Professional Documents

Culture Documents

CB 3688 Us

Uploaded by

Luis Sánchez Jr.Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CB 3688 Us

Uploaded by

Luis Sánchez Jr.Copyright:

Available Formats

B O O M P U M P

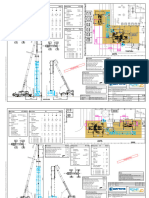

36Z-Meter Truck-Mounted Specifications

Based on Model MACK MRU 688S

with .16H pump cell

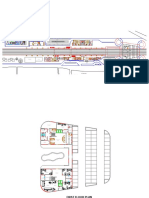

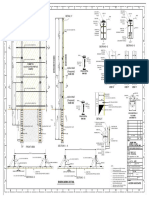

Length 36' 7" (11.14m)

13' 1''

(3.99m) Width 8' 2" (2.50m)

36Z-Meter

Height 13' 1" (3.99m)

4' 3'' Wheelbase 215" (5,461mm)

8 (1.28m) Front axle weight 18,951 lbs (8,596kg)

Rear axle weight 36,264 lbs (16,499kg)

Truck-Mounted Concrete Boom Pump 59''

(1508mm)

190''

(4826mm)

50'' 51''

(1270mm) (1295mm)

Approx. total weight 55,215 lbs (25,045kg)

Weights are approximate and include pump, boom, truck, full hydraulic

21' 8''

(6.60m) oil, driver and some fuel. Varies with options selected.

1 215'' 139'' Dimensions will vary with different truck makes, models and specifications.

36Z-Meter

36Z-Meter

(5461mm) (3538mm)

164''

(4172mm)

36' 7'' Boom Specifications • Multi-Z Design

(11.14m) Height & Reach

Vertical reach 116' 9" (35.59m)

Range Diagram Horizontal reach 104' (31.70m)

Reach from front of truck* 96' 3" (29.34m)

Reach depth 74' 8" (22.76m)

Unfolding height 28' 7" (8.71m)

Better Boom Design 4-Section Boom

Lighter and more resilient, Putzmeister’s “smart design” boom 1st section articulation 103˚

incorporates welding seams below the edge of maximum stress. 2nd section articulation 180˚

The boom is engineered to offer the flexibility to adapt to different 3rd section articulation 246˚

loads and features more straight pipe for a less stressful concrete flow 4th section articulation 234˚

and longer wear on parts. The Multi-Z configuration handles space 1st section length 28' 8" (8.74m)

restrictive areas and can pump even if the boom is not fully extended. 2nd section length 25' 3" (7.70m)

3rd section length 25' 4" (7.72m)

9

4th section length 24' 9" (7.54m)

General Specs

Pipeline size (ID) metric ends 5" (125mm)

Rotation 365˚

End hose — length 10' (3m)

End hose — diameter 5" (125mm)

Outrigger spread L - R — front 20' 7" (6.27m)

hydraulically extend out & down

Outrigger spread L - R — rear 21' 8" (6.60m)

hydraulically swing out & extend down

Pump Specifications 36Z.12L 36Z.16H

Output — rod side 142 yd3/hr (109m3/hr) 210 yd3/hr (160m3/hr)

piston side 85 yd3/hr (65m3/hr) 146 yd3/hr (112m3/hr)

Rack and Pinion Slewing Pressure — rod side 1015 psi (70 bar) 1233 psi (85 bar)

piston side 1624 psi (112 bar)• 1885 psi (130 bar)•

The 36Z-Meter boom features a simple mechanical rack

Material cylinder diameter 9" (230mm) 9" (230mm)

and pinion design for improved weight distribution and

Stroke length 83" (2100mm) 83" (2100mm)

easy serviceability. Putting the pump closer to the cab,

Max strokes per minute —

rack and pinion slewing offers greater reach than rotation

rod side 21 31

bearings on lighter weight models. Specially designed

piston side 13 21

teeth in the system offer smooth rotation and prevent

Volume control 0-Full 0-Full

backlash in the swing gears.

Vibrator Standard Standard

Hard-chromed material cylinders Standard Standard

Hydraulic system Free Flow Free Flow

10

Hydraulic system pressure 5075 psi (350 bar) 5075 psi (350 bar)

Differential cylinder diameter 5.1" (130mm) 5.5" (140mm)

Rod diameter 3.1" (80mm) 3.1" (80mm)

Maximum size aggregate 2.5" (63mm) 2.5" (63mm)

Water tank 185 gal (700L) 185 gal (700L)

Maximum theoretical values listed.

