Professional Documents

Culture Documents

Aisc Edition Member Dimensions and Properties Viewer

Aisc Edition Member Dimensions and Properties Viewer

Uploaded by

Luis Zamora CastilloCopyright:

Available Formats

You might also like

- AISC Properties ViewerDocument81 pagesAISC Properties ViewerHomero Silva100% (22)

- Necchi 524Document55 pagesNecchi 524muh2006No ratings yet

- ME471 Instructor Notes PDFDocument169 pagesME471 Instructor Notes PDFaerogokiNo ratings yet

- Experiment 2 Kinematics of Human MotionDocument8 pagesExperiment 2 Kinematics of Human MotionAldrin Agawin50% (2)

- Textbook ArchiveDocument3 pagesTextbook ArchiveLouie LawNo ratings yet

- BioMEMS Chapter 1Document85 pagesBioMEMS Chapter 1Mohanarajan Mohan KumarNo ratings yet

- AISC Properties ViewerDocument3 pagesAISC Properties Viewerchriscivil12No ratings yet

- Aisc Clean Columns WorksheetDocument5 pagesAisc Clean Columns Worksheetscrbdgharavi100% (1)

- Hollow Section PropertiesDocument6 pagesHollow Section PropertiesAnonymous jLLjBdrNo ratings yet

- 1000x800 Column DesignDocument10 pages1000x800 Column DesigneOzdemir1No ratings yet

- Beam Design With Deflection CheckDocument7 pagesBeam Design With Deflection Checkkiran raghukiranNo ratings yet

- MOMENT CONNECTION-AISC-extended-r5Document24 pagesMOMENT CONNECTION-AISC-extended-r5raghav abudhabi0% (1)

- Building Tech, Utilities, StructuralDocument273 pagesBuilding Tech, Utilities, StructuralEirol GomezNo ratings yet

- Steel Beam Design by KDocument68 pagesSteel Beam Design by KKhandaker Khairul AlamNo ratings yet

- Steel ColumnsDocument40 pagesSteel Columnsagphyo770% (1)

- Type of Soil Support Zone, Z Importance Factor, IDocument7 pagesType of Soil Support Zone, Z Importance Factor, IPrayas SubediNo ratings yet

- Columns DesignDocument60 pagesColumns DesignifsrebraNo ratings yet

- 1.01D21A Post perp-TYPE - II B1 (UC152x152X37) Tob2 (UC203X46)Document49 pages1.01D21A Post perp-TYPE - II B1 (UC152x152X37) Tob2 (UC203X46)balaNo ratings yet

- Base Plate & BoltsDocument3 pagesBase Plate & BoltsarvnndNo ratings yet

- Sizing Steel Sections For BeamsDocument25 pagesSizing Steel Sections For BeamsAnonymous ujfx6mNo ratings yet

- Anchoring Conditions: Non-Cracked Concrete 25 6 900 115 100 10 190 40 31.66667 6.666667 150 Hilti HIT-RE 500-SDDocument11 pagesAnchoring Conditions: Non-Cracked Concrete 25 6 900 115 100 10 190 40 31.66667 6.666667 150 Hilti HIT-RE 500-SDTimothy PinchinNo ratings yet

- Geometry: At-Rest AS5100.3 Cl. 8.3.4Document8 pagesGeometry: At-Rest AS5100.3 Cl. 8.3.4Jem YumenaNo ratings yet

- D12M Off-Spec. Clinker Silo Design CalculationsDocument1 pageD12M Off-Spec. Clinker Silo Design Calculationssami stelNo ratings yet

- DesignDocument13 pagesDesignAnshulGuptaNo ratings yet

- Simplified Torsion Analysis For Steel Beams: Simple Span Beam With Eccentric Concentrated Load Applied at MidspanDocument4 pagesSimplified Torsion Analysis For Steel Beams: Simple Span Beam With Eccentric Concentrated Load Applied at MidspanIhab El AghouryNo ratings yet

- Project Name: Item Description Quantity Unit Rate TotalDocument23 pagesProject Name: Item Description Quantity Unit Rate TotalAlexandruDanielNo ratings yet

- Section Modulus 012004Document2 pagesSection Modulus 012004dakidofdaboomNo ratings yet

- Design of Plate Elements - v1.7Document49 pagesDesign of Plate Elements - v1.7faridullah100% (1)

- Ixx Iyy CalcDocument13 pagesIxx Iyy CalcjurieskNo ratings yet

- Lashing Lug Pedestal Anchor & Concrete DesignDocument23 pagesLashing Lug Pedestal Anchor & Concrete DesignMyunSu GooNo ratings yet

- Steel Beam Design With Gravity Loading Based On AISC Manual 14th Edition (AISC 360-10)Document22 pagesSteel Beam Design With Gravity Loading Based On AISC Manual 14th Edition (AISC 360-10)AlphaNo ratings yet

- Pump Design ComputationDocument41 pagesPump Design ComputationFrank RojasNo ratings yet

- Pile Cap 10 PileDocument3 pagesPile Cap 10 PileShashankSinghNo ratings yet

- Lifting Lug CalculationDocument2 pagesLifting Lug Calculationmih1No ratings yet

