Professional Documents

Culture Documents

23 11 13 - Fuel Oil Piping

Uploaded by

Marianne SolaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

23 11 13 - Fuel Oil Piping

Uploaded by

Marianne SolaCopyright:

Available Formats

SECTION 231113

FUEL OIL PIPING

A. Buried/Underground Piping

1. Steel Pipe: ASTM A53, Schedule 80 B.I. Seamless

Fittings: ASTM A234/A234M, wrought carbon steel and alloy steel welding type.

Joints: ANSI B31.1 / ANSI B31.4 / ANSI B31.9 welded.

Jacket: AWWA C105 polyethylene or double layer, half-lapped 0.25 mm (10 mil)

polyethylene tape.

B. Above Ground Piping

1. Steel Pipe: ASTM A53, Schedule 80 B.I. Seamless

Fittings: ASTM B16.3, malleable iron, or ASTM

A234/A234M, wrought carbon steel and alloy steel welding type.

Joints: NFPA 30, threaded or welded to ANSI B31.1 / ANSI B31.4 / ANSI B31.9

Jacket: AWWA C105 polyethylene or double layer, half- lapped 0.25 mm (10mil)

polyethylene tape.

C. Underground Piping Containment System

1. FRP: ASTM D2310 and ASTM D2996, UL listed filament wound fiberglass

reinforced epoxy pipe with integral epoxy liner and exterior coating.

Fittings: Two piece, compression molded, filament wound fiberglass reinforced

epoxy, mechanically joined.

D. Pipe hangers and supports

1. Conform to NFPA 31 / ANSI B31.1 / ANSI B31.4

2. Hangers for Pipe Sizes 15 to 40 mm (1/2 to 1-1/2 Inch): Carbon steel, adjustable swivel, split ring.

3. Hangers for Pipe Sizes 50 mm (2 inches) and Over: Carbon steel, adjustable, clevis.

4. Multiple or Trapeze Hangers: Steel channels with welded spacers and hanger rods.

5. Wall Support for Pipe Sizes to 80 mm (3 inches): Cast iron hook.

6. Vertical Support: Steel riser clamp or Angle ring.

7. Floor Support: Cast iron adjustable pipe saddle, lock nut, nipple, floor flange, and concrete pier or

steel support.

8. Copper Pipe Support: Carbon steel ring, adjustable, copper plated.

E. Flanges, Unions, and Coupling

1. Pipe Size 50 mm (2 inches) and under: Ferrous pipe: 1034 kPa (150 psi) malleable iron threaded

unions.

Copper tube: 1034 kPa (150 psi) bronze unions with brazed joints.

2. Pipe Size Over mm (2 inches):

Ferrous pipe: 1034 kPa (150 psi) forged steel slip-on flanges; 1.6 mm (1/16 inch) thick preformed

neoprene gaskets.

Copper tube: 1034 kPa (150 psi) forged steel slip-on flanges; 1.6 mm (1/16 inch) thick preformed

neoprene gaskets.

F. Valves and Fitting

1. Gate Valves - MSS SP-80, Class 150, bronze body, bronze trim, rising stem, hand wheel, inside

screw, solid wedge disc, threaded ends

6 STOREY COMMERCIAL/RESIDENTIAL BLDG. MR. & MRS. TONY QUE

23 11 13 - FUEL OIL PIPING MECHANICAL SPECIFICATIONS

R.J. Calpo & Company, Inc. Page 1

2. Globe Valves - MSS SP-80, Class 125, bronze body, bronze trim, hand wheel, bronze disc,

threaded ends.

3. Ball Valves - MSS SP-110, Class 150, 2760 kPa (400 psi) CWP, bronze, two piece body, chrome

plated brass ball, regular port, teflon seats and stuffing box ring, blow-out proof stem, lever handle

(with balancing stops), threaded ends (with union).

4. Swing Check valves - MSS SP-80, Class 125, bronze body and cap, bronze swing disc, threaded

ends.

5. Relief Valves - Bronze body, teflon seat, steel stem and springs, automatic, direct pressure actuated

at maximum 400 kPa (60 psi), UL listed for fuel oil, capacities ASME certified and labeled.

6. Strainers - Threaded brass body for 1200 kPa (175 psi) CWP, Y pattern with 0.8 mm (1/32 inch)

stainless steel perforated screen.

7 . Flexible Connectors - Bronze inner hose and braided exterior sleeve, suitable for minimum 1380

kPa (200 psi) CWP and 121 °C (250 °F).

