Professional Documents

Culture Documents

Wire MEsh Table Computation

Uploaded by

James Michael Bacuna0 ratings0% found this document useful (0 votes)

8 views1 pageWIRE MESH

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentWIRE MESH

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views1 pageWire MEsh Table Computation

Uploaded by

James Michael BacunaWIRE MESH

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Pleating chart & Wire mesh weight chart 1

Pleating chart

Width of opening Required spacing for pleating

4’0 10 inches

6’0 15 inches

8’0 20 inches

10’0 25 inches

12’0 30 inches

14’0 35 inches

16’0 40 inches

18’0 45 inches

20’0 50 inches

How to calculate required spacing

The most used spacing for pleating is 4 inches. However,

you can calculate it more precisely using the following

calculation formula :

Width of railing in linear feet X 2.5 = Total required spacing

for pleating (in inches)

Example : Calculation for a 7 foot rail, namely:

2.5 X 7 = 17.5 inches

Wire mesh weight chart

Opening ( Size ofmesh ) Approximate wire mesh weight (lbs) per 100 sq.ft.

Aluminium Stainless steel Steel Brass Copper

3/32’’ 25 60 59 60 70

1/8’’ 45 77 75 77 85

3/16’’ 38 83 60 83 90

1⁄4’’ 34 66 53 66 75

5/16’’ 26 46 45 - -

3/8’’ 52 108 98 108 105

1⁄2’’ 37 77 77 77 85

5/8’’ 27 79 - - -

3⁄4’’ * 52 156 156 156 180

7/8 ‘’ - - 61 - -

Wire mesh standard weight (lbs per 100 sq. ft.) according to wire gage and metal used.

Data is based on standard mesh size. It may vary according to the wire gage chosen.

* 3⁄4’’ Wire mesh weaved using a 12 gage wire

You might also like

- Specifications: Ragline AngeDocument2 pagesSpecifications: Ragline Angeluis_geronimo_3No ratings yet

- H06157Document3 pagesH06157kirankirkNo ratings yet

- Lift & Tail CalcsDocument3 pagesLift & Tail Calcsnazeer_mohdNo ratings yet

- Aggregate Sieve Analysis Test PDFDocument9 pagesAggregate Sieve Analysis Test PDFYusman FoenayNo ratings yet

- 10507-Hayfield SoftTwistDK (Free)Document4 pages10507-Hayfield SoftTwistDK (Free)lia aryaniNo ratings yet

- Open Uri20201021 4 1fpv57r 1Document4 pagesOpen Uri20201021 4 1fpv57r 1lydia.s.cochraneNo ratings yet

- Optimization of Doubling at Draw Frame FDocument6 pagesOptimization of Doubling at Draw Frame FHamid MovahedNo ratings yet

- Experiment No 2Document10 pagesExperiment No 2Kirby CamposanoNo ratings yet

- Chapter XV Ac-BcDocument14 pagesChapter XV Ac-BcMUHAMMAD KENNYZYRA BINTANG SAM -No ratings yet

- Metal ReinforcementDocument23 pagesMetal ReinforcementEmmanNo ratings yet

- AD 25-170 Data SheetDocument2 pagesAD 25-170 Data Sheetmairimsp2003No ratings yet

- Dragalina Pequeña 8000Document2 pagesDragalina Pequeña 8000J BaLdo Díaz MartínezNo ratings yet

- Sej SleeperDocument3 pagesSej SleeperNipun Narayan100% (1)

- Concrete Estimate ExcelDocument35 pagesConcrete Estimate ExcelFrancis Jan DiscayaNo ratings yet

- Acero Vigas de ConexionDocument7 pagesAcero Vigas de ConexionAndy AICCNo ratings yet

- Seive Analysis of Coarse Aggregate OnlyDocument3 pagesSeive Analysis of Coarse Aggregate OnlyYasirNo ratings yet

- Ficha Tecnica Tanque GLPDocument2 pagesFicha Tecnica Tanque GLPOmar Cueva100% (3)

- ASTM A53 Schedule 40 and Schedule 80 Pipe DimensionsDocument11 pagesASTM A53 Schedule 40 and Schedule 80 Pipe DimensionsjohnmarbautistaNo ratings yet

- 10506-Hayfield SoftTwistDK (Free)Document4 pages10506-Hayfield SoftTwistDK (Free)Kyae ThawNo ratings yet

- Frequency - Wavelength ChartDocument2 pagesFrequency - Wavelength Chartcarlyblack2006No ratings yet

- Experiment No. 3: Sieve Analysis of Coarse and Fine Aggregate DiscussionDocument22 pagesExperiment No. 3: Sieve Analysis of Coarse and Fine Aggregate DiscussionRochelleNo ratings yet

