Professional Documents

Culture Documents

SGL Carbon - Tayson Klett Flange Protection Tape

SGL Carbon - Tayson Klett Flange Protection Tape

Uploaded by

nb878hOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SGL Carbon - Tayson Klett Flange Protection Tape

SGL Carbon - Tayson Klett Flange Protection Tape

Uploaded by

nb878hCopyright:

Available Formats

POLYFLURON® product range supplements

Highest safety for flange connections with “Tayson KLETT®”

The effective protection for your operation personnel and

your equipment

The applicable directives and guidelines for safety and accident

prevention (i. e. European Pressure Equipment Directive,

national laws for safe operation of plants, BG Chemie M 004,

etc.) demand protection against uncontrolled spray-out of

dangerous media at flanged connections.

In case of a leakage, the safety tape deflects the spray of

media and in doing so reduces the line pressure to atmospheric.

For more than 20 years this safety tape is well established

in the industry. Now its assembly is even easier due to a

hook-and-loop fastener.

Advantages ↑ POLYFLURON product range supplements: safety tape

●● Extremely easy and quick assembly

●● Closure allows repeated opening/closing and re-tightening

●● Ideal for explosion-protected areas (electric screw drivers

not required)

●● Very long lifetime

●● UV and impact resistant – suitable for outdoor installation

How does it work?

In case of pipe flange failure, the safety tape reduces the

pressure of the leaking media and reduces it to atmospheric

pressure. An uncontrolled spray-out of the dangerous media

over a wide area in the plant will be prevented by the safety

tape. The safety tape can be used also for vertical pipe

installations: pins on both sides of the tape provide a good fit

on the flanges.

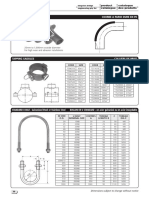

↑ Assembly of the safety tape flange connection

Technical data Assembly

●● Material: Polypropylene, good chemical resistance, Cut required length depending on flange circumference of

UV and impact resistant safety tape “Tayson KLETT” in right width according to the

●● Operation temperatures: table above. The ends should be overlapping with approx.

flange surface temp.: – 40 °C to + 110 °C 40 – 60 mm/1.6 – 2.4 in. Cut a piece of the included hook-and-

●● Rolled tape of 50 m continuous length loop tape, recommended length approx. ¼ of circumference.

The hook-and-loop tape can be fixed already at one end for

better handling. Place the safety tape tightly around the flange

and press the hook-and-loop tape onto the overlapping area.

DIN 2501 PN 10 ANSI B 16.5 150 lb.

DN Units tape length tape width DN Units tape length tape width

fixed/fixed fixed/rotat. 2 rotat. fixed/fixed fixed/rotat. 2 rotat.

25 mm 420 50 50 70 1 in 400 50 50 70

32 mm 500 50 50 70 1¼ in 430 50 50 70

40 mm 530 50 50 70 1½ in 460 50 70 70

50 mm 580 50 70 70 2 in 540 50 70 100

65 mm 640 50 70 70 2½ in 620 50 70 100

80 mm 690 50 70 100 3 in 660 70 70 100

100 mm 750 50 70 100 4 in 780 70 100 100

125 mm 850 70 70 100 5 in 860 70 100 100

150 mm 960 70 70 100 6 in 940 70 100 100

200 mm 1130 70 100 100 8 in 1140 70 100 140

250 mm 1300 70 100 100 10 in 1340 70 100 140

300 mm 1460 70 100 140 12 in 1580 100 100 140

350 mm 1650 70 100 140 14 in 1740 100 140 140

400 mm 1840 100 100 140 16 in 1940 100 140 140

450 mm 1995 100 * * 18 in 2060 100 140 140

500 mm 2170 100 140 140 20 in 2260 100 140 180

600 mm 2510 140 180 180 24 in 2620 140 140 180

* Collars for rotating flanges are not standardized Technical specifications are subject to change without notice

TIS TK.00

03 2019/0.25 E Printed in Germany

®

registered trademarks of SGL Carbon SE

Tayson KLETT® registered trademark of Tayson GmbH

The data contained herein represent the current state of our product knowledge

and are intended to provide general information on our products and their

application spectra. In view of the variety and large number of application

possibilities, these data should be regarded merely as general information that

Graphite Materials & Systems | SGL CARBON GmbH gives no guarantee of any specific properties and/or suitability of those

Sales Europe/Middle East/Africa | pt-europe@sglcarbon.com products for any particular application. Consequently, when ordering a product,

Sales Americas | pt-americas@sglcarbon.com please contact us for specific information on the properties required for the

Sales Asia/Pacific | pt-asia@sglcarbon.com application concerned. On request, our technical service will supply a profile of

www.sglcarbon.com characteristics for your specific application requirements without delay.