* Applies to units mounted on PMA stock truck — MACK MRU 688S

• Standard delivery line system rated at max line pressure of 1233 psi (85 bar)

End hose not to be operated in caution area.

• 116' 9" (35.59m) vertical reach

3 3

• Up to 210 yd /hr (160m /hr) maximum output

Photos and drawings are for illustrative purposes only.

• Versatile 4-section Multi-Z boom design For available options, please refer to price list.

• 5" twin-wall delivery line Authorized Distributor

• Rack and pinion slewing system Putzmeister America, Inc. 12

1733 90th Street

Fuel Economy Sturtevant, WI 53177 USA

Switch gears and save with Putzmeister’s patented Econo-Gear.™ Telephone (262) 886-3200

The exclusive design allows the Mack chassis engine to run at a (800) 884-7210

lower rpm, achieving less stress on wear parts, lower noise levels Facsimile (262) 884-6338

and reduced fuel consumption. Even when pumping a full load, www.putzmeister.com

Econo-Gear makes a significant impact on job site safety and

profitability with an estimated 10-15% savings.

CB 3688 US CB 3688 US Right to make technical amendments reserved. © Putzmeister America, Inc. 2007 Printed in USA (3.50701)

36Z-Meter 5

B O O M P U M P Truck-Mounted Concrete Boom Pump Standard Features

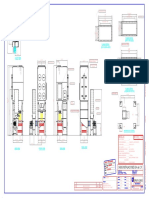

Boom Boom Operation and Control EZ Clean Out RS 907A Hopper S-Valve

F R E E F L O W H Y D R A U L I C S

• 116' 9" (35.59m) vertical reach • Fully proportional HBC radio remote • Large 19.4 cu ft (550L) capacity • Ideal for high pressure applications 6

11

• Low unfolding height • Smooth and precise boom positioning • Hard-faced remixer paddles and harsh mixes

2 9 07

A Oil from Cooler

• Versatile 4-section Multi-Z boom at greater distances • Vibrator • Hard-faced S-Valve

Pedestal Port B

• Manual lubrication • Fully proportional cable remote • Hinged splash guard covers • Gradual 9" to 7" KS

High Pressure

6958

8

with 130' (40m) cable hopper during transit (230 to 180mm) reduction

• Integrated work lights Proximity Switches

• Gauge Port Central (GPC) • Low hopper height allows easy • Thick-walled valve construction

Delivery Line • Modular Boom Controls (MBC) discharge from a mixer truck • Lasting wear over years of use Hydraulic Cylinders

• Equipped with 5" (125mm) • 24V control box • Automatic lubrication

Oil Cooler

twin-wall delivery line on all • Integrated work lights Pedestal

boom sections providing efficient Concrete Pump • Rack and pinion slewing system for better Diverted Oil from Main Pump

concrete delivery • Choose from high pressure or high Outriggers weight distribution, smoother boom rotation Hydraulic Oil Filter

Oil Tank Easy Access Water Box

• Induction-hardened deck pipe volume with the same setup and the potential for greater net reach

• Quick setup on restrictive job sites

with CCI turret elbow • Free flow hydraulic system for smooth, • Fully integrated pedestal design Pump Stroke

• Fully hydraulic outriggers with

• Easy lift-out brackets for simple controllable pumping absorbs all forces High Pressure Side

integral cylinders Boom Pump

Modular Flatpack delivery line replacement • Multi-piece piston cup design • Access opening simplifies changing

• Unique “X” brace outrigger system Material Cylinders

• Standardized elbows and straight of turret pipe Oil to Main Pump

Fully removable, Putzmeister’s modular bolt-on flatpack • Automatic lubrication of the concrete • Front outriggers extend diagonally Agitator

pipe sections • Easy access large single-suction Flushing Valve Pump

and hydraulic system combine versatility and servicing pistons for long service life out and down

convenience. Pump cells can be switched out as jobs • Common component availability filter with indicator gauge Gear Box