- Design of Fixed Base Connection (BP) : Reactions Input Material PropertiesDocument10 pagesDesign of Fixed Base Connection (BP) : Reactions Input Material PropertiesAnand.5No ratings yet

- Spreaer Beam&Lifting Line Beam p5Document2 pagesSpreaer Beam&Lifting Line Beam p5Sabrang LorNo ratings yet

- 498 Plate Girder ShearDocument1 page498 Plate Girder ShearAssem ElhajjNo ratings yet

- Slab S3 PDFDocument1 pageSlab S3 PDFMark Christian EsguerraNo ratings yet

- Analysis STeel Railing PDFDocument1 pageAnalysis STeel Railing PDFJahanzeb KhanNo ratings yet

- Excel Password RemoverDocument6 pagesExcel Password RemoverAxelrose04No ratings yet

- A. Structure Material: 2G1 Concrete Beam Analysis Project: Building: DateDocument7 pagesA. Structure Material: 2G1 Concrete Beam Analysis Project: Building: DatehendyNo ratings yet

- CraneBeam v1 1Document39 pagesCraneBeam v1 1satya_jayantiNo ratings yet

- The Girder Design Is Adequate.: F E JC E Ysh X L R R E JC SH F FDocument22 pagesThe Girder Design Is Adequate.: F E JC E Ysh X L R R E JC SH F FBang OchimNo ratings yet

- Structural SectionsDocument47 pagesStructural Sectionssenthilcivil0% (1)

- Corner Bracing Connection Capacity Based On AISC 360-10/16: Tube A R T B HDocument2 pagesCorner Bracing Connection Capacity Based On AISC 360-10/16: Tube A R T B HKaren Esther Acuña VelasquezNo ratings yet

- Fs Cantilever DesignDocument242 pagesFs Cantilever DesignRaju ShresthaNo ratings yet

- AISC 13th Slip Critical Bolt Capacity ASDDocument1 pageAISC 13th Slip Critical Bolt Capacity ASDdantevariasNo ratings yet

- LRFD Steel BeamDocument30 pagesLRFD Steel Beam정영철100% (1)

- Weight Chart For Hex Head Bolts & Eye BoltsDocument1 pageWeight Chart For Hex Head Bolts & Eye BoltsTuff qualityNo ratings yet

- Moment Baseplate Design Rev. 0Document3 pagesMoment Baseplate Design Rev. 0Bok MortegaNo ratings yet

- Enhanced Steel BeamDocument4 pagesEnhanced Steel BeamBang SutresNo ratings yet

- CalDocument43 pagesCalPrasaad SlvNo ratings yet

- Anchor Steel Supports-LoadsDocument3 pagesAnchor Steel Supports-LoadsНемања КараклајићNo ratings yet

- 21.65 Kips/bolt Shear Strength Controls: Section at ADocument3 pages21.65 Kips/bolt Shear Strength Controls: Section at ASuneesh PNo ratings yet

- Steel Beam Flexural CapacityDocument6 pagesSteel Beam Flexural CapacitykstayroskNo ratings yet

- Design Paramters: With Sagrod at MidspanDocument1 pageDesign Paramters: With Sagrod at MidspanLawrence SaligbonNo ratings yet

- Bearing CheckDocument6 pagesBearing CheckdhanushkaNo ratings yet

- AISC 14 1 Properties ViewerDocument2 pagesAISC 14 1 Properties ViewerTASNIA SIRAJ OISHBYNo ratings yet

- AISC 14 1 Properties ViewerDocument2 pagesAISC 14 1 Properties ViewerTASNIA SIRAJ OISHBYNo ratings yet

- Programas-mas-base-de-Datos ColonosDocument135 pagesProgramas-mas-base-de-Datos ColonosJesus SolorzanoNo ratings yet

- Aisc Tablas de Dimensiones Y Propiedades de Secciones de AcerosDocument3 pagesAisc Tablas de Dimensiones Y Propiedades de Secciones de AcerosJharri E HuertoNo ratings yet

- Aisc Edition Member Dimensions and Properties ViewerDocument4 pagesAisc Edition Member Dimensions and Properties Viewerjuan carlos tinta mamaniNo ratings yet

- Programas Mas Base de DatosDocument100 pagesProgramas Mas Base de DatosJesus SolorzanoNo ratings yet

- Diseño de Elementos en Tracción - LRFDDocument263 pagesDiseño de Elementos en Tracción - LRFDAlejandro CardenasNo ratings yet

- AISC Properties ViewerDocument6 pagesAISC Properties Viewermiguel soto100% (1)

- Welding Drawings 1Document18 pagesWelding Drawings 1muh2006No ratings yet

- Tacoma: Customer Experience Center 1-800-331-4331Document22 pagesTacoma: Customer Experience Center 1-800-331-4331muh2006No ratings yet

- Torsion Spring Instruction ManualDocument4 pagesTorsion Spring Instruction Manualmuh2006No ratings yet

- Mooncalendar Worksheet-2021Document6 pagesMooncalendar Worksheet-2021muh2006100% (1)

- Lateral Force Resisting System: Shear Walls 1Document42 pagesLateral Force Resisting System: Shear Walls 1muh2006No ratings yet

- FEMA P-2139-1 Commonalities 508Document154 pagesFEMA P-2139-1 Commonalities 508muh2006No ratings yet

