemical Resistance Resistant to many chemicals. Please ask for a detailed chemical resis

tance table,

Thermal Resistance

Exposure* Dry heat

.1

Permanent +50 · C

Short-term max. 7d +80 ' C

Short-term max. 12 h +100 · C

Short-term moisUwet heat' up to +80°C where exposure is only occasional

(steam cleaning etc.)

'No simultaneous chemical and mechanical exposure.

System Information

System Structure Self-smoothing system 1 mm:

®

Primer: 1 x Sikafloor -161

J

Wearing course: Sikafloor· -263 SL + silicaflour

Self-smoothing system 1.5 - 3.0 mm:

Primer: 1 x Sikafloor~-161

Wearing course: Sikafloor®-263 SL + quartz sand (0 .1 - 0.3 mm)

Broadcast system approx. 4 mm:

Primer' : 1 x Sikafloor®-161

®

Base coat: 1 x Sikafloor -263 SL + quartz sand (0.1 - 0.3 mm)

Broadcasting: quartz sand (0.4 - 0.7 mm) broadcast to excess

Seal coat: 1 x Sikafloor®-264

Application Details

Consumption! Dosage

Coating System Product Consumption

Priming Sikafloor"'-161 0.35 - 0.55 kg/m'

Levelling (optional) Sikafloor"'-161 levelling Refer to PDS of

Self-smoothing mortar Sikafloor"'-161

wearing course : 1 pbw Sikafioor®-263 SL + 1.2 kg/m'/mm binder +

1mm 1 pbw silicaflour 0.25 kg/m'/mm

silicaflour

Self-smoothing Sikafloor"'-263 SL 1.9 kg/m' mixture (0.95

wearing course quartz sand (0 .1 - 0.3 mm) kg/m' binder + 0.95

(Film thickness - 1.5 kg/m' quartz sand) per

- 3.0 mm) mm layer thickness

Broadcast system 1 pbw Sikafioor"'-263 SL 2.00 kg/m'

(Film thickness - 4.0 1 pbw quartz sand (0.1 - 2.00 kg/m'

mm) 0.3 mm) + broadcasting

quartz sand 0.4 -0.7 mm + - 6.0 kg/m'

Seal coal Sikafloor®-264 - 0.7 kg/m

These figures are theoretical and do not allow for any additional material due to

surface porosity. surface profile , variations in level and wastage etc.

2 Sikafloor 263 SL 2/6

Substrate Quality The concrete substrate must be sound and of sufficient compressive stre ngth

(minimum 25 Nlmm?) with a minimum pull off stl'ength 01 1.5 Ni mn{

The substrate mu st be clea n, dry and free of all contam in ants su ell as

dirt, oil , ~ rease ; CO' tings and surface treatments . etc.

If in doubt , app ly a test area first.

Su bs trate Prep arat ion Concrete sub strates must be prep ared mechanically usin!;l Cl brasive blast

cl eaning or sca nfylllg equi pment to rem ove cement laitan ce and achi eve

an open textured su rfa ce.

VV ak concrete must be removed and surface defects such as blowholes

and voids must be fully exposed.

Repairs to substrate, filling of blowholes/voids and surface levelling can

be carried out using appropriate products from the Sikafloor , SikaOut)

and SikaGarl' range of materials.

Tile concrete or screed substrate has to be primed or levelled in mder to

achieve an even surface.

High spots must be removed by e.g. grinding.

All dust, loose and friable material must be completely removed from all

surfaces before application of the product, preferably by brush and/or

vacuum.

Application Conditions I Limitations

Substrate Temperature +10°C min. / +30°C max

Ambient Temperature +1O°C min. / +30°C max

Substrate Moisture Content <= 4% pbw moisture content.

Test method: Sika-Tramex meter or CM - measurement or Oven-dry

method.

No rising moisture according to ASTM (Polyethylene-sheet).

Relative Air Humidity 80% Lh. max.

Dew Point Beware of condensation!

The substrate and uncured floor must be at least 3°C above dew point to

reduce the risk of condensation or blooming on the floor finish

Application Instructions

-- --------

Mixing PartA: part B = 79: 21 (by weight)

Mixing Time Prior to mixing, stir partA mechanically. When all of part B has been added

to part A, mix continuously for 2 minutes until a uniform mix has been

achieved.

When parts A and B have been mixed, add the quartz sand 0.08 - 0.25 mm

and/or Sikafloor'" Filler-1 and mix for a further 2 minutes until a uniform

mix has been achieved.

To ensure thorough mixing pour materials into another container and mix

again to achieve a consistent mix.

Over mixing must be avoided to minimize air entrainment.

Mixing Tools Sikafloor' -263 SL must be thoroughly mixed using a low speed stirrer

(30Q...: 400 rpm) or other suitable equipment.