You might also like

- 16-400 enDocument145 pages16-400 enluis_erf22No ratings yet

- A Formula For Academic SuccessDocument1 pageA Formula For Academic SuccessAnirban Banerjee100% (1)

- The Big Book Study GuideDocument552 pagesThe Big Book Study GuideJay Smith100% (2)

- Tecumseh EuropaDocument109 pagesTecumseh EuropaArseniyeIII100% (2)

- Torque FlexitallicDocument2 pagesTorque FlexitallicLuis Arturo Ramirez Esteban100% (1)

- HJR 192Document2 pagesHJR 192Sue Rhoades100% (14)

- The Theme of The DoubleDocument3 pagesThe Theme of The DoubleGiada ZanellaNo ratings yet

- Fan SpecificationDocument3 pagesFan SpecificationEmrah MertyürekNo ratings yet

- Innovations Fischer.: Looking For - Look ForDocument14 pagesInnovations Fischer.: Looking For - Look ForChandru MohanNo ratings yet

- Hunsone CNC Machine CatalogueDocument38 pagesHunsone CNC Machine CatalogueLucy MontfortNo ratings yet

- A. K. Steels: Cutting Rate ListDocument2 pagesA. K. Steels: Cutting Rate ListRam PatelNo ratings yet

- Drills 7 TappersDocument10 pagesDrills 7 TappersBe HappyNo ratings yet

- m1tr SS Anchor BoltDocument1 pagem1tr SS Anchor BoltLeo SerasingheNo ratings yet

- ColumnsDocument4 pagesColumnstejassidhpuraNo ratings yet

- Bill Ra07 Aipl 9.5.19Document59 pagesBill Ra07 Aipl 9.5.19Shabab AnwerNo ratings yet

- MONTABERTDocument6 pagesMONTABERTMiguelNo ratings yet

- CABLE TRAY BOQ-20221001 FDocument2 pagesCABLE TRAY BOQ-20221001 FsparkCENo ratings yet

- 5.0 Dredging Pipeline & FloatersDocument9 pages5.0 Dredging Pipeline & Floatersisrat jahan100% (2)

- Round Cutting ListDocument2 pagesRound Cutting ListSachin PatelNo ratings yet

- RZ Neurosurgical Micro InstrumentsDocument11 pagesRZ Neurosurgical Micro InstrumentssigmakarsaNo ratings yet

- Diepa B50 - High Performance Rotation Resistant Steel Wire RopeDocument1 pageDiepa B50 - High Performance Rotation Resistant Steel Wire RopeKonstantinos SynodinosNo ratings yet

- U-Bolt 2Document1 pageU-Bolt 2Nanang RisdiantoNo ratings yet

- Rubber JointsDocument19 pagesRubber Jointsvalentinlupascu33No ratings yet

- MURAFLEX 2020 Low RizeDocument4 pagesMURAFLEX 2020 Low RizeanisyariskiNo ratings yet

- Fittings & Flanges For Pipe Series 2410 and 3410 Using The TaperTaper Adhesive-Bonded Joint FP657-10 0898Document40 pagesFittings & Flanges For Pipe Series 2410 and 3410 Using The TaperTaper Adhesive-Bonded Joint FP657-10 0898nidhinNo ratings yet

- Jayant Test SievesDocument2 pagesJayant Test SievesM PankajNo ratings yet

- 07 Equipment GFDocument34 pages07 Equipment GFimtiyazNo ratings yet

- Ficha Técnica Tornos Convencionales CDS CW - Compressed1 PDFDocument1 pageFicha Técnica Tornos Convencionales CDS CW - Compressed1 PDFedisonNo ratings yet

- RZ BipoSytle II Non-Stick ForcepsDocument5 pagesRZ BipoSytle II Non-Stick ForcepssigmakarsaNo ratings yet

- Yadon YC1Document1 pageYadon YC1Baihaki St100% (1)

