Professional Documents

Culture Documents

Research Paper Maintenance Strategy and Decision Making - Ahp Method

Uploaded by

prasad kOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Research Paper Maintenance Strategy and Decision Making - Ahp Method

Uploaded by

prasad kCopyright:

Available Formats

Chandrahas, et al.

, International Journal of Advanced Engineering Research and Studies E-ISSN2249–8974

Proceedings of BITCON-2015 Innovations For National Development

National Conference on : Innovations In Mechanical Engineering For Sustainable Development

Research Paper

MAINTENANCE STRATEGY AND DECISION MAKING –

AHP METHOD

Chandrahas1, Santosh Kumar Mishra2 and Deepak Mahapatra2

Address for Correspondence

1

Student, 2 Faculty at Bhilai Institute of Technology, Durg (CG) India

ABSTRACT:

Maintenance strategy plays a very important role in all kind of manufacturing industries. Each maintenance strategy has their

characteristics, importance and drawbacks. Performance of a machine depends on the type of maintenance strategies

employed on it. Machines used in industries need proper maintenance because failure of machine may cause the production

loss. Maintenance strategy may vary from one machine to another machine because of the various conflicting factors like

safety, cost, customer satisfaction etc. Factors affecting machines performance need to identify and control. Use of

inappropriate maintenance strategy may increase the maintenance cost. Increase in maintenance cost will increase the

production cost. Selection of a maintenance strategy to a particular machine or group of machines is a problem of decision

making and it is always a challenging task for maintenance Manager/Engineer. By using the decision making tools like

AHP, this problem can be solved. Use of AHP method also facilitates to calculate the weight of factors through which

decision maker can analyze the difference between actual condition and required condition. Present research work shows

that the problem of selecting an optimum maintenance strategy to a machine can be overcome by using decision making tool

(AHP).

KEYWORDS: Analytical Hierarchy Process, Decision Making, Maintenance Strategy.

1. INTRODUCTION: structure and evaluated using only a series of pair

According to Jureen Thor et al. (2013), Maintenance wise judgments. Massinio Bertolin et al. (2005)

has emerged since the construction of physical presents a Lexicographic goal programming (LGP)

structures such as ships and machines. In general, approach to define the best strategies for the

maintenance is defined as the combination of all maintenance of critical centrifugal pumps in an oil

technical and administrative actions, including refinery for each pump failure mode , the model

supervision and action indented to retain the machine allows to take into account the maintenance policy

or restore it to a state in which it can perform a Borden in terms of inspection or repair and in terms

required function. Effective maintenance ultimately of the manpower involved , linking them to

aims to determine suitable action’s that can keep efficiency risk as peats quantified as in FMECA

machine performance at acceptable level and extend methodology through the use of the classic parameter

the life cycle of the machine. Different types of occurrence , severity and detestability , evaluated

maintenance alternatives have been proposed to through an adequate application of AHP technique.

achieve the ultimate goal. However, a maintenance Ling Wang et al. (2007) analyzed deal with the

policy implemented in a similar machine but in uncertain judgment of decision makers, a fuzzy

different manufacturing environments may not modification of the AHP method is applied as an

produce similar results because of various operating evaluation tool where uncertain and imprecise

factors such as humidity, temperature and work load. judgments of decision makers are translated into

In addition, decision making in maintenance fuzzy numbers. In order to avoid fuzzy priority

selection is often accompanied by diverse constraints calculation and fuzzy ranking procedures in the

and economic perspectives. Examples of these traditional fuzzy AHP methods, a new fuzzy

constraints include operator safety issues, prioritization method is proposed. This fuzzy

government regulation, resource limitation and prioritization method can derive crisp priorities from

budget, consequently the selection of a suitable a consistent or inconsistent fuzzy judgment matrix by

maintenance policy becomes a crucial decision solving an optimization problem with non linear

making process to obtain high levels of success for constraints. Maria Scocorro et al. (2008) proposes

the firm beneficiaries in manufacturing industry. the use of a multi- criteria technique, namely the

