Professional Documents

Culture Documents

Manufacturing BOM / Multi Level

Manufacturing BOM / Multi Level

Uploaded by

Julver Goyzueta ArceOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manufacturing BOM / Multi Level

Manufacturing BOM / Multi Level

Uploaded by

Julver Goyzueta ArceCopyright:

Available Formats

Manufacturing BOM / Multi Level

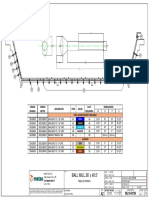

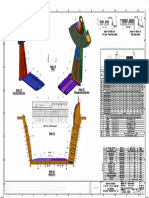

Item Number: N031060199 ERP Plant: Created by: C_KalLau

Item Description: GRATING TankCell® e30 Created on: 01.02.2016

Technical Description: NO I-DART V-BELT DRIVE WITH KICKPLATE Item Weight: 2546 Modified on: 04.02.2016

LEFT

BOM Revision: 1

Related document: OU600740496, 0 (Manufacturing Drawing)

L F/N Material B Description Manufacturer, Mfg. Code Qty Weight (kg) Length

O Standard

Document M Technical Description Material Standard Width

Ref Des

1 1 N031060197 X GRATING TankCell® e30 EA (each) 0

NO I-DART V-BELT DRIVE LEFT 1.0 0

OU600740497, 0 (Manufacturing

Drawing)

1 2 N031024962 X COVER ASSEMBLY EA (each) 79

1.0 79

OU600583426, 0 (Manufacturing

Drawing)

1 3 N031051970 X COVER EA (each) 10

1.0 10

OU600705288, 0 (Manufacturing

Drawing)

Spare Part: Y=Yes, N=No Printed: 25.05.2016

Page: 1 (8)

1 2 3 4 5 6 7 8

GENERAL TOLERANCES Values in millimetres

ISO 2768-1 EN ISO 13920 EN ISO 9013 DIN 6935

Basic size range

LINEAR

A DIMENSIONS

> 0,5

≤ 3

> 3

≤ 6

> 6

≤ 30

> 30

≤ 120

> 120

≤ 400

> 400

≤ 1000

> 1000

≤ 2000

> 2000

≤ 4000

> 4000 > 8000 > 12 000 > 16 000 > 20 000

≤ 8000 ≤ 12 000 ≤ 16 000 ≤ 20 000 A

Machining ISO 2768-m ± 0,1 ± 0,1 ± 0,2 ± 0,3 ± 0,5 ± 0,8 ± 1,2 ± 2

Chamfers and external radii ± 0,2 ± 0,5 ± 1

Welding ISO 13920-B ± 1 (Range 2-30) ± 2 ± 2 ± 3 ± 4 ± 6 ± 8 ± 10 ± 12 ± 14 ± 16

Thermal cutting ISO 9013-2 ≥ 3 < 10 ≥ 10 < 35 ≥ 35 < 125 ≥ 125 < 315 ≥ 315 < 1000 ≥ 1000 < 2000 ≥ 2000 < 4000

Quality of cut surface

3,15 < t ≤ 6,3 ± 0,7 ± 0,8 ± 0,9 ± 1,1 ± 1,2 ± 1,3 ± 1,3

6,3 < t ≤ 10 ± 1 ± 1,1 ± 1,3 ± 1,4 ± 1,5 ± 1,6 ± 1,7 ISO 9013-44

10 < t ≤ 50 ± 1,8 ± 1,8 ± 1,8 ± 1,9 ± 2,3 ± 3 ± 4,2

Shorter side

ANGULAR

DIMENSIONS ≤ 10 > 10 ≤ 50 > 50 ≤ 120 > 120 ≤ 400 > 400 ≤ 1000 > 1000

229

293

Machining ISO 2768-m ± 1° ± 0°30' ± 0°20' ± 0°10' ± 0°5'

40

Welding ISO 13920-B ± 13 mm/m ± 9 mm/m ± 6 mm/m

Bending SEE DIN 6935

B GEOMETRICAL TOLERANCES Machining ISO 2768-K Welding ISO 13920-F B

1076

C C

2866

1

1790

3

D 2

D

3876

E 0 kallau 01.02.2016 pekkall 03.02.2016 juhkau 03.02.2016 FOR FABRICATION E

REV. NAME DATE NAME DATE NAME DATE

REVISION TEXT

PREPARED CHECKED APPROVED

DOCUMENT TITLE

MANUFACTURING DRAWING

COMPLETE S-TYPE CLAMP FOR GRATING:

GRATING

NOTES: TANK MAIN ASSEMBLY

1. ALL GRATINGS HOT-DIP GALVANIZED & ACCORDING TO STANDARD DIN 24537 TankCell® e30

REPLACED BY

SP 40 - 50,8 OR EQUIVALENT

F 2. ALL GRATINGS FIXED TO THE BRIDGE WITH S-TYPE CLAMPS. REPLACES LANGUAGE UNITS SCALE SIZE SHEET OF SHEETS F

3. MINIMUM 4 FIXINGS PER GRATING. EN mm 1:40 A3 1 / 1

4. ALL FIXINGS HOT-DIP GALVANIZED. The content of these documents are the sole property of Outotec Oyj. Any rights not expressly granted

herein are reserved. Reproduction, transfer or distribution of part or all of the contents in any form without

DOCUMENT ID REVISION

prior written permission of Outotec is prohibited. OU600740496 0

1 2 3 4 5 6 7 8

Manufacturing BOM / Multi Level

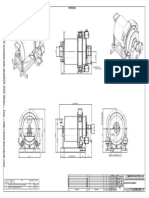

Item Number: N031060197 ERP Plant: Created by: C_KalLau

Item Description: GRATING TankCell® e30 Created on: 01.02.2016

Technical Description: NO I-DART V-BELT DRIVE LEFT Item Weight: 0 Modified on: 04.02.2016

Ref Des:

BOM Revision: 1

Related document: OU600740497, 0 (Manufacturing Drawing)

L F/N Material B Description Manufacturer, Mfg. Code Qty Weight (kg) Length

O Standard

Document M Technical Description Material Standard Width

Ref Des

2 10 N048374205 GRATING SP 34.3x50.8/40x5mm DIN 24537 M^2 (square meter) 0 2866.0 mm

STEEL EN 10025-2 - S235JR 11.108616 0

3876.0 mm

Spare Part: Y=Yes, N=No Printed: 25.05.2016

Page: 2 (8)

1 2 3 4 5 6 7 8 9 10 11 12

GENERAL TOLERANCES Values in millimetres

ISO 2768-1 EN ISO 13920 EN ISO 9013 DIN 6935

Basic size range

LINEAR > 0,5 > 3 > 6 > 30 > 120 > 400 > 1000 > 2000 > 4000 > 8000 > 12 000 > 16 000 > 20 000

DIMENSIONS ≤ 3 ≤ 6 ≤ 30 ≤ 120 ≤ 400 ≤ 1000 ≤ 2000 ≤ 4000 ≤ 8000 ≤ 12 000 ≤ 16 000 ≤ 20 000

A Machining ISO 2768-m ± 0,1 ± 0,1 ± 0,2 ± 0,3 ± 0,5 ± 0,8 ± 1,2 ± 2 A

Chamfers and external radii ± 0,2 ± 0,5 ± 1

Welding ISO 13920-B ± 1 (Range 2-30) ± 2 ± 2 ± 3 ± 4 ± 6 ± 8 ± 10 ± 12 ± 14 ± 16

Thermal cutting ISO 9013-2 ≥ 3 < 10 ≥ 10 < 35 ≥ 35 < 125 ≥ 125 < 315 ≥ 315 < 1000 ≥ 1000 < 2000 ≥ 2000 < 4000

Quality of cut surface

3,15 < t ≤ 6,3 ± 0,7 ± 0,8 ± 0,9 ± 1,1 ± 1,2 ± 1,3 ± 1,3

6,3 < t ≤ 10 ± 1 ± 1,1 ± 1,3 ± 1,4 ± 1,5 ± 1,6 ± 1,7 ISO 9013-44

10 < t ≤ 50 ± 1,8 ± 1,8 ± 1,8 ± 1,9 ± 2,3 ± 3 ± 4,2

Shorter side

ANGULAR

DIMENSIONS ≤ 10 > 10 ≤ 50 > 50 ≤ 120 > 120 ≤ 400 > 400 ≤ 1000 > 1000

Machining ISO 2768-m ± 1° ± 0°30' ± 0°20' ± 0°10' ± 0°5'

40

Welding ISO 13920-B ± 13 mm/m ± 9 mm/m ± 6 mm/m

Bending SEE DIN 6935

GEOMETRICAL TOLERANCES Machining ISO 2768-K Welding ISO 13920-F

B B

C C

0

3876 -10

876 1000 1000 1000

D D

1076

335

2866 -10

485

0

E E

BEARING BAR DIRECTION

1790

1305

F COMPLETE S-TYPE CLAMP FOR GRATING: F

NOTES:

1. ALL GRATINGS HOT-DIP GALVANIZED & ACCORDING TO STANDARD DIN 24537

SP 40 - 50,8 OR EQUIVALENT

842 1743 491 800 2. ALL GRATINGS FIXED TO THE BRIDGE WITH S-TYPE CLAMPS.

