Professional Documents

Culture Documents

Geotechnical Consultants For DA Approvals - Geotechnical Site Investigation, Geotechnical Design and Footing Inspections!

Uploaded by

kaung sanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Geotechnical Consultants For DA Approvals - Geotechnical Site Investigation, Geotechnical Design and Footing Inspections!

Uploaded by

kaung sanCopyright:

Available Formats

Geotechnical Consultants for DA

approvals - Geotechnical Site

Investigation, Geotechnical Design and

Footing Inspections!

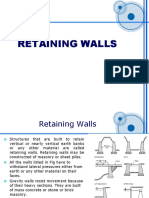

Gravity wall

Construction types of gravity retaining walls: Gravity walls depend on their mass

(stone, concrete or other heavy material) to resist pressure from behind and may

have a 'batter' setback to improve stability by leaning back toward the retained soil.

For short landscaping walls, they are often made from mortarless stone or

segmental concrete units (masonry units). Dry-stacked gravity walls are somewhat

flexible and do not require a rigid footing in frost areas.

Earlier in the 20th century, taller retaining walls were often gravity walls made from

large masses of concrete or stone. Today, taller retaining walls are increasingly built

as composite gravity walls such as: geosynthetics such as geocell cellular

confinement earth retention or with precast facing; gabions (stacked steel wire

baskets filled with rocks); crib walls (cells built up log cabin style from precast

concrete or timber and filled with granular material); or soil-nailed walls (soil

reinforced in place with steel and concrete rods).

Cantilevered wall

Counterfort/Buttress on Cantilevered Wall: Cantilevered retaining walls are made

from an internal stem of steel-reinforced, cast-in-place concrete or mortared

masonry (often in the shape of an inverted T). These walls cantilever loads (like a

beam) to a large, structural footing, converting horizontal pressures from behind

the wall to vertical pressures on the ground below. Sometimes cantilevered walls

are buttressed on the front, or include a counterfort on the back, to improve their

strength resisting high loads. Buttresses are short wing walls at right angles to the

main trend of the wall. These walls require rigid concrete footings below seasonal

frost depth. This type of wall uses much less material than a traditional gravity wall.

Sheet pile wall

Sheet pile wall: Sheet pile retaining walls are usually used in soft soils and tight

spaces. Sheet pile walls are made out of steel, vinyl or wood planks which are

driven into the ground. For a quick estimate the material is usually driven 1/3 above

ground, 2/3 below ground, but this may be altered depending on the environment.

Taller sheet pile walls will need a tie-back anchor, or "dead-man" placed in the soil

a distance behind the face of the wall, that is tied to the wall, usually by a cable or a

rod. Anchors are then placed behind the potential failure plane in the soil.

Bored pile wall

Bored pile retaining walls are built by assembling a sequence of bored piles,

proceeded by excavating away the excess soil. Depending on the project, the bored

pile retaining wall may include a series of earth anchors, reinforcing beams, soil

improvement operations and shotcrete reinforcement layer. This construction

technique tends to be employed in scenarios where sheet piling is a valid

construction solution, but where the vibration or noise levels generated by a pile

driver are not acceptable.

Anchored wall

See also: Tieback (geotechnical)

An anchored retaining wall can be constructed in any of the aforementioned styles

but also includes additional strength using cables or other stays anchored in the

rock or soil behind it. Usually driven into the material with boring, anchors are then

expanded at the end of the cable, either by mechanical means or often by injecting

pressurized concrete, which expands to form a bulb in the soil. Technically

complex, this method is very useful where high loads are expected, or where the

wall itself has to be slender and would otherwise be too weak.

You might also like

- Retaing WallsDocument13 pagesRetaing Walls24x7civilconsultantNo ratings yet

- Retaining Wall TypesDocument3 pagesRetaining Wall TypesTarang ChhedaNo ratings yet

- Retaining Wall: For Most Readers To Understand. Please HelpDocument7 pagesRetaining Wall: For Most Readers To Understand. Please HelpbaktinusantaraNo ratings yet

- Retaining WallsDocument12 pagesRetaining WallsSIZA THE POETNo ratings yet

- Retaining Wall Edit 1Document39 pagesRetaining Wall Edit 1Yash ChourasiaNo ratings yet

- RETAINING WALL TYPES AND DESIGNDocument57 pagesRETAINING WALL TYPES AND DESIGNUriel Alexander RamirezNo ratings yet

