Professional Documents

Culture Documents

Gore Sealant Technologies: For Reliable Sealing of Standard EN Flanges

Gore Sealant Technologies: For Reliable Sealing of Standard EN Flanges

Uploaded by

rijalharunOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gore Sealant Technologies: For Reliable Sealing of Standard EN Flanges

Gore Sealant Technologies: For Reliable Sealing of Standard EN Flanges

Uploaded by

rijalharunCopyright:

Available Formats

GORE Sealant Technologies ®

torquing recommendations

For reliable sealing of standard EN flanges EN

In order to achieve a reliable seal, it is essential that as much

surface pressure as possible is exerted. However, it is important Gasket Types

that the maximum permissible surface pressure Qsmax (see pro-

duct data sheet) and the torque recommendations of the flange

manufacturer are not exceeded. Our torquing recommendations

for customary standard flange types are listed below. Please

note that, if applicable, proof of tightness and strength (for ex-

ample as defined by EN1591-1) is to be documented by the user.

Installation Instructions

• choose the correct gasket size for the nominal diameter

and nominal pressure of the flange

• ensure that the sealing surfaces are clean, dry and free

of grease GORE® Universal Pipe Gasket (Style 800)

• position the gasket so that it is exactly at the center of

the flange (use the position of the bolts to help you)

• lubricate the bolts, nuts and washers well

• first tighten the nuts so that they are finger-tight, then apply

the torque in a star pattern sequence by means of three

incremental adjustments:

1st adjustment: 30 %

2nd adjustment: 60 %

3rd adjustment: 100 %

4th adjustment: check all bolts in a circular sequence,

retorquing where necessary.

GORE® GR Sheet Gasketing

Please consult the latest FSA/ESA* guidelines for more details

on installation. These are available on request.

* FSA, Fluid Sealing Association/ESA, European Sealing Association e.V.

GORE Sealant Technologies

®

torquing recommendations

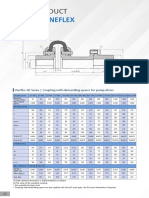

GORE® Universal Pipe Gasket (Style 800)

GORE® GR Sheet Gasketing EN

Bolt Torque

PN6 PN10 PN16 PN25 PN40

DN Nm ft-lbs Nm ft-lbs Nm ft-lbs Nm ft-lbs Nm ft-lbs

10 20 10 35 30 35 30 35 30 35 30

15 20 10 35 30 35 30 35 30 35 30

20 20 10 35 30 35 30 35 30 35 30

Steel flanges

25 20 10 35 30 35 30 35 30 35 30

32 40 30 90 70 90 70 90 70 90 70

40 45 30 90 70 90 70 90 70 90 70

50 45 30 90 70 90 70 90 70 90 70

65 65 50 90 70 90 70 90 70 90 70

80 130 100 90 70 90 70 90 70 90 70

100 130 100 90 70 90 70 170 130 170 130

125 90 70 110 80 100 70 300 220 300 220

150 90 70 180 130 170 130 300 220 300 220

200 120 90 190 140 170 130 320 240 430 320

250 120 90 170 130 300 220 440 320 600 440

300 180 130 170 130 300 220 440 320 600 440

Torque values require: Torque Estimation Conditions:

• Use of well lubricated bolts, Grade 5.6 or better • Gasket dimensions per EN1514-1 Form IBC

• Use of any available gasket thickness • Flange dimensions per EN 1092-1 Type 11 Form B

• Installation practices that follow Fluid Sealing Association • For the applicable pressure please perform

(FSA/ESA) guidelines knowledgeable calculation.

• Suggested torque values are based on best practices.

In general, 70% bolt yield is targeted.

• Friction Factor μ = 0.12 (Nut Factor K = 0.15)

• Follows Gore global torque estimation method.