2. REVIEW OF RESEARCH WORKS ON analysis hierarchy process, as a potential decision

MAINTENANCE STRATEGY SELECTION - making method for use in management maintenance

In last few decades there were lots of research work processes. In this case the problem corneous the

had been done all over the world on maintenance selection of a parts clearing system for diesel engine

strategy selections. Few of them are introduced in maintenance. A hierarchical structure is built for the

this research work. M. Bevilacqua et al. (March prequalification of the criteria and the alternatives

2000), the research work is all about the selection of within the system. By applying the analytical

maintenance strategy in a plant which is still in hierarchy process, the criteria can be prioritized and

construction phase. Possible alternatives are the alternatives can be organized in descending order

considered preventive, condition based, corrective so that the best parts clearing system may be selected.

and opportunistic maintenance. There are Ming- feng yang et al. 2008. In this paper an AHP

approximate 200 facilities for which best approach is used evaluating food quality management

maintenance policy have to select. The machines are of Bakery Sector. In this approach triangular numbers

clustered in three homogeneous groups after a were introduced into the conventional AHP in order

criticality analysis based on internal procedures of to improve the degree of judgments of decision

the oil refinery. With AHP technique, several aspects, maker(s). Using of AHP approach to evaluating food

which characterize each of the above mentioned quality Management of Bakery sector alternative

maintenance strategies, are arranged in hierarchic results in the following two major advantages

Int. J. Adv. Engg. Res. Studies/IV/II/Jan.-March,2015/256-258

Chandrahas, et al., International Journal of Advanced Engineering Research and Studies E-ISSN2249–8974

(i)Numbers are preferable to extend the range of crisp of consistency problem structure, concept, core

comparison matrix of the conversion matrix of the process and accuracy of final results.

convection AHP method. (ii)Adoption of numbers 3. FIELD OF MCDM (AHP) METHOD:

can allow decision makers to have freedom of In our day to day life from morning market to

estimation regarding the food quality management of business market we need to make decisions with

Bakery sector selection. Mansoore Momani et al. some genuine logics and sense. The purpose is to get

(2011) studied the selection of maintenance strategies better outputs and results. Now a day’s decision

in Electro Fan Company. It is studied that the making tools are getting rapidly popular in various

evaluation of maintenance strategies for each piece of fields like Maintenance strategy selection, Supply

equipment is a multiple criteria decision making chain management, Agriculture, Medical Science,

(MCDM) problem. To deal with the uncertain Food industry, Education, Automobile industry,

judgment of decision makers are translated into fuzzy Project selection etc.

numbers. A specific example of selection of 4. COMPARATIVE STUDY OF

maintenance strategies in this company with the MAINTENANCE STRATEGIES:

application of proposed fuzzy TOPSIS method is When there is need to identify the various

given, showing that the preventive maintenance alternatives to take in consideration for the selection

strategy is the most suitable for equipment. Jureen of best maintenance strategy, it is always helpful to

Thor et al. July 2013 reviewed and compared compare the alternatives by important factors like

analytic hierarchy process, elimination and compared philosophy, reliability level, percentage in use,

analytic reality, simple additive weighting and advantages, disadvantages etc. It simplifies the

technique for order preference by similarity to ideal understanding between various points and conditions.

solution. The comparisons were based on the aspects

Table no.1 Comparative study of maintenance strategies

S.N. Factors Corrective Maintenance Preventive Maintenance Condition Based Maintenance

1. Nature Run-to-failure Time based maintenance Predictive maintenance,

monitor as per assets condition

2. Basic Allow machinery to run to Schedule maintenance Schedule maintenance activities

Philosophy failure activities at pre-determined when mechanical or operational

Repair or replace damaged time intervals. conditions warrant.

equipment when obvious Repair or replace damaged Repair or replace damaged

problem occur. equipment before obvious equipment before obvious

problem occur. problem occur.

3. On the basis of Small parts and Equipment subjected to wear. Equipment with random failure

Reliability equipment. Consumer-able equipment patterns.