- Concrete Crib Walls Provide Low-Cost Retaining Wall Option Under 40 CharactersDocument4 pagesConcrete Crib Walls Provide Low-Cost Retaining Wall Option Under 40 CharactersJulie BajadoNo ratings yet

- Retaining WallDocument3 pagesRetaining WallKarthick RNo ratings yet

- Retaining Wall DesignDocument11 pagesRetaining Wall DesignMustefa Mohammed AdemNo ratings yet

- Types of Retaining WallsDocument8 pagesTypes of Retaining WallscedaserdnaNo ratings yet

- Types of Retaining WallsDocument4 pagesTypes of Retaining Wallsallen2912No ratings yet

- Unit 7 Retaining WallsDocument8 pagesUnit 7 Retaining WallsFaher Gaosel WatamamaNo ratings yet

- Constec3 Retaining WallDocument9 pagesConstec3 Retaining WallHakimi RizqyNo ratings yet

- Choosing The Correct WallsDocument4 pagesChoosing The Correct WallsAmirazam HaqestaNo ratings yet

- Retaining Wall Types, Processes and Excavation MethodsDocument7 pagesRetaining Wall Types, Processes and Excavation Methodsian100% (1)

- Retaining WallsDocument6 pagesRetaining WallsmikiNo ratings yet

- Types of Embedded Earth Retaining WallsDocument17 pagesTypes of Embedded Earth Retaining WallsTun Sheikh HambaleeNo ratings yet

- Week4-RetainingWallsDocument46 pagesWeek4-RetainingWallsAteafac Anastasia NjuafacNo ratings yet

- Retaining Wall (R1)Document68 pagesRetaining Wall (R1)Edmund Chui100% (1)

- Retaining WallDocument62 pagesRetaining WallParam SinghNo ratings yet

- Twana Akram Omar PDFDocument41 pagesTwana Akram Omar PDFDaniel BriñezNo ratings yet

- Retaining WallDocument41 pagesRetaining WallAlnazer100% (1)

- Retaining Wall Guide: Types, Design & MoreDocument36 pagesRetaining Wall Guide: Types, Design & MoreShivang Kumar50% (2)

- Retaining Walls - Failure ModesDocument8 pagesRetaining Walls - Failure ModesAbukalam MullaNo ratings yet

- RETAINING WALL GUIDEDocument2 pagesRETAINING WALL GUIDEDanuNo ratings yet

- Type of Retaining Wall Assignment 4Document8 pagesType of Retaining Wall Assignment 4Usama EjazNo ratings yet

- Assignment 1 Ceb 605Document11 pagesAssignment 1 Ceb 605ShyamalNo ratings yet

- Earth Retaining StructuresDocument42 pagesEarth Retaining StructuresAr. Soumya P SNo ratings yet

- Retaining WallDocument4 pagesRetaining WallSupun KulathungaNo ratings yet

- Types of Retaining WallsDocument10 pagesTypes of Retaining WallssopnanairNo ratings yet

- Learning Outcome 4 Retaining WallsDocument9 pagesLearning Outcome 4 Retaining WallsChris FindlayNo ratings yet

- Retaining Wall PDFDocument18 pagesRetaining Wall PDFG. M. BayazidNo ratings yet

- Retaining Wall: Retaining Walls Are Built in Order To Hold Back Ground Which Would Otherwise MoveDocument8 pagesRetaining Wall: Retaining Walls Are Built in Order To Hold Back Ground Which Would Otherwise MoveBee-thumb FairusNo ratings yet

- 06 Retaining WallsDocument58 pages06 Retaining WallsGarima Mehta100% (1)

- Types of Retainin StructuresDocument5 pagesTypes of Retainin StructuresEsraa elsayed SalamaNo ratings yet

- Retainingwall Wiki 03Document1 pageRetainingwall Wiki 0395abarcaNo ratings yet

- 13.0 Investigation & Evaluation of Claims Involving Retaining WallsDocument14 pages13.0 Investigation & Evaluation of Claims Involving Retaining WallsShabbir LokhandwalaNo ratings yet

- Earth Retaining Structures-1 PDFDocument27 pagesEarth Retaining Structures-1 PDFSury100% (1)

- Building Materials Seminar ReportDocument63 pagesBuilding Materials Seminar ReportTejas Joshi100% (1)

- Types Quay WallDocument8 pagesTypes Quay WallSâu HeoNo ratings yet

- Retaining Wall Reader - NotesDocument6 pagesRetaining Wall Reader - NotesmurtazaNo ratings yet