GORE Sealant Technologies

®

torquing recommendations

GORE® Universal Pipe Gasket (Style 800) EN

Bolt Torque

Glass-lined steel flanges

DN bolts Nm ft-lbs

25 4x M12 30 20

32 4 x M16 50 40

40 4 x M16 60 40

50 4 x M16 80 60

65 4 x M16 95 70

80 8 x M16 65 50

100 8 x M16 70 50

125 8 x M16 85 60

150 8 x M20 120 90

200 8 x M20 165 120

250 12 x M20 130 100

300 12 x M20 150 110

Torque Values Require: Torque estimation conditions:

• Use of well lubricated bolts, Grade 5.6 or better • Gasket dimensions per EN1514-1 Form IBC with reduced

inner diameter according to Gore specification.

• Use of any available gasket thickness

(recommended: 6mm (1/4”)) • Flange dimensions per DIN 2873, PN10

• Installation practices that follow Fluid Sealing Association • For the applicable pressure please perform knowledgeable

(FSA/ESA) guidelines calculation.

• Suggested torque values are based on best practices.

In general, 20MPa average gasket stress is targeted.

• Friction Factor μ = 0.12 (Nut Factor K = 0.15)

• Follows Gore global torque estimation method.

GORE Sealant Technologies ®

torquing recommendations

GORE® Universal Pipe Gasket (Style 800) EN

Bolt Torque

DN Nm ft-lbs

25 15 10

32 25 20

Plastic flanges

40 30 20

50 40 30

65 50 40

80 30 20

100 35 25

125 45 30

150 60 40

200 85 60

250 65 50

300 75 60

Torque Values Require: Torque estimation conditions:

• Use of well lubricated bolts, Grade 5.6 or better • Gasket dimensions per EN1514-1 Form IBC

• Use of any available gasket thickness • Flange dimensions per EN 1092-1 Type 11 Form B (sealing

surfaces)

• Installation practices that follow Fluid Sealing Association

(FSA/ESA) guidelines • For the applicable pressure please perform knowledgeable

calculation.

• Suggested torque values are based on best practices.

In general, 10MPa average gasket stress is targeted.

• Friction Factor μ = 0.12 (Nut Factor K = 0.15)

• Follows Gore global torque estimation method.

FOR INDUSTRIAL USE ONLY.

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

For a complete listing of local sales offices please visit gore.co.uk/sealants.

North America / South America Europe / Middle East / Russia / Africa Asia / Australia

W. L. Gore & Associates Inc. (USA) W. L. Gore & Associates GmbH (Germany) W. L. Gore & Associates (China)

Tel.: +1.800.654.4229 Tel.: +49.89.4612.2215 Tel.: +86.21.5172.8299

SEAL-63-TEC-EN-JUN13

Fax: +1.410.506.8585 Fax: +49.89.4612.43780 Fax: +86.21.6247.9199

E-mail: sealants@wlgore.com E-mail: sealants_EU@wlgore.com E-mail: sealants_AP@wlgore.com

All technical information and advice given here is based on our previous experiences and/or test results. We give this information to the best of our knowledge,

but assume no legal responsibility. Customers are asked to check the suitability and usability in the specific application, since the performance of the product

can only be judged when all necessary operating data are available. Specifications are subject to change without notice. Gore’s terms and conditions of sale

apply to the purchase and sale of the product.

GORE and designs are trademarks of W. L. Gore & Associates. © 2011-2013 W. L. Gore & Associates GmbH

You might also like

- Manual Partes Martillo Pb420Document3 pagesManual Partes Martillo Pb420PD Jose JuanNo ratings yet

- An Internship Report OnDocument40 pagesAn Internship Report OnRaunak Thapa100% (6)

- Pluralsight - Introduction To The BABOK Guide and Business Analysis Key TermsDocument8 pagesPluralsight - Introduction To The BABOK Guide and Business Analysis Key TermsYertNo ratings yet

- Torque FlexitallicDocument2 pagesTorque FlexitallicLuis Arturo Ramirez Esteban100% (1)

- Winpack180 FlyerDocument2 pagesWinpack180 FlyerTamil KumarNo ratings yet

- Gre Bolt Length-2000m 2432Document20 pagesGre Bolt Length-2000m 2432ABDUL KADHARNo ratings yet

- Beam Design To BS8110 & Deflection CheckDocument1 pageBeam Design To BS8110 & Deflection CheckSumedha MayadunnaNo ratings yet