- Notes On Nuts&BoltsDocument6 pagesNotes On Nuts&BoltsgiovanniNo ratings yet

- Sieve Analysis of AggregatesDocument6 pagesSieve Analysis of AggregatesEj DiazNo ratings yet

- Specs For Cable and GlandsDocument6 pagesSpecs For Cable and Glandspraveen kumar vengadasamyNo ratings yet

- NozzlesDocument13 pagesNozzlesShafreej HidayathNo ratings yet

- Tool LifeDocument22 pagesTool LifeDhruv Bhalala100% (1)

- Astm A53Document2 pagesAstm A53joseocsilvaNo ratings yet

- Cge Drill PipesDocument3 pagesCge Drill Pipesallen wongNo ratings yet

- Produccion de Cover Produccion de Cover Ausenco: Curvas en BandaDocument9 pagesProduccion de Cover Produccion de Cover Ausenco: Curvas en Bandajorge lopezNo ratings yet

- CE 405 Experiment 2Document6 pagesCE 405 Experiment 2Irish AnneNo ratings yet

- Epiroc Drill StringsDocument16 pagesEpiroc Drill StringsCarlos Regaliza100% (1)

- Ton Miles Jar, Stuck Pipe, Working CasingDocument3 pagesTon Miles Jar, Stuck Pipe, Working CasingJaimeQuisbertNo ratings yet

- Data Sheet - Carbon Steel Pipe - Fiorella RepreDocument5 pagesData Sheet - Carbon Steel Pipe - Fiorella RepreNéstor Ramírez PeñalozaNo ratings yet

- Weight Bar Stem Brio Tech Catalog Revised 1.01s 125Document1 pageWeight Bar Stem Brio Tech Catalog Revised 1.01s 125Mohsin PvNo ratings yet

- Tormach CNC Mill 4Th Axis TablesDocument3 pagesTormach CNC Mill 4Th Axis TablesBen LernerNo ratings yet

- American & Efird Thread Consumption EstimatorDocument2 pagesAmerican & Efird Thread Consumption Estimatorمصطفى عبدالرحيمNo ratings yet

- Flakiness ElongationDocument4 pagesFlakiness ElongationrisrizNo ratings yet

- Horizontal Milling Machine Catalog PDFDocument2 pagesHorizontal Milling Machine Catalog PDFDharmik SoniNo ratings yet

- Universal Milling Machine Catalog PDFDocument2 pagesUniversal Milling Machine Catalog PDFDharmik SoniNo ratings yet

- Filter MeshDocument38 pagesFilter MeshKhoh Kai Sheng100% (1)

- Table - SelectionDocument2 pagesTable - SelectionSoumya SameerNo ratings yet

- Containers For Every Need: Maersk Equipment GuideDocument12 pagesContainers For Every Need: Maersk Equipment GuideSharath RadhakrishnanNo ratings yet

- Master Rigger Reference Material: Crane Institute CertificationDocument3 pagesMaster Rigger Reference Material: Crane Institute CertificationKintali VinodNo ratings yet

- Pipes b16.25 PDFDocument11 pagesPipes b16.25 PDFAsep DarojatNo ratings yet

- Homemade DIY Tent - InstructionsDocument16 pagesHomemade DIY Tent - InstructionsTimothy LucasNo ratings yet

- Calculations TW-H-27,5-200 (Double Drum) Rev. 1.1Document1 pageCalculations TW-H-27,5-200 (Double Drum) Rev. 1.1phankhoa83-1No ratings yet

- Desidn AopDocument73 pagesDesidn AopDavid LambertNo ratings yet

- Maryland Metrics - Thread Data ChartsDocument3 pagesMaryland Metrics - Thread Data ChartsVIVEK UPADHYAYNo ratings yet

- Wire MeshDocument32 pagesWire MeshChandravadanNo ratings yet

- Grain Size Analysis by Wet and Dry Sieve Analysis: 1. ObjectiveDocument4 pagesGrain Size Analysis by Wet and Dry Sieve Analysis: 1. ObjectiveMuhammad AfrasiyabNo ratings yet

- Grain Size of SoilDocument4 pagesGrain Size of SoilAhmadjakwarNo ratings yet

- Dry and Wet AnalysisDocument4 pagesDry and Wet AnalysisManish SolankiNo ratings yet

- Wave Fold Ready Made White Chain InstructionsDocument2 pagesWave Fold Ready Made White Chain InstructionsZamad Anwar AbbasiNo ratings yet

- SEARCH ADS PipaDocument25 pagesSEARCH ADS PipaAndry LauNo ratings yet

- Containers For Every Need: Maersk Equipment GuideDocument12 pagesContainers For Every Need: Maersk Equipment GuideungureanualexandraanaNo ratings yet

