Professional Documents

Culture Documents

CAD Design Software Guide

Uploaded by

CC OoiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CAD Design Software Guide

Uploaded by

CC OoiCopyright:

Available Formats

Computer aided design CAD

Contents

[hide]

1 Introduction

2 Benefits of CAD

3 Computer aided manufacturing

4 BIM

5 Common standards and collaborative practices

6 Software

7 Related articles on Designing Buildings Wiki

8 External references

Introduction

The term computer aided design (CAD) refers to the use of computers to create graphical representations

of physical objects to assist in the design process. It can also refer to the use of computers to prepare

presentational images or to prepare production information enabling objects to be manufactured, although

sometimes this is referred to as computer aided drafting as it does not necessarily involve designing. In

combination, these processes may be referred to as computer-aided design and drafting (CADD).

CAD can be used to create 2D or 3D representations, and can also be used to generate animations and

other presentational material. It may allow the addition of supplementary information such as dimensions,

descriptions of components, references to specifications and so on.

Specialist CAD software is available for specific purposes, and a wide range of software applications

have been developed for use in the design and construction of built assists such as buildings.

Benefits of CAD

CAD can be used to help:

Improve the speed of production.

Improve the quality of drawn information.

Reduce development costs.

Generate visualisations during the design process to help decision making.

Improve accuracy.

Reduce errors.

Enable changes to be made more easily and so facilitate the consideration of a wider range of options.

Allow drawings to be generated at a wide range of scales, and with the addition of accurate information

such as dimensions.

Allow easy re-use of information.

Computer aided manufacturing

The combination of computer aided draughting and computer aided manufacturing (CAM) has

allowed computer numerical control (CNC) of highly-automated end-to-

end component designand manufacture. Computers can produce files that translate design

information into commands to operate machines, singularly or collectively, to perform pre-set sequences

of tasks in the production of building components.

See Computer aided manufacturing for more information.

More recently, the range of possibilities has been increased further by the introduction of economically

viable 3D printing.

BIM

The introduction of building information modelling (BIM) allows further reduction of errors and

improvement to the quality of information and can enable the automatic generation ofquantities, cost

estimates, ordering and tracking information.

BIM is a very broad term that describes the process of creating and managing a digital modelof

a building or other facility (such as a bridge, highway, tunnel, and so on), which includes:

Level 0: Unmanaged CAD.

Level 1: Managed CAD in 2D or 3D.

Level 2: Managed 3D environment with data attached, but created in separate disciplinemodels.

Level 3: Single,

online, project model with construction sequencing, cost and lifecyclemanagement information.

See Building information modelling for more information.

Common standards and collaborative practices

Particularly important to the effective use of CAD is the ability to share and re-use information, and this

requires the disciplined application of agreed standards of drawing preparation acrossproject teams. This

means that the effective use of CAD is as much about collaborative practices as it is about software.

Project standards can be formalised as standard methods and procedures (SMP's) which should be

agreed as early in the project as possible and should describe how information is structured, how it will be

produced and how it will be managed and exchanged.

The SMP might include agreed standards and procedures for:

Software.

Layering.

Zoning.

Co-ordination

Origin.

Orientation.

Fonts, line types and weights.

Dimensions, abbreviations and symbols.

File structure and file naming.

Standard templates (for example, drawing titles).

Page sizes and scales.

Permissions and change control procedures.

The great variety in the extent to which CAD and building information modelling can be used on

a project means that it is important to clearly define what is expected and to set this out intender

documents and appointment documents.