Non-critical equipment Equipment with known Critical equipment

Equipment unlikely to fail. failure pattern. Equipment not subjected to

Redundant systems Manufacturer wear.

recommendations System which failure may be

induced by incorrect preventive

maintenance.

4. Advantages Low cost Cost effective in many Increased component

Less staff capital intensive processes. operational life/availability.

Flexibility allows for the Decrease in equipment or

adjustment of maintenance process downtime.

periodically. Decrease in costs for parts and

Increased component life labors.

cycle. Better product quality

Energy savings Improved worker and

Reduced equipment or environmental safety.

process failure. Energy savings.

Estimated 12-18% cost Improved worker morale.

savings over CM. Estimated 8-12% cost savings

over PM.

5. Disadvantages Increased cost due to Catastrophic failure still Increased investment in

unplanned downtime of likely to occur. diagnostic equipment.

equipment. Labor intensive Increased investment in staff

Increased labor cost, Includes performance of training.

especially if overtime unneeded maintenance. Savings potential not readily

needed. Potential for incidental seen by management.

Cost involved with repair damage to components in

or replacement of conducting unneeded

equipment. maintenance.

Possible secondary or

process damage from

equipment failure.

6. Maintenance 55% Reactive 31% preventive maintenance 12% predictive maintenance

Strategy used maintenance used in used in industry. used in industry.

in industry. industry.

7. Equation Breakdown cost = labor + Preventive Maintenance cost Condition Based Maintenance

downtime = labor + downtime due to Cost = labor + downtime due to

(PM) cost planned shutdown (CBM) cost planned shutdown

8. Example Lubricate motors when Lubricate pumps every 2000 Conduct scans on pumps and

they become noisy or in hours. panels to determine if and when

vibrations occur. work is required.

Int. J. Adv. Engg. Res. Studies/IV/II/Jan.-March,2015/256-258

Chandrahas, et al., International Journal of Advanced Engineering Research and Studies E-ISSN2249–8974

5. SELECTION OF CRITERIA AND SUB- Criteria Decision Making tools facilitate to rank these

CRITERIA criteria’s with respect to the others. Most general

Selection of criteria is also a very important factor in criteria and sub criteria for manufacturing industries.

the process of selecting the best maintenance According to Ling Wang (2007), the important

strategy. Criteria’s which highly influence the criteria’s and sub-criteria’s are classified in table

performance of machine or to achieve the goal of form.

company, need to be analyzed very carefully. Multi-

Table no.2 Classifying Criteria and Sub-Criteria

Criteria Sub- Criteria

Cost of poor maintenance practices (A1)

Cost (A) Cost of using spare parts (A2)

Staff training cost (A3)

Environmental effects (B1)

Safety (B) Personnel safety (B2)

Role of professional specialist (C1)

Value –Added(C) Spare parts quality and availability (C2)

Customer satisfaction (C3)

Equipment and Technology(D) Fault Identification (D1)

Feasibility (D2)

Table no.3 Comparisons between Criteria’s

Factor Factor Weight

More important than Equal Less important than Factor

Cost 9 7 5 3 1 3 5 7 9 Safety

Cost 9 7 5 3 1 3 5 7 9 Add- Value

Cost 9 7 5 3 1 3 5 7 9 Equipment and Technology

Safety 9 7 5 3 1 3 5 7 9 Add-value

Safety 9 7 5 3 1 3 5 7 9 Equipment and Technology

Add- 9 7 5 3 1 3 5 7 9 Equipment and Technology

Value

6. STRATEGY OF DATA COLLECTION REFERENCES:

Data collection is a very important task in the 1. Al-Najjar, B. and I. Alsyouf, 2003, selecting the most

efficient maintenance approach using fuzzy multiple

selection of maintenance strategy by using the

criteria decision making. International J. Production

MCDM Methods. Appropriate well planned data Economics, pp: 84.

