Professional Documents

Culture Documents

Reyes SQM Sec 2.13

Reyes SQM Sec 2.13

Uploaded by

KupayOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Reyes SQM Sec 2.13

Reyes SQM Sec 2.13

Uploaded by

KupayCopyright:

Available Formats

SECTION 2.

13 - HIGH VOLUME PRODUCTION TRIAL

(HVPT)

***** PRODUCTION PREPARATION *****

PURPOSE: To explain the procedure for conducting a High Volume

Production Trial.

EXPLANATION:

The goal of a High Volume Production Trial (HVPT) is to identify and

countermeasure any quality or productivity problems prior to Start of

Production in a Mass Production setting. The HVPT is a confirmation of

supplier readiness for mass production. It must be conducted early

enough to allow adequate time for improvement and countermeasure

confirmation. Requirements and timing will be provided by Reyes

Program Management Division.

Prior to the HVPT, it is the supplier’s responsibility to run production trials

at the manufacturing location using Mass Production conditions (i.e. line-

speed, tooling, cycle time, etc.) as closely as possible. The HVPT should

be the culmination of these trials and all other elements of a successful

part and process evaluation plan.

SUPPPLIER RESPONSIBILITY:

1. The HVPT shall be completed per the timing indicated on the

REYES Master Schedule. The supplier must include the specific

timing on the Quality Assurance Schedule. In some cases, REYES

SPPT will coordinate specific dates with the supplier. The trial

must be conducted early enough to allow adequate follow-up for

problems discovered prior to SOP. REYES reserves the right to

visit the supplier during any and all trials.

2. The supplier must include all required processes in the HVPT,

with special attention paid to bottlenecks, final assembly and

new processes, facilities or cells. All processes should be run in

the correct sequence and notations made to indicate any

processes which had to be run “off-line” due to new model/old

model build out or change over requirements.

3. Trials must be representative of Mass Production.

A. Facilities, tooling, and equipment must be complete.

B. Operators must be trained and must be those who will be

used for Mass Production. The trial should include

operators on all shifts.

Revision 1 Reyes Automotive Group Section 2.13

March 2006 San Antonio, TX Page 1 of 4

SECTION 2.13 - HIGH VOLUME PRODUCTION TRIAL

(HVPT)

***** PRODUCTION PREPARATION *****

C. Trials shall be performed for each machine (e.g. die, mold

cavity, etc.) or process (e.g. assembly line).

D. Production method must be the same as Mass Production

and include:

1) Written Standardized work

2) Mass Production Quality Control system

3) Tool changes and set-ups

4) Mass Production line speed

E. Material must be the same as Mass Production materials,

and should be produced at the required capacity set by

REYES and/or a quantity equivalent to Mass Production

scale.

Note: All Direct Run Good Parts can be used to

support mass production shipments providing no

late ECI changes or other tuning as required by

REYES occur (any reworked parts must be approved

by REYES Quality). These parts need to be

identified as HVPT Parts or be traceable by date

code (date code is the preferred method). REYES

will not accept trial parts produced prior to supplier

receipt of Provisional Approval.

4. Trial targets for quality and quantity must be clearly specified.

Definitions

Quality – Parts produced which satisfy the approved Part

Inspection Standard, the Part Mass Production Drawing,

and boundary sample (if applicable).

Quantity – Rate of Direct Run Good Parts (no re-worked

parts) which satisfy REYES’s demand (Mass Production

volume requirement).