• Hard-chromed material cylinders • Rear outriggers swing out and

require or when maintenance is necessary. This feature and easy replacement • Condensation trap in the tank Port A

also provides easier access to the S-Valve and shift cylinders. • Redundant proximity sensor system extend down Main Pumps

for water collection

with function indicators • Four outrigger pads in two Accumulator Pump EZ Clean

Clean Out • Two spacious decks for convenient Out RS 907

3 • Fully adjustable volume control for side compartments Low Pressure

• Fast and easy clean out pipe and hose storage Series

very slow pumping with full concrete • Bubble level indicators Change-over Hose

• Manual lubrication Hopper

• 406 psi (28 bar) hydraulically- pressure and boom speed

driven water pump • Side-mounted aluminum toolboxes Fill Stroke Low

• Modular pump control box S-Valve

• Wash out kit and hose • Integrated work lights

Pressure Side

• Integrated 185 gallon (700L) • Breakaway rear steps

water tank

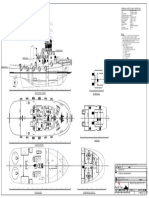

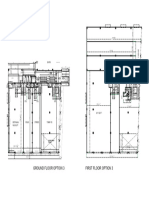

Putzmeister Free Flow Hydraulics in a Closed Loop System

The pumps at the heart of Putzmeister’s free The closed loop also requires far less oil to

flow pumping system are bi-directional, run the system, as a larger reservoir is not

variable displacement piston pumps. necessary to cool all of the oil.

7

Depending on stroke, oil flows in a closed

loop from either port A or port B on the pump Speed and timing are also critical to superior

Convenience and Control to the hydraulic cylinders. performance. Quicker and more responsive

The Frequency Hopping system on the standard HBC proportional

than a hydraulic signal, the electrical system

radio remote ensures minimal interference with other frequency

transmitters. Radiomatic Power Boost further enhances reception Depending on specific pump cell size, up to on a Putzmeister pump minimizes the time it

quality with a 50-100% increase in signal power. A fully proportional The PRO-VANTAGE ® Warranty Plan extends the 20% of the oil leaves the simple closed loop takes to change direction at stroke end.

cable remote is also standard. Unlike other remote control systems, coverage on all Putzmeister BSF boom pumps for a

total of 36 months or 6,600 hours at no extra charge.

system during each stroke through a flushing

the radio and cable remote systems are completely independent,

offering redundancies to ensure complete proportional operation valve on the main pump and cycles to a An electrical signal precisely synchronizes

with either the radio or cable remote in the event of a problem. cooler before it returns to the hydraulic oil the drive cylinders with the accumulator

tank. Removing and cooling only this minimal system that controls the S-Valve in the hopper.

4

amount of oil is possible because, unlike an Reserved energy in a nitrogen bladder sends a

open loop system, the oil flows freely without supercharged blast of oil at precisely the right

passing through any unnecessary valves that moment to facilitate a smooth and fast shift of

can generate heat. the S-Valve from one position to another.

Key Advantages of Putzmeister’s Free Flow Hydraulics:

• Constant pressure on material in the delivery • There is greater pump output due to the

One Boom, Multiple Uses line ensures pumping is smooth and the flow

of concrete is consistent.

efficient use of all available energy.

• Rapid changeover of the stroke means

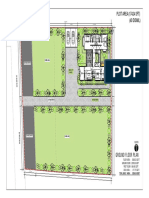

One of our most popular models, the 36Z-Meter offers the best of or fly the boom to a placing tower. Putzmeister’s detach units feature

RS 907A Hopper • The intelligent design eliminates wear-inducing higher outputs, a smoother flow of

everything: great reach, powerful pumping performance and a the quickest and easiest truck-to-tower conversion for greater efficiency.

Putzmeister’s EZ Clean Out RS 907A hopper is engineered for pressure peaks, increases service life and concrete and less boom bounce.

convenient footprint on-site. In addition, this model is available The Series II Detach Boom Kit can be installed with your initial boom

performance and easy maintenance. Offering 19.4 cu. ft. (550L) capacity, makes our pumps extremely powerful.

the hopper features hard-faced remixer paddles and vibrator. The unique as a detach boom to enhance your options – pump from the truck pump order or added at a later date.

design of the splash guard protects the unit from splattering during

pumping and folds down and latches to cover the hopper during transit.

