Professional Documents

Culture Documents

Vitamin Productions

Uploaded by

Sithambaran KamacheeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vitamin Productions

Uploaded by

Sithambaran KamacheeCopyright:

Available Formats

Vitamin B12 Bioprocess Design:

Part II. Reactor, downstream and control

Lopez Galvan, M., Heredia Arroyo, S., Rodriguez Calado, S.

Universitat Autònoma de Barcelona

Introduction & Objectives

Vitamin B12, also called cobalamin is a water-soluble vitamin with a key role in the normal functioning of the brain and nervous system.

The main objective is to design an efficient purification process for vitamin B12 in a crystalline form. This vitamin will be earmarked for human consumption, which will define its purity

(>90%). The aim is to supply the 30% market demand, about 10.000 kg of each vitamin.

The project is also focused on providing lifecycle adaptation that maintain process control and high product quality via Quality by Design (QbD) concept.

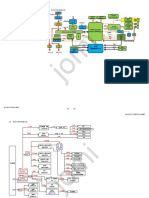

Flow Diagram

Upstream:

Q=23m3/batch - Seed Reactor 1

Q=4,6m3/batch - Seed Reactor 2

Q=66,5m3/batch

Reactor:

1

- Batch

- 142 kg de vit b12

unpurified/ batch

- Volume: 120 m3

Q=3,7m3/batch Downstream:

2

3 - 11 steps

- Yield: 81%

- Acid pH (4,5-6)

- 115 kg vit B12

pure/batch

- Operating time : 162h

4 - 88 batch/ year

5 - Total B12 production:

9.867 kg

Figure 1. Flow diagram of vitamin B12 production in Pseudomonas denitrificans. In green color represent the upstream, in orange the reactor and in violet the Downstream

process. Flow diagram created with SuperPro Designer.

1. Solid-liquid separation. 2. Cellular disruption. P. 3 . Solid-liquid 4. Vitamin purity 80%. Acetone

Volume reduction of 66% Denitrificans produces separation. Discarding precipitation + leaching. Enogh 5. Vitamin purity ≤ 90%. Ready

throw a rotatory vacuum intracellular. KCN addition, solid phase via rotatory purity to be sold for animal for selling.

filtration cianocobalamin formation. vacuum filtration. consumption.

Growing Strategy Downstream Alternatives Critical control points

1. Solid-líquid separation

Instrumentation for process control is installed as a

P. Denitrificans growing in two Centrifugation + Charcoal column

filtration adsorption vehicle to set up a Quality-by-Design (QbD)

steps:

program. Details of BC bioreactor control and

- P. denitrificans growth. High

DO in bioreactor. instrumentation:

- Vitamin B12 production. Low 2. Cellular disruption

↑[O2] inhibits

DO. Enzimàtica o forces de

vitamin B12 Pasteuritzation

cisalla

production

because of

intracellular

medium 3. Liquid separation from disruption impurities

oxidation. It is Charcoal column

Filtration

used a DO step- adsorption

wise reduction

strategy.

4. B12 purity ~ 80%

Filtration + precipitation + Evaporation

decantation

Figure 2. Time courses of vitamin B12 CO2 control during

Figure 3. Bioconversion bioreactor control diagram created

production under 2nd phase to 5. B12 purity ≤90% with Edraw.

the DO-stat and DO step-wise control maximize B12 Evaporation +

Leaching+ EIC+

strategies. productivity. crystallization

crystallization

Conclusions

The annual vitamin B12 production before downstream processing is 12.193kg (in 88 batches). With this total product amount, the product recovery yield should not be lower than 81% in

order to supply the 30% of the expected market for human consumption. The process is controlled following the principles of Quality by Design (QbD), showing special interest in bioreactor

control.

References

[1] Demain, A. L. (2007). The business of biotechnology. INDUSTRIAL BIOTECHNOLOGY, vol.3 no.3, 269-283.

[2] Ze-Jian Wang, H.-Y. W.-m.-P.-L. (2014). Enhance Vitamin B12 Production by Online CO2 Concentration Control Optimization in 120m3 Fermentation. J Bioproces Biotechniques, 4-14.

[3] Ze-Jian Wang, P. W.-L. (2011). Optimization of nutrictional requeriments and ammonium feeding strategies for improving vitamin B12 production by Pseudomnas denitrificans. African

Journal of Biotechnology, 10551-10561.