sheet must take all the required information from the 2. Alsyouf Imad 2009, Maintenance practices in Swedish

expert when ask for any decision. Inappropriate way Industries: survey results, department of mechanical

engineering , school of technology and design, Vaxjo

of data collection may lead to fail the purpose of

University, SE-35195, vaxjo Sweden.

analysis. When a question is asked to an expert there 3. Artiba, Abdhakim; riane, dr. Fauad(2005), Maintenance

must be no any confusion related to understanding strategy and reliability optimization Bradford, GBR;

meaning of question. Logic must be arises in the Emerald Group publication ltd, 2005,p6

4. Asma M. A. Bahurmoz (2006) The Analytic Hierarchy

mind of the decision maker at the time of answering.

Process: A Methodology for Win- Win Management

A sample paper of questionnaire is added in this JKAU: Econ. & Adm., Vol. 20 No. 1, pp: 3-16 (2006

research paper (table no. 3). Data collected from A.D./1427 A.H.)

sample questionnaire are required to put in matrix 5. Jurrenthor, siewhong ding, shahrulkamarddin (2013),

comparison of multi-criteria decision making methods

form and then after it can be calculated by AHP

from the maintenance alternative selection perspective ,

process. Tools like MATLAB etc can be used for International journal of Engineering and Science,

matrix calculation for large size of data calculation. ISSN(e)-2319-1813, ISSN(p)-2319- 1805

7. CONCLUSIONS: 6. Mansour Momeni, Mohammad Reza Fathi, Mohammad

Karimi Zarchi and Sirous Azzizollahi (2011), A Fuzzy

This research paper aims to show how a typical

TOPSIS-Based Approach to Maintenance Strategy

problem of maintenance strategy selection can be Selection: A Case Study, Middle-East Journal of

simplified by using a decision making tools. Using Scientific Research 8(3):699-706, 2011

the advantages and facilities of MCDM methods 7. Mark Velasquez1 and Patrick T. Hester2(2013) An

Analysis of Multi-Criteria Decision Making Methods,

helps to control the factor which influences to

International Journal of Operations Research Vol. 10,

achieve the goal of company. In this paper review of No. 2, 56066 (2013)

various researches suggest that large scope of 8. Massimo Bertolini, Maurizio Bevilacqua(2005), A

applicability of MCDM methods. Comparative study combined goal programming – AHP approach to

maintenance selection problem, Reliability Engineering

of alternatives can help to understand the condition of

and System Safety 91 (2005) 839-848

problem and also at the time of decision making i.e. 9. M. Bevilacqua, M. Braglia(2000), The analytic

to fulfill questionnaire part for data collection. hierarchy process applied to maintenance strategy

Selection of any criteria is also a challenging task but selection, Reliability Engineering and System Safety 70

(2000) 71–83

it can be well estimated by review of various research

10. Ling Wang, Jian Chu, Jun Wu, 2007, Selection of

studies at different conditions in different companies. optimum maintenance strategies based on a fuzzy

It can be concluded at the end of this research paper analytic hierarchy process, Int. j. Production

that for the general problem of maintenance strategy Economics 107(2007) 151-163-50

selection above steps can be taken in the account and Note: This Paper/Article is scrutinised and reviewed by

Scientific Committee, BITCON-2015, BIT, Durg, CG, India

along with this sensitivity analysis can also be

implemented so that influence in output can be

measured by changing the criteria weight.

Int. J. Adv. Engg. Res. Studies/IV/II/Jan.-March,2015/256-258

You might also like

- Maintenance Strategy Selection A Case Study PDFDocument22 pagesMaintenance Strategy Selection A Case Study PDForlandoduran50% (2)

- Selection of Optimum Maintenance Strategies Based JOURNAL ELSEVIER PDFDocument13 pagesSelection of Optimum Maintenance Strategies Based JOURNAL ELSEVIER PDFMary Jane DuranNo ratings yet

- Decision Making With Analytical Hierarchy Process For Selection of Furnace For Foundry IndustryDocument8 pagesDecision Making With Analytical Hierarchy Process For Selection of Furnace For Foundry IndustryTJPRC PublicationsNo ratings yet