- Gravity CantileverDocument3 pagesGravity Cantileverfaroukm91No ratings yet

- Lecture23 Retaining WallsDocument76 pagesLecture23 Retaining WallsMayMSTNo ratings yet

- Types of Retaining WallsDocument3 pagesTypes of Retaining WallsAfiq FuadNo ratings yet

- Retainingwall Wiki 02Document1 pageRetainingwall Wiki 0295abarcaNo ratings yet

- Jagan'S College of Engineering and Technology: Choutapalem (V), Nellore (D)Document26 pagesJagan'S College of Engineering and Technology: Choutapalem (V), Nellore (D)Sandeep HøñeyNo ratings yet

- Retaining Walls and Road PavementDocument14 pagesRetaining Walls and Road PavementPraise SamuelNo ratings yet

- Building Construction & Materials Sem - V Unit-2 19.07.2021Document55 pagesBuilding Construction & Materials Sem - V Unit-2 19.07.2021hyperloop707 designNo ratings yet

- Retaining WallsDocument76 pagesRetaining WallsbetongleeNo ratings yet

- BQS552 Earth Retaining StructureDocument93 pagesBQS552 Earth Retaining StructureShakir ZufayriNo ratings yet

- Retaining Wall Types NewDocument33 pagesRetaining Wall Types NewIsbel100% (1)

- Design of Retaining Wall: A Mini Project Report ONDocument40 pagesDesign of Retaining Wall: A Mini Project Report ONMohnika SamineniNo ratings yet

- Sumit - Dart WallDocument5 pagesSumit - Dart WallshariqueNo ratings yet

- Masonarywall 160825234415 PDFDocument36 pagesMasonarywall 160825234415 PDFDrNallaShivamNo ratings yet

- Importance of raft and mat foundations and reinforced concrete shear wallsDocument4 pagesImportance of raft and mat foundations and reinforced concrete shear wallsIZni AZemiNo ratings yet

- Case Study of Failure of Retaining WallDocument31 pagesCase Study of Failure of Retaining WallRahul Ramesh88% (8)

- The Modern Bricklayer - A Practical Work on Bricklaying in all its Branches - Volume III: With Special Selections on Tiling and Slating, Specifications Estimating, EtcFrom EverandThe Modern Bricklayer - A Practical Work on Bricklaying in all its Branches - Volume III: With Special Selections on Tiling and Slating, Specifications Estimating, EtcRating: 5 out of 5 stars5/5 (1)

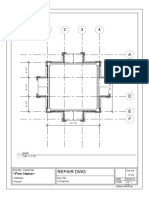

- Plan PDFDocument20 pagesPlan PDFkaung sanNo ratings yet

- Plan 1Document10 pagesPlan 1kaung sanNo ratings yet

- Repair Project2Document1 pageRepair Project2kaung sanNo ratings yet

- 'DCedum, F R (m0 FygVdawmfDocument331 pages'DCedum, F R (m0 FygVdawmfhapmalaysiaNo ratings yet

- Plan 1Document4 pagesPlan 1kaung sanNo ratings yet

- WelcomeDocument5 pagesWelcomeCatNo ratings yet

- Repair ProjectDocument1 pageRepair Projectkaung sanNo ratings yet

- ပဌာနပါဠိDocument498 pagesပဌာနပါဠိkaung sanNo ratings yet

- Dhamma NewsDocument126 pagesDhamma Newskaung sanNo ratings yet

- Tip 5 Steps To Great Renders From Lumion (2019 Update) - Lumion 3D Rendering Software 2Document1 pageTip 5 Steps To Great Renders From Lumion (2019 Update) - Lumion 3D Rendering Software 2kaung san100% (1)

- Tip 5 Steps To Great Renders From Lumion (2019 Update) - Lumion 3D Rendering Software 2Document1 pageTip 5 Steps To Great Renders From Lumion (2019 Update) - Lumion 3D Rendering Software 2kaung san100% (1)

- Screenshot 2019-10-23 at 2.50.00 PMDocument1 pageScreenshot 2019-10-23 at 2.50.00 PMkaung sanNo ratings yet

- Tip 5 Steps To Great Renders From Lumion (2019 Update) - Lumion 3D Rendering Software 2Document1 pageTip 5 Steps To Great Renders From Lumion (2019 Update) - Lumion 3D Rendering Software 2kaung san100% (1)

- Tip 5 Steps To Great Renders From Lumion (2019 Update) - Lumion 3D Rendering Software 2Document1 pageTip 5 Steps To Great Renders From Lumion (2019 Update) - Lumion 3D Rendering Software 2kaung san100% (1)