You might also like

- 17ips72 R4 PDFDocument2 pages17ips72 R4 PDFVasil Stoianov67% (6)

- Power Supply Wiring For 120V Unit: Service Diagram, Combined Bassman 100T Power Amp PCB AssyDocument4 pagesPower Supply Wiring For 120V Unit: Service Diagram, Combined Bassman 100T Power Amp PCB AssymidexNo ratings yet

- ACR2000 Service ManualDocument152 pagesACR2000 Service Manualrysogt100% (4)

- VDDC Vcc3V3-St: PWM - 100Hz/100Khz Hi: Max Lum Lo: Min LumDocument13 pagesVDDC Vcc3V3-St: PWM - 100Hz/100Khz Hi: Max Lum Lo: Min LumTavi DumitrescuNo ratings yet

- FCC Facilities KFUPMDocument8 pagesFCC Facilities KFUPMAMANo ratings yet

- Behringer EPR900 Powered Speaker Schematics PDFDocument14 pagesBehringer EPR900 Powered Speaker Schematics PDFAlvaro Canaviri Mamani100% (1)

- Process Scheduling, Resource & Inventory Tracking ToolsDocument16 pagesProcess Scheduling, Resource & Inventory Tracking ToolsSithambaran KamacheeNo ratings yet

- MuscleSpikerShield.v.1.3.updatedValues - 2 - PCB Schemes PDFDocument1 pageMuscleSpikerShield.v.1.3.updatedValues - 2 - PCB Schemes PDFManvendra singhNo ratings yet

- Mb3 - Bp1: Hella Romania S.R.L. Compressed Air Preparation Zbv-Automation GMBHDocument9 pagesMb3 - Bp1: Hella Romania S.R.L. Compressed Air Preparation Zbv-Automation GMBHREMUSNo ratings yet

- Ee-101 Main Switch Boards Single Line Diagram - MSB 1Document1 pageEe-101 Main Switch Boards Single Line Diagram - MSB 1Vo Minh ThongNo ratings yet

- Tweaker40 PowDocument1 pageTweaker40 PowDrazenNo ratings yet

- Installation: X1 D6X5L MM X6Document2 pagesInstallation: X1 D6X5L MM X6rizky andika suwardiNo ratings yet

- Lspic (8) - 36V 07 01 08Document1 pageLspic (8) - 36V 07 01 08luispacheNo ratings yet

- COMPIC52Document1 pageCOMPIC52wesnen laraNo ratings yet

- 2-Way Active Crossover With Linear PhaseDocument3 pages2-Way Active Crossover With Linear PhaseKiril PahlevNo ratings yet

- Changhong-JUC7 820 00188290-MSD3663LSADocument15 pagesChanghong-JUC7 820 00188290-MSD3663LSAventasenlinea1231No ratings yet

- 0K6 PotDocument1 page0K6 PotcbsomtecladosNo ratings yet

- Attention For My GirlfriendDocument1 pageAttention For My Girlfriendmybabe9435No ratings yet

- TOA Bandpass FilterDocument1 pageTOA Bandpass FilterTaulan SyahNo ratings yet

- Cube 180Document1 pageCube 180Gregorio AndradeNo ratings yet

- The Super Cub Guitar Amp ManualDocument10 pagesThe Super Cub Guitar Amp Manualzewdaroo9599No ratings yet

- Posisi Normal sebelum di RunDocument1 pagePosisi Normal sebelum di RunDwiky PurbacNo ratings yet

- Detail 1 On/Off Control Valve Detail 2 On/Off Control Valve: Yanacocha Gold Mill ProjectDocument1 pageDetail 1 On/Off Control Valve Detail 2 On/Off Control Valve: Yanacocha Gold Mill ProjectNavarro Zavala AntonyNo ratings yet

- Power LayoutDocument1 pagePower LayoutJoane ColipanoNo ratings yet

- 12V Power Supply SchematicDocument1 page12V Power Supply Schematicatomo33100% (2)

- Eurolive B415Dsp: Service ManualDocument25 pagesEurolive B415Dsp: Service ManualJohn Gemmell100% (2)

- Behringer B215DDocument3 pagesBehringer B215DEdgar PadillaNo ratings yet

- Jhust GeneratorDocument1 pageJhust GeneratorKovács TamásNo ratings yet

- Prpic 7Document1 pagePrpic 7ReginaldoPereiraNo ratings yet

- Circuit diagram voltage limiterDocument1 pageCircuit diagram voltage limitercbsomtecladosNo ratings yet