- FEMA P-2139-4 Steel 508Document208 pagesFEMA P-2139-4 Steel 508muh2006No ratings yet

- FEMA P-2139-2 Wood 508Document366 pagesFEMA P-2139-2 Wood 508muh2006No ratings yet

- Wind Loads On Non Standard Building Configurations: Presented By: Donald R. Scott, S.EDocument32 pagesWind Loads On Non Standard Building Configurations: Presented By: Donald R. Scott, S.Emuh2006No ratings yet

- Welding Symbols 3Document8 pagesWelding Symbols 3muh2006No ratings yet

- Iraqi Seismic Code 1997-Arabic-EnglishDocument102 pagesIraqi Seismic Code 1997-Arabic-Englishmuh2006100% (1)

- Dictionary of Islamic Terms PDFDocument68 pagesDictionary of Islamic Terms PDFmuh2006No ratings yet

- Bracing Example - Manual CalculationDocument51 pagesBracing Example - Manual Calculationmuh2006100% (1)

- ATTAR Phased Array Visualisation ToolDocument3 pagesATTAR Phased Array Visualisation ToolGOUTHAM RATHINAMNo ratings yet

- Material Balance Applied To Oil ReservoirsDocument25 pagesMaterial Balance Applied To Oil ReservoirsHamaamNo ratings yet

- Outgassing 101 1 EpoxyTechDocument10 pagesOutgassing 101 1 EpoxyTechLarry Wayne Sumpter, JrNo ratings yet

- MSC Nastran - Basic AnalysisDocument51 pagesMSC Nastran - Basic AnalysisroylmechNo ratings yet

- Stiffness: Stiffness Is The Extent To Which It (AnDocument18 pagesStiffness: Stiffness Is The Extent To Which It (AnDuke StonerNo ratings yet

- Two Phase FlowDocument3 pagesTwo Phase FlowNITESH SAHNo ratings yet

- Nb2O5 - Modificação de Superfície de T-Nb2O 5 Com NB de Baixa Cristalinidade2ó5para Aumentar A Degradação Fotocatalítica Da Rodamina BDocument6 pagesNb2O5 - Modificação de Superfície de T-Nb2O 5 Com NB de Baixa Cristalinidade2ó5para Aumentar A Degradação Fotocatalítica Da Rodamina Bhenrique cechinelNo ratings yet

- EEET2334 35 Tutorial 4Document4 pagesEEET2334 35 Tutorial 4Kenny MakNo ratings yet

- PUC II Phy Imp Fix Questions Also Previous Year QuestionsDocument30 pagesPUC II Phy Imp Fix Questions Also Previous Year Questionsrathnavathirathna178No ratings yet

- TPC Fze - Process PackagesDocument8 pagesTPC Fze - Process PackagesanilNo ratings yet

- Palawan State University: Puerto Princesa CityDocument3 pagesPalawan State University: Puerto Princesa CityKent Aldwin MangalinoNo ratings yet

- Boiler Installation and SetupDocument30 pagesBoiler Installation and Setupcakhokhe100% (1)

- Final Report Mini ProjectDocument26 pagesFinal Report Mini ProjectAmirul HasanNo ratings yet

- 38lha 40lha h15 1pd Rev2Document28 pages38lha 40lha h15 1pd Rev2nhatNo ratings yet

- Neutron Activation AnalysisDocument20 pagesNeutron Activation AnalysisDesinta Puspitasari100% (1)

- 23-2 Design of Floor Diaphragms MoroderDocument9 pages23-2 Design of Floor Diaphragms Morodersbarwal9No ratings yet

- Experimental Monitoring of The Humber Bridge UsingDocument7 pagesExperimental Monitoring of The Humber Bridge Using정주호No ratings yet

- Physics 240 Chapter 21 NotesDocument2 pagesPhysics 240 Chapter 21 NotesJohn DunnuckNo ratings yet

- Subject Code Theory of Metal CuttingDocument2 pagesSubject Code Theory of Metal CuttingShimada TadaNo ratings yet

- Schaeffer Vibration White Paper PDFDocument17 pagesSchaeffer Vibration White Paper PDFnaufal labibNo ratings yet

- Design of Radial GatesDocument23 pagesDesign of Radial GatesWilliam MataNo ratings yet

- ALUMINIUMTECHNOLOGIES Week3Document84 pagesALUMINIUMTECHNOLOGIES Week3HaiLuuNo ratings yet

- Plasma Arc Machining: BY Rajnish Bhusal Department of Mechanical Engineering, RitmDocument20 pagesPlasma Arc Machining: BY Rajnish Bhusal Department of Mechanical Engineering, RitmSudeep Kumar SinghNo ratings yet

- Resistance Temperature DetectorsDocument1 pageResistance Temperature DetectorsBramJanssen76No ratings yet

- A Hot-Cracking Mitigation Technique For Welding High-Strength Aluminum AlloyDocument9 pagesA Hot-Cracking Mitigation Technique For Welding High-Strength Aluminum Alloydavid perezNo ratings yet

- Part 13-Level 2Document8 pagesPart 13-Level 2ammarmpNo ratings yet

Aisc Edition Member Dimensions and Properties Viewer

Aisc Edition Member Dimensions and Properties Viewer

Uploaded by

Luis Zamora CastilloOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aisc Edition Member Dimensions and Properties Viewer

