Professional Documents

Culture Documents

Tabel Mas Dede

Uploaded by

Tiara NurmalidhaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tabel Mas Dede

Uploaded by

Tiara NurmalidhaCopyright:

Available Formats

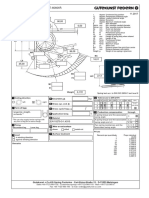

Roughing 𝛻 Finishing 𝛻𝛻

Depth of cut Depth of cut Coolant and

α :о 4˙˙˙10˙s α . 2˙˙˙S ˙s lubricant for

Cutting

Cutting Speed

Cutting Speed

Material Angles

v m min U

Tool

Depth of cut

Depth of cut

v m min U

Roughing Finishing

s mm U

s mm U

α mm

α mm

Feed

Feed

ᵒ β γ 𝛻 𝛻𝛻

Steel W 6̊ 62̊ 20̊ 14 0.5 4 20 0.2 1

Strength HSS 22 1 10 30 0.5 1 E E о.P

50 kg/mm2 H 5̊ 67̊ 18̊ 150 2.5 15 250 0.25 1.9

W 8̊ 68̊ 14̊ 10 0.5 4 15 0.2 1

50 – 70 kg/mm2 HSS 20 1 10 24 0.5 1 E E о.P

H 5̊ 75̊ 10̊ 120 2.5 15 200 0.25 1.5

14̊

W 8̊ 68̊ 8 0.5 4 12 0.2 1

70 – 85 kg/mm2 HSS 15 1 10 20 0.5 1 E E о.P

10̊

H 5̊ 75̊ 80 2 15 140 0.2 1.5

W 8̊ 76̊ 6̊ 6 0.5 3 8 0.2 1

Tool steel HSS 12 1 8 16 0.5 1 E E о.P

H 5̊ 79̊ 6̊ 30 0.6 5 50 0.15 1

W = Tool steel H = Cemended carbide R = Rape-seed oil

dr = dry

Hss = High – speed steel E = Diluted soluble oil P = Kerosene

For thread cutting v will be about 1⁄2 of the cutting speed for longitudinal turning

You might also like

- Motor Handle For Manual Rotating RBSDocument1 pageMotor Handle For Manual Rotating RBSIrfhan FebrianNo ratings yet

- K 5Document44 pagesK 5Ricardo Rincon Vega100% (1)

- (MM) (Nos) Total KG (MM) (Nos) Total KG KG / PC KG / PC: HMG / Ministry of Local DevelopmentDocument1 page(MM) (Nos) Total KG (MM) (Nos) Total KG KG / PC KG / PC: HMG / Ministry of Local DevelopmentRanjit Kumar ShahNo ratings yet

- Corniere Equal LegDocument7 pagesCorniere Equal LegVonjinantenaina VolamalalaNo ratings yet

- Split Plummer Block Housings SNL and SE Series For Bearings On An Adapter Sleeve With Standard Seals-SE 507-606 + 1306 K + H 306Document2 pagesSplit Plummer Block Housings SNL and SE Series For Bearings On An Adapter Sleeve With Standard Seals-SE 507-606 + 1306 K + H 306AbhishekNo ratings yet

- Metric DIN 6885 SpecDocument4 pagesMetric DIN 6885 SpecDobrica PetrovicNo ratings yet

- Z-Carb JetStream SpeedFeedDocument2 pagesZ-Carb JetStream SpeedFeedalphatoolsNo ratings yet

- Time Study of Gate Valve Body 24X150 1setupDocument4 pagesTime Study of Gate Valve Body 24X150 1setupdada kolekarNo ratings yet

- Din 9427 - Metric Socket Button Head Cap ScrewsDocument1 pageDin 9427 - Metric Socket Button Head Cap ScrewsAlexis BarolinNo ratings yet

- Saw Blades and Bevel Cutters For GF and RA MachinesDocument5 pagesSaw Blades and Bevel Cutters For GF and RA MachinesVan DantNo ratings yet

- Fisa Tehnica Freza AntiexDocument1 pageFisa Tehnica Freza AntiexMihai PersinaruNo ratings yet