- Borjalilu Ghambari 2018 Optimal Maintenance Strategy Selection Based On A Fuzzy Analytical Network Process A Case StudyDocument10 pagesBorjalilu Ghambari 2018 Optimal Maintenance Strategy Selection Based On A Fuzzy Analytical Network Process A Case StudyteddiyfentawNo ratings yet

- How To Choose Between Maintenance Policies 6Document14 pagesHow To Choose Between Maintenance Policies 6orlandoduran100% (1)

- A Comparison of Multi-Criteria Decision Making Approaches For Maintenance Strategy Selection (A Case Study) 1 PDFDocument19 pagesA Comparison of Multi-Criteria Decision Making Approaches For Maintenance Strategy Selection (A Case Study) 1 PDFanandagholapNo ratings yet

- 2 1 1 JiomDocument8 pages2 1 1 Jiomjerome okoyeNo ratings yet

- SSRN-id1914158 2Document10 pagesSSRN-id1914158 2Abdelghani BouchaalaNo ratings yet

- Application of Topsis in Selection of Maintenance Model For Gas A Processing PlantDocument6 pagesApplication of Topsis in Selection of Maintenance Model For Gas A Processing PlantInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- SSRN Id1914158Document9 pagesSSRN Id1914158Abdelghani BouchaalaNo ratings yet

- Maintenance Strategy SelectionDocument5 pagesMaintenance Strategy SelectionChris HeydenrychNo ratings yet

- Development of A Maintenance Performance Measurement Framework Using The Analytic Network Process Anp For Maintenance Performance in PDFDocument14 pagesDevelopment of A Maintenance Performance Measurement Framework Using The Analytic Network Process Anp For Maintenance Performance in PDFAlejandro100% (1)

- Machine Selection by AHP and TOPSIS Methods: KeywordsDocument7 pagesMachine Selection by AHP and TOPSIS Methods: KeywordsMilan KolarevicNo ratings yet

- Publicacion de MttoDocument6 pagesPublicacion de MttoRaul CastroNo ratings yet

- IJETR031106Document5 pagesIJETR031106erpublicationNo ratings yet

- A Fuzzy TOPSIS-Based Approach To Maintenance Strategy Selection: A Case StudyDocument8 pagesA Fuzzy TOPSIS-Based Approach To Maintenance Strategy Selection: A Case StudyteddiyfentawNo ratings yet

- Maintenance Strategies To Reduce Downtime Due To Machine Positional ErrorsDocument8 pagesMaintenance Strategies To Reduce Downtime Due To Machine Positional ErrorsHugoCabanillasNo ratings yet

- Machine Selection by AHP and TOPSIS MethodsDocument8 pagesMachine Selection by AHP and TOPSIS MethodsHarshitMittalNo ratings yet

- 1 s2.0 S1877042812036774 MainDocument6 pages1 s2.0 S1877042812036774 MainFranco Diaz RiffoNo ratings yet

- Literature Review (Charles Dissertation)Document7 pagesLiterature Review (Charles Dissertation)Jeff EmiNo ratings yet

- Maintenance Policy Selection Model - A Case Study in The Palm Oil IndustryDocument21 pagesMaintenance Policy Selection Model - A Case Study in The Palm Oil IndustryCamilo Andrés VargasNo ratings yet

- Maintenance Performance Metrics For ManuDocument7 pagesMaintenance Performance Metrics For ManuMesay BarekewNo ratings yet

- Maintenance Strategies and Innovative Approaches in The Pharmaceutical Industry: An Integrated Management System (IMS)Document9 pagesMaintenance Strategies and Innovative Approaches in The Pharmaceutical Industry: An Integrated Management System (IMS)Fawaz Nasser AL-HeibshyNo ratings yet

- Research Proposal (M04EKM) - Syed Shah Areeb Hussain - 0541198Document14 pagesResearch Proposal (M04EKM) - Syed Shah Areeb Hussain - 0541198areeb_hussain0% (1)