3. MINIMUM 4 FIXINGS PER GRATING.

4. ALL FIXINGS HOT-DIP GALVANIZED.

G G

0 kallau 01.02.2016 pekkall 03.02.2016 juhkau 03.02.2016 FOR FABRICATION

REV. NAME DATE NAME DATE NAME DATE

REVISION TEXT

PREPARED CHECKED APPROVED

DOCUMENT TITLE

MANUFACTURING DRAWING

GRATING

NO I-DART V-BELT DRIVE LEFT

H REPLACED BY TankCell® e30 H

REPLACES LANGUAGE UNITS SCALE SIZE SHEET OF SHEETS

EN mm 1:25 A2 1 / 1

The content of these documents are the sole property of Outotec Oyj. Any rights not expressly granted

herein are reserved. Reproduction, transfer or distribution of part or all of the contents in any form without

DOCUMENT ID REVISION

prior written permission of Outotec is prohibited. OU600740497 0

1 2 3 4 5 6 7 8 9 10 11 12

You might also like

- 2008 Nissan Teana J32 Service Manual-EMDocument148 pages2008 Nissan Teana J32 Service Manual-EMMrihex100% (3)

- Astm E2550 - Ensaio de Tga Pa12Document5 pagesAstm E2550 - Ensaio de Tga Pa12Italo MartinsNo ratings yet

- David DeAngelo News Letters - Vol 1Document403 pagesDavid DeAngelo News Letters - Vol 1theseductivecharacterNo ratings yet

- (M2209908381) - #40x30T DETA User ManualDocument67 pages(M2209908381) - #40x30T DETA User ManualtuxNo ratings yet

- 660D14 Painting Schedule For Silo 1 - Rev 0Document1 page660D14 Painting Schedule For Silo 1 - Rev 0Mohammad AdilNo ratings yet

- f18p01 m00 000 General ArrangementDocument1 pagef18p01 m00 000 General ArrangementAngga Purnama PutraNo ratings yet

- Monitoring Open OrderDocument66 pagesMonitoring Open OrderdbedadaNo ratings yet

- SIG-De-21 Lógica de Control Con Interruptores de Temperatura - TD03-B108-E-11Document7 pagesSIG-De-21 Lógica de Control Con Interruptores de Temperatura - TD03-B108-E-11Jorge PalacioNo ratings yet

- ML19-0199 PernosDocument1 pageML19-0199 PernosElias PaxiNo ratings yet

- Pierre MagisDocument11 pagesPierre MagisArpan MahajanNo ratings yet

- Electric Specification: 1. Components Characteristics and AdjustmentsDocument9 pagesElectric Specification: 1. Components Characteristics and AdjustmentsMoreno Adrian BenitezNo ratings yet

- Cerro Verde Production Unit Expansion: Coarse Ore Vibrating Screens Lifting Pipe Details Document No. SN-100462-MD21Document5 pagesCerro Verde Production Unit Expansion: Coarse Ore Vibrating Screens Lifting Pipe Details Document No. SN-100462-MD21jhonNo ratings yet

- Presentation 1Document64 pagesPresentation 1Henry ArrvalNo ratings yet

- Cerro Verde Production Unit Expansion: Calculations For Coarse Ore Vibrating Screens Document No. SN-100462-MD09Document4 pagesCerro Verde Production Unit Expansion: Calculations For Coarse Ore Vibrating Screens Document No. SN-100462-MD09jhonNo ratings yet

- New Microsoft Office Excel WorksheetDocument10 pagesNew Microsoft Office Excel WorksheetACCOUNTS AMBIKAPURNo ratings yet

- 9075 Reflux Classifier BrochureDocument4 pages9075 Reflux Classifier BrochureNeeraj Agrawal100% (1)

- Cerro Verde Production Unit Expansion: Bill of Materials Per Operating Screen Document No. SN-100462-MD03Document7 pagesCerro Verde Production Unit Expansion: Bill of Materials Per Operating Screen Document No. SN-100462-MD03jhonNo ratings yet