You might also like

- CAD Engineering Essentials: Hands-on Help for Small Manufacturers and Smart Technical People: No Nonsence Manuals, #3From EverandCAD Engineering Essentials: Hands-on Help for Small Manufacturers and Smart Technical People: No Nonsence Manuals, #3Rating: 4.5 out of 5 stars4.5/5 (4)

- Drone Fusion360Document65 pagesDrone Fusion360Joanna Carvalho100% (1)

- 6 Week Training ReportDocument32 pages6 Week Training ReportRavi KumarNo ratings yet

- Computer Aided DesignDocument7 pagesComputer Aided DesignRicardo AqpNo ratings yet

- HyperMill 2018 1Document16 pagesHyperMill 2018 1Kang Balyes TeaNo ratings yet

- AutoCAD NotesDocument87 pagesAutoCAD NotesShirley Munoz100% (1)

- Autocad Hand Book First Edition CollegesDocument58 pagesAutocad Hand Book First Edition CollegesJeketera Shadreck100% (1)

- INTRODUCTION TO COMPUTER AIDED DESIGN RahulDocument6 pagesINTRODUCTION TO COMPUTER AIDED DESIGN RahulRishabhNo ratings yet

- CCCDocument37 pagesCCCCC OoiNo ratings yet

- CobieDocument2 pagesCobieCC OoiNo ratings yet

- 3D Cad - An Emergent Tool For Concept DesignDocument4 pages3D Cad - An Emergent Tool For Concept DesignAdvanced Research PublicationsNo ratings yet

- List of BS CodeDocument8 pagesList of BS CodeCC OoiNo ratings yet

- List of BS CodeDocument8 pagesList of BS CodeCC OoiNo ratings yet

- Computer Applications in SocietyDocument2 pagesComputer Applications in SocietyTegoshi Yuya77% (13)

- History of CAD: Drafting Machine and Used PDP-1 Computer From Digital Equipment Corp., A Vector - Refresh Display and ADocument24 pagesHistory of CAD: Drafting Machine and Used PDP-1 Computer From Digital Equipment Corp., A Vector - Refresh Display and ANina MiskovetsNo ratings yet

- Computer-Aided Design (CAD) Is TheDocument3 pagesComputer-Aided Design (CAD) Is TheAhmed AdelNo ratings yet

- CadDocument8 pagesCadLuck VelascoNo ratings yet

- Autocad Form One and TwoDocument58 pagesAutocad Form One and Twobrandon.dube2026No ratings yet

- Computer Aided Drawing and Design NotesrDocument16 pagesComputer Aided Drawing and Design NotesrMue ngineerNo ratings yet

- Computer-aided-WPS OfficeDocument6 pagesComputer-aided-WPS OfficeKurmi MainaNo ratings yet

- CAD DraftingDocument1 pageCAD DraftingIkechukwu OkekeNo ratings yet

- Cadd Overview 2Document2 pagesCadd Overview 2Jonaed BhuiyanNo ratings yet

- Architects Guide To 3D ModelingDocument25 pagesArchitects Guide To 3D ModelingOzgur OzkanNo ratings yet

- 11Document23 pages11snoozermanNo ratings yet

- Computer-Integrated Manufacturing (CIM) Is TheDocument24 pagesComputer-Integrated Manufacturing (CIM) Is TheBhupinder Singh MakanNo ratings yet

- History of CAD Software DevelopmentDocument1 pageHistory of CAD Software Developmentvitor basilioNo ratings yet

- Cadsystems - PPT: Computer-Aided DesignDocument8 pagesCadsystems - PPT: Computer-Aided DesignMichael DineshNo ratings yet

- Computer-Aided Design (CAD), Also Known As Computer-Aided Design and Drafting (CADD)Document15 pagesComputer-Aided Design (CAD), Also Known As Computer-Aided Design and Drafting (CADD)mech118No ratings yet

- What Is A Computer Aided DraftingDocument3 pagesWhat Is A Computer Aided DraftingLlyann espadaNo ratings yet

- Study of Computer Aided Design and Mechanical Design by Computer SoftwareDocument6 pagesStudy of Computer Aided Design and Mechanical Design by Computer SoftwareAmba Lrcfools InfosNo ratings yet

- Two-Dimensional Three-DimensionalDocument1 pageTwo-Dimensional Three-DimensionalTim SellNo ratings yet

- Overview of CAD SoftwareDocument4 pagesOverview of CAD SoftwareLakshika SubodhaniNo ratings yet

- (MFG Engg HDBK, CHP 9) : 9.1.1 What Is CAD?Document2 pages(MFG Engg HDBK, CHP 9) : 9.1.1 What Is CAD?Sufian HijazNo ratings yet