- 1000 WOG, Economical Type 2-PC Body, Full Port Thread Ends Ball ValveDocument4 pages1000 WOG, Economical Type 2-PC Body, Full Port Thread Ends Ball ValveabrahamNo ratings yet

- 2009manual ST-2TDocument12 pages2009manual ST-2TJean Michel BattailNo ratings yet

- Folha TecnicaDocument2 pagesFolha TecnicaHugo de LimaNo ratings yet

- Brochure Multi Purpose CylindersDocument10 pagesBrochure Multi Purpose Cylinderscrni rokoNo ratings yet

- Flange Assembly - : Step 1. - Step 2. - Step 3.Document2 pagesFlange Assembly - : Step 1. - Step 2. - Step 3.MouchartStéphanieNo ratings yet

- Boting Procedure Hard Rock MinovaDocument34 pagesBoting Procedure Hard Rock MinovaPradhith KattaNo ratings yet

- Gmv5 - Ducted Hi Esp VRFDocument1 pageGmv5 - Ducted Hi Esp VRFAvk SanjeevanNo ratings yet

- Commodities CatalogueDocument28 pagesCommodities CatalogueCaiqueFrancoNo ratings yet

- Beam Design To BS8110, Deflection Check & Design For TortionDocument2 pagesBeam Design To BS8110, Deflection Check & Design For TortionSumedha MayadunnaNo ratings yet

- Rotating - Iapetus J Tech201010142Document8 pagesRotating - Iapetus J Tech201010142RenardNo ratings yet

- Maximum Bolt Torque For FlangesDocument1 pageMaximum Bolt Torque For FlangesmohdNo ratings yet

- Flanges Connecting Dimension According To DIN EN 1092-1 and DIN 2501-1Document2 pagesFlanges Connecting Dimension According To DIN EN 1092-1 and DIN 2501-1Lasandu WanniarachchiNo ratings yet

- Nation Parts Guide PG 29Document1 pageNation Parts Guide PG 29ramsi17No ratings yet

- Bollard Catalogue PDFDocument16 pagesBollard Catalogue PDFHaris PrasetiyoNo ratings yet

- 3c - BridgeDocument1 page3c - BridgeBambang SasikiranaNo ratings yet

- Lightweight High Strength Corrosion Resistant Economical Easy To Install Long Service LifeDocument2 pagesLightweight High Strength Corrosion Resistant Economical Easy To Install Long Service LifeKY WongNo ratings yet

- Extruder Brochure - Old SeriesDocument4 pagesExtruder Brochure - Old SeriesAmirmasoudNo ratings yet

- Brise de Roche Js 333-A9900-01 SPECIFICATIONDocument1 pageBrise de Roche Js 333-A9900-01 SPECIFICATIONhamzaNo ratings yet

- Profile Cylinder ISO 15552, PRA Series: AventicsDocument7 pagesProfile Cylinder ISO 15552, PRA Series: AventicsMohammed SAKINENo ratings yet

- Putz Manual - Part2Document2 pagesPutz Manual - Part2Vijay BhureNo ratings yet

- Din933 HDG8.8Document1 pageDin933 HDG8.8minhhieu.qcNo ratings yet

- SGL Carbon - Tayson Klett Flange Protection TapeDocument2 pagesSGL Carbon - Tayson Klett Flange Protection Tapenb878hNo ratings yet

- Noreva-CatalogueDocument24 pagesNoreva-CatalogueAntonio CardosoNo ratings yet

- Koolfog Misting DesignDocument4 pagesKoolfog Misting DesignAhmed NabilNo ratings yet

- Folha TecnicaDocument3 pagesFolha TecnicaHugo de LimaNo ratings yet

- Change Torque Chart 11-30-2017Document1 pageChange Torque Chart 11-30-2017Titino AlejandroNo ratings yet

- STUD BOLT LENGTH (HD-HD, HD-BLD, VS-VS, VS-BLD) - 2000M & 2400 R0 - 15 April 13Document38 pagesSTUD BOLT LENGTH (HD-HD, HD-BLD, VS-VS, VS-BLD) - 2000M & 2400 R0 - 15 April 13윤병택No ratings yet