- Bolts Torque ChartDocument13 pagesBolts Torque ChartkhaireddinNo ratings yet

- CertikinDocument9 pagesCertikinAshok BhandaryNo ratings yet

- Sanitary - Final KTMDocument108 pagesSanitary - Final KTMKrijan MaliNo ratings yet

- Material Unit. Qty Usman Ent UnitDocument4 pagesMaterial Unit. Qty Usman Ent Unitasad115222No ratings yet

- BR Wipers LD ENDocument7 pagesBR Wipers LD ENab hadi hafizin ab kaharNo ratings yet

- Zhengtan Belting Rubber Conveyor BeltDocument24 pagesZhengtan Belting Rubber Conveyor BeltJohn Renzel Rivera IIINo ratings yet

- Crouse Hinds Liquidtight Conduit Catalog PageDocument1 pageCrouse Hinds Liquidtight Conduit Catalog PageJorge Calcaneo MartinezNo ratings yet

- ChevronDocument4 pagesChevronanon_464848664No ratings yet

- XS User's Guide 20082807Document32 pagesXS User's Guide 20082807Pudji WidodoNo ratings yet

- Fittings & Flanges For Pipe Series 2432 and 3432: Bondstrand Product DataDocument12 pagesFittings & Flanges For Pipe Series 2432 and 3432: Bondstrand Product DataDanilo FornaroNo ratings yet

- Power Press Punching Machine JB23 Series: The Machine of Whole Structure and CharacteristicsDocument2 pagesPower Press Punching Machine JB23 Series: The Machine of Whole Structure and CharacteristicsRadiadores PlanosNo ratings yet

- Beam Design To BS8110, Deflection Check & Design For TortionDocument2 pagesBeam Design To BS8110, Deflection Check & Design For TortionSumedha MayadunnaNo ratings yet

- Beam Design To BS8110 & Deflection CheckDocument1 pageBeam Design To BS8110 & Deflection CheckSumedha MayadunnaNo ratings yet

- Din933 HDG8.8Document1 pageDin933 HDG8.8minhhieu.qcNo ratings yet

- Anugrah Raya: Shear ConnectorDocument6 pagesAnugrah Raya: Shear ConnectordedeNo ratings yet

- Bxa 80090 8CFDocument1 pageBxa 80090 8CFFrancisco NascimentoNo ratings yet

- DADEX Nikasi Price List 05th April 2023Document1 pageDADEX Nikasi Price List 05th April 2023Jugno Shah100% (2)

- CAMF5/55-160-BBCF: Multifunction Tool For Bonded Semiconductor and InsulationDocument2 pagesCAMF5/55-160-BBCF: Multifunction Tool For Bonded Semiconductor and InsulationEslam SadekNo ratings yet

- Wpa-80080-6cfDocument1 pageWpa-80080-6cfshaker76No ratings yet

- Archt 33 AssignmentDocument4 pagesArcht 33 AssignmentKean Matthew SantiagoNo ratings yet

- GRP Pipebend DetailsDocument4 pagesGRP Pipebend DetailsNuraNo ratings yet

- Nikasi Price List 16th Aug 2023Document1 pageNikasi Price List 16th Aug 2023H Hameed100% (1)

- GORE Torque Tables DIN en PDFDocument4 pagesGORE Torque Tables DIN en PDFFernando Bórquez MartínezNo ratings yet

- 13 565Document4 pages13 565Nabeel SheikhNo ratings yet

- 2014 LTA CatalogDocument12 pages2014 LTA Catalogjerimiah_manzonNo ratings yet

- OSBORN Crimped Cup BrushDocument2 pagesOSBORN Crimped Cup BrushThái Mai ĐìnhNo ratings yet

- 4 - HANBELT Conveyor Belt Catalogue RevisadoDocument4 pages4 - HANBELT Conveyor Belt Catalogue RevisadoRafael QueirozNo ratings yet

- Orient-Catalogue For Glass InsulatorsDocument4 pagesOrient-Catalogue For Glass Insulatorspham thangNo ratings yet

- Commodities CatalogueDocument28 pagesCommodities CatalogueCaiqueFrancoNo ratings yet

- Orient-Polymer Long Rod Insulator - Silicone Rubber Composite Type CatalogueDocument5 pagesOrient-Polymer Long Rod Insulator - Silicone Rubber Composite Type CataloguekavithaNo ratings yet

