Professional Documents

Culture Documents

Metric Thread EN 60423 (For Cable Glands EN 50 262)

Uploaded by

Karnan ThirugnanamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Metric Thread EN 60423 (For Cable Glands EN 50 262)

Uploaded by

Karnan ThirugnanamCopyright:

Available Formats

Appendix

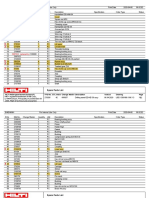

Selection Table T21

ÖLFLEX®

T21: Thread Dimensions for Cable Glands

■ Thread dimensions and bore dimensions – Technical data for assembly

Metric thread EN 60423 (for cable glands EN 50 262)

UNITRONIC®

Metric thread ø D1 P ø D2 Nominal Thread ø D3

M12 x 1.5 12 1.5 10.6 12.3 – 0.2

M16 x 1.5 16 1.5 14.6 16.3 – 0.2

M20 x 1.5 20 1.5 18.6 20.3 – 0.2

M25 x 1.5 25 1.5 23.6 25.3 – 0.2

M32 x 1.5 32 1.5 30.6 32.3 – 0.2

ETHERLINE®

M40 x 1.5 40 1.5 38.6 40.4 – 0.3

M50 x 1.5 50 1.5 48.6 50.4 – 0.3

M63 x 1.5 63 1.5 61.6 63.4 – 0.3 D1 = core diameter

D2 = outside diameter

M75 x 1,5 75 1,5 73,6 75,4 – 0,3 D3 = bore diameter

M90 x 2 90 2 88,8 90,4 – 0,3 P = pitch

M110 x 2 110 2 108,8 110,4 – 0,3

HITRONIC®

Metric thread DIN 13 part 6 and 7 (for cable glands according to DIN 89 280)

Metric thread ø D1 P ø D2 Nominal Thread ø D3

M18 x 1.5 18 1.5 16.4 18.3 – 0.2

M24 x 1.5 24 1.5 22.4 24.3 – 0.2

M30 x 2 30 2 27.8 30.3 – 0.2

EPIC®

M36 x 2 36 2 33.8 36.3 – 0.2

M45 x 2 45 2 42.8 45.4 – 0.3

M56 x 2 56 2 53.8 56.4 – 0.3

M72 x 2 72 2 69.8 72.5 – 0.4

M80 x 2 80 2 77.8 80.5 – 0.4

SKINTOP®

M105 x 2 105 2 102.8 105.5 – 0.4

Technical data for assembly DIN 40430

PG thread ø D1 P ø D2 Nominal Thread ø D3

PG 7 12.5 1.27 11.3 13.0 ± 0.2

SILVYN®

PG 9 15.2 1.41 13.9 15.7 ± 0.2

PG 11 18.6 1.41 17.3 19.0 ± 0.2

PG 13.5 20.4 1.41 19.1 21.0 ± 0.2

PG 16 22.5 1.41 21.2 23.0 ± 0.2

PG 21 28.3 1.588 26.8 28.8 ± 0.2

FLEXIMARK®

PG 29 37.0 1.588 35.5 37.5 ± 0.3

PG 36 47.0 1.588 45.5 47.5 ± 0.3 D1 = core diameter

D2 = Outside diameter

PG 42 54.0 1.588 52.5 54.5 ± 0.3 D3 = bore diameter

PG 48 59.3 1.588 57.8 59.8 ± 0.3 P = pitch

ACCESSORIES

Technical data for assembly ANSI B1.20.2 – 1983

NPT thread ø D1 P Nominal Thread ø D3

NPT 1/4" 13.7 1.41 14.1 – 0.2

NPT 3/8" 17.1 1.41 17.4 – 0.2

NPT 1/2" 21.3 1.81 21.6 – 0.2

NPT 3/4" 26.7 1.81 27.0 – 0.2

APPENDIX

NPT 1" 33.4 2.21 33.7 – 0.2

D1 = core diameter

NPT 1 1/4" 42.2 2.21 42.5 – 0.2 D3 = bore diameter

P = pitch

NPT 1 1/2" 48.3 2.21 48.7 – 0.2

NPT 2" 60.3 2.21 60.7 – 0.2

For current information see www.lappgroup.com/products 1045

Appendix

T21 Selection Table

ÖLFLEX®

T21: Tightening Torque Values and Dimensions for Cable Glands

■ Tightening torque* for SKINTOP® glands metric

Table of the recommended tightening torque (cap nut, connection thread) for SKINTOP® metric version for attainment of degree of

UNITRONIC®

protection and strain relief of category A acc. to EN 50262. Further information regarding degree of protection please see product page.