- TR Stud Anchor: Features Material SpecificationsDocument2 pagesTR Stud Anchor: Features Material SpecificationsHauzhiNo ratings yet

- Haitian - Iapetus II - Spec - 20140418Document10 pagesHaitian - Iapetus II - Spec - 20140418Diki DikiNo ratings yet

- PVC UDocument16 pagesPVC UpETARNo ratings yet

- Hunsone CNC Machine CatalogueDocument38 pagesHunsone CNC Machine CatalogueLucy MontfortNo ratings yet

- Housings and Inserts ZEN CatalogueDocument14 pagesHousings and Inserts ZEN CatalogueKoen BidlotNo ratings yet

- Lightweight High Strength Corrosion Resistant Economical Easy To Install Long Service LifeDocument2 pagesLightweight High Strength Corrosion Resistant Economical Easy To Install Long Service LifeNelson P. ColoNo ratings yet

- Built Up Box PlatesDocument16 pagesBuilt Up Box Platesvrajan1988No ratings yet

- For Butterfly Valve Manual Gear Box: (Tecfly and Teclarge) - General Use: Mounts On The Full Range of Butterfly ValveDocument1 pageFor Butterfly Valve Manual Gear Box: (Tecfly and Teclarge) - General Use: Mounts On The Full Range of Butterfly Valvevicenteiii miderNo ratings yet

- Bronze Relief Valve DN10 DN15 DN20Document2 pagesBronze Relief Valve DN10 DN15 DN20billNo ratings yet

- U-Bolt 2Document1 pageU-Bolt 2Nanang RisdiantoNo ratings yet

- Specification: JU18000/13700j JU20000 /15800j JU20000/j JU24000/jDocument1 pageSpecification: JU18000/13700j JU20000 /15800j JU20000/j JU24000/jLuis Gustavo Rodrigues PereiraNo ratings yet

- Torque Table UPG GR ASME Raised Steel Ring Full GasketDocument1 pageTorque Table UPG GR ASME Raised Steel Ring Full GasketgonzalezlopezjNo ratings yet

- Tyre Coupling With Spacer UNEFLEX SD SeriesDocument3 pagesTyre Coupling With Spacer UNEFLEX SD SeriesGabriel MoreiraNo ratings yet

- MTB Sport: Frame Sizes Height To Size ConverterDocument1 pageMTB Sport: Frame Sizes Height To Size ConverterSaint PiscesNo ratings yet

- Application: Atlanta DWV Sanitary Pipe IsDocument2 pagesApplication: Atlanta DWV Sanitary Pipe IsBruce DoyaoenNo ratings yet

- Disc Type Non Slam Check ValveDocument2 pagesDisc Type Non Slam Check ValveDinesh ChouguleNo ratings yet

- Plat Lantai Plat Lantai Kantilever: TumpuanDocument38 pagesPlat Lantai Plat Lantai Kantilever: TumpuanyansorNo ratings yet

- New Atlanta DWV 2021 1Document2 pagesNew Atlanta DWV 2021 1Glenn RamosNo ratings yet

- ROTH en Type A1T Rubber Expansion Joint DatasheetDocument3 pagesROTH en Type A1T Rubber Expansion Joint DatasheetzoupezeenNo ratings yet

- (Eng) DAEMO FULL LINEUP - Catalog - 16p - 140211 (7th)Document16 pages(Eng) DAEMO FULL LINEUP - Catalog - 16p - 140211 (7th)Mahendra Tyre Works RaigarhNo ratings yet

- Hydraulic Shears For Thick and Long Plates: WWW - Adira.ptDocument2 pagesHydraulic Shears For Thick and Long Plates: WWW - Adira.ptJohan SneiderNo ratings yet

- 13 565Document4 pages13 565Nabeel SheikhNo ratings yet

- Database Management Systems: Understanding and Applying Database TechnologyFrom EverandDatabase Management Systems: Understanding and Applying Database TechnologyRating: 4 out of 5 stars4/5 (8)

- Flow Around A Cylinder PDFDocument15 pagesFlow Around A Cylinder PDFSANDOVAL ANDREA VALENTINA NORE�ANo ratings yet