- PART B - Polar Cush VCDocument14 pagesPART B - Polar Cush VCdennisNo ratings yet

- A Combined Goal Programming AHP ApproachDocument10 pagesA Combined Goal Programming AHP Approachtarkan varmaNo ratings yet

- Part BDocument15 pagesPart BdennisNo ratings yet

- Articulo 3 EaDocument16 pagesArticulo 3 EadanielNo ratings yet

- Implementation of Total Productive MaintenanceDocument17 pagesImplementation of Total Productive MaintenanceChinmay DalviNo ratings yet

- ID 13MPMM2014Shaglufetal 2Document9 pagesID 13MPMM2014Shaglufetal 2SalmaanCadeXaajiNo ratings yet

- Quantifying The Effects of Production Maintenance Decisions Using Discrete Event SimulationDocument9 pagesQuantifying The Effects of Production Maintenance Decisions Using Discrete Event SimulationDavid NyanguNo ratings yet

- 2020 ZeinalnezhadDocument14 pages2020 ZeinalnezhadDaniel Huachani CoripunaNo ratings yet

- An Evaluation System of The Setting Up of Predictive Maintenance ProgrammesDocument19 pagesAn Evaluation System of The Setting Up of Predictive Maintenance Programmesfaz143No ratings yet

- Maintenance Performance MetricsDocument32 pagesMaintenance Performance MetricsMiguel OrtizNo ratings yet

- Maintenance Management of Tractors and Agricultural Machinery PDFDocument13 pagesMaintenance Management of Tractors and Agricultural Machinery PDFIg0r91100% (1)

- Ranking of Equipments On The Basis of Criticality: A Case StudyDocument5 pagesRanking of Equipments On The Basis of Criticality: A Case Studyਸੁਖਜੀਤ ਸਿੰਘNo ratings yet

- Chor Fi 2015Document6 pagesChor Fi 2015farihoumaima07No ratings yet

- QRCMDocument7 pagesQRCMAiyappa DevrajNo ratings yet

- Avcn Nshkhiem345Document2 pagesAvcn Nshkhiem345Khiem NguyenNo ratings yet

- A Review of Supplier Selection Methods in Manufact PDFDocument9 pagesA Review of Supplier Selection Methods in Manufact PDFyskdonNo ratings yet

- An Integer Linear ProgrammingDocument26 pagesAn Integer Linear ProgrammingFilipe CarneiroNo ratings yet

- 03 AbstractDocument18 pages03 Abstractarif ayazNo ratings yet

- Analyzing The Productivity of Maintenance Systems Using SystemDocument11 pagesAnalyzing The Productivity of Maintenance Systems Using Systemtomo tomoNo ratings yet

- A Delay Time Degradation Model For Optimal Preventive Maintenance Schedule Fora Gas Processing PlantDocument11 pagesA Delay Time Degradation Model For Optimal Preventive Maintenance Schedule Fora Gas Processing PlantInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Using Fuzzy Delphi Method in Maintenance PDFDocument10 pagesUsing Fuzzy Delphi Method in Maintenance PDFMarco Antônio SabaráNo ratings yet

- Ahpmaintenance3 ADocument12 pagesAhpmaintenance3 AJ.ReyesNo ratings yet

- A Revised FMEA Application To The Quality Control ManagementDocument23 pagesA Revised FMEA Application To The Quality Control ManagementchrysobergiNo ratings yet

- Gestión de MttoDocument23 pagesGestión de MttoDaniel VilcapomaNo ratings yet

- Advances in Engineering Software: Orlando DuránDocument9 pagesAdvances in Engineering Software: Orlando DuránorlandoduranNo ratings yet

- Kumar 2017Document42 pagesKumar 2017mellouli mohjaNo ratings yet

- Paper Berikut Adalah Contoh Publikasi Dalam Jurnal Internasional, Yaitu Business Process Management Journal, Vol.14 No. 2, ISSN: 1463-7154, 2008Document15 pagesPaper Berikut Adalah Contoh Publikasi Dalam Jurnal Internasional, Yaitu Business Process Management Journal, Vol.14 No. 2, ISSN: 1463-7154, 2008sita deliyana FirmialyNo ratings yet