Aisc Edition Member Dimensions and Properties Viewer

Uploaded by

Luis Zamora CastilloCopyright:

Available Formats

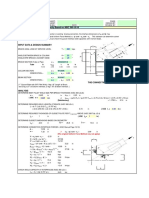

"AISC 14.1 Properties Viewer.

xls" Program

Version 1.0

AISC 14th EDITION MEMBER DIMENSIONS AND PROPERTIES VIEWER

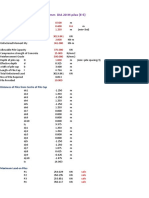

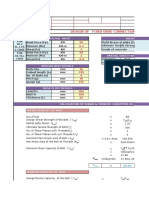

W, S, M, HP Shapes C, MC Shapes WT, ST, MT Shapes Single Angles Double Angles Rectangular HSS

Y Y Y Y Y Y

k1=0.6875

k tf=0.51 tf=0.436 b=3.5 t(des)=0.349

bf=6.52 t=0.375

y(bar)=1.27 x(bar)=1.56

x(bar)=0.634 tf=0.44 d=6 t=0.75 X

d=10.5 T X d=10 X X d=3.5 h=5 X

d=6.17 X y(bar)=2.55

tw=0.3 tw=0.24 tw=0.26 b=8 y(bar)=1

(0, 3/8, or 3/4

bf=5.81 bf=2.6 gap) b=5

W10X30 C10X15.3 WT6X15 L8X6X3/4 2L3-1/2X3-1/2X3/8 HSS5X5X3/8

A= 8.84 in.^2 A= 4.48 in.^2 A= 4.4 in.^2 A= 9.99 in.^2 A= 5 in.^2 A= 6.18 in.^2

d= 10.5 in. d= 10 in. d= 6.17 in. d= 6 in. d= 3.5 in. h= 5 in.

tw = 0.3 in. tw = 0.24 in. tw = 0.26 in. b= 8 in. b= 3.5 in. b= 5 in.

bf = 5.81 in. bf = 2.6 in. bf = 6.52 in. t= 0.75 in. t= 0.375 in. t(des) = 0.349 in.

tf = 0.51 in. tf = 0.436 in. tf = 0.44 in. k(des) = 1.25 in. wt./ft. = 17 plf. wt./ft. = 22.37 plf.

k(des) = 0.81 in. k(des) = 1 in. k(des) = 0.74 in. k(det) = 1.25 in. Ix = 5.72 in.^4 Ix = 21.7 in.^4

k(det) = 1.125 in. k(det) = 1 in. k(det) = 1.125 in. wt./ft. = 33.8 plf. Sx = 2.3 in.^3 Sx = 8.68 in.^3

k1 = 0.6875 in. T= 8 in. gage = 3.5 in. Ix = 63.5 in.^4 rx = 1.07 in. rx = 1.87 in.

T= 8.25 in. gage = 1.5 in. wt./ft. 15 plf. Sx = 11.7 in.^3 y(bar) = 1 in. Zx = 10.6 in.^3

gage = 2.75 in. rts = 0.868 in. bf/(2*tf) 7.41 rx = 2.52 in. Zx = 4.12 in.^3 Iy = 21.7 in.^4

wt./ft. = 30 plf. ho = 9.56 in. d/tw 23.7 y(bar) = 2.55 in. yp = 0.357 in. Sy = 8.68 in.^3

bf/(2*tf) 5.7 wt./ft. = 15.3 plf. Ix = 13.5 in.^4 Zx = 21.1 in.^3 Iy = 10.8 in. ry = 1.87 in.

h/tw = 29.5 eo = 0.796 in. Sx = 2.75 in.^3 yp = 1.34 in. Sy = 3.09 in. Zy = 10.6 in.^3

Ix = 170 in.^4 Ix = 67.3 in.^4 rx = 1.75 in. Iy = 30.8 in.^4 ry = 1.47 in. h(flat) = 3.3125 in.

Sx = 32.4 in.^3 Sx = 13.5 in.^3 y(bar) = 1.27 in. Sy = 6.92 in.^3 Zy = 5 b(flat) = 3.3125 in.

rx = 4.38 in. rx = 3.88 in. Zx = 4.83 in.^3 ry = 1.75 in. ro(bar) = 1.99 J= 36.1 in.^4

Zx = 36.6 in.^3 Zx = 15.9 in.^3 yp = 0.337 in. x(bar) = 1.56 in. H= 0.832 C= 14.9 in.^3

Iy = 16.7 in.^4 Iy = 2.27 in.^4 Iy = 10.2 in.^4 Zy = 12.5 in.^3 Qs = 1 A(surf) = 1.57 ft^2/ft

Sy = 5.75 in.^3 Sy = 1.15 in.^3 Sy = 3.12 in.^3 xp = 0.624 in.