- BECIS DANONE Projectboard 2x1.5 CDocument1 pageBECIS DANONE Projectboard 2x1.5 CKita MediaNo ratings yet

- BEKO Z1J194-11 PSU Schematic For Chassis LX LCD TV PDFDocument2 pagesBEKO Z1J194-11 PSU Schematic For Chassis LX LCD TV PDFreza dian humkiNo ratings yet

- A Bru140032 140513 TSC/RP Tsc/Va: 4812315771-Reva-Ver1 PDFDocument16 pagesA Bru140032 140513 TSC/RP Tsc/Va: 4812315771-Reva-Ver1 PDFjunior Oliveira100% (1)

- 12MVA T/F Switchboard PanelDocument2 pages12MVA T/F Switchboard PaneldipenstarNo ratings yet

- HCD-ECL77BT/ECL99BT Block Diagram and Schematic SectionsDocument14 pagesHCD-ECL77BT/ECL99BT Block Diagram and Schematic SectionsAmin Santana100% (1)

- Dreamy Saxophone PieceDocument1 pageDreamy Saxophone PieceAntoine LagneauNo ratings yet

- RankineTemplate KOTAODocument8 pagesRankineTemplate KOTAONamik HadziibrahimovicNo ratings yet

- Simple Rankine Cycle AnalysisDocument8 pagesSimple Rankine Cycle AnalysisJamie SmithNo ratings yet

- Schematic of the PCB for the Behringer Europort EPA900 power supplyDocument14 pagesSchematic of the PCB for the Behringer Europort EPA900 power supplyJimNo ratings yet

- Behringer EPR900 Powered Speaker SchematicsDocument14 pagesBehringer EPR900 Powered Speaker SchematicsMichell Hernandez100% (2)

- Canadian Environmental Quality Guidelines Summary TableDocument15 pagesCanadian Environmental Quality Guidelines Summary TableLenin Jorge Villanueva DuranNo ratings yet

- Fa + Mainboard Hk.t.rt2959p67Document17 pagesFa + Mainboard Hk.t.rt2959p67pedroNo ratings yet

- FCC Reactor Overhead Line Vapor Isolation Valve Gines IMI ZJ FCCU Budapest 2017Document49 pagesFCC Reactor Overhead Line Vapor Isolation Valve Gines IMI ZJ FCCU Budapest 2017vivek_recNo ratings yet

- Power Input Power Control For Single 12V 2in1 PowerDocument12 pagesPower Input Power Control For Single 12V 2in1 PowerMargarita GarittaNo ratings yet

- FA + Mainboard MSD3463-T5C1 Solo FuenteDocument2 pagesFA + Mainboard MSD3463-T5C1 Solo FuenteFrancisco Antonio100% (1)

- CANCER Epigenetic ModificationsDocument1 pageCANCER Epigenetic ModificationsgustavopsoNo ratings yet

- Main Power: 12V TO 5VDocument13 pagesMain Power: 12V TO 5VAnalia Grilli100% (1)

- Alim Knit (BD) LTD.: Recommended Process Flow DiagramDocument1 pageAlim Knit (BD) LTD.: Recommended Process Flow DiagramKamrul HasanNo ratings yet

- Catalogo Pompe Pumps 2016Document25 pagesCatalogo Pompe Pumps 2016Anonymous SdGzDJISbjNo ratings yet

- Configuring SELCO Sigma S6500 UI ModuleDocument1 pageConfiguring SELCO Sigma S6500 UI ModuleZubair RajpootNo ratings yet

- 3-1. Hydraulic SystemDocument31 pages3-1. Hydraulic SystemBreyner Romero SantosNo ratings yet

- Mounting Pad Relay CircuitDocument1 pageMounting Pad Relay CircuitNgọc Hưng TạNo ratings yet

- TT50 2Document12 pagesTT50 2Tognon MarcoNo ratings yet

- An SEO-optimized title for an aircraft instrument panel documentDocument1 pageAn SEO-optimized title for an aircraft instrument panel documentMrWannNo ratings yet

- Wed Sep 30 17:24:56 2020 Case: NHT and GRU - HSC Flowsheet: Case (Main)Document1 pageWed Sep 30 17:24:56 2020 Case: NHT and GRU - HSC Flowsheet: Case (Main)AsifNo ratings yet