- Tugas Tek GambarDocument19 pagesTugas Tek GambarRichard LexonNo ratings yet

- Computer Aided DesignDocument3 pagesComputer Aided DesignCora MangubatNo ratings yet

- CAD/CAM and CNC Technologies Streamline Marine ManufacturingDocument14 pagesCAD/CAM and CNC Technologies Streamline Marine ManufacturingHaiqal MarizanNo ratings yet

- Unit VI CAD Customization & Automation (08 HRS) : Limitations of 2D DrawingsDocument26 pagesUnit VI CAD Customization & Automation (08 HRS) : Limitations of 2D DrawingsPavansatya AdabalaNo ratings yet

- CAD Design of Jigs and FixturesDocument18 pagesCAD Design of Jigs and Fixturesprajari ghoshNo ratings yet

- Applying Pro/ENGINEER for CADCAM SimulationsDocument9 pagesApplying Pro/ENGINEER for CADCAM SimulationsHafiezul HassanNo ratings yet

- AutoCAD NotesDocument88 pagesAutoCAD NotesInaam UllahNo ratings yet

- Assignment 1 CadcamDocument3 pagesAssignment 1 CadcamLuqman HakimNo ratings yet

- Cadd OverviewDocument3 pagesCadd OverviewJonaed BhuiyanNo ratings yet

- Advantages of CAD Over Conventional Drawing Techniques (Assignnet 1)Document9 pagesAdvantages of CAD Over Conventional Drawing Techniques (Assignnet 1)Firdaus Khan100% (1)

- Unit I Fundamentals of Computer GraphicsDocument25 pagesUnit I Fundamentals of Computer GraphicsChockalingamNo ratings yet

- Cad/Cam: Md. Mazharul HelalDocument42 pagesCad/Cam: Md. Mazharul HelalGreen University TextileNo ratings yet

- Unit 6Document3 pagesUnit 6Mayur GhadageNo ratings yet

- Term Paper of Mechanical SciencesDocument12 pagesTerm Paper of Mechanical SciencesamitmaheshpurNo ratings yet

- Design and Fabrication Ofoldham CouplingDocument25 pagesDesign and Fabrication Ofoldham CouplingSanjeev Kumar0% (1)

- Chapter 1Document8 pagesChapter 1Rheymarkbutron RamadaNo ratings yet

- What Is Cad and Its Uses?: Quality of 3D RepresentationDocument5 pagesWhat Is Cad and Its Uses?: Quality of 3D RepresentationZeeshan NazirNo ratings yet

- Computer: Computer-Aided Design (CAD), Also Known As Computer-Aided Design and Drafting (CADD)Document3 pagesComputer: Computer-Aided Design (CAD), Also Known As Computer-Aided Design and Drafting (CADD)Singh VadanNo ratings yet

- CADM Mod 2Document39 pagesCADM Mod 2Aswin MNo ratings yet

- CAD101 XCDocument2 pagesCAD101 XCveryofficialemailaddress69No ratings yet

- Computer Aided Design: Introduction To CADDocument6 pagesComputer Aided Design: Introduction To CADRishabhNo ratings yet

- Powerful 3 Axis CNC Programming OperationsDocument28 pagesPowerful 3 Axis CNC Programming OperationsNanda KishoreNo ratings yet

- Introduction To CAD: BackgroundDocument4 pagesIntroduction To CAD: BackgroundmoonirNo ratings yet

- Chapter 1Document7 pagesChapter 1Filiz ÖztürkNo ratings yet

- The Evolution and Impact of ComputerDocument4 pagesThe Evolution and Impact of ComputerRuwan PareraNo ratings yet

- February 5, 1999 R/L 2/2000: Standard SoftwareDocument3 pagesFebruary 5, 1999 R/L 2/2000: Standard SoftwareMEGAN ASBROCKNo ratings yet

- Computer-Aided Design: Product Lifecycle ManagementDocument1 pageComputer-Aided Design: Product Lifecycle ManagementgwenashleyNo ratings yet

- Assignment MachiningDocument4 pagesAssignment MachiningAhmad HazimNo ratings yet