ry = 1.37 in. ry = 0.711 in. ry = 1.52 in. Iz = 16.6 in.^4 Round HSS & Pipes

Zy = 8.84 in.^3 x(bar) = 0.634 in. Zy = 4.78 in.^3 Sz = 5.82 in.^3 Y

rts = 1.6 in. Zy = 2.34 in.^3 Qs = 0.707 rz = 1.29 in. t(nom)=0.28

ho = 9.99 in. xp = 0.224 in. J= 0.228 in.^4 TAN(a) = 0.55

J= 0.622 in.^4 J= 0.209 in.^4 Cw = 0.267 in.^6 Qs = 1

Cw = 414 in.^6 Cw = 45.5 in.^6 a= 1.74 in. J= 1.9 in.^4 Plates O.D.=6 X

a= 41.51 in. a= 23.74 in. ro(bar) = 2.54 in. Cw = 7.28 in.^6 Y

Wno = 14.5 in.^2 ro(bar) = 4.19 in. H= 0.83 a= 3.15 in. t=0.3125 I.D.=5.48

Sw = 10.7 in.^4 H= 0.884 ro(bar) = 3.95 in. X

Qf = 7.02 in.^3 H= – b=4 HSS6X0.280

Qw = 18.2 in.^3 A= 4.69 in.^2

t= 0.3125 in. O.D. = 6 in.

b= 4 in. I.D. = 5.48 in.

wt./ft. = 4.25 plf. t(nom) = 0.28 in.

A= 1.25 in.^2 t(des) = 0.26 in.

Reference: Ix = 0.010 in.^4 wt./ft. = 17.12 plf.

The shapes contained in this database are taken from the "AISC Shapes Database" Sx = 0.065 in.^3 Ix = Iy = 19.3 in.^4

Version 14.1 (Oct. 2013) from the www.AISC.org website as well as those listed in rx = 0.090 in. Sx = Sy = 6.45 in.^3

the AISC 14th Edition Manual of Steel Construction (2011).

Iy = 1.67 in.^4 rx = ry = 2.03 in.

Sy = 0.83 in.^3 Zx = Z y = 8.57 in.^3

ry = 1.15 in. J= 38.7 in.^4

J= 1.68 in.^4 C= 12.9 in.^3

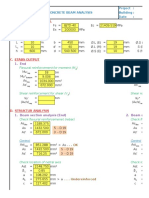

"AISC 14.1 Properties Viewer.xls" Program

Version 1.0

NOMENCLATURE FOR AISC VERSION 14.1 MEMBER PROPERTIES AND DIMENSIONS:

A= Cross-sectional area of member (in.^2)

d= Depth of member, parallel to Y-axis (in.)

h= Depth of member, parallel to Y-axis (in.)

tw = Thickness of web of member (in.)

bf = Width of flange of member, parallel to X-axis (in.)

b= Width of member, parallel to X-axis (in.)

tf = Thickness of flange of member (in.)

k= Distance from outer face of flange to web toe of fillet (in.)

k1 = Distance from web centerline to flange toe of fillet (in.)

T= Distance between fillets for wide-flange or channel shape = d(nom)-2*k(det) (in.)

gage = Standard gage (bolt spacing) for member (in.) (Note: gages for angles are available by viewing comment box at cell K18.)

Ix = Moment of inertia of member taken about X-axis (in.^4)

Sx = Elastic section modulus of member taken about X-axis (in.^3)

rx = Radius of gyration of member taken about X-axis (in.) = SQRT(I x/A)

Iy = Moment of inertia of member taken about Y-axis (in.^4)

Sy = Elastic section modulus of member taken about Y-axis (in.^3)

ry = Radius of gyration of member taken about Y-axis (in.) = SQRT(I y/A)

Zx = Plastic section modulus of member taken about X-axis (in.^3)

Zy = Plastic section modulus of member taken about Y-axis (in.^3)

rts = SQRT(SQRT(Iy*Cw)/Sx) (in.)

xp = horizontal distance from designated member edge to plastic neutral axis (in.)

yp = vertical distance from designated member edge to plastic neutral axis (in.)

ho = Distance between centroid of flanges, d-tf (in.)

J= Torsional moment of inertia of member (in.^4)

Cw = Warping constant (in.^6)

C= Torsional constant for HSS shapes (in.^3)

a= Torsional property, a = SQRT(E*Cw/G*J) (in.)

E= Modulus of elasticity of steel = 29,000 ksi

G= Shear modulus of elasticity of steel = 11,200 ksi

Wno = Normalized warping function at a point at the flange edge (in.^2)

Sw = Warping statical moment at a point on the cross section (in.^4)

Qf = Statical moment for a point in the flange directly above the vertical edge of the web (in.^3)

Qw = Statical moment at the mid-depth of the section (in.^3)

x(bar) = Distance from outside face of web of channel shape or outside face of angle leg to Y-axis (in.)

y(bar) = Distance from outside face of outside face of flange of WT or angle leg to Y-axis (in.)

eo = Horizontal distance from the outer edge of a channel web to its shear center (in.) = (approx.) t f*(d-tf)^2*(bf-tw/2)^2/(4*Ix)-tw/2

xo = x-coordinate of shear center with respect to the centroid of the section (in.)

yo = y-coordinate of shear center with respect to the centroid of the section (in.)

ro(bar) = Polar radius of gyration about the shear center = SQRT(xo^2+yo^2+(Ix+Iy)/A) (in.)

H= Flexural constant, H = 1-(xo^2+yo^2)/ro(bar)^2)

LLBB = Long legs back-to-back for double angles

SLBB = Short legs back-to-back for double angles

h(flat) = The workable flat (straight) dimension along the height, h (in.)

b(flat) = The workable flat (straight) dimension along the width, b (in.)