Example 1

Supplier A – Dedicated REYES Facility

Operating Constraints*

Total daily operating time = 8.5 hours -20 minutes real allowance

-30 minutes meal break

-19 minutes for Quality checks

Revision 1 Reyes Automotive Group Section 2.13

March 2006 San Antonio, TX Page 2 of 4

SECTION 2.13 - HIGH VOLUME PRODUCTION TRIAL

(HVPT)

***** PRODUCTION PREPARATION *****

Net Operating Time = 7 hours 21 minutes

REYES daily requirement = 200 parts

200

Therefore, parts per hour to meet REYES demand = --------- = 27.21 parts per

hour

7.35hrs

Example 2

Supplier B – Shared Facility

Operating Constraints*

Total daily operating time = 8.5 hours -20 minutes rest allowance

-30 minutes meal break

-19 minutes for Quality Checks

-50 minutes for changeover

-151 minutes to produce another part

Net Operating Time = 4 hours

REYES daily requirement = 200 parts

200

Therefore, parts per hour to meet REYES demand = --------- = 50 parts per hr

4 hrs

* NOTE: The supplier should incorporate their own unique

operating constraints when calculating net operating

time.

5. During each individual trial, production must be continuous at

Mass Production speed with the output of the process constantly

recorded, typically for a period of 1 hour. The process should

then be stopped, reviewed, and countermeasured for

improvement and then tried again. This cycle should be

repeated until the target criteria for the process output is

achieved. The supplier must record results on the High Volume

Production Trial Status Sheet. The sheet is then evaluated

and graded Pass/Fail by the REYES evaluation team.

Revision 1 Reyes Automotive Group Section 2.13

March 2006 San Antonio, TX Page 3 of 4

SECTION 2.13 - HIGH VOLUME PRODUCTION TRIAL

(HVPT)

***** PRODUCTION PREPARATION *****

6. The supplier should track problems found, countermeasures, and

follow-up items, and document them on a Problem Follow-Up

Sheet. The supplier should also consider workability, safety, and

ergonomics issues, as well as problems related to parts and

capacity.

7. When the trial is completed, the supplier must submit the High

Volume Production Trial Status Sheet with results, and the

Problem Follow-Up Sheet to both REYES Program Management

and REYES Quality.

Note: The supplier must complete and submit any

additional documentation (e.g. preparation

checksheet), as requested by REYES to support this

activity.

8. If the supplier is unable to achieve target levels after

countermeasuring the process, they must notify REYES Program

Management and REYES Quality immediately. This notification

should include the supplier’s plan for achieving the target.

Revision 1 Reyes Automotive Group Section 2.13

March 2006 San Antonio, TX Page 4 of 4

You might also like

- QMS 065 Manufacturing Rework Procedure SampleDocument5 pagesQMS 065 Manufacturing Rework Procedure Sampleevil genius100% (1)

- Production Part Approval Process PPAPDocument4 pagesProduction Part Approval Process PPAPtintucinNo ratings yet

- Product Qualification Requirements 2.0Document3 pagesProduct Qualification Requirements 2.0Amit SinghNo ratings yet

- Multiple IntelligencesDocument10 pagesMultiple IntelligencesDianne Mojico100% (1)

- Quality ToolDocument7 pagesQuality ToolAhmed M. HashimNo ratings yet

- Stage 1 Audit Report and SummaryDocument39 pagesStage 1 Audit Report and Summaryabie mumuNo ratings yet

- P-PRD-04 Initial Flow ControlDocument4 pagesP-PRD-04 Initial Flow ControlPk NimiwalNo ratings yet

- 21 Health Benefits of Bitter KolaDocument4 pages21 Health Benefits of Bitter Kolaserjio47No ratings yet

- II. Capacity Planning: I. Key InformationDocument7 pagesII. Capacity Planning: I. Key Informationqzm74lNo ratings yet

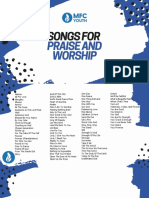

- MFC Youth Songboard 2020Document1,221 pagesMFC Youth Songboard 2020Shea SancoverNo ratings yet

- Site Validation Master Plan: Releasing Its Full PotentialDocument32 pagesSite Validation Master Plan: Releasing Its Full PotentialnophadonNo ratings yet

- Practical Guide To Production Planning & Control [Revised Edition]From EverandPractical Guide To Production Planning & Control [Revised Edition]Rating: 1 out of 5 stars1/5 (1)