B O O M P U M P

36Z-Meter Truck-Mounted Specifications

Based on Model MACK MRU 688S

with .16H pump cell

Length 36' 7" (11.14m)

13' 1''

(3.99m) Width 8' 2" (2.50m)

36Z-Meter

Height 13' 1" (3.99m)

4' 3'' Wheelbase 215" (5,461mm)

8 (1.28m) Front axle weight 18,951 lbs (8,596kg)

Rear axle weight 36,264 lbs (16,499kg)

Truck-Mounted Concrete Boom Pump 59''

(1508mm)

190''

(4826mm)

50'' 51''

(1270mm) (1295mm)

Approx. total weight 55,215 lbs (25,045kg)

Weights are approximate and include pump, boom, truck, full hydraulic

21' 8''

(6.60m) oil, driver and some fuel. Varies with options selected.

1 215'' 139'' Dimensions will vary with different truck makes, models and specifications.

36Z-Meter

36Z-Meter

(5461mm) (3538mm)

164''

(4172mm)

36' 7'' Boom Specifications • Multi-Z Design

(11.14m) Height & Reach

Vertical reach 116' 9" (35.59m)

Range Diagram Horizontal reach 104' (31.70m)

Reach from front of truck* 96' 3" (29.34m)

Reach depth 74' 8" (22.76m)

Unfolding height 28' 7" (8.71m)

Better Boom Design 4-Section Boom

Lighter and more resilient, Putzmeister’s “smart design” boom 1st section articulation 103˚

incorporates welding seams below the edge of maximum stress. 2nd section articulation 180˚

The boom is engineered to offer the flexibility to adapt to different 3rd section articulation 246˚

loads and features more straight pipe for a less stressful concrete flow 4th section articulation 234˚

and longer wear on parts. The Multi-Z configuration handles space 1st section length 28' 8" (8.74m)

restrictive areas and can pump even if the boom is not fully extended. 2nd section length 25' 3" (7.70m)

3rd section length 25' 4" (7.72m)

9

4th section length 24' 9" (7.54m)

General Specs

Pipeline size (ID) metric ends 5" (125mm)

Rotation 365˚

End hose — length 10' (3m)

End hose — diameter 5" (125mm)

Outrigger spread L - R — front 20' 7" (6.27m)

hydraulically extend out & down

Outrigger spread L - R — rear 21' 8" (6.60m)

hydraulically swing out & extend down

Pump Specifications 36Z.12L 36Z.16H

Output — rod side 142 yd3/hr (109m3/hr) 210 yd3/hr (160m3/hr)

piston side 85 yd3/hr (65m3/hr) 146 yd3/hr (112m3/hr)

Rack and Pinion Slewing Pressure — rod side 1015 psi (70 bar) 1233 psi (85 bar)

piston side 1624 psi (112 bar)• 1885 psi (130 bar)•

The 36Z-Meter boom features a simple mechanical rack

Material cylinder diameter 9" (230mm) 9" (230mm)

and pinion design for improved weight distribution and

Stroke length 83" (2100mm) 83" (2100mm)

easy serviceability. Putting the pump closer to the cab,

Max strokes per minute —

rack and pinion slewing offers greater reach than rotation

rod side 21 31

bearings on lighter weight models. Specially designed

piston side 13 21

teeth in the system offer smooth rotation and prevent

Volume control 0-Full 0-Full

backlash in the swing gears.

Vibrator Standard Standard

Hard-chromed material cylinders Standard Standard

Hydraulic system Free Flow Free Flow

10

Hydraulic system pressure 5075 psi (350 bar) 5075 psi (350 bar)

Differential cylinder diameter 5.1" (130mm) 5.5" (140mm)

Rod diameter 3.1" (80mm) 3.1" (80mm)

Maximum size aggregate 2.5" (63mm) 2.5" (63mm)

Water tank 185 gal (700L) 185 gal (700L)

Maximum theoretical values listed.

* Applies to units mounted on PMA stock truck — MACK MRU 688S

• Standard delivery line system rated at max line pressure of 1233 psi (85 bar)

End hose not to be operated in caution area.

• 116' 9" (35.59m) vertical reach

3 3

• Up to 210 yd /hr (160m /hr) maximum output

Photos and drawings are for illustrative purposes only.

• Versatile 4-section Multi-Z boom design For available options, please refer to price list.

• 5" twin-wall delivery line Authorized Distributor

• Rack and pinion slewing system Putzmeister America, Inc. 12

1733 90th Street

Fuel Economy Sturtevant, WI 53177 USA

Switch gears and save with Putzmeister’s patented Econo-Gear.™ Telephone (262) 886-3200

The exclusive design allows the Mack chassis engine to run at a (800) 884-7210

lower rpm, achieving less stress on wear parts, lower noise levels Facsimile (262) 884-6338

and reduced fuel consumption. Even when pumping a full load, www.putzmeister.com

Econo-Gear makes a significant impact on job site safety and

profitability with an estimated 10-15% savings.