- Carpitella2021Document14 pagesCarpitella2021Betinho ArtilheiroNo ratings yet

- Benifits and CostDocument19 pagesBenifits and CostKamel MahmoudNo ratings yet

- A LiteratureDocument22 pagesA LiteratureFeung Rabil. SatyasaiNo ratings yet

- Maintenance PerformanceDocument16 pagesMaintenance PerformanceThiago Luiz De SouzaNo ratings yet

- Selection of Diagnostic Techniques and Instrumentation in A Predictive Maintenance Program. A Case StudyDocument17 pagesSelection of Diagnostic Techniques and Instrumentation in A Predictive Maintenance Program. A Case StudyDayan AGUILAR RINCONNo ratings yet

- An Objective-Oriented and Product-Line-Based Manufacturing Performance MeasurementDocument11 pagesAn Objective-Oriented and Product-Line-Based Manufacturing Performance MeasurementGalih PermadiNo ratings yet

- A Time-Based Quantitative Approach For Selecting Lean Strategies For Manufacturing OrganisationsDocument23 pagesA Time-Based Quantitative Approach For Selecting Lean Strategies For Manufacturing OrganisationsIlse Guadalupe EncinasNo ratings yet

- 1 s2.0 S0098135423000467 MainDocument19 pages1 s2.0 S0098135423000467 MainFrank Joel Herrera ApaesteguiNo ratings yet

- K.I.T'S College of Engineering Department of Mechanical Engineering Subject: Mechanical System DesignDocument1 pageK.I.T'S College of Engineering Department of Mechanical Engineering Subject: Mechanical System Designprasad kNo ratings yet

- Project Guide: Prof. A.T.PatilDocument11 pagesProject Guide: Prof. A.T.Patilprasad kNo ratings yet

- CrankshaftDocument1 pageCrankshaftmahendraNo ratings yet

- 1Document1 page1prasad kNo ratings yet

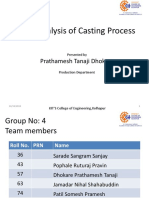

- Title: Analysis of Casting Process: Prathamesh Tanaji DhokareDocument7 pagesTitle: Analysis of Casting Process: Prathamesh Tanaji Dhokareprasad kNo ratings yet

- Honda Motor Europe LogisticsDocument28 pagesHonda Motor Europe Logisticsprasad kNo ratings yet

- Proposed Project Title:: Implementation of Value Stream Maping, 7quality Control Tools, and 5S SponsoredDocument10 pagesProposed Project Title:: Implementation of Value Stream Maping, 7quality Control Tools, and 5S Sponsoredprasad kNo ratings yet

- Maintenance Management Practices: A Retrospective and Literature ReviewDocument18 pagesMaintenance Management Practices: A Retrospective and Literature Reviewprasad kNo ratings yet

- How To StudyDocument56 pagesHow To StudySteve NtepNo ratings yet

- Masho ZinabuDocument93 pagesMasho ZinabuNejash Abdo Issa100% (1)

- The Assessment of Mindfulness With Self-Report MeasuresDocument30 pagesThe Assessment of Mindfulness With Self-Report MeasureskarmajigaNo ratings yet

- Discourse Analysis Interview PDFDocument15 pagesDiscourse Analysis Interview PDFNiwre Evo OmotsosircNo ratings yet

- Business ResearchDocument34 pagesBusiness ResearchFil Grace Bayta AycoNo ratings yet

- A Compilation of Reaction Papers: in Partial Fulfillment of The Requirements in B.PRAC 100 (Business Practicum)Document29 pagesA Compilation of Reaction Papers: in Partial Fulfillment of The Requirements in B.PRAC 100 (Business Practicum)COLDF1R3No ratings yet

- From Mafia To Organised Crime A Comparative Analysis of Policing ModelsDocument321 pagesFrom Mafia To Organised Crime A Comparative Analysis of Policing ModelsLaura Panait100% (1)