- 00 Saip 72Document6 pages00 Saip 72Erin JohnsonNo ratings yet

- Plant Performance & Efficiency Monitoring: Introduction & Familiarization Module - Part 1Document19 pagesPlant Performance & Efficiency Monitoring: Introduction & Familiarization Module - Part 1Youcef NasriNo ratings yet

- Production Planning & ControlDocument46 pagesProduction Planning & ControlAbdullah Sabry Azzam100% (3)

- Establishing A CGMP Laboratory Audit System: A Practical GuideFrom EverandEstablishing A CGMP Laboratory Audit System: A Practical GuideNo ratings yet

- QMS 065 SampleDocument6 pagesQMS 065 SamplebaluchakpNo ratings yet

- 4100F-QAS-151 (Supplier Quality Assurance Manual)Document35 pages4100F-QAS-151 (Supplier Quality Assurance Manual)Sanjay KumarNo ratings yet

- 1.Pv Liquid FDADocument52 pages1.Pv Liquid FDAjadhavshiv100% (1)

- 2 Run at Rate ProcedureDocument7 pages2 Run at Rate ProcedureiandriiNo ratings yet

- Guidelines On Testing DP SystemsDocument28 pagesGuidelines On Testing DP SystemsFrancis ButlerNo ratings yet

- CUET - General Test - SQPDocument9 pagesCUET - General Test - SQPRahul GuptaNo ratings yet

- 3.6 Initial SupplyDocument2 pages3.6 Initial SupplySunil Kumar92% (12)

- Pilotplantscaleuptechniquesusedinpharmaceuticalmanufacturing 131002222820 Phpapp02Document73 pagesPilotplantscaleuptechniquesusedinpharmaceuticalmanufacturing 131002222820 Phpapp02Gautam SharmaNo ratings yet

- Facility ValidationDocument12 pagesFacility ValidationDoan Chi ThienNo ratings yet

- PPAP TrainingDocument19 pagesPPAP TrainingAndy Kelly100% (1)

- Open Response To The Confused SSPXDocument33 pagesOpen Response To The Confused SSPXgilbertnunesNo ratings yet

- Saudi Aramco Inspection ChecklistDocument23 pagesSaudi Aramco Inspection ChecklistjahaanNo ratings yet

- Durat Is Well Experienced in Pre-Commissioning and Commissioning Activities and Can Provide The inDocument13 pagesDurat Is Well Experienced in Pre-Commissioning and Commissioning Activities and Can Provide The inEduardo Papupita NúñezNo ratings yet

- Make It! The Engineering Manufacturing Solution: Engineering the Manufacturing SolutionFrom EverandMake It! The Engineering Manufacturing Solution: Engineering the Manufacturing SolutionNo ratings yet

- Pilot Plant Scale-Up Technique: by SunilboreddyDocument73 pagesPilot Plant Scale-Up Technique: by Sunilboreddyvignesh murugesanNo ratings yet

- IB Math Applications Syllabus Sample Problems PDFDocument267 pagesIB Math Applications Syllabus Sample Problems PDFD FlynnNo ratings yet

- GUIDELINES Book - For Construction On PEAT - SOILDocument146 pagesGUIDELINES Book - For Construction On PEAT - SOILatokkuNo ratings yet

- Pilot Plant Scale-Up TechniqueDocument27 pagesPilot Plant Scale-Up TechniqueVidvendu GuptaNo ratings yet

- AC7108 Rev. F - Audit Criteria For Chemical ProcessingDocument74 pagesAC7108 Rev. F - Audit Criteria For Chemical ProcessingfdsbdfsbhdgndsnNo ratings yet

- Donner Company Case AnalysisDocument5 pagesDonner Company Case Analysisarvinddj80% (5)

- Week 5 - Production SmoothingDocument34 pagesWeek 5 - Production SmoothingQuynh Chau Tran100% (1)

- Joint ReviewDocument126 pagesJoint ReviewDIVAKAR PANIGRAHI100% (1)

