Professional Documents

Culture Documents

RESULTS Metrology Part 2

RESULTS Metrology Part 2

Uploaded by

Sarra Noraizeddin0 ratings0% found this document useful (0 votes)

3 views2 pagesThe document presents results from measuring the dimensions of injection molded workpieces. Figure 1 shows the dimensions being measured on parts A through E. Table 1 lists the nominal dimensions from the mold and actual measured dimensions. Table 2 then calculates the percentage error between the nominal and actual dimensions for each part and dimension. The largest percentage error was 1.54% for the point to point dimension of part A, while the other errors were all under 1%.

Original Description:

metrology

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document presents results from measuring the dimensions of injection molded workpieces. Figure 1 shows the dimensions being measured on parts A through E. Table 1 lists the nominal dimensions from the mold and actual measured dimensions. Table 2 then calculates the percentage error between the nominal and actual dimensions for each part and dimension. The largest percentage error was 1.54% for the point to point dimension of part A, while the other errors were all under 1%.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views2 pagesRESULTS Metrology Part 2

RESULTS Metrology Part 2

Uploaded by

Sarra NoraizeddinThe document presents results from measuring the dimensions of injection molded workpieces. Figure 1 shows the dimensions being measured on parts A through E. Table 1 lists the nominal dimensions from the mold and actual measured dimensions. Table 2 then calculates the percentage error between the nominal and actual dimensions for each part and dimension. The largest percentage error was 1.54% for the point to point dimension of part A, while the other errors were all under 1%.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

RESULTS

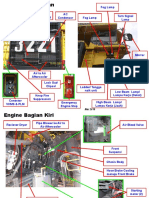

a)

B A

E C

Figure 1: Dimension of workpiece

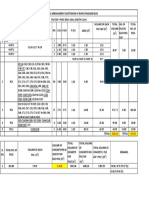

Part Dimensions Injection Dimensions Actual (mm)

Moulding (mm)

A (Pt to Pt) 62.59 63.57

A (Ln to Pt) 62.58 63.55

B 29.69(diameter) 29.83 (diameter)

C (Pt to Pt) 90.44 90.67

C (Ln to Pt) 90.35 90.63

D (Pt to Pt) 62.95 63.10

D (Ln to Pt) 62.91 63.07

E (Pt to Pt) 90.37 90.65

E (Ln to Pt) 90.37 90.64

Table 1: Dimensions workpiece

Example Calculation:

𝐼𝑛𝑗𝑒𝑐𝑡𝑖𝑜𝑛 𝑚𝑜𝑢𝑙𝑑𝑖𝑛𝑔 𝑑𝑖𝑚𝑒𝑛𝑠𝑖𝑜𝑛 − 𝑎𝑐𝑡𝑢𝑎𝑙 𝑑𝑖𝑚𝑒𝑛𝑠𝑖𝑜𝑛

𝑃𝑒𝑟𝑐𝑒𝑛𝑡𝑎𝑔𝑒 𝑒𝑟𝑟𝑜𝑟 = | | × 100%

𝑎𝑐𝑡𝑢𝑎𝑙 𝑑𝑖𝑚𝑒𝑛𝑠𝑖𝑜𝑛

62.59 − 63.57

=| | × 100%

63.57

= 1.54%

Part Dimensions Dimensions Actual Percentage Error

Injection (mm) (%)

Moulding (mm)

A (Pt to Pt) 62.59 63.57 1.54

A (Ln to Pt) 62.58 63.55 1.53

B 29.69(diameter) 29.83 (diameter) 0.47

C (Pt to Pt) 90.44 90.67 0.25

C (Ln to Pt) 90.35 90.63 0.31

D (Pt to Pt) 62.95 63.10 0.24

D (Ln to Pt) 62.91 63.07 0.25

E (Pt to Pt) 90.37 90.65 0.31

E (Ln to Pt) 90.37 90.64 0.30

Table 2:Dimensions with percentage error workpiece

You might also like

- Test Bank For Immunology and Serology in Laboratory Medicine 4th Edition TurgeonDocument24 pagesTest Bank For Immunology and Serology in Laboratory Medicine 4th Edition TurgeonDavidLarsonDDSfgaq100% (42)