- The Production Solution For High-Precision Micro-Threads From Diameter M1.0Document5 pagesThe Production Solution For High-Precision Micro-Threads From Diameter M1.0Marcos PauloNo ratings yet

- CC Class I CapacitoresDocument5 pagesCC Class I CapacitoresCicero MelloNo ratings yet

- EPSM CR W PN EbookDocument12 pagesEPSM CR W PN EbookRJAP85No ratings yet

- Hexagon Socket Head Cap Screws: (Technical Data)Document1 pageHexagon Socket Head Cap Screws: (Technical Data)ilo iloNo ratings yet

- BearingDocument2 pagesBearingLeo FirstsonNo ratings yet

- MC Gill Cam Follower BearingsDocument2 pagesMC Gill Cam Follower BearingsRaphael RezendeNo ratings yet

- Din 1705Document2 pagesDin 1705venkatesan veerasamyNo ratings yet

- Tabela VCorte RecartilhadoDocument1 pageTabela VCorte Recartilhadocaeiro60No ratings yet

- UNP UPN DatasheetDocument3 pagesUNP UPN DatasheetHaytham SemaanNo ratings yet

- About WELDA Anchor PlateDocument1 pageAbout WELDA Anchor PlateFircijevi KurajberiNo ratings yet

- Fraisage Carbure Face MillDocument15 pagesFraisage Carbure Face MillJeremybelangerNo ratings yet

- 【Discontinued Model】SCS Series (1MB)Document38 pages【Discontinued Model】SCS Series (1MB)phanuekmkwaptNo ratings yet

- Z-Carb Corner Radius SpeedFeedDocument2 pagesZ-Carb Corner Radius SpeedFeedalphatoolsNo ratings yet

- Bushing QD SpecDocument11 pagesBushing QD Speceng_moh04No ratings yet

- BC-LP-001 2021-22Document2 pagesBC-LP-001 2021-22Ravikant YadavNo ratings yet

- Bbs 2Document1 pageBbs 2srikanth varmaNo ratings yet

- Metric Low Head CapDocument1 pageMetric Low Head CapBala Lakshman0% (1)

- SBD Plummer Block Housings For Bearings On An Adapter Sleeve and A Stepped Shaft - TCM - 12-231180Document3 pagesSBD Plummer Block Housings For Bearings On An Adapter Sleeve and A Stepped Shaft - TCM - 12-231180gopalNo ratings yet

- SBD Plummer Block Housings For Bearings On An Adapter Sleeve and A Stepped Shaft - TCM - 12-231180Document3 pagesSBD Plummer Block Housings For Bearings On An Adapter Sleeve and A Stepped Shaft - TCM - 12-231180gopalNo ratings yet

- Datasheet Mola de Torção 16161RDocument1 pageDatasheet Mola de Torção 16161RBruno SantosNo ratings yet

- Practice01 01: Din Standerd - N5Document1 pagePractice01 01: Din Standerd - N5ابراهيم الزهرانيNo ratings yet

- Cobalt Catalog Forged-Chains-SprocketsDocument12 pagesCobalt Catalog Forged-Chains-SprocketsporometalNo ratings yet

- 300p9010034e - BZZ HydroDocument1 page300p9010034e - BZZ HydroEng-Mohammed SalemNo ratings yet

- THD Take-Up Housings For Spherical Roller Bearings On An Adapter Sleeve and A Plain Shaft - TCM - 12-231181 PDFDocument2 pagesTHD Take-Up Housings For Spherical Roller Bearings On An Adapter Sleeve and A Plain Shaft - TCM - 12-231181 PDFJorge A VilalNo ratings yet

- CNC Collet Chuck CatalagueDocument6 pagesCNC Collet Chuck CatalaguethingsneededforNo ratings yet

- Catalogo 2 MicrotechDocument30 pagesCatalogo 2 MicrotechDavid GüdelNo ratings yet