A(surf) = The total surface area of a rectangular or square HSS section (ft.^2/ft.)

STD = Standard weight (Schedule 40) pipe section

XS = Extra strong (Schedule 80) pipe section

XXS = Double-extra strong pipe section

You might also like

- AISC Properties ViewerDocument81 pagesAISC Properties ViewerHomero Silva100% (22)

- Necchi 524Document55 pagesNecchi 524muh2006No ratings yet

- ME471 Instructor Notes PDFDocument169 pagesME471 Instructor Notes PDFaerogokiNo ratings yet

- Experiment 2 Kinematics of Human MotionDocument8 pagesExperiment 2 Kinematics of Human MotionAldrin Agawin50% (2)

- Textbook ArchiveDocument3 pagesTextbook ArchiveLouie LawNo ratings yet

- BioMEMS Chapter 1Document85 pagesBioMEMS Chapter 1Mohanarajan Mohan KumarNo ratings yet

- AISC Properties ViewerDocument3 pagesAISC Properties Viewerchriscivil12No ratings yet

- Aisc Clean Columns WorksheetDocument5 pagesAisc Clean Columns Worksheetscrbdgharavi100% (1)

- Hollow Section PropertiesDocument6 pagesHollow Section PropertiesAnonymous jLLjBdrNo ratings yet

- 1000x800 Column DesignDocument10 pages1000x800 Column DesigneOzdemir1No ratings yet

- Beam Design With Deflection CheckDocument7 pagesBeam Design With Deflection Checkkiran raghukiranNo ratings yet

- MOMENT CONNECTION-AISC-extended-r5Document24 pagesMOMENT CONNECTION-AISC-extended-r5raghav abudhabi0% (1)

- Building Tech, Utilities, StructuralDocument273 pagesBuilding Tech, Utilities, StructuralEirol GomezNo ratings yet

- Steel Beam Design by KDocument68 pagesSteel Beam Design by KKhandaker Khairul AlamNo ratings yet

- Steel ColumnsDocument40 pagesSteel Columnsagphyo770% (1)

- Type of Soil Support Zone, Z Importance Factor, IDocument7 pagesType of Soil Support Zone, Z Importance Factor, IPrayas SubediNo ratings yet

- Columns DesignDocument60 pagesColumns DesignifsrebraNo ratings yet

- 1.01D21A Post perp-TYPE - II B1 (UC152x152X37) Tob2 (UC203X46)Document49 pages1.01D21A Post perp-TYPE - II B1 (UC152x152X37) Tob2 (UC203X46)balaNo ratings yet

- Base Plate & BoltsDocument3 pagesBase Plate & BoltsarvnndNo ratings yet

- Sizing Steel Sections For BeamsDocument25 pagesSizing Steel Sections For BeamsAnonymous ujfx6mNo ratings yet

- Anchoring Conditions: Non-Cracked Concrete 25 6 900 115 100 10 190 40 31.66667 6.666667 150 Hilti HIT-RE 500-SDDocument11 pagesAnchoring Conditions: Non-Cracked Concrete 25 6 900 115 100 10 190 40 31.66667 6.666667 150 Hilti HIT-RE 500-SDTimothy PinchinNo ratings yet

- Geometry: At-Rest AS5100.3 Cl. 8.3.4Document8 pagesGeometry: At-Rest AS5100.3 Cl. 8.3.4Jem YumenaNo ratings yet

- D12M Off-Spec. Clinker Silo Design CalculationsDocument1 pageD12M Off-Spec. Clinker Silo Design Calculationssami stelNo ratings yet

- DesignDocument13 pagesDesignAnshulGuptaNo ratings yet

- Simplified Torsion Analysis For Steel Beams: Simple Span Beam With Eccentric Concentrated Load Applied at MidspanDocument4 pagesSimplified Torsion Analysis For Steel Beams: Simple Span Beam With Eccentric Concentrated Load Applied at MidspanIhab El AghouryNo ratings yet

- Project Name: Item Description Quantity Unit Rate TotalDocument23 pagesProject Name: Item Description Quantity Unit Rate TotalAlexandruDanielNo ratings yet

- Section Modulus 012004Document2 pagesSection Modulus 012004dakidofdaboomNo ratings yet

- Design of Plate Elements - v1.7Document49 pagesDesign of Plate Elements - v1.7faridullah100% (1)

- Ixx Iyy CalcDocument13 pagesIxx Iyy CalcjurieskNo ratings yet

- Lashing Lug Pedestal Anchor & Concrete DesignDocument23 pagesLashing Lug Pedestal Anchor & Concrete DesignMyunSu GooNo ratings yet

- Steel Beam Design With Gravity Loading Based On AISC Manual 14th Edition (AISC 360-10)Document22 pagesSteel Beam Design With Gravity Loading Based On AISC Manual 14th Edition (AISC 360-10)AlphaNo ratings yet

- Pump Design ComputationDocument41 pagesPump Design ComputationFrank RojasNo ratings yet

- Pile Cap 10 PileDocument3 pagesPile Cap 10 PileShashankSinghNo ratings yet

- Lifting Lug CalculationDocument2 pagesLifting Lug Calculationmih1No ratings yet