- Lab Test Results SummaryDocument1 pageLab Test Results SummaryYogie Fian ZahriNo ratings yet

- V Lift Presentation JBPDocument9 pagesV Lift Presentation JBPrekyhoffman0% (1)

- Roland KC-350 Parts List DespieceDocument31 pagesRoland KC-350 Parts List Despiecelperez_110824No ratings yet

- 3 - Heating - Calculation - Tool - EmptyDocument7 pages3 - Heating - Calculation - Tool - EmptyThaigroup CementNo ratings yet

- KOMPONEN - HD785-7 SippDocument23 pagesKOMPONEN - HD785-7 Sippziky dun100% (1)

- Delhi NCR Hni Sample WF Ns.Document6 pagesDelhi NCR Hni Sample WF Ns.Soumen BeraNo ratings yet

- Iec 61241-14.2004Document42 pagesIec 61241-14.2004Leonardo Gonçalves GomideNo ratings yet

- IntertextDocument17 pagesIntertextJamailla MelendrezNo ratings yet

- Name Project Schedule of Borepile: Rebart Length (M) L1 L2 L3 L4Document4 pagesName Project Schedule of Borepile: Rebart Length (M) L1 L2 L3 L4donny chandraNo ratings yet

- 3DPIPE-r Srini (Baf)Document11 pages3DPIPE-r Srini (Baf)babuNo ratings yet

- 3DPIPE-r Srini (Baf)Document11 pages3DPIPE-r Srini (Baf)babuNo ratings yet

- ANOVADocument3 pagesANOVAChristian M. MortelNo ratings yet

- Lab Report1Document5 pagesLab Report1Aisha NurymgaliNo ratings yet

- FootingDocument7 pagesFootingHsaam HsaamNo ratings yet

- Grafik Impact HusniDocument5 pagesGrafik Impact HusniHusni Dey HaqNo ratings yet

- 1 PDFDocument1 page1 PDFID SkechtNo ratings yet

- DOE-Factorial Design R6Document8 pagesDOE-Factorial Design R6Anju AmbekarNo ratings yet

- WORKSHOP 9 - SAG SABC Circuit Model Fit: FlowsheetDocument4 pagesWORKSHOP 9 - SAG SABC Circuit Model Fit: FlowsheetFer MabNo ratings yet

- #MOCK JEE Main Practice Test-21 - Errors & ExperimentsDocument5 pages#MOCK JEE Main Practice Test-21 - Errors & ExperimentsNP VijayNo ratings yet

- MISMO Preparation 14th Nov, 22Document22 pagesMISMO Preparation 14th Nov, 22Raeed khanNo ratings yet

- Regresi BergandaDocument2 pagesRegresi BergandaAbigail GultomNo ratings yet

- IMS - Baseline PM62LN EN 2017Document1 pageIMS - Baseline PM62LN EN 2017Sahrul RomadhonNo ratings yet

- 01 Belt Con ZTB2 WDocument2 pages01 Belt Con ZTB2 WBùi Hắc HảiNo ratings yet

- Limestone Limestone Clinker Mixed Mat. Mixed Mat. ClayDocument2 pagesLimestone Limestone Clinker Mixed Mat. Mixed Mat. ClayBùi Hắc HảiNo ratings yet

- Engineering Surveying Engg5051 2008 s2 (1) - DipCivil-FormulaSheetDocument7 pagesEngineering Surveying Engg5051 2008 s2 (1) - DipCivil-FormulaSheetDonNo ratings yet

- Chapter # 9Document8 pagesChapter # 9meerab zahidNo ratings yet

- THINDocument1 pageTHIN64010675No ratings yet

- Soil Mechanics - Chapter 2 ExamplesDocument12 pagesSoil Mechanics - Chapter 2 ExamplesSelino CruzNo ratings yet

- Physics 73.1 R&D Part 2Document4 pagesPhysics 73.1 R&D Part 2ggwp21No ratings yet