- Cotter PinsDocument1 pageCotter Pinsdiyanto AntoNo ratings yet

- Holding Bar (Optional) : Back Plunger Type Dial Indicators Series 1Document1 pageHolding Bar (Optional) : Back Plunger Type Dial Indicators Series 1somkiat kongprasiatNo ratings yet

- Acople 5R10Document1 pageAcople 5R10Jose Emilio Carrero AngaritaNo ratings yet

- Bolt A325 A490 PDFDocument2 pagesBolt A325 A490 PDFmostapha soubraNo ratings yet

- Chaín AgriculturalDocument3 pagesChaín AgriculturalWilheam Mamani CasillaNo ratings yet

- Metric Fasteners: K-Lock Nut W/ Free Spinning External Tooth LWDocument1 pageMetric Fasteners: K-Lock Nut W/ Free Spinning External Tooth LWYossiNo ratings yet

- ASME-18.2.6 Dimension STD For ASTM 325 Inch BoltDocument1 pageASME-18.2.6 Dimension STD For ASTM 325 Inch BoltFouad AliNo ratings yet

- Carbitool Catalogue 2020Document184 pagesCarbitool Catalogue 2020AustechsawNo ratings yet

- Cover Assy. SAI Valve-N7040290Document22 pagesCover Assy. SAI Valve-N7040290M Senthil SenthilNo ratings yet

- Dimensions Mechanical & Performance RequirementsDocument7 pagesDimensions Mechanical & Performance RequirementsLorena PessanhaNo ratings yet

- Tme RX: Technical Data SheetDocument3 pagesTme RX: Technical Data SheetEnrique HortaNo ratings yet

- Catalog EDocument315 pagesCatalog EUsman HamidNo ratings yet

- ISO 2768 Machining Tolerance StandardDocument2 pagesISO 2768 Machining Tolerance Standardlohith.raviNo ratings yet

- AS3600 Punching - PS1Document1 pageAS3600 Punching - PS1Yugatheeran ThavaratnasingamNo ratings yet

- Detail "A" Barrel Details: Ext Ext Ext Ext ExtDocument1 pageDetail "A" Barrel Details: Ext Ext Ext Ext Extton carolinoNo ratings yet

- Turnbuckle AssembliesDocument4 pagesTurnbuckle AssembliesarbiNo ratings yet

- Data Expansion Joint (Bellows)Document3 pagesData Expansion Joint (Bellows)Sreesanth SaruvilNo ratings yet

- Technical Information: Various Kinds of Bending Processes Various Kinds of Bending ProcessesDocument2 pagesTechnical Information: Various Kinds of Bending Processes Various Kinds of Bending ProcessesأبومحمدالزياتNo ratings yet

- 01.01. 100mm Dia. Water Meter Assembly. (Strainer)Document1 page01.01. 100mm Dia. Water Meter Assembly. (Strainer)Amadou MokshaNo ratings yet

- Catalog of Milling Solution 2020Document31 pagesCatalog of Milling Solution 2020vedrenne92No ratings yet

- Hyundai Steel Products GuideDocument40 pagesHyundai Steel Products GuidecarloNo ratings yet

- Database Management Systems: Understanding and Applying Database TechnologyFrom EverandDatabase Management Systems: Understanding and Applying Database TechnologyRating: 4 out of 5 stars4/5 (8)

- The RBG Blueprint For Black Power Study Cell GuidebookDocument8 pagesThe RBG Blueprint For Black Power Study Cell GuidebookAra SparkmanNo ratings yet

- LM2576/LM2576HV Series Simple Switcher 3A Step-Down Voltage RegulatorDocument21 pagesLM2576/LM2576HV Series Simple Switcher 3A Step-Down Voltage RegulatorcgmannerheimNo ratings yet

- 50114a Isolemfi 50114a MonoDocument2 pages50114a Isolemfi 50114a MonoUsama AwadNo ratings yet

- Case Study 2Document5 pagesCase Study 2api-247285537100% (1)

- Radon-222 Exhalation From Danish Building Material PDFDocument63 pagesRadon-222 Exhalation From Danish Building Material PDFdanpalaciosNo ratings yet