- Grinding Mill DrawingDocument1 pageGrinding Mill DrawingHans ManriqueNo ratings yet

- Tac4598 - 3350KW - Instruction ManualDocument48 pagesTac4598 - 3350KW - Instruction ManualMiguel Angel RodriguezNo ratings yet

- Induction Motor Data: Siemens Industry, Inc. Norwood, OhioDocument3 pagesInduction Motor Data: Siemens Industry, Inc. Norwood, OhioelvisNo ratings yet

- Less Is MoreDocument3 pagesLess Is Moresnarf273No ratings yet

- Power Circuit For D.O.L. Starting For Motor Rotation Refer To Installation Layout Sn-100462-D001Document1 pagePower Circuit For D.O.L. Starting For Motor Rotation Refer To Installation Layout Sn-100462-D001jhonNo ratings yet

- World Non US Gasification DatabaseDocument9 pagesWorld Non US Gasification DatabaseKhairi Maulida AzhariNo ratings yet

- ) Mets: Iqdilution BookDocument106 pages) Mets: Iqdilution BookDanilNo ratings yet

- Heat Treatment of Iron Ore PelletDocument39 pagesHeat Treatment of Iron Ore PelletPRASSAN SHAH100% (1)

- Grinding Mill Plan PDFDocument1 pageGrinding Mill Plan PDFBender Doblador RodriguezNo ratings yet

- SIG de 22 Diagrama de Cableado TD3 B102 E 10Document10 pagesSIG de 22 Diagrama de Cableado TD3 B102 E 10Jorge PalacioNo ratings yet

- 00-Eng-Mv90-Ror-Vertical Impact Crusher - Spare Parts ManualDocument10 pages00-Eng-Mv90-Ror-Vertical Impact Crusher - Spare Parts ManualMartín Lescano ParedesNo ratings yet

- RME Data Sheet - RUSSELL Mill Relining MachineDocument1 pageRME Data Sheet - RUSSELL Mill Relining MachineСергейNo ratings yet

- Parts Manual: CascadeDocument14 pagesParts Manual: CascadeAlvaro PradaNo ratings yet

- Planos SAG Shell PDFDocument1 pagePlanos SAG Shell PDFA̶l̶x̶a̶n̶d̶e̶r̶ PaniNo ratings yet

- Pages From SAG - MILL-2Document3 pagesPages From SAG - MILL-2David Chijchiapaza PacoNo ratings yet

- Cerro Verde Production Unit Expansion: Non Destructive Examination Requirements Document No. SN-100462-MD12Document3 pagesCerro Verde Production Unit Expansion: Non Destructive Examination Requirements Document No. SN-100462-MD12jhonNo ratings yet

- 2100-S-40535_0.pdfDocument1 page2100-S-40535_0.pdfstefano.herradaNo ratings yet

- 2100-S-40533_0.pdfDocument1 page2100-S-40533_0.pdfstefano.herradaNo ratings yet

- 015-80T3-FW8 - Rev 1Document1 page015-80T3-FW8 - Rev 1José Luis TolaNo ratings yet

- Vertical Curve Radius Calculations: Pt. Vortex IndonesiaDocument4 pagesVertical Curve Radius Calculations: Pt. Vortex IndonesiaWaris La Joi WakatobiNo ratings yet

- Haver BoeckerDocument5 pagesHaver BoeckerAliNo ratings yet

- 2100-S-40532_0.pdfDocument1 page2100-S-40532_0.pdfstefano.herradaNo ratings yet

- 2100-S-40534_0.pdfDocument1 page2100-S-40534_0.pdfstefano.herradaNo ratings yet

- Rev3Document2 pagesRev3Deyvi Osmar Zegarra Villena0% (1)

- Waste Management World - August 2015Document53 pagesWaste Management World - August 2015Elmihra MundiNo ratings yet

- Ws Tyler Uml Class PartsDocument4 pagesWs Tyler Uml Class Partsyolimar escorciaNo ratings yet

- COBRAS 2015 Outotec SulfurHandlingDocument18 pagesCOBRAS 2015 Outotec SulfurHandlingIrsan Bin MustaminNo ratings yet

- Lainas SAG MillDocument1 pageLainas SAG MillDavid SalasNo ratings yet

- Dm-dcld-f-cm-0017 Rev 4 Ems Test ChargesDocument112 pagesDm-dcld-f-cm-0017 Rev 4 Ems Test ChargesPervaiz BaigNo ratings yet