- Cycl2000Document2 pagesCycl2000John TauloNo ratings yet

- Results:: Graph of Percentage Finer Passing Against Sieve SizeDocument6 pagesResults:: Graph of Percentage Finer Passing Against Sieve SizeLim KElvinNo ratings yet

- Design and Analysis of Experiments 8th Edition Montgomery Solutions ManualDocument26 pagesDesign and Analysis of Experiments 8th Edition Montgomery Solutions Manualjamesreedycemzqadtp96% (23)

- MetnumDocument25 pagesMetnumNissa OktaviaNo ratings yet

- Fluid FrictionDocument11 pagesFluid FrictionChandni SeelochanNo ratings yet

- Measurements Yaqeen Batch-IIDocument7 pagesMeasurements Yaqeen Batch-IIMuhammad TahirNo ratings yet

- DCC20063 - AssignmentDocument6 pagesDCC20063 - Assignmentdelvinceimpin796No ratings yet

- Kurva Analisa Saringan: Diameter Partikel (MM)Document11 pagesKurva Analisa Saringan: Diameter Partikel (MM)A FenoldiNo ratings yet

- Dimensions of Sprocket: Single-Strand Double-Strand Quadrup-StrandDocument1 pageDimensions of Sprocket: Single-Strand Double-Strand Quadrup-Strandวิทวัส นิเทียนNo ratings yet

- Physics Lab 3 Motion Along RampDocument3 pagesPhysics Lab 3 Motion Along RampKestin ComeauxNo ratings yet

- Black Book For MathematicsDocument171 pagesBlack Book For Mathematicsgargimane811No ratings yet

- Pipes & Fittings Astm: Product CatalogueDocument12 pagesPipes & Fittings Astm: Product CatalogueSanjeev GoelNo ratings yet

- ChocolatosDocument1 pageChocolatosHariyono Rudi NovantoNo ratings yet

- TheoryDocument63 pagesTheoryNavin RaiNo ratings yet

- In-Lab Sharp-Edged Orifice Meter ReportDocument9 pagesIn-Lab Sharp-Edged Orifice Meter ReportLiliane AlameddineNo ratings yet

- Errors - (1 To 50) VERNIER, SCREW GAUGEDocument6 pagesErrors - (1 To 50) VERNIER, SCREW GAUGEadvaitkshirasgar786No ratings yet

- Coal Resources (SR)Document1 pageCoal Resources (SR)Jagat RayaNo ratings yet

- Studs & Runner Table-0.5 MMDocument1 pageStuds & Runner Table-0.5 MMvtalexNo ratings yet

- R FDocument1 pageR FBagus SusantoNo ratings yet

- Vernier Callipers Prac 1Document35 pagesVernier Callipers Prac 1Shaik Ismail BashaNo ratings yet

- Dynamic Cone Penetrometer TestDocument3 pagesDynamic Cone Penetrometer TestArdyan BadrizaNo ratings yet

- Unit and Dimentions QueDocument11 pagesUnit and Dimentions Quekadamshlok462No ratings yet

- Highway Laboratory Civil Engineering Department: Practical 1: Elongation Index TestDocument2 pagesHighway Laboratory Civil Engineering Department: Practical 1: Elongation Index TestKayaNo ratings yet

- Important QuestionsDocument36 pagesImportant QuestionsKimbu DragonNo ratings yet

- Teardown Dec 12th, 2022Document1 pageTeardown Dec 12th, 2022zunnajmi bimasetyoNo ratings yet

- Week 4 Detailed SolutionDocument8 pagesWeek 4 Detailed Solutionrvrconsultancy2003No ratings yet

- Properties of Triangular PurlinDocument4 pagesProperties of Triangular PurlinMN ChandrasekaranNo ratings yet

- FM200 Cal1Document2 pagesFM200 Cal1Flash GuaranteeNo ratings yet

- Batas Cair: Konsistensi Tanah (Atterberg Limit Test) Astm 4318 Batas Cair (LL)Document5 pagesBatas Cair: Konsistensi Tanah (Atterberg Limit Test) Astm 4318 Batas Cair (LL)dzakirezaharbaNo ratings yet