- Fundamentals of Public Health ManagementDocument3 pagesFundamentals of Public Health ManagementHPMA globalNo ratings yet

- UT Dallas Syllabus For Govt4396.002.08s Taught by Gregory Thielemann (Gregt)Document2 pagesUT Dallas Syllabus For Govt4396.002.08s Taught by Gregory Thielemann (Gregt)UT Dallas Provost's Technology GroupNo ratings yet

- CV & Surat Lamaran KerjaDocument2 pagesCV & Surat Lamaran KerjaAci Hiko RickoNo ratings yet

- Friction: Ultiple Hoice UestionsDocument5 pagesFriction: Ultiple Hoice Uestionspk2varmaNo ratings yet

- postedcontentadminuploadsFAQs20for20Organization PDFDocument10 pagespostedcontentadminuploadsFAQs20for20Organization PDFMohd Adil AliNo ratings yet

- Mosfet Irfz44Document8 pagesMosfet Irfz44huynhsang1979No ratings yet

- Perancangan Crushing Plant Batu Andesit Di PT Nurmuda Cahaya Desa Batujajar Timur Kecamatan Batujajar Kabupaten Bandung Barat Provinsi Jawa BaratDocument8 pagesPerancangan Crushing Plant Batu Andesit Di PT Nurmuda Cahaya Desa Batujajar Timur Kecamatan Batujajar Kabupaten Bandung Barat Provinsi Jawa BaratSutan AdityaNo ratings yet

- Progressive Muscle RelaxationDocument4 pagesProgressive Muscle RelaxationEstéphany Rodrigues ZanonatoNo ratings yet

- 20-Admission of PatientDocument3 pages20-Admission of Patientakositabon100% (1)

- NCP - Major Depressive DisorderDocument7 pagesNCP - Major Depressive DisorderJaylord Verazon100% (1)

- Miguel Augusto Ixpec-Chitay, A097 535 400 (BIA Sept. 16, 2013)Document22 pagesMiguel Augusto Ixpec-Chitay, A097 535 400 (BIA Sept. 16, 2013)Immigrant & Refugee Appellate Center, LLCNo ratings yet

- Triaxial Shear TestDocument10 pagesTriaxial Shear TestAfiqah Nu'aimiNo ratings yet

- ML Ass 2Document6 pagesML Ass 2Santhosh Kumar PNo ratings yet

- Sandstorm Absorbent SkyscraperDocument4 pagesSandstorm Absorbent SkyscraperPardisNo ratings yet

- Presentation About GyroscopesDocument24 pagesPresentation About GyroscopesgeenjunkmailNo ratings yet

- Literatura Tecnica 3Document10 pagesLiteratura Tecnica 3Christian PerezNo ratings yet

- Physics Education Thesis TopicsDocument4 pagesPhysics Education Thesis TopicsPaperWriterServicesCanada100% (2)

- Clockwork Dragon's Expanded ArmoryDocument13 pagesClockwork Dragon's Expanded Armoryabel chabanNo ratings yet

- Quarter 1-Week 2 - Day 2.revisedDocument4 pagesQuarter 1-Week 2 - Day 2.revisedJigz FamulaganNo ratings yet

- Recitation Math 001 - Term 221 (26166)Document36 pagesRecitation Math 001 - Term 221 (26166)Ma NaNo ratings yet

- Unsuccessful MT-SM DeliveryDocument2 pagesUnsuccessful MT-SM DeliveryPitam MaitiNo ratings yet

- Rana2 Compliment As Social StrategyDocument12 pagesRana2 Compliment As Social StrategyRanaNo ratings yet

- 2016 Closing The Gap ReportDocument64 pages2016 Closing The Gap ReportAllan ClarkeNo ratings yet

- Man and Historical ActionDocument4 pagesMan and Historical Actionmama.sb415No ratings yet

- Miniature Daisy: Crochet Pattern & InstructionsDocument8 pagesMiniature Daisy: Crochet Pattern & Instructionscaitlyn g100% (1)