- Type Delta Type Globus: Lined Ball Check ValveDocument2 pagesType Delta Type Globus: Lined Ball Check ValveandrebitaNo ratings yet

- Structures - Suplimentory Data - EnC CheckDocument78 pagesStructures - Suplimentory Data - EnC Checkdinesh kumarNo ratings yet

- Wpa 80063 8CFDocument1 pageWpa 80063 8CFjorgeNo ratings yet

- Hra Panel SpecDocument4 pagesHra Panel SpecMuhammad Arslan Khurshid BhattiNo ratings yet

- PVC-U Ball Valve +GF+ Type 546: Dimensions and Spare Parts ListDocument11 pagesPVC-U Ball Valve +GF+ Type 546: Dimensions and Spare Parts ListpauloNo ratings yet

- APCP 2018 - Second AnnouncementDocument31 pagesAPCP 2018 - Second AnnouncementerliaramithaNo ratings yet

- Pre-K Lesson Plan 3Document3 pagesPre-K Lesson Plan 3api-575652729No ratings yet

- Socialization SyllabusDocument6 pagesSocialization SyllabusIpsha GuhaNo ratings yet

- Oracle Weblogic Content: BasicsDocument3 pagesOracle Weblogic Content: BasicsAjay Kumar MattupalliNo ratings yet

- Set 2 Soal Uji Pengetahuan PPG 2017Document17 pagesSet 2 Soal Uji Pengetahuan PPG 2017heryanto sinagaNo ratings yet

- KITSEN IF Fastform Slab Formworks SolutionDocument15 pagesKITSEN IF Fastform Slab Formworks SolutionLuis Gustavo Rodrigues PereiraNo ratings yet

- Update: City of Watertown Tax Sale Certificate Auction June 21, 2018Document7 pagesUpdate: City of Watertown Tax Sale Certificate Auction June 21, 2018NewzjunkyNo ratings yet

- Log Cabin House UZES 44 44 MM Insulation PLUS BRF 70 m2Document7 pagesLog Cabin House UZES 44 44 MM Insulation PLUS BRF 70 m2Matthew TownsendNo ratings yet

- Af Realty v. DieselmanDocument38 pagesAf Realty v. DieselmanMarianne DomingoNo ratings yet

- Study Material Dialogue Writing 2022 2Document3 pagesStudy Material Dialogue Writing 2022 2ghghghgNo ratings yet

- Sandidates Tournament 2014 PDFDocument237 pagesSandidates Tournament 2014 PDFJose Torres100% (2)

- NP 7410 V1P3Document316 pagesNP 7410 V1P3HenryGalt100% (1)

- 3234 FU Tiller 105 105Document14 pages3234 FU Tiller 105 105saidloubarNo ratings yet

- Ngọc 31201022522 - Nguyễn Phan Bảo: Câu HỏiDocument4 pagesNgọc 31201022522 - Nguyễn Phan Bảo: Câu HỏiNGỌC NGUYỄN PHAN BẢONo ratings yet

- Academic vs. Professional WritingDocument28 pagesAcademic vs. Professional WritingEmelou Lisbo DumasNo ratings yet

- Dear Students, Welcome in The World of Digital CommunicationDocument14 pagesDear Students, Welcome in The World of Digital CommunicationneetaNo ratings yet

- Cost Accounting: Sixteenth Edition, Global EditionDocument32 pagesCost Accounting: Sixteenth Edition, Global EditionAhmed El KhateebNo ratings yet

- DMDocument14 pagesDMPhani KumarNo ratings yet

- BASHFantasyLoSTablet OptimizedDocument190 pagesBASHFantasyLoSTablet OptimizedSharis Luik100% (2)

- Gaurav Sharma: Curriculum VitaeDocument2 pagesGaurav Sharma: Curriculum Vitaejassi7nishadNo ratings yet

- The Peofessionalization of TeachingDocument8 pagesThe Peofessionalization of TeachingJiarah Acay100% (1)

- Activity 1.1 The Twin ParadoxDocument1 pageActivity 1.1 The Twin ParadoxBlessed May PastranaNo ratings yet

- TPA Bullet NotesDocument166 pagesTPA Bullet NotesvarshiniNo ratings yet

- Quest To Learn: Developing The School For Digital KidsDocument165 pagesQuest To Learn: Developing The School For Digital KidsThe MIT Press100% (2)