Tightening torque in Nm

Thread

Polymer Metal

M12 x 1.5 1.5 8

M16 x 1.5 3.0 10

M20 x 1.5 6.0 12

ETHERLINE®

M25 x 1.5 8.0 12

M32 x 1.5 10.0 18

M40 x 1.5 13.0 18

M50 x 1.5 15.0 20

M63 x 1.5 16.0 20

M63 x 1.5 plus - 25

M75 x 1.5 - 30

HITRONIC®

M90 x 2 - 45

M110 x 2 - 55

* Note: For ATEX cable glands please find the tightening torques in the corresponding operation manuals. (Operation manual attached to the delivery bag)

■ Tightening torque values* according to DIN/VDE 0619, Point 7 for SKINTOP® glands PG

Torque for the intermediary in Nm Torque for the cap nut in Nm

Thread

Polymer Metal Polymer

EPIC®

PG 7 2.5 6.25 1.7

PG 9 3.75 6.25 2.5

PG 11 3.75 6.25 2.5

PG 13.5 3.75 6.25 2.5

PG 16 5.0 7.5 3.3

SKINTOP®

PG 21 7.5 10.0 5.0

PG 21 7.5 10.0 5.0

PG 29 7.5 10.0 5.0

PG 36 7.5 10.0 5.0

PG 42 7.5 10.0 5.0

PG 48 7.5 10.0 5.0

Above values obtain as tightening torques for the connection thread, as well as maximal tightening torques for the cap nuts under in standard regulated

SILVYN®

temperature. To prevent damages of the outer sheath please note that the different cable materials require various torques.

■ Fitting dimensions and widths across flats

FLEXIMARK®

The diameter A indicates the assembly space required for the relevant hexagon. This diameter corresponds to the width across corner of

the hexagon, plus an assembly tolerance.

SW øA SW øA SW øA

9 10,4 27 30,6 47 52,5

11 12,5 28 31,8 50 58,3

13 14,9 29 32,5 53 60,0

ACCESSORIES

14 16,0 30 34,0 54 61,0

15 17,1 32 36,2 55 62,0

16 18,2 33 37,2 57 64,4

17 19,4 36 40,5 60 67,5

18 20,4 37 41,5 64 72,3

19 22,0 39 44,0 65 73,1

20 22,7 40 45,2 66 74,5

21 23,9 41 46,1 67 74,5

APPENDIX

22 25,0 42 47,0 95 105

24 27,3 45 51,2 115 127

25 28,3 45 51,2 135 150

26 29,5 46 52,5

1046 For current information see www.lappgroup.com/products

You might also like

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Cable Gland Catalogue 2017Document184 pagesCable Gland Catalogue 2017spurgeon04No ratings yet

- How To Specify A Capillary Seal AssemblyDocument4 pagesHow To Specify A Capillary Seal AssemblyKarnan ThirugnanamNo ratings yet

- Level Instruments: G.E.T. Training (DP Type, Magnétostrictive, GWR Type, Non Contact Type RADAR Etc.,)Document22 pagesLevel Instruments: G.E.T. Training (DP Type, Magnétostrictive, GWR Type, Non Contact Type RADAR Etc.,)Karnan ThirugnanamNo ratings yet

- How To Specify A Capillary Seal AssemblyDocument4 pagesHow To Specify A Capillary Seal AssemblyKarnan ThirugnanamNo ratings yet

- Section 4 Ranging The Transmitter: Rosemount 1199Document10 pagesSection 4 Ranging The Transmitter: Rosemount 1199Karnan ThirugnanamNo ratings yet

- Fundamentals of Pressure and Temperature Measurement: Example - Calculation at .25 PsigDocument4 pagesFundamentals of Pressure and Temperature Measurement: Example - Calculation at .25 PsigPriscila Perez HerreraNo ratings yet

- Section 4 Ranging The Transmitter: Rosemount 1199Document10 pagesSection 4 Ranging The Transmitter: Rosemount 1199Karnan ThirugnanamNo ratings yet

- 8150 TerminalBoxes EK00 III enDocument37 pages8150 TerminalBoxes EK00 III enKarnan ThirugnanamNo ratings yet

- Identity and Analysis of Total Petroleum HydrocarbonsDocument22 pagesIdentity and Analysis of Total Petroleum HydrocarbonsRoy Allan T. RamoNo ratings yet

- 2013oct 076-081 McfarlaneDocument6 pages2013oct 076-081 McfarlaneKarnan ThirugnanamNo ratings yet

- Requisitions IndexDocument13 pagesRequisitions IndexKarnan ThirugnanamNo ratings yet

- Rosemount 1199: Product Data SheetDocument14 pagesRosemount 1199: Product Data SheetKarnan ThirugnanamNo ratings yet

- Appleton Cable GlandsDocument15 pagesAppleton Cable GlandsbookbumNo ratings yet

- Swagelok FittingsDocument68 pagesSwagelok FittingsKarnan ThirugnanamNo ratings yet

- Identity and Analysis of Total Petroleum HydrocarbonsDocument22 pagesIdentity and Analysis of Total Petroleum HydrocarbonsRoy Allan T. RamoNo ratings yet

- 012100Document148 pages012100Karnan ThirugnanamNo ratings yet

- Link NetworkDocument2 pagesLink NetworkKarnan ThirugnanamNo ratings yet

- 22 BeDocument488 pages22 BeKay DevNo ratings yet

- Plant Engineering 0498Document6 pagesPlant Engineering 0498Karnan ThirugnanamNo ratings yet

- Datasheet Sensor Bently 3300 XL 8mmDocument14 pagesDatasheet Sensor Bently 3300 XL 8mmCharles Matos0% (1)