- Design of Fixed Base Connection (BP) : Reactions Input Material PropertiesDocument10 pagesDesign of Fixed Base Connection (BP) : Reactions Input Material PropertiesAnand.5No ratings yet

- Spreaer Beam&Lifting Line Beam p5Document2 pagesSpreaer Beam&Lifting Line Beam p5Sabrang LorNo ratings yet

- 498 Plate Girder ShearDocument1 page498 Plate Girder ShearAssem ElhajjNo ratings yet

- Slab S3 PDFDocument1 pageSlab S3 PDFMark Christian EsguerraNo ratings yet

- Analysis STeel Railing PDFDocument1 pageAnalysis STeel Railing PDFJahanzeb KhanNo ratings yet

- Excel Password RemoverDocument6 pagesExcel Password RemoverAxelrose04No ratings yet

- A. Structure Material: 2G1 Concrete Beam Analysis Project: Building: DateDocument7 pagesA. Structure Material: 2G1 Concrete Beam Analysis Project: Building: DatehendyNo ratings yet

- CraneBeam v1 1Document39 pagesCraneBeam v1 1satya_jayantiNo ratings yet

- The Girder Design Is Adequate.: F E JC E Ysh X L R R E JC SH F FDocument22 pagesThe Girder Design Is Adequate.: F E JC E Ysh X L R R E JC SH F FBang OchimNo ratings yet

- Structural SectionsDocument47 pagesStructural Sectionssenthilcivil0% (1)

- Corner Bracing Connection Capacity Based On AISC 360-10/16: Tube A R T B HDocument2 pagesCorner Bracing Connection Capacity Based On AISC 360-10/16: Tube A R T B HKaren Esther Acuña VelasquezNo ratings yet

- Fs Cantilever DesignDocument242 pagesFs Cantilever DesignRaju ShresthaNo ratings yet

- AISC 13th Slip Critical Bolt Capacity ASDDocument1 pageAISC 13th Slip Critical Bolt Capacity ASDdantevariasNo ratings yet

- LRFD Steel BeamDocument30 pagesLRFD Steel Beam정영철100% (1)

- Weight Chart For Hex Head Bolts & Eye BoltsDocument1 pageWeight Chart For Hex Head Bolts & Eye BoltsTuff qualityNo ratings yet

- Moment Baseplate Design Rev. 0Document3 pagesMoment Baseplate Design Rev. 0Bok MortegaNo ratings yet

- Enhanced Steel BeamDocument4 pagesEnhanced Steel BeamBang SutresNo ratings yet

- CalDocument43 pagesCalPrasaad SlvNo ratings yet

- Anchor Steel Supports-LoadsDocument3 pagesAnchor Steel Supports-LoadsНемања КараклајићNo ratings yet

- 21.65 Kips/bolt Shear Strength Controls: Section at ADocument3 pages21.65 Kips/bolt Shear Strength Controls: Section at ASuneesh PNo ratings yet

- Steel Beam Flexural CapacityDocument6 pagesSteel Beam Flexural CapacitykstayroskNo ratings yet

- Design Paramters: With Sagrod at MidspanDocument1 pageDesign Paramters: With Sagrod at MidspanLawrence SaligbonNo ratings yet

- Bearing CheckDocument6 pagesBearing CheckdhanushkaNo ratings yet

- AISC 14 1 Properties ViewerDocument2 pagesAISC 14 1 Properties ViewerTASNIA SIRAJ OISHBYNo ratings yet

- AISC 14 1 Properties ViewerDocument2 pagesAISC 14 1 Properties ViewerTASNIA SIRAJ OISHBYNo ratings yet

- Programas-mas-base-de-Datos ColonosDocument135 pagesProgramas-mas-base-de-Datos ColonosJesus SolorzanoNo ratings yet

- Aisc Tablas de Dimensiones Y Propiedades de Secciones de AcerosDocument3 pagesAisc Tablas de Dimensiones Y Propiedades de Secciones de AcerosJharri E HuertoNo ratings yet

- Aisc Edition Member Dimensions and Properties ViewerDocument4 pagesAisc Edition Member Dimensions and Properties Viewerjuan carlos tinta mamaniNo ratings yet

- Programas Mas Base de DatosDocument100 pagesProgramas Mas Base de DatosJesus SolorzanoNo ratings yet

- Diseño de Elementos en Tracción - LRFDDocument263 pagesDiseño de Elementos en Tracción - LRFDAlejandro CardenasNo ratings yet

- AISC Properties ViewerDocument6 pagesAISC Properties Viewermiguel soto100% (1)

- Welding Drawings 1Document18 pagesWelding Drawings 1muh2006No ratings yet

- Tacoma: Customer Experience Center 1-800-331-4331Document22 pagesTacoma: Customer Experience Center 1-800-331-4331muh2006No ratings yet

- Torsion Spring Instruction ManualDocument4 pagesTorsion Spring Instruction Manualmuh2006No ratings yet

- Mooncalendar Worksheet-2021Document6 pagesMooncalendar Worksheet-2021muh2006100% (1)

- Lateral Force Resisting System: Shear Walls 1Document42 pagesLateral Force Resisting System: Shear Walls 1muh2006No ratings yet