- Introduction To CADDocument3 pagesIntroduction To CADMaaruf Khan PathanNo ratings yet

- Cad 20S3 2023 178-1891Document13 pagesCad 20S3 2023 178-1891vipinNo ratings yet

- Future of CAD CAMDocument7 pagesFuture of CAD CAMtuongnvNo ratings yet

- Moi University School of Information Science Dit 010: Management Information System Section A Question OneDocument7 pagesMoi University School of Information Science Dit 010: Management Information System Section A Question OneKiprotich KibetNo ratings yet

- Streamlining Product Documentation Across The Manufacturing Enterprise With 3dvia ComposerDocument9 pagesStreamlining Product Documentation Across The Manufacturing Enterprise With 3dvia Composerpaulf1_85No ratings yet

- Visual Graphic Design - VGD4: Computer Aided Design (CAD)Document14 pagesVisual Graphic Design - VGD4: Computer Aided Design (CAD)JD SalviejoNo ratings yet

- Technical Drafting Methods: DraftersDocument4 pagesTechnical Drafting Methods: DraftersRamkrishnaSutharNo ratings yet

- Professional Indemnity Insurance Requirements: Total Income of Over 200,000 and Up To 700,000Document2 pagesProfessional Indemnity Insurance Requirements: Total Income of Over 200,000 and Up To 700,000CC OoiNo ratings yet

- ParadiseDocument1 pageParadiseCC OoiNo ratings yet

- PokémonDocument1 pagePokémonCC OoiNo ratings yet

- HeavenDocument1 pageHeavenCC OoiNo ratings yet

- Checking Sub Girder For Ton Test Pile Total Kentledge Load Ton Total Loading Area Sub GirderDocument4 pagesChecking Sub Girder For Ton Test Pile Total Kentledge Load Ton Total Loading Area Sub GirderCC OoiNo ratings yet

- SOP For Construction Industry To Operate During MCODocument7 pagesSOP For Construction Industry To Operate During MCOWH TNo ratings yet

- C 001 Code of Conduct of Registered Person (Rev.1 - 27.10.2016) PDFDocument12 pagesC 001 Code of Conduct of Registered Person (Rev.1 - 27.10.2016) PDFNurul'Ain Haniyun Mohamad FodziNo ratings yet

- Common Mistakes On Building DrawingsDocument2 pagesCommon Mistakes On Building DrawingsCC OoiNo ratings yet

- Asset InformationDocument3 pagesAsset InformationCC OoiNo ratings yet

- Malaysia Construction Law GuideDocument17 pagesMalaysia Construction Law GuideCC OoiNo ratings yet

- Frequently Asked Question 20.4.2017 (PPC)Document7 pagesFrequently Asked Question 20.4.2017 (PPC)beeepppNo ratings yet

- Cyber HygieneDocument1 pageCyber HygieneCC OoiNo ratings yet

- Cricket Ball: Jump To Navigationjump To SearchDocument7 pagesCricket Ball: Jump To Navigationjump To SearchCC OoiNo ratings yet

- Cyber HygieneDocument1 pageCyber HygieneCC OoiNo ratings yet

- Cyber SecurityDocument1 pageCyber SecurityCC OoiNo ratings yet

- BimDocument5 pagesBimCC OoiNo ratings yet

- Asset Information Requirements AIRDocument3 pagesAsset Information Requirements AIRCC OoiNo ratings yet

- Computer Numerical ControlDocument1 pageComputer Numerical ControlCC OoiNo ratings yet

- CladdingDocument7 pagesCladdingCC OoiNo ratings yet

- Type of Construction ContractDocument3 pagesType of Construction ContractCC OoiNo ratings yet

- Advanced Construction MethodDocument1 pageAdvanced Construction MethodCC OoiNo ratings yet

- SubcontractorDocument2 pagesSubcontractorCC OoiNo ratings yet

- Common Data EnvironmentDocument3 pagesCommon Data EnvironmentCC OoiNo ratings yet

- Act 177 (2016)Document577 pagesAct 177 (2016)Nerissa ZahirNo ratings yet

- Structural Steel Design CourseDocument3 pagesStructural Steel Design CourseCC OoiNo ratings yet