- Released FOR Manufacturing: 2509 ANTAMINA PERU SMC 100/14400 Truck Bridge Assembly Truck Bridge Steel Structure - RightDocument1 pageReleased FOR Manufacturing: 2509 ANTAMINA PERU SMC 100/14400 Truck Bridge Assembly Truck Bridge Steel Structure - RightCarlos ParedesNo ratings yet

- METSO DOA Dimesion ReportDocument8 pagesMETSO DOA Dimesion ReportNaresh KumarNo ratings yet

- Manual Original HP400 TerciariaDocument76 pagesManual Original HP400 TerciariaGilberto Garnica MurilloNo ratings yet

- Hoja de Cálculo Sin Título - ChancadoDocument40 pagesHoja de Cálculo Sin Título - ChancadoJr.JeanNo ratings yet

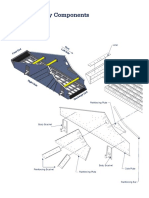

- H-Class / Hummer Body Components: How Do I Order?Document2 pagesH-Class / Hummer Body Components: How Do I Order?yolimar escorciaNo ratings yet

- Katalog enDocument75 pagesKatalog enErsin SucuNo ratings yet

- A1752902-48 Conveyor Parts Manual CON-203-4-J1349Document15 pagesA1752902-48 Conveyor Parts Manual CON-203-4-J1349waltergv100% (1)

- Item Section Size Material Grade Length (MM) Mass (KG) Per ItemDocument1 pageItem Section Size Material Grade Length (MM) Mass (KG) Per ItemMohammad AdilNo ratings yet

- Cerro Verde Production Unit Expansion: Ludowici Vibrating Screens Installation Sequence Document No. SN-100462-MD18Document5 pagesCerro Verde Production Unit Expansion: Ludowici Vibrating Screens Installation Sequence Document No. SN-100462-MD18jhonNo ratings yet

- Supply Chain EssentiallsDocument13 pagesSupply Chain EssentiallsChristopher Bustillos GuzmanNo ratings yet

- Week 01Document8 pagesWeek 01Pskaruppiah KarupsNo ratings yet

- Dimensional Drawing: UPS 762UP110G01 Vendor Instruction English Plant Name: DG Khan Hub Contract Number: 15 - 45366Document3 pagesDimensional Drawing: UPS 762UP110G01 Vendor Instruction English Plant Name: DG Khan Hub Contract Number: 15 - 45366Atiq_2909No ratings yet

- Simu Presentacion Exam3Document1 pageSimu Presentacion Exam3Edwin Barboza DuranNo ratings yet

- HEPICS Whitepaper Improved MP1000 Liner PerformanceDocument3 pagesHEPICS Whitepaper Improved MP1000 Liner PerformanceYousef AlipourNo ratings yet

- SIG-De-14 Dibujo de Dimensiones Drive 8V - TD6-B121-E-05Document2 pagesSIG-De-14 Dibujo de Dimensiones Drive 8V - TD6-B121-E-05Jorge PalacioNo ratings yet

- Ws Tyler XL Class PartsDocument6 pagesWs Tyler XL Class Partsyolimar escorciaNo ratings yet

- Enbio-S 2022 01 Service Technical-SpecificationDocument11 pagesEnbio-S 2022 01 Service Technical-Specificationsat.au.autoclavesNo ratings yet

- Tankcell® Flotation Machine: Bolt ConnectionsDocument6 pagesTankcell® Flotation Machine: Bolt ConnectionsJulver Goyzueta Arce100% (1)

- Manual de Variador DeltaDocument129 pagesManual de Variador DeltaJulver Goyzueta ArceNo ratings yet

- Motor WegDocument56 pagesMotor WegJulver Goyzueta ArceNo ratings yet

- Tankcell® Flotation Machine: Bolt ConnectionsDocument6 pagesTankcell® Flotation Machine: Bolt ConnectionsJulver Goyzueta Arce100% (1)

- Siemens Ultrasonic Transmitter 7ML1201Document3 pagesSiemens Ultrasonic Transmitter 7ML1201Julver Goyzueta ArceNo ratings yet

- Certified: Project ImplementationDocument1 pageCertified: Project ImplementationJulver Goyzueta ArceNo ratings yet

- OU600732294 - R1 - GENERAL ARRANGEMENT - Certified PDFDocument1 pageOU600732294 - R1 - GENERAL ARRANGEMENT - Certified PDFJulver Goyzueta ArceNo ratings yet