- NHT PDFDocument1 pageNHT PDFAsifNo ratings yet

- 01 l9 TrunkingDocument1 page01 l9 TrunkingimranNo ratings yet

- Hyundai 130w 3 HydDocument2 pagesHyundai 130w 3 Hyddwight100% (48)

- Psudig SCHDocument2 pagesPsudig SCHTspi RitzelNo ratings yet

- Plant Box Design DiagramDocument1 pagePlant Box Design Diagramfrancis sebastian lagamayoNo ratings yet

- FiltrationDocument39 pagesFiltrationAli HyderNo ratings yet

- Cane and Sugar Production-Final PDFDocument422 pagesCane and Sugar Production-Final PDFSithambaran Kamachee100% (1)

- PandatoysDocument16 pagesPandatoysSithambaran KamacheeNo ratings yet

- Chapter 5 FiltrationDocument26 pagesChapter 5 FiltrationRalph Evidente100% (1)

- ChE 436 Exam 1 Practice Closed BookDocument5 pagesChE 436 Exam 1 Practice Closed BookSithambaran KamacheeNo ratings yet

- Example For ChemistryDocument13 pagesExample For ChemistrySithambaran KamacheeNo ratings yet

- MATLAB FINALtutorialAssignment 1 Answpage 3Document1 pageMATLAB FINALtutorialAssignment 1 Answpage 3Sithambaran KamacheeNo ratings yet

- ProjectDocument4 pagesProjectSithambaran KamacheeNo ratings yet

- Txy DiagramDocument4 pagesTxy DiagramSithambaran KamacheeNo ratings yet

- Topic 6 - Conditional StatementDocument19 pagesTopic 6 - Conditional StatementSithambaran KamacheeNo ratings yet

- ChE 344 Chemical Reaction Engineering Final ExamDocument10 pagesChE 344 Chemical Reaction Engineering Final ExamSithambaran KamacheeNo ratings yet

- Gantt Chart ILAB 6-2Document3 pagesGantt Chart ILAB 6-2Sithambaran KamacheeNo ratings yet

- Environmental Act NewDocument1 pageEnvironmental Act NewSithambaran KamacheeNo ratings yet

- MATLAB FINALtutorialAssignment 1 Answpage 2 PDFDocument1 pageMATLAB FINALtutorialAssignment 1 Answpage 2 PDFSithambaran KamacheeNo ratings yet

- Approximation Error Analysis ChartDocument11 pagesApproximation Error Analysis ChartSithambaran KamacheeNo ratings yet

- MATLAB FINALtutorialAssignment 1 Answpage 2 PDFDocument1 pageMATLAB FINALtutorialAssignment 1 Answpage 2 PDFSithambaran KamacheeNo ratings yet

- Bioreactor yield and respiratory quotient calculationsDocument1 pageBioreactor yield and respiratory quotient calculationsSithambaran KamacheeNo ratings yet

- Simulation and Optimization in The Process of Toluene Liquid-Phase Catalytic OxidationDocument3 pagesSimulation and Optimization in The Process of Toluene Liquid-Phase Catalytic OxidationSithambaran KamacheeNo ratings yet

- Yield of EPADocument1 pageYield of EPASithambaran KamacheeNo ratings yet

- Optimization of Nutritional Requirements and Ammonium Feeding Strategies For Improving Vitamin B Production by Pseudomonas DenitrificansDocument11 pagesOptimization of Nutritional Requirements and Ammonium Feeding Strategies For Improving Vitamin B Production by Pseudomonas DenitrificansSithambaran KamacheeNo ratings yet

- AcknowledgementDocument1 pageAcknowledgementSithambaran KamacheeNo ratings yet

- The Table Below Shows The Chemical and Biochemical Properties of Each ElementDocument4 pagesThe Table Below Shows The Chemical and Biochemical Properties of Each ElementSithambaran KamacheeNo ratings yet

- The Table Below Shows The Chemical and Biochemical Properties of Each ElementDocument4 pagesThe Table Below Shows The Chemical and Biochemical Properties of Each ElementSithambaran KamacheeNo ratings yet

- Bitumen Est EquipmentDocument44 pagesBitumen Est EquipmentgjaggaraoNo ratings yet