- Slinky GuideDocument24 pagesSlinky GuidepusicantonijeNo ratings yet

- CV - New Format - SabbirDocument3 pagesCV - New Format - SabbirmizanNo ratings yet

- Timeless Sales Strategies: How To Leverage On Powerful Online and Offline Strategies To Boost Your Sales!Document20 pagesTimeless Sales Strategies: How To Leverage On Powerful Online and Offline Strategies To Boost Your Sales!EpiphaneNo ratings yet

- Ground Floor Plan: General NotesDocument1 pageGround Floor Plan: General NotesChaturbhuj Ikat FabricsNo ratings yet

- Parts of A RevolverDocument3 pagesParts of A RevolverDumb CoffeeNo ratings yet

- Aptitude Problems On Trains3 (WWW - Students3k.com)Document6 pagesAptitude Problems On Trains3 (WWW - Students3k.com)Srinivas RaghavanNo ratings yet

- JBL Tune 660NC SpecSheet EnglishDocument2 pagesJBL Tune 660NC SpecSheet EnglishCaroAntifazNo ratings yet

- PCS 7 Water Templates V902 enDocument115 pagesPCS 7 Water Templates V902 enABI RAJESH GANESHA RAJANo ratings yet

- Araling Panlipunan: Quarter 3-Module 5 Dahilan at Epekto NG Ikalawang Yugto NG Kolonyalismo at ImperyalismoDocument19 pagesAraling Panlipunan: Quarter 3-Module 5 Dahilan at Epekto NG Ikalawang Yugto NG Kolonyalismo at ImperyalismohomidiNo ratings yet

- GRADES 1 To 12 Daily Lesson LogDocument10 pagesGRADES 1 To 12 Daily Lesson LogJing ReginaldoNo ratings yet

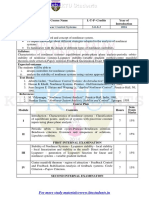

- FE Credit System SyllabusDocument36 pagesFE Credit System SyllabusHarshvardhanUpadhyayNo ratings yet

- CA3046Document6 pagesCA3046erdem10139No ratings yet

- Blind StitchDocument27 pagesBlind StitchSiddharth JhaNo ratings yet

- Newton's Laws of MotionDocument28 pagesNewton's Laws of MotionChi Koy100% (12)

- Upsetting of Bimetallic Components in Closed DieDocument6 pagesUpsetting of Bimetallic Components in Closed DieSatyajeet BeheraNo ratings yet

- Finite Element - Exam PrepDocument5 pagesFinite Element - Exam PrepLil A Nano World schwiftyNo ratings yet

- An Introduction To The Indian Stock MarketDocument7 pagesAn Introduction To The Indian Stock MarketsandystaysNo ratings yet

- EDUC 201 - OBE-Based SyllabusDocument7 pagesEDUC 201 - OBE-Based SyllabusJohn Fredric Vince OrendainNo ratings yet

- PR FormDocument29 pagesPR FormIta NurjanahNo ratings yet

- Ice ScrambbleDocument15 pagesIce ScrambbleJay ArNo ratings yet

- Controlled Documents and Quality Records: - Definitions and Objectives - Documentation Control ProceduresDocument5 pagesControlled Documents and Quality Records: - Definitions and Objectives - Documentation Control ProceduresAmer RahmahNo ratings yet

- BJ SqueezecementingDocument77 pagesBJ SqueezecementingAbdullahAliNo ratings yet

- Spoon Catalog66web 1Document44 pagesSpoon Catalog66web 1Tariq Zuhluf100% (1)

- EE467 Non Linear Control SystemsDocument2 pagesEE467 Non Linear Control SystemsAmal Santhosh PulianmackalNo ratings yet

- Shortest Between Two: Distance LinesDocument14 pagesShortest Between Two: Distance LinesAmit Bikram MishraNo ratings yet

- Corporate Report 2017Document44 pagesCorporate Report 2017LOLA PATRICIA MORALES DE LA CUBANo ratings yet

- Promissory NoteDocument10 pagesPromissory NoteMALKANI DISHA DEEPAKNo ratings yet