CB 3688 US CB 3688 US Right to make technical amendments reserved. © Putzmeister America, Inc. 2007 Printed in USA (3.50701)

You might also like

- 47M Pump SpecsDocument3 pages47M Pump SpecsJuanNo ratings yet

- 63Z-5 Brochure USDocument6 pages63Z-5 Brochure USCris BandaNo ratings yet

- TBS 130 TB 4119-3 UsDocument2 pagesTBS 130 TB 4119-3 UsFeroz HameedNo ratings yet

- Updated Drawing - 15 JulyDocument1 pageUpdated Drawing - 15 JulynehalNo ratings yet

- LG959 LG958L Wheel Loader BrochureDocument4 pagesLG959 LG958L Wheel Loader BrochureAntonyNo ratings yet

- S500LCVGaint ENDocument2 pagesS500LCVGaint ENEbran AndromedaNo ratings yet

- Horyong Truck Mounted Concrete Pump - CompressedDocument28 pagesHoryong Truck Mounted Concrete Pump - CompressedSetavietnam Setavietnam0% (1)

- 2017puspabarx05617 Mse Co3 Yash GoyalDocument7 pages2017puspabarx05617 Mse Co3 Yash GoyalYash GoyalNo ratings yet

- Deister Plano T006AC1R-GA - R0Document1 pageDeister Plano T006AC1R-GA - R0David100% (1)

- Kentucky Designated Roadways For Truck DriversDocument1 pageKentucky Designated Roadways For Truck DriversWBKONo ratings yet

- FH3 6 - OAI10 - AG 01 ModelDocument1 pageFH3 6 - OAI10 - AG 01 Modelomar javier colunga palominoNo ratings yet

- Principal Particulars - Keppel Bay: E 13.8.15 C.G. Vessel Up-Dated To New Name and LayoutDocument1 pagePrincipal Particulars - Keppel Bay: E 13.8.15 C.G. Vessel Up-Dated To New Name and LayoutmanjuNo ratings yet

- Engine: 800 LX Material Handler W/two Piece 68' (20.73 M) Young AttachmentDocument6 pagesEngine: 800 LX Material Handler W/two Piece 68' (20.73 M) Young AttachmentBart JohnNo ratings yet

- Acad Lotes Cristian 03-Model-A1Document1 pageAcad Lotes Cristian 03-Model-A1Diana Yuleysi Benavidez RubioNo ratings yet

- Loteamiento Indert - Fulgencio Yegros 2-A3Document1 pageLoteamiento Indert - Fulgencio Yegros 2-A3Nadia Macarena Valdez FrancoNo ratings yet

- Shiplift Docking Plan For ICGS VIKRAM - 23032018 (Keel Beam) 1Document2 pagesShiplift Docking Plan For ICGS VIKRAM - 23032018 (Keel Beam) 1Kyaw Win TunNo ratings yet

- S-18-13306 - DR7050 - A - V-169AB-01 Stack (Max.31t)Document3 pagesS-18-13306 - DR7050 - A - V-169AB-01 Stack (Max.31t)Hanif Nur Fauzi MargonoNo ratings yet

- Romeo S1Document1 pageRomeo S1glenn villacruzNo ratings yet

- Tallest Buildings Structures World Throughout History 8 PDFDocument1 pageTallest Buildings Structures World Throughout History 8 PDF1DC20AT025 Ganesh AkshayNo ratings yet

- Ground Floor Plan - Approved1312281787270-ModelDocument1 pageGround Floor Plan - Approved1312281787270-Modelajith kumarNo ratings yet

- A2 - 170gsm Matt - Image Color 1Document1 pageA2 - 170gsm Matt - Image Color 1palaniNo ratings yet

- Topography MapDocument1 pageTopography Mapmr.kyawminwinNo ratings yet

- Parking CirculationDocument1 pageParking CirculationDimpleNo ratings yet

- 7th (Refuge) FLOOR PLAN: Sarthak Patel Municipal Drawings Smt.K.L.Tiwari Coa 4Th Year 18/09/2019 Sheet NoDocument1 page7th (Refuge) FLOOR PLAN: Sarthak Patel Municipal Drawings Smt.K.L.Tiwari Coa 4Th Year 18/09/2019 Sheet Nosarthak patelNo ratings yet