G. Fuel Oil Pumps

1. Positive-displacement, Rotary type

2. Acceptable manufacturers:

a. Rotan

b. Tuthill

C. Kawamoto

3. Casing: Bronze, rated for 860 kPa (125 psi) working pressure with integral pressure relief valve.

4. Impeller: Steel gear with crescent Carbon vane

5. Drive: Direct close coupled with flexible coupling.

6. Accessories: Adjustable pressure control valve, bleed valve, mechanical seal.

END OF SECTION

6 STOREY COMMERCIAL/RESIDENTIAL BLDG. MR. & MRS. TONY QUE

23 11 13 - FUEL OIL PIPING MECHANICAL SPECIFICATIONS

R.J. Calpo & Company, Inc. Page 2

You might also like

- Fuel Handling SystemDocument4 pagesFuel Handling SystemRoel FranciscoNo ratings yet

- SECTION 15100 ValvesDocument10 pagesSECTION 15100 ValvesintequabNo ratings yet

- Domestic and Industrial Water Piping Guide DesignDocument7 pagesDomestic and Industrial Water Piping Guide DesignEddito CachoNo ratings yet

- Specification For Fire Pump - Part 10Document5 pagesSpecification For Fire Pump - Part 10Melisa MackNo ratings yet

- STD 15257Document8 pagesSTD 15257TrefastoreNo ratings yet

- 23 22 13 Steam and Condensate PipingDocument15 pages23 22 13 Steam and Condensate PipingchabibNo ratings yet

- Valves and Related ComponentsDocument7 pagesValves and Related ComponentsSalim BakhshNo ratings yet

- Domestic Water Piping Materials and InstallationDocument16 pagesDomestic Water Piping Materials and InstallationChase GietterNo ratings yet

- B1a1 Pipe ClassDocument1 pageB1a1 Pipe Classbrujula27No ratings yet

- Asme Sa 106 Grade B PipesDocument1 pageAsme Sa 106 Grade B PipesFerroPipENo ratings yet

- Mechanical BookDocument221 pagesMechanical BookPwan Khurana100% (1)

- Documents Plc150Document7 pagesDocuments Plc150Anonymous cuOIjrLINo ratings yet

- Piping Spec: CS150 - Carbon Steel Class 150 Piping StandardDocument4 pagesPiping Spec: CS150 - Carbon Steel Class 150 Piping Standardbmanojkumar16No ratings yet

- 8-1286-2 Pipe Class HF-10: Standard SpecificationDocument2 pages8-1286-2 Pipe Class HF-10: Standard SpecificationStuart WickensNo ratings yet

- Standard Specification: UOP LLC - 25 East Algonquin Road - Des Plaines, Illinois 60017-5017 - USADocument2 pagesStandard Specification: UOP LLC - 25 East Algonquin Road - Des Plaines, Illinois 60017-5017 - USAStuart WickensNo ratings yet

- Water SystemDocument9 pagesWater SystemArun GuptaNo ratings yet

- PipingDocument7 pagesPipingAshar HassanNo ratings yet

- STD 15080Document4 pagesSTD 15080dineshinnaci123No ratings yet

- Critical valve repair kits and sealsDocument30 pagesCritical valve repair kits and sealsFrendy RianNo ratings yet

- Project Standard Specification: Compressed-Air Piping 15481-Page 1/9Document9 pagesProject Standard Specification: Compressed-Air Piping 15481-Page 1/9adel rihanaNo ratings yet

- 8-1285-2 Pipe Class HF-7: Standard SpecificationDocument2 pages8-1285-2 Pipe Class HF-7: Standard SpecificationStuart WickensNo ratings yet

- Flanged Standard Bore Ball Valves: ANSI CLASS 150 & 300Document8 pagesFlanged Standard Bore Ball Valves: ANSI CLASS 150 & 300marpadanNo ratings yet

- Filtro DuplexDocument8 pagesFiltro DuplexGuillermo ArandaNo ratings yet

- Pipe Class Data Sheet - Rev.1Document4 pagesPipe Class Data Sheet - Rev.1bonnicoNo ratings yet

- Asme Sa 210 Grade C TubesDocument1 pageAsme Sa 210 Grade C TubesFerroPipENo ratings yet

- Pipe Material and Welding Procedure SpecificationDocument39 pagesPipe Material and Welding Procedure Specificationmanojballa100% (1)

- Pipe and Pipe FittingsDocument21 pagesPipe and Pipe FittingsAdamNo ratings yet

- Pipe Material DetailsDocument5 pagesPipe Material DetailsHaitNo ratings yet

- Stainless Steel Pipe and Fittings SpecificationDocument10 pagesStainless Steel Pipe and Fittings SpecificationCassy AbulenciaNo ratings yet

- Mep Approved Material Specifications: Technical Assessment GuideDocument44 pagesMep Approved Material Specifications: Technical Assessment GuideriyasNo ratings yet