Application Method I Tools Prior to application, confirm substrate moisture content, r.h. and dew point.

If > 4% pbw moisture content, Sikafloor® EpoCem ® may be applied as a

T.M.B. (temporary moisture barrier) system.

Levelling:

Rough surfaces need to be levelled first. Therefore use e.g. Sikafloor®

161 levelling mortar (see POS).

Wearing course smooth:

Sikafloor®-263 SL is poured, spread evenly by means of a serrated trowel.

After spreading the material evenly, turn the serrated trowel and smooth

the surface in order to achieve an aesthetically higher grade of finish.

Roll immediately in two directions with a spiked roller to ensure even

thickness.

3 Sikafloor' 263 SL 316

Broadcast system

Sikafl oo r -26 3 SL i - pourp.d , sp r ' rl evenly lly means of a serrated trowel

Then , level and remove any entrapped air with 3 spiked ro ll er' nd after

abo ut 15 minu te!3 (at +20uC) but be fore 30 minutes (at +20· C). broad

ca t with qUelrtz sa nd, at first Ii htl yan then to exces

Clean ing of Tools CI an II lools ilml application equi pme nt with Til inner C immediately

after use .

HClrd ened nd/or Gur d Ill, t ri l e n only b I'emoved mecll anically.

Potl ife Temperature Time

+ 10°C - 50 minutes

+ 20°C - 25 minutes

+ 30vC - 15 mi nu tes

Waiting Time I Overcoating Before applying Sikafloor -263 SL on Sikafloor -1 6 1 allow:

Substrate temperature Minimum Maximum

+ 10· C 24 hours 3 days

+ 20°C 12 hours 2 days

+ 30°C 8 hours 1 day

Before applying Sikafloor0-263 SL on Sikafloor®-263 SL allow

Substrate temperature Minimum Maximum

+1 DoC 30 hours 3 days

+20 oe 24 hours 2 days

+30 oe 16 hours 1 daY'

Times are approximate and will be affected by changing ambient condi

tions particularly temperature and relative humidity.

Notes on Application I limitations Do not apply Sikafloor~-263 SL on substrates with rising moisture.

Do not blind the primer.

Freshly applied Sikafloor®-263 SL must be protected from damp, con

densation and water for at least 24 hours .

Avoid puddles on the surface with the primer.

For areas with limited exposure and nomlally absorbent concrete substrates

priming with Sikafloor®-161 is not necessary for broadcast systems.

For roller I textured coatings: Uneven substrates as well as inclusions of

dirt cannot and should not be covered by thin sealer coats. Therefore both

substrate and adjacent areas must always be prepared and cleaned

thoroughly prior to application.

Tools

Recommended Supplier of Tools:

PPW-Polyplan-Werkzeuge GmbH, Phone: +49 40/5597L

www.polyplan .com. Serrated trowel for smooth wearing layer:

e.g , Large-Surface Scrapper No. 565, Toothed blades No. 25

Serrated trowel for textured wearing layer:

e.g. Trowel No. 999 or Adhesive Spreader No.777, Toothed blades No. 23

The incorrect assessment and treatment of cracks may lead to a redu ce d

service life and reflective cracking ,

For exact colour matching, ensure the Sikafioor -264 in each area is applied

from the same control batch numbers.

Under certain conditions, underfloor heating combined with high point loading ,

may lead to imprints in the resin.

If heating is required do not use gas, oil, paraffin or other fossil fuel heaters,

these produce large quantities of both CO and H 0 water vapour, which may

adversely affect the finish. For heating Jse onll electric powered waml air

blower systems .

lise 9001 Jlisa 14~~1 J

\BVQlf \BVQlf

4 Sika floor 263 SL 4/6

Curing Details

Applied Product ready for use

Temperature Foot traffic Light traffic Full cure

+1O°C - 72 hours - 6 days -10days

+20 °C - 24 hours - 4 days - 7 days

+30 °C - 18 hours - 2 days - 5 days

Note: Times are approximate and will be affected by changing ambient conditions.

- .

Cleaning I Maintenance

Methods To maintain the appearance of the floor after application, Sikafloor~-263

SL must have all spillages removed immediately and must be regularly

cleaned using rotary brush, mechanical scrubbers, scrubber dryer, high

pressure washer, wash and vacuum techniques etc. using suitable de

tergents and waxes.

Value Base All technical data stated in this Product Data Sheet are based on labora

tory tests . Actual measured data may vary due to circumstances beyond

our control.

Local Restrictions Please note that as a result of specific local regulations the performance

of this product may vary from country to country. Please consult the loca l

Product Data Sheet for the exact description of the application fields .

Health and Safety Information, For information and advice on the safe handling , storage and disposa l of

chemical products, users should refer to the most recent Material Safety

Data Sheet containing physical, ecological, toxicological and other safety

related data.