- Huawei Parameter StrategyDocument22 pagesHuawei Parameter StrategyTùng NguyễnNo ratings yet

- Saic-A-2001 Rev 62Document21 pagesSaic-A-2001 Rev 62pradeepthalava97No ratings yet

- VCC Phased PPAP Requirements Handbook - V2Document14 pagesVCC Phased PPAP Requirements Handbook - V2medi38No ratings yet

- Gemba Walk Management ChecklistDocument15 pagesGemba Walk Management ChecklistSudhagar100% (1)

- PerformanceTest Updated9octDocument38 pagesPerformanceTest Updated9octHossein100% (1)

- 2008 NPRA Q&A and Technology ForumDocument90 pages2008 NPRA Q&A and Technology ForumTuan YusoffNo ratings yet

- Yoganidra History and Context PDFDocument23 pagesYoganidra History and Context PDFhari hara100% (1)

- How To Conduct A Ball Mill AuditDocument7 pagesHow To Conduct A Ball Mill Auditsafwat hassan100% (1)

- Creating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowFrom EverandCreating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowRating: 4 out of 5 stars4/5 (1)

- Advics Na SRM - Iii-03 HVPTDocument4 pagesAdvics Na SRM - Iii-03 HVPTRaju Wadekar PatilNo ratings yet

- Sample Acceptance Test Procedure(s)Document58 pagesSample Acceptance Test Procedure(s)Chris RufuNo ratings yet

- OPERATIONS MANAGEMENT - Model Questions and AnswersDocument34 pagesOPERATIONS MANAGEMENT - Model Questions and AnswersAkshay KsNo ratings yet

- PPAPDocument11 pagesPPAPvikasavhadNo ratings yet

- NEOPRSP011 - Rev. 00 - Pages 11 - Plant Operation Quality Assurance ProcedureDocument13 pagesNEOPRSP011 - Rev. 00 - Pages 11 - Plant Operation Quality Assurance Procedurealialharbi021No ratings yet

- Process Validation and Revalidation in Medical Device ProductionDocument7 pagesProcess Validation and Revalidation in Medical Device ProductionBREWSKINo ratings yet

- PPAPDocument4 pagesPPAPMattNo ratings yet

- Stitch Fix Testing Standard Operating Procedure (Sop) : Page - 1Document16 pagesStitch Fix Testing Standard Operating Procedure (Sop) : Page - 1Doulat RamNo ratings yet

- 2009-10 XAT Tutorial - v5Document33 pages2009-10 XAT Tutorial - v5hamed51060No ratings yet

- IMSPTCH07-revised On 13.04.2023Document9 pagesIMSPTCH07-revised On 13.04.2023madhuramfoods.chiralaNo ratings yet

- EMIN Manufacturing - Excellence - KPIs - Guide - April 2022 V23Document33 pagesEMIN Manufacturing - Excellence - KPIs - Guide - April 2022 V23jd1654068No ratings yet

- Apqp Progress Report CoversheetDocument3 pagesApqp Progress Report Coversheetponrajan1979No ratings yet

- APQP Progress Report - CoversheetDocument3 pagesAPQP Progress Report - CoversheetAman AwachatNo ratings yet

- Reference ToC For Final Project Report - NEWDocument4 pagesReference ToC For Final Project Report - NEWJosé Carlos Cardoso GamaNo ratings yet

- 10 - Managing ChangexDocument26 pages10 - Managing ChangexAdriana HubleaNo ratings yet

- Dokumen - Tips - Validation Pharma Industry Pharmaceutics Pharmaceutical ValidationDocument34 pagesDokumen - Tips - Validation Pharma Industry Pharmaceutics Pharmaceutical ValidationAmjed AL-ShammkhNo ratings yet

- FDA Guidance Part 6Document7 pagesFDA Guidance Part 6Thrinath KumarNo ratings yet