- Lec01 SlidesDocument58 pagesLec01 SlidesConnor KaminskaNo ratings yet

- CT753 - 2020 08 29T04 26 21.878Z - Simulation - ModelingDocument73 pagesCT753 - 2020 08 29T04 26 21.878Z - Simulation - ModelingAnish shahNo ratings yet

- Fisa Tehnica Detector de Gaz Metan Adresabil Cu Sirena UniPOS FD71CNGDocument2 pagesFisa Tehnica Detector de Gaz Metan Adresabil Cu Sirena UniPOS FD71CNGAugustin CatineanNo ratings yet

- Site Layout OptimizationDocument30 pagesSite Layout OptimizationRyan SatriaNo ratings yet

- NG Registration Guide KopiDocument21 pagesNG Registration Guide KopiMarkus TNo ratings yet

- Viewsonic G220f - Service ManualDocument71 pagesViewsonic G220f - Service ManualtongshadowNo ratings yet

- Paper 6D Elective Law Summary of 50 Case StudiesDocument15 pagesPaper 6D Elective Law Summary of 50 Case StudiesArpit jainNo ratings yet

- Ronnie Earl and The Broadcasters - Just For Today (Liner Notes)Document6 pagesRonnie Earl and The Broadcasters - Just For Today (Liner Notes)Stony Plain RecordsNo ratings yet

- General Ledger Accounts Meaning and Definition: AccountingDocument2 pagesGeneral Ledger Accounts Meaning and Definition: AccountingEinah EinahNo ratings yet

- RFP For Procurement of Network Access Control (Nac) Solution With Manageable Network SwitchesDocument66 pagesRFP For Procurement of Network Access Control (Nac) Solution With Manageable Network SwitchesShailja vermaNo ratings yet

- Lesson 1 The Statement of Financial PositionDocument11 pagesLesson 1 The Statement of Financial PositionFranchesca Calma100% (1)

- KFC Project CorpDocument14 pagesKFC Project CorpShreyaNo ratings yet

- 2890 - Mandatory Telematics in Brazil Information BulletinDocument4 pages2890 - Mandatory Telematics in Brazil Information Bulletinpoonam18No ratings yet

- Topic 10 Parol Evidence RuleDocument3 pagesTopic 10 Parol Evidence RuleAisyah SyuhadaNo ratings yet

- Coffeehouse Business Plan: " You Deserve A Good Taste "Document12 pagesCoffeehouse Business Plan: " You Deserve A Good Taste "Do DoNo ratings yet

- Unit-3 HTML Tools and EditorsDocument7 pagesUnit-3 HTML Tools and EditorsAslam NizamiNo ratings yet

- Boundary ValueDocument1 pageBoundary ValueRey BustamanteNo ratings yet

- Jhonson M9106 AGA2Document3 pagesJhonson M9106 AGA2Matheus LucareviskiNo ratings yet

- Product Leaflet - Buddy MIG 400i 500iDocument2 pagesProduct Leaflet - Buddy MIG 400i 500idherendra chhadodiNo ratings yet

- Strategic Management: Date For Submission: Please Refer To The Timetable On IlearnDocument6 pagesStrategic Management: Date For Submission: Please Refer To The Timetable On Ilearnzebst loveNo ratings yet

- Arihant Computer Science Cbse Class 12 Term 2 WWW - Examsakha.in PDFDocument130 pagesArihant Computer Science Cbse Class 12 Term 2 WWW - Examsakha.in PDFAman Singh50% (2)

- TIMKEN - Zespoy Ozyskowe Typu E PDFDocument13 pagesTIMKEN - Zespoy Ozyskowe Typu E PDFPlamen KangalovNo ratings yet

- 1Document619 pages1Sandra MichelleNo ratings yet

- CHAPTER 2 Modern Auditing: Assurance Service and The Integrity of Financial Reporting FINANCIAL STATEMENT AUDITS AND AUDITORS' RESPONSIBILITIESDocument22 pagesCHAPTER 2 Modern Auditing: Assurance Service and The Integrity of Financial Reporting FINANCIAL STATEMENT AUDITS AND AUDITORS' RESPONSIBILITIESAkbar BhahestyNo ratings yet

- Arrestallamas - 6B00 - TBDocument4 pagesArrestallamas - 6B00 - TBWiliam SeguraNo ratings yet

- Dual Axis Solar Tracking SystemDocument4 pagesDual Axis Solar Tracking Systemvidyadhar GNo ratings yet

- MicroeconomicsDocument22 pagesMicroeconomicsVic Gerome Dela CruzNo ratings yet