- ASTM E 11-01 Standard Specification For Wire Cloth and Sieves For Testing PurposesDocument5 pagesASTM E 11-01 Standard Specification For Wire Cloth and Sieves For Testing PurposesPablo Antonio Valcárcel VargasNo ratings yet

- Chain Lengths - 25Ft, 10Ft & 5M: Pitch Conversion ChartDocument2 pagesChain Lengths - 25Ft, 10Ft & 5M: Pitch Conversion ChartDipeshNo ratings yet

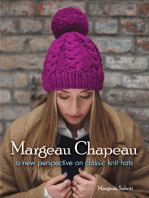

- Margeau Chapeau: A New Perspective on Classic Knit HatsFrom EverandMargeau Chapeau: A New Perspective on Classic Knit HatsRating: 3.5 out of 5 stars3.5/5 (6)

- 25 Stylish Knitted Slippers: Fun Designs for Clogs, Moccasins, Boots, Animal Slippers, Loafers, & MoreFrom Everand25 Stylish Knitted Slippers: Fun Designs for Clogs, Moccasins, Boots, Animal Slippers, Loafers, & MoreRating: 4 out of 5 stars4/5 (1)

- Webinar Notes Template 0109-10-2021Document4 pagesWebinar Notes Template 0109-10-2021James Michael BacunaNo ratings yet

- Lecture On Gantt ChartDocument3 pagesLecture On Gantt ChartJames Michael BacunaNo ratings yet

- Printing View As of Nov 27, 2022Document1 pagePrinting View As of Nov 27, 2022James Michael BacunaNo ratings yet

- Network DiagramDocument2 pagesNetwork DiagramJames Michael BacunaNo ratings yet

- Adr 81Document2 pagesAdr 81Talib AbuNo ratings yet

- Overallocated Resources ReportDocument1 pageOverallocated Resources ReportJames Michael BacunaNo ratings yet

- Map 1 - DataDocument21 pagesMap 1 - DataJames Michael BacunaNo ratings yet

- Team Planner - OverallocationDocument2 pagesTeam Planner - OverallocationJames Michael BacunaNo ratings yet

- Printing ViewsDocument1 pagePrinting ViewsJames Michael BacunaNo ratings yet

- Activity EV 102922Document10 pagesActivity EV 102922James Michael BacunaNo ratings yet

- Pritning View1Document1 pagePritning View1James Michael BacunaNo ratings yet

- Management Trainee - QualificationsDocument1 pageManagement Trainee - QualificationsJames Michael BacunaNo ratings yet

- Pritning ViewDocument1 pagePritning ViewJames Michael BacunaNo ratings yet

- Report As of May 8, 2022Document1 pageReport As of May 8, 2022James Michael BacunaNo ratings yet

- Brochure Disp Helix enDocument10 pagesBrochure Disp Helix enJames Michael BacunaNo ratings yet

- Architectural99.9Document24 pagesArchitectural99.9James Michael BacunaNo ratings yet

- The Design Process For A RC WallDocument5 pagesThe Design Process For A RC WallJames Michael BacunaNo ratings yet

- Conversion Tables: Square MeasureDocument2 pagesConversion Tables: Square MeasureElma LlagasNo ratings yet

- Standard Structural LoadsDocument8 pagesStandard Structural Loadswiggly18No ratings yet

- Structural Analysis and Design CriteriaDocument4 pagesStructural Analysis and Design CriteriaJoseph Cloyd L. Lamberte78% (9)

- Checklist of Requirements For New Gasoline Stations PDFDocument2 pagesChecklist of Requirements For New Gasoline Stations PDFERWINLAV2000No ratings yet

- Conversions Template v2 0Document25 pagesConversions Template v2 0James Michael BacunaNo ratings yet

- RFID Customer Care: 500.00 Total PaymentsDocument1 pageRFID Customer Care: 500.00 Total PaymentsJames Michael BacunaNo ratings yet

- Stone Retaining Wall DesignDocument25 pagesStone Retaining Wall DesignSafi Zabihullah Safi81% (16)

- Angle Bar1Document3 pagesAngle Bar1Ghie GhieNo ratings yet

- TECH2 - Wyntk - Asce Occupancy Categories PDFDocument3 pagesTECH2 - Wyntk - Asce Occupancy Categories PDFJames Michael BacunaNo ratings yet

- Load On BuildingDocument131 pagesLoad On BuildingAnonymous j19GEvKNNo ratings yet

- Etabs TutorialDocument10 pagesEtabs Tutorialsalahaddinsharif67% (3)

- Day 10 - Wind Analysis PDFDocument10 pagesDay 10 - Wind Analysis PDFpramods_8No ratings yet

- Square - Tubing - REGAN PDFDocument2 pagesSquare - Tubing - REGAN PDFJames Michael BacunaNo ratings yet