- Orifice Plate2Document3 pagesOrifice Plate2Karnan ThirugnanamNo ratings yet

- Boiler Drum Level ControlDocument3 pagesBoiler Drum Level ControlUrej Bandiola100% (1)

- Orifice Plate2Document3 pagesOrifice Plate2Karnan ThirugnanamNo ratings yet

- Boiler Drum Level ControlDocument3 pagesBoiler Drum Level ControlUrej Bandiola100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Countersunk Screw With Hexagon Socket Head ISO 10642 Steel 10.9Document10 pagesCountersunk Screw With Hexagon Socket Head ISO 10642 Steel 10.9Alex DeschevogNo ratings yet

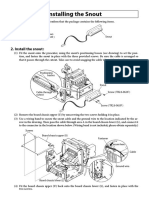

- Canon PC Boklet Trimmer d1Document67 pagesCanon PC Boklet Trimmer d1ralf1k1hlerNo ratings yet

- Ru-510 e A4fc955099Document20 pagesRu-510 e A4fc955099pjte39No ratings yet

- Plan de MantenimientoDocument2 pagesPlan de Mantenimientooperaciones operacionesNo ratings yet

- 1/4-28 UNF to NPT pipe adapters dimensionsDocument1 page1/4-28 UNF to NPT pipe adapters dimensionsKaiser46Li206No ratings yet

- M & H Valve: Distributor Price ListDocument36 pagesM & H Valve: Distributor Price Listjuan rodriguezNo ratings yet

- Impresoras TPU500Document1 pageImpresoras TPU500Roger FermatNo ratings yet

- 2005 S003 NBPG Rfi 04952 - R00Document1 page2005 S003 NBPG Rfi 04952 - R00RPDeshNo ratings yet

- Grupo de Montagem Group Index Alpha Grupos de Montaje Groupes de MontageDocument437 pagesGrupo de Montagem Group Index Alpha Grupos de Montaje Groupes de MontagewanderNo ratings yet

- Yakima Fat Cat 6 InstructionsDocument18 pagesYakima Fat Cat 6 InstructionsLt. DanNo ratings yet

- Bolt Din 933Document2 pagesBolt Din 933anNo ratings yet

- PARTS LIST FOR RADIATOR AND COOLING SYSTEM COMPONENTSDocument529 pagesPARTS LIST FOR RADIATOR AND COOLING SYSTEM COMPONENTSSularia NicuNo ratings yet

- Spencer Glover - BPR - 6 Fasteners and Structural Steel (133-150) PDFDocument18 pagesSpencer Glover - BPR - 6 Fasteners and Structural Steel (133-150) PDFSpencer GloverNo ratings yet

- Click To View Juki - DDL9000B - 1Document63 pagesClick To View Juki - DDL9000B - 1johnsuca81No ratings yet

- 18BME1008Document6 pages18BME1008SRIKANTH K 15PHD1093No ratings yet

- Cupcake Build Sequence - Batch 10Document171 pagesCupcake Build Sequence - Batch 10Luciano de Souza FerreiraNo ratings yet

- DD-HD 30 SchematicsDocument13 pagesDD-HD 30 SchematicsBenoit GrégoireNo ratings yet

- Quot. Installation Thermowell RTD at HRSG StackDocument29 pagesQuot. Installation Thermowell RTD at HRSG StackTito Andy WicaksonoNo ratings yet

- Genuine Cummins Parts - OP6095-03Document4 pagesGenuine Cummins Parts - OP6095-03EPESANo ratings yet

- Wireline Core Barrel N-n2-n3 Cam Latch - 595x842Document12 pagesWireline Core Barrel N-n2-n3 Cam Latch - 595x842Abiot Tarekegn DagnewNo ratings yet

- Latch Beam Lock AssemblyDocument1 pageLatch Beam Lock AssemblyDaniel Curi ResendeNo ratings yet

- Section 2 PDFDocument5 pagesSection 2 PDFimanNo ratings yet

- Equivalences FixationsDocument30 pagesEquivalences FixationsFred100% (4)

- Lock RekeyingDocument17 pagesLock RekeyingPrathusha RNo ratings yet

- Catalogo ContinentalDocument255 pagesCatalogo ContinentalGabriel Castillo MuñozNo ratings yet

- Manual de Partes XP375&HP375&P425WCU 22592075 Parts 01-03-07Document83 pagesManual de Partes XP375&HP375&P425WCU 22592075 Parts 01-03-07nestor coaquiraNo ratings yet

- Singer - 4423 - 44S Parts ListDocument25 pagesSinger - 4423 - 44S Parts ListbianchifanNo ratings yet

- CNC Milling Machine Explode ViewDocument1 pageCNC Milling Machine Explode ViewLam quocNo ratings yet

- Traduccion de InglesDocument3 pagesTraduccion de Inglesjimmy RobinsonNo ratings yet

- Multipoint Socket Profile VW 010 43: KonzernnormDocument4 pagesMultipoint Socket Profile VW 010 43: KonzernnormRicardo Vitoriano100% (1)