- Hy-Lok Tube Fittings Catalog No. H-200TFDocument76 pagesHy-Lok Tube Fittings Catalog No. H-200TFJit BNo ratings yet

- Asme Sa 333 Grade 1 PipesDocument1 pageAsme Sa 333 Grade 1 PipesFerroPipENo ratings yet

- Tube Fittings: Size From 1/16" Thru 2" (2mm Thru 50mm)Document5 pagesTube Fittings: Size From 1/16" Thru 2" (2mm Thru 50mm)Jit BNo ratings yet

- ValvesDocument7 pagesValvesAnonymous NR3qZ30No ratings yet

- B3000 & Eb3000Document1 pageB3000 & Eb3000husamNo ratings yet

- 7a. Steel Pipeline FittingDocument37 pages7a. Steel Pipeline Fittingamaliabdulkader100% (1)

- RV/RR - DETAIL DRAWING OF RESILIENT SEATED AND BUTTERFLY VALVESDocument64 pagesRV/RR - DETAIL DRAWING OF RESILIENT SEATED AND BUTTERFLY VALVESduc22198No ratings yet

- Technical Catalouge PDFDocument41 pagesTechnical Catalouge PDFDhanish KumarNo ratings yet

- 1/27/2019 /conversion/tmp/scratch/407716113Document10 pages1/27/2019 /conversion/tmp/scratch/407716113Maki DizonNo ratings yet

- Pipe FittingsDocument40 pagesPipe FittingsLucky Jaswal100% (1)

- 220523-General-Duty Valves For Plumbing PipingDocument9 pages220523-General-Duty Valves For Plumbing PipingAttef BedaweNo ratings yet

- Acceptance CriteriaDocument10 pagesAcceptance CriteriaRavindra S. Jivani100% (2)

- Standard Specification: UOP LLC - 25 East Algonquin Road - Des Plaines, Illinois 60017-5017 - USADocument3 pagesStandard Specification: UOP LLC - 25 East Algonquin Road - Des Plaines, Illinois 60017-5017 - USAStuart WickensNo ratings yet

- Piping Spec: CS300 TFS 1022: Engineering StandardDocument4 pagesPiping Spec: CS300 TFS 1022: Engineering Standardbmanojkumar16No ratings yet

- BIll of Mterial WDS LineDocument9 pagesBIll of Mterial WDS LineBayu Permana RydhaNo ratings yet

- CMPC Pulp: Valve Metallurgy Under RevisionDocument4 pagesCMPC Pulp: Valve Metallurgy Under RevisionCesar Eugenio Sanhueza ValdebenitoNo ratings yet

- Piping Systems and AccessoriesDocument16 pagesPiping Systems and AccessoriesYoussef100% (1)

- Carbon Steel Strainer Fig 34 HP-Technical InformationDocument3 pagesCarbon Steel Strainer Fig 34 HP-Technical InformationSouljah KhifferNo ratings yet

- Asme Sa 210 Grade A 1 TubesDocument1 pageAsme Sa 210 Grade A 1 TubesFerroPipENo ratings yet

- Shinyi Catalogue 2017Document64 pagesShinyi Catalogue 2017Huy NguyễnNo ratings yet

- FastnersDocument18 pagesFastnersraghbirNo ratings yet

- Expansion Compensation For PlumbingDocument6 pagesExpansion Compensation For Plumbingabdullah sahibNo ratings yet

- 1824 000 PI SPC 0003 - 7 - IFP - CleanedDocument22 pages1824 000 PI SPC 0003 - 7 - IFP - CleanedJudith HidalgoNo ratings yet

- Asme Sa 333 Grade 6 PipesDocument1 pageAsme Sa 333 Grade 6 PipesFerroPipENo ratings yet

- Valve StandardsDocument10 pagesValve StandardsMorteza alizadehNo ratings yet

- Table BrenchDocument11 pagesTable BrenchLuis GonzalezNo ratings yet

- Kirloskar Romak Pump - RMK: ISO 2858 / DIN EN 22858 / ISO 5199Document8 pagesKirloskar Romak Pump - RMK: ISO 2858 / DIN EN 22858 / ISO 5199Amit pumpXpertzNo ratings yet

- Refrigeration DX Piping and Specialties (Rev. 11-16Document5 pagesRefrigeration DX Piping and Specialties (Rev. 11-16T0 R3dNo ratings yet

- Piping Class CS1 300 4Document3 pagesPiping Class CS1 300 4rakicbg100% (1)

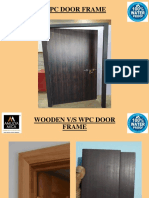

- Everything about WPC Door FramesDocument18 pagesEverything about WPC Door Framesrishi gupta100% (1)

- CPLAST 114 Technical Data SheetDocument2 pagesCPLAST 114 Technical Data Sheetraviteja036No ratings yet