- CBSE Class 6 Science Practice Worksheets PDFDocument2 pagesCBSE Class 6 Science Practice Worksheets PDFsifat mongaNo ratings yet

- Project Portfolio: by Braden Gyorko and Daniel PerezDocument22 pagesProject Portfolio: by Braden Gyorko and Daniel Perezapi-319418673No ratings yet

- Wind Gear Oil Wind Turbine Vestas V52 850 KW Gearbox Upgrade BÖRSTAD Wind Farm ASWI9006UKDocument1 pageWind Gear Oil Wind Turbine Vestas V52 850 KW Gearbox Upgrade BÖRSTAD Wind Farm ASWI9006UKThiagoPinheiroNo ratings yet

- Instruction Manual: Heto Gel Dryer GD-2Document16 pagesInstruction Manual: Heto Gel Dryer GD-2Eclecticindia EclecticindiaNo ratings yet

- Pure Air FiltrationDocument6 pagesPure Air FiltrationkambiadoNo ratings yet

- Examining Explosives Handling Sensitivity of Trinitrotoluene (TNT) With Different Particle SizesDocument7 pagesExamining Explosives Handling Sensitivity of Trinitrotoluene (TNT) With Different Particle SizesMarrauNo ratings yet

- D352004107-MKT-001 Rev 02 Drilling Solutions MissionDocument13 pagesD352004107-MKT-001 Rev 02 Drilling Solutions MissionAshok SureshNo ratings yet

- Sauer-Danfoss Next Generation Hydrostatic Transmission ProductsDocument54 pagesSauer-Danfoss Next Generation Hydrostatic Transmission ProductsJose Manuel Barroso PantojaNo ratings yet

- Drug InspectorDocument33 pagesDrug InspectorsharaniyasyamNo ratings yet

- UP5 11cTAS 8Document12 pagesUP5 11cTAS 8Kudzie Maphy MasaireNo ratings yet

- Compressor Cross References PDFDocument324 pagesCompressor Cross References PDFRamon SanhuezaNo ratings yet

- Design of WTPDocument7 pagesDesign of WTPmirza_adil99No ratings yet

- 02Document10 pages02ZenPhiNo ratings yet

- Grade 7 - Science: Activity WorksheetsDocument58 pagesGrade 7 - Science: Activity WorksheetsMariz RaymundoNo ratings yet

- General Chemistry Lab Experiment 4 Limiting Reactant CompressDocument7 pagesGeneral Chemistry Lab Experiment 4 Limiting Reactant CompressKatherine Sagastume SerapioNo ratings yet

- Amc Resi Drill PdsDocument1 pageAmc Resi Drill PdsMiguel PeralNo ratings yet

- Coa 100Document16 pagesCoa 100naren_013No ratings yet

- 845 Training ReportDocument75 pages845 Training ReportDHANANJAY NERKAR100% (1)

- Manual de Servicio Bomba Manitex y NationalDocument22 pagesManual de Servicio Bomba Manitex y NationalAngel DlsgNo ratings yet

- Wagner Apprentice Program Offers Tools For SuccessDocument4 pagesWagner Apprentice Program Offers Tools For Successabduallah muhammadNo ratings yet

- MANUAL Euroclean-GD930Document2 pagesMANUAL Euroclean-GD930Julio HernandezNo ratings yet

- EADOX-MAR Comparison Chart & DetailsDocument4 pagesEADOX-MAR Comparison Chart & Detailsjeykumar.BalannairNo ratings yet

- Air Sentry Dessicant Breathers BrochureDocument14 pagesAir Sentry Dessicant Breathers BrochureNelson PeraltaNo ratings yet

- Mechanical: OperationsDocument222 pagesMechanical: OperationsParv DadhichNo ratings yet

- Aquatic Center Renovation Project - Fort Lauderdale, FL Parks & RecDocument3 pagesAquatic Center Renovation Project - Fort Lauderdale, FL Parks & RecCoach David Antonio Ferreiras J.No ratings yet

- Price List E-Katalog 27 Des 2022 UpdateDocument1 pagePrice List E-Katalog 27 Des 2022 UpdateAbdull 0106No ratings yet

- Electrolux z7040 PDFDocument8 pagesElectrolux z7040 PDFRobert RomanNo ratings yet

- 0620 s11 QP 63Document16 pages0620 s11 QP 63Waleed ShabirNo ratings yet