- Example of An Introductory Paragraph With A Thesis StatementDocument7 pagesExample of An Introductory Paragraph With A Thesis Statementwfwpbjvff100% (1)

- Adama Science and Technology University (Astu) School of Electrical Engineering and Computing (Soeec) MSC in Computer Science and EngineeringDocument21 pagesAdama Science and Technology University (Astu) School of Electrical Engineering and Computing (Soeec) MSC in Computer Science and EngineeringhghgNo ratings yet

- MELCDocument42 pagesMELCMark Marasigan100% (2)

- Accredited by NAAC A++ Greenfields, Vaddeswaram-522502, Guntur District, Andrapradesh, INDIADocument4 pagesAccredited by NAAC A++ Greenfields, Vaddeswaram-522502, Guntur District, Andrapradesh, INDIAGopinath GangadhariNo ratings yet

- Running Head: Starbucks Marketing Research and Environmental Paper 1Document16 pagesRunning Head: Starbucks Marketing Research and Environmental Paper 1reetayanNo ratings yet

- Orphan Children Architecture SynopsisDocument9 pagesOrphan Children Architecture SynopsisSubramanian Radhakkrishnan67% (3)

- Sample Academic Work - Diligent Problem SolverDocument4 pagesSample Academic Work - Diligent Problem Solverapi-461213065No ratings yet

- Allama Iqbal Open University, Islamabad (Department of English Language and Applied Linguistics) WarningDocument3 pagesAllama Iqbal Open University, Islamabad (Department of English Language and Applied Linguistics) Warningiqra hamidNo ratings yet

- Technology For Learning and TeachingDocument7 pagesTechnology For Learning and TeachingRiza BeltranNo ratings yet

- Axtelle 1950 Science EducationDocument3 pagesAxtelle 1950 Science EducationAnis NadhifahNo ratings yet

- RUBRIC - Replicate An Experiment - SF MilestoneDocument1 pageRUBRIC - Replicate An Experiment - SF Milestone[AP-STUDENT] Realiza Joy PabloNo ratings yet

- Research Project Report: Artificial Intelligence (AI) Applications in Online Shopping in IndiaDocument25 pagesResearch Project Report: Artificial Intelligence (AI) Applications in Online Shopping in IndiaRitika MishraNo ratings yet

- Java Thesis IdeasDocument7 pagesJava Thesis Ideasafjrtdoda100% (1)

- G5 Fraklin Capstone Chap 1 5 Final PaperDocument37 pagesG5 Fraklin Capstone Chap 1 5 Final PaperCyrelleNo ratings yet

- Subject: Topic: Date: Module No.: Essential ReadingsDocument6 pagesSubject: Topic: Date: Module No.: Essential ReadingsJudea SantiagoNo ratings yet

- NRes1 Course Unit 4Document5 pagesNRes1 Course Unit 4Giselle EstoquiaNo ratings yet

- Daniele Monticelli CVDocument14 pagesDaniele Monticelli CVJeet SinghNo ratings yet

- Indian Beer Going Global and Understanding Indian Liquor MarketDocument2 pagesIndian Beer Going Global and Understanding Indian Liquor MarketDhanasekar VelusamyNo ratings yet

- Supply Chain Risk ManagementDocument22 pagesSupply Chain Risk ManagementAB shahedNo ratings yet

- Mental Health in The Canadian Construction IndustryDocument14 pagesMental Health in The Canadian Construction IndustryTwinkle RamnialNo ratings yet

- A Journalistic Study On "Use of Social Media in News Gathering"Document8 pagesA Journalistic Study On "Use of Social Media in News Gathering"Editor IJTSRDNo ratings yet

- Thesis Topics Related Construction ManagementDocument8 pagesThesis Topics Related Construction Managementlauraarrigovirginiabeach100% (1)

- Eapp1112 q1 Mod7Document28 pagesEapp1112 q1 Mod7Frulein BalanlayNo ratings yet