- GQP 050 SedimentDocument4 pagesGQP 050 Sedimentashvini_alokNo ratings yet

- Lecture 3 (B) - Types of Production Processes Oct 2022Document20 pagesLecture 3 (B) - Types of Production Processes Oct 2022dub911No ratings yet

- Productivity Monitoring & Resource Leveling Problem StatementDocument1 pageProductivity Monitoring & Resource Leveling Problem StatementNeeraj PartetyNo ratings yet

- Production Planning and Control: Prepared By, Mr. Nishant AgrawalDocument52 pagesProduction Planning and Control: Prepared By, Mr. Nishant AgrawalColonel AlbalNo ratings yet

- RCAF Ontario Station - Sep 1942Document39 pagesRCAF Ontario Station - Sep 1942CAP History LibraryNo ratings yet

- Design Optimization of A Large Scale RooftopDocument13 pagesDesign Optimization of A Large Scale RooftopLucia NunezNo ratings yet

- SPLM Analytic Geometry Part 2Document85 pagesSPLM Analytic Geometry Part 2Joey TelinNo ratings yet

- BIOS Setup User GuideDocument30 pagesBIOS Setup User GuidespyonthiefNo ratings yet

- Effect of Vine Cutting Length and Angle-1035Document8 pagesEffect of Vine Cutting Length and Angle-1035Lindsay MyersNo ratings yet

- Base Station Antenna: 1.4m 6port 3H Antenna With Integrated RCUDocument2 pagesBase Station Antenna: 1.4m 6port 3H Antenna With Integrated RCUДмитрийNo ratings yet

- Student Support Material Class XII PhysicsDocument291 pagesStudent Support Material Class XII PhysicsHemanshi KocharNo ratings yet

- Marketing Management Chapter 2 PDFDocument22 pagesMarketing Management Chapter 2 PDFsakil ahamedNo ratings yet

- A1657810355 - 23435 - 24 - 2019 - PEA 306 Time and WorkDocument87 pagesA1657810355 - 23435 - 24 - 2019 - PEA 306 Time and WorkRakesh MoparthiNo ratings yet

- Factor Analysis SPSSDocument6 pagesFactor Analysis SPSSNeelima Varma NadimpalliNo ratings yet

- DsvdsDocument2 pagesDsvdsnehelet920No ratings yet

- Post Ap PDFDocument41 pagesPost Ap PDFMartin Sebastian Gomez GalizziNo ratings yet

- BBM NotesDocument47 pagesBBM NotesPraise Worthy100% (1)

- Social End Ethical ProjectDocument20 pagesSocial End Ethical ProjectPrathmesh VashisthNo ratings yet

- How To Repair WMI On A Windows XP System - EhowDocument2 pagesHow To Repair WMI On A Windows XP System - EhowMwawiNo ratings yet

- Long Term Internship BComCA) - VI Sem 2023-24 (1) - 1Document11 pagesLong Term Internship BComCA) - VI Sem 2023-24 (1) - 1maheswarilokku5No ratings yet

- Theories On Entrepreneurial MotivationDocument19 pagesTheories On Entrepreneurial MotivationDisha Barai67% (3)

- Topical Steroid Abuse PPT For Family PhysiciansDocument74 pagesTopical Steroid Abuse PPT For Family Physiciansdevsuman sharmaNo ratings yet

- Quorum Sensing - WikipediaDocument75 pagesQuorum Sensing - WikipediaHamza MalikNo ratings yet

- 3cce171c-d4d7-49b0-8dda-425b225fb1f5 (1)Document2 pages3cce171c-d4d7-49b0-8dda-425b225fb1f5 (1)j4606074No ratings yet

- Ronalia Hydropower ProjectDocument70 pagesRonalia Hydropower ProjectTOOBABINTE ARIFNo ratings yet

![Practical Guide To Production Planning & Control [Revised Edition]](https://imgv2-2-f.scribdassets.com/img/word_document/235162742/149x198/2a816df8c8/1709920378?v=1)