- FEMA P-2139-1 Commonalities 508Document154 pagesFEMA P-2139-1 Commonalities 508muh2006No ratings yet

- FEMA P-2139-4 Steel 508Document208 pagesFEMA P-2139-4 Steel 508muh2006No ratings yet

- FEMA P-2139-2 Wood 508Document366 pagesFEMA P-2139-2 Wood 508muh2006No ratings yet

- Wind Loads On Non Standard Building Configurations: Presented By: Donald R. Scott, S.EDocument32 pagesWind Loads On Non Standard Building Configurations: Presented By: Donald R. Scott, S.Emuh2006No ratings yet

- Welding Symbols 3Document8 pagesWelding Symbols 3muh2006No ratings yet

- Iraqi Seismic Code 1997-Arabic-EnglishDocument102 pagesIraqi Seismic Code 1997-Arabic-Englishmuh2006100% (1)

- Dictionary of Islamic Terms PDFDocument68 pagesDictionary of Islamic Terms PDFmuh2006No ratings yet

- Bracing Example - Manual CalculationDocument51 pagesBracing Example - Manual Calculationmuh2006100% (1)

- ATTAR Phased Array Visualisation ToolDocument3 pagesATTAR Phased Array Visualisation ToolGOUTHAM RATHINAMNo ratings yet

- Material Balance Applied To Oil ReservoirsDocument25 pagesMaterial Balance Applied To Oil ReservoirsHamaamNo ratings yet

- Outgassing 101 1 EpoxyTechDocument10 pagesOutgassing 101 1 EpoxyTechLarry Wayne Sumpter, JrNo ratings yet

- MSC Nastran - Basic AnalysisDocument51 pagesMSC Nastran - Basic AnalysisroylmechNo ratings yet

- Stiffness: Stiffness Is The Extent To Which It (AnDocument18 pagesStiffness: Stiffness Is The Extent To Which It (AnDuke StonerNo ratings yet

- Two Phase FlowDocument3 pagesTwo Phase FlowNITESH SAHNo ratings yet

- Nb2O5 - Modificação de Superfície de T-Nb2O 5 Com NB de Baixa Cristalinidade2ó5para Aumentar A Degradação Fotocatalítica Da Rodamina BDocument6 pagesNb2O5 - Modificação de Superfície de T-Nb2O 5 Com NB de Baixa Cristalinidade2ó5para Aumentar A Degradação Fotocatalítica Da Rodamina Bhenrique cechinelNo ratings yet

- EEET2334 35 Tutorial 4Document4 pagesEEET2334 35 Tutorial 4Kenny MakNo ratings yet

- PUC II Phy Imp Fix Questions Also Previous Year QuestionsDocument30 pagesPUC II Phy Imp Fix Questions Also Previous Year Questionsrathnavathirathna178No ratings yet

- TPC Fze - Process PackagesDocument8 pagesTPC Fze - Process PackagesanilNo ratings yet

- Palawan State University: Puerto Princesa CityDocument3 pagesPalawan State University: Puerto Princesa CityKent Aldwin MangalinoNo ratings yet

- Boiler Installation and SetupDocument30 pagesBoiler Installation and Setupcakhokhe100% (1)

- Final Report Mini ProjectDocument26 pagesFinal Report Mini ProjectAmirul HasanNo ratings yet

- 38lha 40lha h15 1pd Rev2Document28 pages38lha 40lha h15 1pd Rev2nhatNo ratings yet

- Neutron Activation AnalysisDocument20 pagesNeutron Activation AnalysisDesinta Puspitasari100% (1)

- 23-2 Design of Floor Diaphragms MoroderDocument9 pages23-2 Design of Floor Diaphragms Morodersbarwal9No ratings yet

- Experimental Monitoring of The Humber Bridge UsingDocument7 pagesExperimental Monitoring of The Humber Bridge Using정주호No ratings yet

- Physics 240 Chapter 21 NotesDocument2 pagesPhysics 240 Chapter 21 NotesJohn DunnuckNo ratings yet

- Subject Code Theory of Metal CuttingDocument2 pagesSubject Code Theory of Metal CuttingShimada TadaNo ratings yet

- Schaeffer Vibration White Paper PDFDocument17 pagesSchaeffer Vibration White Paper PDFnaufal labibNo ratings yet

- Design of Radial GatesDocument23 pagesDesign of Radial GatesWilliam MataNo ratings yet

- ALUMINIUMTECHNOLOGIES Week3Document84 pagesALUMINIUMTECHNOLOGIES Week3HaiLuuNo ratings yet

- Plasma Arc Machining: BY Rajnish Bhusal Department of Mechanical Engineering, RitmDocument20 pagesPlasma Arc Machining: BY Rajnish Bhusal Department of Mechanical Engineering, RitmSudeep Kumar SinghNo ratings yet

- Resistance Temperature DetectorsDocument1 pageResistance Temperature DetectorsBramJanssen76No ratings yet

- A Hot-Cracking Mitigation Technique For Welding High-Strength Aluminum AlloyDocument9 pagesA Hot-Cracking Mitigation Technique For Welding High-Strength Aluminum Alloydavid perezNo ratings yet

- Part 13-Level 2Document8 pagesPart 13-Level 2ammarmpNo ratings yet