- Elev FinDocument1 pageElev FinDanzel C DayondonNo ratings yet

- El PalmarrDocument1 pageEl PalmarrRUSSHSoftNo ratings yet

- Diagrama HidráulicoDocument1 pageDiagrama Hidráulicostephanie.silvaNo ratings yet

- 8 DuctosDocument1 page8 DuctosSami DominguezNo ratings yet

- AA-25 Anden de Carga BOHDocument1 pageAA-25 Anden de Carga BOHGabriel Yañez JimenezNo ratings yet

- Green Strip RWHDocument1 pageGreen Strip RWHaravindswaroop00No ratings yet

- GBR 2Document1 pageGBR 2Syahrul RomadhonNo ratings yet

- Annex 24 6710 5802339Document1 pageAnnex 24 6710 5802339bharath8006No ratings yet

- Parcel Post ExpoDocument1 pageParcel Post ExpovladimiraNo ratings yet

- Detail 'X'Document1 pageDetail 'X'kunal singhNo ratings yet

- Mesa Verde NPDocument1 pageMesa Verde NPapi-19487128No ratings yet

- A2 - 170gsm Matt - Image Color 3Document1 pageA2 - 170gsm Matt - Image Color 3palaniNo ratings yet

- Palfinger PK 15500 Performance C PDFDocument2 pagesPalfinger PK 15500 Performance C PDFSaajan Samuel Naidu100% (2)

- Option 3Document1 pageOption 3Sunil RawtaniNo ratings yet

- 06 Uke12tenorplanformsDocument1 page06 Uke12tenorplanformsarantxa16No ratings yet

- Salem (H) C&M Division Jurisidiction Map: Dharmapuri DistrictDocument1 pageSalem (H) C&M Division Jurisidiction Map: Dharmapuri DistrictboopathiNo ratings yet

- STC800 SanyDocument3 pagesSTC800 SanySwarup DasNo ratings yet

- SS Master PlanDocument1 pageSS Master Planabir senguptaNo ratings yet

- Highly Portable ScreenerDocument2 pagesHighly Portable ScreenerСтоян МитевNo ratings yet

- B923 Dtw-Build UpDocument1 pageB923 Dtw-Build UpeoqdinizadaNo ratings yet

- GURAVDocument1 pageGURAVApna gharNo ratings yet

- Hastinapuram Residential Cellar PlanDocument1 pageHastinapuram Residential Cellar PlanNagi ReddyNo ratings yet

- Designer Portfolio-7Document29 pagesDesigner Portfolio-7andalibNo ratings yet

- Typical Floor PlanDocument1 pageTypical Floor PlanShashanktsNo ratings yet

- DV Seatless Piston Valve AO 3inch - 150 Lbs 5 Inches PEDocument1 pageDV Seatless Piston Valve AO 3inch - 150 Lbs 5 Inches PELUCAS100% (1)

- App PlanDocument1 pageApp PlanMohamed AbuthalibNo ratings yet

- Toyota-Corolla 1998 en US Diagrama Electrico Tablero B55a406dbcDocument2 pagesToyota-Corolla 1998 en US Diagrama Electrico Tablero B55a406dbcJulio huanriNo ratings yet

- Existing Layout PlanDocument1 pageExisting Layout PlancinchmakNo ratings yet

- Gray PlatformsDocument1 pageGray Platformsapi-319390606No ratings yet

- Single Line Sistem Sulselra 2015Document1 pageSingle Line Sistem Sulselra 2015fadelNo ratings yet

- KDK MP 19 A PDFDocument2 pagesKDK MP 19 A PDFrafael_figueroaNo ratings yet

- Kubota Tier III Engine, 40km/hr Ensure Unrivalled Driving AbilityDocument2 pagesKubota Tier III Engine, 40km/hr Ensure Unrivalled Driving AbilityPronto AccessNo ratings yet

- Fourth Floor PlanDocument1 pageFourth Floor Planvenkatalakshmi natarasanNo ratings yet

- Borrador 1Document1 pageBorrador 1Kevin Ademir Fuertez MamaniNo ratings yet

- Ground Floor LayoutDocument1 pageGround Floor LayoutAnkit KujurNo ratings yet

- Basic Ship TheoryDocument83 pagesBasic Ship TheorySidik SetiawanNo ratings yet

- Speed Time Curve - TractionDocument36 pagesSpeed Time Curve - TractionAlok Jain100% (2)