- BUYERS GUIDE: 3 SIGNS TO FINE LINE HOMES' EXPERTISEDocument6 pagesBUYERS GUIDE: 3 SIGNS TO FINE LINE HOMES' EXPERTISEkaung sanNo ratings yet

- Computer EngineeringDocument14 pagesComputer EngineeringJeff GicharuNo ratings yet

- Culvert 1x2x2 0.50 CushionDocument22 pagesCulvert 1x2x2 0.50 CushionubiakashNo ratings yet

- Audit Checklist For PlantDocument16 pagesAudit Checklist For PlantNash C. UsopNo ratings yet

- EGD Lab ManualDocument15 pagesEGD Lab ManualRajesh ANo ratings yet

- ResearchDocument2 pagesResearchSalman AliNo ratings yet

- Yogesh CV PDFDocument3 pagesYogesh CV PDFYogesh JadhavNo ratings yet

- SGS IND Construction Material Inspection in India A4 EN 10 PDFDocument2 pagesSGS IND Construction Material Inspection in India A4 EN 10 PDFIndra MishraNo ratings yet

- Python - Lab 3Document11 pagesPython - Lab 3salin chaudharyNo ratings yet

- Ms Project Report PDFDocument7 pagesMs Project Report PDFKhaja MohiddinNo ratings yet

- MBM Engineering CollegeDocument3 pagesMBM Engineering CollegeDeep Raj JangidNo ratings yet

- 42 GCSC PDFDocument6 pages42 GCSC PDFMary MorseNo ratings yet

- TOPIC (All Caps, Font 22, Bold, No Underline and No Italics, Centered)Document4 pagesTOPIC (All Caps, Font 22, Bold, No Underline and No Italics, Centered)Pawan GuptaNo ratings yet

- Ethics Position PaperDocument8 pagesEthics Position Papercwise2100% (1)

- Syed Sohail Hamid Zaidi: A: Technical Aspects and Areas of ExpertiseDocument13 pagesSyed Sohail Hamid Zaidi: A: Technical Aspects and Areas of ExpertiseAfrasyab KhanNo ratings yet

- Internship Program - I IP-I (IP201) Final PresentationDocument27 pagesInternship Program - I IP-I (IP201) Final PresentationSaurav ChoudhuryNo ratings yet

- Key Changes For 2017 BPVCDocument56 pagesKey Changes For 2017 BPVCJeganeswaranNo ratings yet

- TS00E v1.2 Student Noteset PDFDocument303 pagesTS00E v1.2 Student Noteset PDFpatrick morris100% (1)

- 2-Ideal Pharmaceutical FactoryDocument22 pages2-Ideal Pharmaceutical FactorymariumNo ratings yet

- Is 2026 4 1977Document35 pagesIs 2026 4 1977just_4_u_dear_in9549No ratings yet

- Construction Workers Fall Accidents from ScaffoldingDocument5 pagesConstruction Workers Fall Accidents from ScaffoldingNikola LopacaninNo ratings yet

- The Three Phase System Delta To Wye Balance and Unbalanced LoadDocument7 pagesThe Three Phase System Delta To Wye Balance and Unbalanced LoadNiño John JaymeNo ratings yet

- Span Thickness Limits For Deflection ControlDocument8 pagesSpan Thickness Limits For Deflection Controlf81lNo ratings yet

- What Are The Fundamental Properties of MaterialsDocument1 pageWhat Are The Fundamental Properties of MaterialsArden Antonio CabaisNo ratings yet

- Yield Stress Sa 240 304Document1 pageYield Stress Sa 240 304faizalNo ratings yet

- LRFD Section 3.76 Concrete Pile Cap DesignDocument21 pagesLRFD Section 3.76 Concrete Pile Cap DesignNurali MamenNo ratings yet

- 2361Document103 pages2361Alen AnušićNo ratings yet

- IIT Madras Bolted Connections GuideDocument30 pagesIIT Madras Bolted Connections GuidepjuvvadiNo ratings yet

- Steel Pipe PilesDocument12 pagesSteel Pipe PilesSteven LiyantoNo ratings yet

- STRUCTURAL PEER REVIEW GUIDEDocument3 pagesSTRUCTURAL PEER REVIEW GUIDEaltarzakov100% (2)

- CE Marking ThesisDocument47 pagesCE Marking ThesisScott TrainorNo ratings yet