- Applied Physics Lab Lab 03: Compound Pendulum: Section: BEE-10A Group: B4 Group MembersDocument6 pagesApplied Physics Lab Lab 03: Compound Pendulum: Section: BEE-10A Group: B4 Group MembersAli Haider100% (1)

- Physics Expt 0 - Vernier and Screw GaugeDocument7 pagesPhysics Expt 0 - Vernier and Screw GaugeDebayan MaitiNo ratings yet

- RicisDocument1 pageRicisHariyono Rudi NovantoNo ratings yet

- Truebeam Solid Phantom Measurements: 20 1013.2 T P (Pa)Document5 pagesTruebeam Solid Phantom Measurements: 20 1013.2 T P (Pa)ismaileldesokygodaNo ratings yet

- Roof Beam Design CalculationDocument11 pagesRoof Beam Design CalculationArnold VercelesNo ratings yet

- Marshall Stability Test PDFDocument8 pagesMarshall Stability Test PDFAnonymous FO4sHLLONo ratings yet

- W3schools: HTML5 IntroductionDocument7 pagesW3schools: HTML5 Introductionanon_723287062No ratings yet

- 4 P's of Rural MarketingDocument45 pages4 P's of Rural Marketingsushantgawali0% (2)

- Facturaev3 2 2bDocument81 pagesFacturaev3 2 2bJulian Martin De MingoNo ratings yet

- Department of Labor: 05 097Document8 pagesDepartment of Labor: 05 097USA_DepartmentOfLaborNo ratings yet

- Gas Solubility in Dilute Solutions: A Novel Molecular Thermodynamic PerspectiveDocument17 pagesGas Solubility in Dilute Solutions: A Novel Molecular Thermodynamic PerspectiveTiên PhạmNo ratings yet

- Handbook3 VitaminA-1 PDFDocument5 pagesHandbook3 VitaminA-1 PDFJorge Luis RodríguezNo ratings yet

- Medical Technologist Career JournalDocument3 pagesMedical Technologist Career Journalapi-262497770No ratings yet

- AdverbDocument3 pagesAdverbKadarAwalehNo ratings yet

- LM64P89L SharpElectrionicComponentsDocument25 pagesLM64P89L SharpElectrionicComponentshome madeNo ratings yet

- Paysliper Template Grid2Document5 pagesPaysliper Template Grid2Jeeva KumarNo ratings yet

- Applications in Ch4Document7 pagesApplications in Ch4(FU HCM) Trần Thanh HiệpNo ratings yet

- Hard Drawn Steel WireDocument13 pagesHard Drawn Steel WireKristoffer MosshedenNo ratings yet

- Linear OrganizationDocument30 pagesLinear OrganizationNikhila SomankoppaNo ratings yet

- Arctic ExplorerDocument10 pagesArctic ExploreradventurecanadaNo ratings yet

- Copper-Alloy Plate and Sheet For Pressure Vessels, Condensers, and Heat ExchangersDocument7 pagesCopper-Alloy Plate and Sheet For Pressure Vessels, Condensers, and Heat ExchangersSharad KokateNo ratings yet

- HR Management MidtermDocument4 pagesHR Management MidtermshabanaNo ratings yet

- MIS ProjectDocument27 pagesMIS ProjectPallav MowkeNo ratings yet

- BookDocument2 pagesBooktomas.titus.gutuNo ratings yet

- What Was and What Might Have Been: The Threats and Wars in Afghanistan and IraqDocument32 pagesWhat Was and What Might Have Been: The Threats and Wars in Afghanistan and IraqHoover InstitutionNo ratings yet

- This+is+Grammar+Basic+3+ +정답Document20 pagesThis+is+Grammar+Basic+3+ +정답Cube LeeNo ratings yet

- Dr. Radhika P C Types of HotelsDocument14 pagesDr. Radhika P C Types of HotelsVineetNo ratings yet

- An Interdisciplinary Environmental EducationDocument10 pagesAn Interdisciplinary Environmental EducationCarolNo ratings yet

- Bab IvDocument20 pagesBab IvBernadettaNo ratings yet