- Varroc Group PresentationDocument14 pagesVarroc Group PresentationvijaysinhjagtapNo ratings yet

- K VJKZ JKB Wu K&&M: Mvwywzk MGM Vi G WJK ÁvbDocument75 pagesK VJKZ JKB Wu K&&M: Mvwywzk MGM Vi G WJK ÁvbRajin Mahmud KhanNo ratings yet

- 815 F.2d 918 1987 A.M.C. 1521Document11 pages815 F.2d 918 1987 A.M.C. 1521Scribd Government DocsNo ratings yet

- Surveying ReviewerDocument65 pagesSurveying ReviewerJAYVEE LASCUNANo ratings yet

- Jeppview For Windows: List of Pages in This Trip KitDocument61 pagesJeppview For Windows: List of Pages in This Trip KitJosé Alejandro Díaz Espinosa100% (1)

- New York Tourist Map PDFDocument1 pageNew York Tourist Map PDFRaquelNo ratings yet

- Aventador Oil ChangeDocument4 pagesAventador Oil Changeharmeet kaur100% (2)

- NHW 4e Upp-Int WB Answer KeyDocument12 pagesNHW 4e Upp-Int WB Answer KeySophia KastrovskayaNo ratings yet

- Quick User's Guide For DH-VO... K1 Dump-Through: 1 - IntroductionDocument5 pagesQuick User's Guide For DH-VO... K1 Dump-Through: 1 - Introductionניקולאי איןNo ratings yet

- Cali BookDocument16 pagesCali BookHitesh MalikNo ratings yet

- Infraset Product Catalogue (2014)Document55 pagesInfraset Product Catalogue (2014)Christian JordaanNo ratings yet

- Sales Order Life CycleDocument44 pagesSales Order Life Cyclemoin786mirzaNo ratings yet

- Vector Shipping Cor V Adelfo MacasaDocument2 pagesVector Shipping Cor V Adelfo Macasasmtm06100% (2)

- Honda City Hatchback 2022 PriceDocument1 pageHonda City Hatchback 2022 PriceAlice TanNo ratings yet

- Ghana PortDocument36 pagesGhana PortRavi KumarNo ratings yet

- Significance of Lipids in Biological Membranes and Transport MechanismsDocument9 pagesSignificance of Lipids in Biological Membranes and Transport Mechanismsroshan khan100% (2)

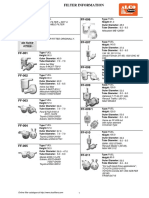

- Filter InformationDocument255 pagesFilter InformationHari NotoNo ratings yet

- Training Package On Power, Auxiliary and Control Circuit of AC Electric Locomotive PDFDocument64 pagesTraining Package On Power, Auxiliary and Control Circuit of AC Electric Locomotive PDFVikas RanaNo ratings yet

- Megapolis Plan Jan16 EnglishDocument116 pagesMegapolis Plan Jan16 Englishariyamanjula2914No ratings yet

- Rig Move Procedures DevelopmentDocument31 pagesRig Move Procedures DevelopmentCarlos Santos100% (1)

- Loco Diesel Shed PuleraDocument23 pagesLoco Diesel Shed PuleraAnupamNo ratings yet

- Four Wheel SteeringDocument7 pagesFour Wheel SteeringsamratsamudraguptaNo ratings yet

- ICBC - Proving Your Driving Experience PDFDocument1 pageICBC - Proving Your Driving Experience PDFbianca7sallesNo ratings yet

- Your Boarding Pass To Jakarta - ETIHAD AIRWAYSDocument2 pagesYour Boarding Pass To Jakarta - ETIHAD AIRWAYSKrishna Kalyan dakiNo ratings yet

- International Trade Compliance: Paris, ESGCI - 4SCM - Feb.8 2021Document48 pagesInternational Trade Compliance: Paris, ESGCI - 4SCM - Feb.8 2021Amine loubabNo ratings yet

- Unicornchet - Alphabet EngDocument33 pagesUnicornchet - Alphabet Engsweet.cahrolNo ratings yet

- DP Requirements For Drilling and Intervention UnitsDocument38 pagesDP Requirements For Drilling and Intervention UnitsRoyNo ratings yet

- Dry Bulk Cargo Handling in Perlis PortDocument5 pagesDry Bulk Cargo Handling in Perlis PortShahrul ShafiqNo ratings yet