Disclaimer The information. and. In particular, Ih e recommendations relating to the application and end-use

of Sika products. are given in good faith based on Sika's current knowledge and experience of

the products when properly stored, handled and applied under normal conditions in accordance

with Sika's recommendations. In practice, the differences in materials, substrates and actual site

conditions are such that no warranty in respect of merchantability or of fitness for a particular

purpose, nor any liability arising out of any legal relationship whatsoever, can be inferred either

from thiS information. or from any written recommendations, or from any other advice offered. The

user of the product must test the product's suita bility for the intended application and purpose.

Sika reserves the riglll to change the properties of its products. The proprietary rights of third

parties must be observed. All order s are accepted subject to our current terms of sale and

delivery Users must always refer to the most recent issue of the local Product Data Sheet for th e

product concerned, copies of which will be supplied on request.

5 Sikafloor )(iJ SL 5/6

You might also like

- Building Code2Document128 pagesBuilding Code2appleaeroNo ratings yet

- 3 Discus4Document5 pages3 Discus4tuonghaiNo ratings yet

- 3 Discus4Document5 pages3 Discus4tuonghaiNo ratings yet

- 3 Discus4Document5 pages3 Discus4tuonghaiNo ratings yet

- 3 Discus4Document5 pages3 Discus4tuonghaiNo ratings yet

- Building Code1 PDFDocument33 pagesBuilding Code1 PDFDao Ba ThanhNo ratings yet

- Myanmar National Building Code soils and foundationsDocument100 pagesMyanmar National Building Code soils and foundationsHeinMinn AungNo ratings yet

- 3 Discus4Document5 pages3 Discus4tuonghaiNo ratings yet

- MNBC 2012 Provisional Part 5A (Lighting)Document41 pagesMNBC 2012 Provisional Part 5A (Lighting)Htoo Kyi WynnNo ratings yet

- Topic - Connections - Typical Joints PDFDocument56 pagesTopic - Connections - Typical Joints PDFKanako NozawaNo ratings yet

- ICAO Doc 9137 Airport Services Manual Part 2 Pavement Surface ConditionsDocument0 pagesICAO Doc 9137 Airport Services Manual Part 2 Pavement Surface Conditionsbugerkng100% (3)

- ICAO Airport Services Manual Part 6 Control of ObstaclesDocument0 pagesICAO Airport Services Manual Part 6 Control of ObstaclesSubhash RamisettyNo ratings yet

- Airport Services Manual: Doc 9137 AN/898Document56 pagesAirport Services Manual: Doc 9137 AN/898tuonghaiNo ratings yet

- Acid Flooring SystemDocument6 pagesAcid Flooring SystemtuonghaiNo ratings yet

- Handouts Chapter6Document18 pagesHandouts Chapter6anku4frenzNo ratings yet

- Floor Cracking: How, What, Where?: Fred Goodwin, FICRI Fellow Scientist BASF Construction Chemicals Beachwood OHDocument71 pagesFloor Cracking: How, What, Where?: Fred Goodwin, FICRI Fellow Scientist BASF Construction Chemicals Beachwood OHtuonghaiNo ratings yet

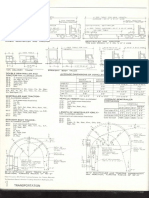

- 2.3 Truck Dimensions PDFDocument1 page2.3 Truck Dimensions PDFtuonghaiNo ratings yet

- B1e 001Document21 pagesB1e 001Mario HanamiciNo ratings yet

- Joints Details PDFDocument1 pageJoints Details PDFtuonghaiNo ratings yet

- Appendix SDocument29 pagesAppendix SNero PereraNo ratings yet

- Different Between Seismic and WindDocument4 pagesDifferent Between Seismic and WindtuonghaiNo ratings yet

- Guide To The Use of The Wind Load Provisions of ASCE 7-02Document138 pagesGuide To The Use of The Wind Load Provisions of ASCE 7-02tuonghaiNo ratings yet

- Appendix SDocument29 pagesAppendix SNero PereraNo ratings yet

- B RSoekhoe MScThesis Appendices PDFDocument109 pagesB RSoekhoe MScThesis Appendices PDFtuonghaiNo ratings yet

- Continuous Flight Auger Bored Piles WallDocument60 pagesContinuous Flight Auger Bored Piles WalltuonghaiNo ratings yet

- PAN Food 2nd Site Audit @14.april.2017 PDFDocument14 pagesPAN Food 2nd Site Audit @14.april.2017 PDFtuonghaiNo ratings yet

- Foundation Code 2004Document64 pagesFoundation Code 2004Patie Zheng100% (2)

- Arc Reinforcement Handbook 6ed 2010Document78 pagesArc Reinforcement Handbook 6ed 2010Anthony L. FelderNo ratings yet