- Planning For Advanced Manufacturing Technology A Research FrameworkDocument21 pagesPlanning For Advanced Manufacturing Technology A Research FrameworkkarahandevrimNo ratings yet

- Bharat Forge CaseDocument33 pagesBharat Forge Caseeverakash_104355063No ratings yet

- Class Notes CAD CAMDocument73 pagesClass Notes CAD CAMAntony NjorogeNo ratings yet

- 12-CAD-CAM Modified by MR - Sanjay Kumar-11.9.2013 PDFDocument58 pages12-CAD-CAM Modified by MR - Sanjay Kumar-11.9.2013 PDFRajaReddyNo ratings yet

- Referat CNC EnglezaDocument12 pagesReferat CNC EnglezaArtur DonNo ratings yet

- Computer Integrated Manufacturing (Cim)Document12 pagesComputer Integrated Manufacturing (Cim)Aditya Narayan SahooNo ratings yet

- Mechanical Department Information Brochure 04082022Document4 pagesMechanical Department Information Brochure 04082022Vineeth AlluriNo ratings yet

- Dsa 5300Document8 pagesDsa 5300Nguyen Van ToanNo ratings yet

- OPERATIONS MANAGEMENT AssignmentDocument6 pagesOPERATIONS MANAGEMENT AssignmentRajesh Singh100% (1)

- List of PG CollegesDocument11 pagesList of PG CollegeschandussctNo ratings yet

- Course Catalogue ADTECShah AlamDocument67 pagesCourse Catalogue ADTECShah AlamMohammed HanafiNo ratings yet

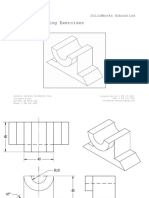

- SolidWorks Education Detailed Drawing ExercisesDocument51 pagesSolidWorks Education Detailed Drawing ExercisestotoNo ratings yet

- Cad Cam Lab ManualDocument51 pagesCad Cam Lab ManualRahul Reddy100% (1)

- Open Inventor PDFDocument8 pagesOpen Inventor PDFMuchlis EkoNo ratings yet

- MCADD Course StructureDocument5 pagesMCADD Course Structurelimin98No ratings yet

- English For I.T.: Computer-Aided TechnologiesDocument2 pagesEnglish For I.T.: Computer-Aided TechnologiesDenisaBotasNo ratings yet

- LECTURE - 1 - Introduction To CAD-CAMDocument32 pagesLECTURE - 1 - Introduction To CAD-CAMRakibul Haque100% (1)

- Introduction To CIMDocument6 pagesIntroduction To CIMzuhaib alamNo ratings yet

- 3D Printing Group 7 ReportDocument19 pages3D Printing Group 7 ReportMark CrisostomoNo ratings yet

- Camworks 3 Axis Milling: Camworks 3 Axis Millingfor 3D Toolpaths, Roughing, and FinishingDocument2 pagesCamworks 3 Axis Milling: Camworks 3 Axis Millingfor 3D Toolpaths, Roughing, and FinishingsaptagunungNo ratings yet

- Advance CadDocument16 pagesAdvance Cadqadir aliNo ratings yet

- Intro - Desain Berbasis KomputerDocument19 pagesIntro - Desain Berbasis KomputerakbarNo ratings yet

- Introduction to Fashion Design TechnologyDocument24 pagesIntroduction to Fashion Design TechnologySharifah Nurhuda HaziqahNo ratings yet

- Design Methods in Architecture Heath T Method in Architecture John Wiley Chichester 1984 256pp 17-95-1986 Design StudiesDocument1 pageDesign Methods in Architecture Heath T Method in Architecture John Wiley Chichester 1984 256pp 17-95-1986 Design StudiesVivi BarqueroNo ratings yet

- MSME Tool Room Training & ServicesDocument24 pagesMSME Tool Room Training & ServicesHarish BhatiaNo ratings yet

- Fabbing Practices - An Ethnography in Fab Lab AmsterdamDocument96 pagesFabbing Practices - An Ethnography in Fab Lab Amsterdamaghalim86No ratings yet