- Clay Products Manufacturing and PropertiesDocument41 pagesClay Products Manufacturing and PropertiesSwapna PandeNo ratings yet

- Alkali Aggregate Reaction, Alkali Carbonate Reaction and Pyrite AttackDocument3 pagesAlkali Aggregate Reaction, Alkali Carbonate Reaction and Pyrite AttackVasanthapragash NadarajhaNo ratings yet

- Scope of Work: 1.1.1 Panels For Equipment PanelDocument11 pagesScope of Work: 1.1.1 Panels For Equipment PanelsudhirNo ratings yet

- Precast Concrete ConstructionDocument71 pagesPrecast Concrete ConstructionMahad AbdiNo ratings yet

- Silk Screen Ceramic Frit GlassDocument3 pagesSilk Screen Ceramic Frit GlassHan JoeNo ratings yet

- Frontmatters EIM LM 02.06.15Document5 pagesFrontmatters EIM LM 02.06.15Owen CajarteNo ratings yet

- 09 MaschinenfabrikReinhausen on-LoadTap-ChangerDocument16 pages09 MaschinenfabrikReinhausen on-LoadTap-ChangerRahul SharmaNo ratings yet

- 35 11 SG FTV BrochureDocument8 pages35 11 SG FTV Brochuresyed aliNo ratings yet

- Sustanaible Architecture With Stainless SteelDocument19 pagesSustanaible Architecture With Stainless SteelRobbie1286No ratings yet

- Use of Waste Plastic in Concrete Mixture As Aggregate ReplacementDocument4 pagesUse of Waste Plastic in Concrete Mixture As Aggregate ReplacementIJAERS JOURNALNo ratings yet

- Sae Astm Aisi ChartDocument1 pageSae Astm Aisi ChartOmar Jesus CocaNo ratings yet

- Spliced I-Girder Concrete Bridge SystemDocument193 pagesSpliced I-Girder Concrete Bridge SystemJessie Radaza TutorNo ratings yet

- Eifeler Coating Application - ChartDocument1 pageEifeler Coating Application - Chartykc38No ratings yet

- Basell 2427KDocument2 pagesBasell 2427KPhuoc TranNo ratings yet

- Tica SpecDocument29 pagesTica SpecCong ThanhNo ratings yet

- ASTM A126 (China Suggested Chemical Composition)Document3 pagesASTM A126 (China Suggested Chemical Composition)EduardoNo ratings yet

- Introduction Historical Prospective, Importance of Materials PDFDocument33 pagesIntroduction Historical Prospective, Importance of Materials PDFsayiramNo ratings yet

- Sor 16-17 PDFDocument524 pagesSor 16-17 PDFRamuCivilNo ratings yet

- Design Recommendations for Screw Machine ProductsDocument23 pagesDesign Recommendations for Screw Machine Productsashwin josephNo ratings yet

- Flange Dimensions Based On Tables D and E of BS 10: 1962Document6 pagesFlange Dimensions Based On Tables D and E of BS 10: 1962윤규섭No ratings yet

- Cordivari Technical Sheet VASO STORAGE 2Document4 pagesCordivari Technical Sheet VASO STORAGE 2Tuan SsvcNo ratings yet

- B111B111M-11 Standard Specification For Copper and Copper-Alloy Seamless Condenser Tubes and Ferrule StockDocument12 pagesB111B111M-11 Standard Specification For Copper and Copper-Alloy Seamless Condenser Tubes and Ferrule StockSalma FarooqNo ratings yet

- Bond Strength of Mortar To Masonry Units: Standard Test Method ForDocument8 pagesBond Strength of Mortar To Masonry Units: Standard Test Method Foranon_694321072100% (1)

- Measuring Concrete Work 1Document19 pagesMeasuring Concrete Work 1Akbar RafeekNo ratings yet

- NDT Defects RecordsDocument1 pageNDT Defects RecordsAnonymous OEUUoKHYRNo ratings yet

- Chapter 1 - Loading, Unloading, Carriage & Setting Out: Item No. Unit Rate (RS.) DescriptionDocument38 pagesChapter 1 - Loading, Unloading, Carriage & Setting Out: Item No. Unit Rate (RS.) DescriptionAbhijeet SahuNo ratings yet

- Chemical Resistance of Mortars, Grouts, and Monolithic Surfacings and Polymer ConcretesDocument6 pagesChemical Resistance of Mortars, Grouts, and Monolithic Surfacings and Polymer ConcretesAmiine BkdNo ratings yet

- 12 Basic Plumbing Supplies For Home Tool Kits - DIY GuyDocument8 pages12 Basic Plumbing Supplies For Home Tool Kits - DIY GuyuraiNo ratings yet