- Guidelines For VNA (Very Narrow Aisle) Forklift and Racking System PDFDocument42 pagesGuidelines For VNA (Very Narrow Aisle) Forklift and Racking System PDFtuonghai67% (3)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Geotechnical Module: Powerful Software Featuring Intuitive WorkflowDocument4 pagesGeotechnical Module: Powerful Software Featuring Intuitive WorkflowMuhammadAviCennaNo ratings yet

- Sentron: Reliable - From ExperienceDocument16 pagesSentron: Reliable - From ExperiencehaydarNo ratings yet

- Privilege Speech of Hon. Rex Sarabia, Member of The Sangguniang Panlungsod NG Iloilo Delivered On June 7, 2023 During The Regular Session of The Sangguniang Panlungsod NG IloiloDocument4 pagesPrivilege Speech of Hon. Rex Sarabia, Member of The Sangguniang Panlungsod NG Iloilo Delivered On June 7, 2023 During The Regular Session of The Sangguniang Panlungsod NG IloiloSelurongNo ratings yet

- Sumalinog Teodoro Jr. LPDocument5 pagesSumalinog Teodoro Jr. LPDAITO CHRISTIAN DHARELNo ratings yet

- The Guitar in The Middle Ages and RenaisDocument4 pagesThe Guitar in The Middle Ages and RenaisТаня АфанасьеваNo ratings yet

- 1.trijang Rinpoche Bio CompleteDocument265 pages1.trijang Rinpoche Bio CompleteDhamma_Storehouse100% (1)

- Poem PDFDocument6 pagesPoem PDFTaylor JohnsNo ratings yet

- Drug Treatment of AnemiaDocument6 pagesDrug Treatment of Anemiavingul2006No ratings yet

- Solid Free Form:: Quilt Flatten Quilt QuiltDocument3 pagesSolid Free Form:: Quilt Flatten Quilt QuiltNaganthrakumar RamaswamyNo ratings yet

- Hypothesis of The Origin of LanguageDocument6 pagesHypothesis of The Origin of LanguageJefferson KagiriNo ratings yet

- Loop Quantum GravityDocument69 pagesLoop Quantum GravityAnderson BernardiNo ratings yet

- Industrial Pollution Crisis in GujaratDocument2 pagesIndustrial Pollution Crisis in GujaratsmagrurakNo ratings yet

- RTC Invoice 2965 Gj29es2223100505Document1 pageRTC Invoice 2965 Gj29es2223100505Alok PandeyNo ratings yet

- Prof (1) F P Kelly - ProbabilityDocument78 pagesProf (1) F P Kelly - ProbabilitycoolmohitNo ratings yet

- Module 2: Hematopoiesis I. General Principles of HematopoiesisDocument13 pagesModule 2: Hematopoiesis I. General Principles of HematopoiesisJane JapoleNo ratings yet

- Quiz 2 AnswersDocument6 pagesQuiz 2 Answerselliott.rillstoneNo ratings yet

- PRACH Optimization - V1Document11 pagesPRACH Optimization - V1Tulipe Pivoine100% (5)

- La Villa Fact Sheet 2021-2022-UpdatedDocument4 pagesLa Villa Fact Sheet 2021-2022-Updatedsweta suresh ganvirNo ratings yet

- PU Timing Belt-SINOCONVE Belt 2022Document25 pagesPU Timing Belt-SINOCONVE Belt 2022Marcelo Renteria VidaurreNo ratings yet

- Aronne Armanini (Auth.) - Principles of River Hydraulics-Springer International Publishing (2018)Document230 pagesAronne Armanini (Auth.) - Principles of River Hydraulics-Springer International Publishing (2018)Matija LozicNo ratings yet

- Quality Testing of Honey StandardsDocument33 pagesQuality Testing of Honey StandardsK. N RaoNo ratings yet

- Chapter 7 STRDocument10 pagesChapter 7 STRmedrekNo ratings yet

- Technical Sheet: Choline Chloride 60% VegetalDocument3 pagesTechnical Sheet: Choline Chloride 60% VegetalAnice CharafNo ratings yet

- FM 4 Fluid Kinematics CompleteDocument48 pagesFM 4 Fluid Kinematics Completeالياس يونس مرغلانيNo ratings yet

- Zoom Basic Functions - FinalDocument31 pagesZoom Basic Functions - FinalWenshy LavadorNo ratings yet

- Morteza MirzaeiDocument3 pagesMorteza MirzaeiUmitNo ratings yet

- BFV WeightDocument8 pagesBFV WeightBhargav PatelNo ratings yet

- Chem 136-LAB ADocument3 pagesChem 136-LAB Asidro12388% (8)

- LugeonDocument13 pagesLugeonRojan MaghsoodifarNo ratings yet

- NetWorking Flashcards - QuizletDocument262 pagesNetWorking Flashcards - QuizletGB ReddyNo ratings yet