Professional Documents

Culture Documents

Boiler Feed Pump

Boiler Feed Pump

Uploaded by

Ritik Raj SinghCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Boiler Feed Pump

Boiler Feed Pump

Uploaded by

Ritik Raj SinghCopyright:

Available Formats

Boiler feed pumps

High speed , multistage centrifugal pumps are the preferred type due to their

ability to supply large quantities of water and to provide it at steady flow

avoiding shock loads on pipe lines and valves.

Materials

Nozzle plate- Creep resistant steel

Blades-Stainless iron

Bearings-White metalled ( oil lubricated )

Turbine glands- Carbon

Turbine casing- Cast steel

Turbine wheel- Stainless steel

Shaft- Nickel Chrome steel

Wear rings- Leaded bronze

Impeller-Stainless steel or monel

Diffuser ring- Aluminium bronze

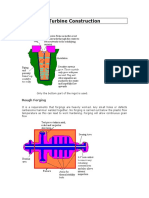

The impulse Curtis wheel ( velocity compounded ) rotates at speeds of around

7000 rpm. Velocity compounding means that there is very little pressure drop

across the stages reducing the need for fine clearances. This allows the turbine

to be run up quickly from cold.

The balance chamber must have a diameter greater than the suction wear ring.

If the pump is designed to be supercavitating hard metal inducers are fitted

which screw into the water. Any cavitation occurs on this which is made

sacrificial.

Inlet steam pressure around 60 bar, outlet around 3 bar.

Expansion down to lower pressures would require excessively large casings and

would lead to problems of centrifugal stresses due to the larger blading

required.

Carbon seals are used instead of labyrinths for simplicity and to

keep the length of the unit down to a minimum. Due to the different

coefficients of expansions between the carbon and the steel a madrill must be

used to set the correct running clearance. For multistage pumps an extra end

bearing is required and hence additional packed gland.

The pump is dynamically balanced by means of the balance

chamber leak off to the suction eye, and the dam edges on the back of the

impeller

Balancing of two stage pumps

Feed pumps of this type of balance are best started against either

a closed or spring loaded discharge v/v to ensure rapid build up of pressure

Bearings

Water lubricated bearings- Steel backing onto which is sintered a layer of

porous bronze impregnated with PTFE (0.025mm thick). This PTFE is

transferred to the shaft so providing very low coefficients of friction

Bearings operate at 115oC with water supplied at 5.5bar 70 oC.

Bearing clearance- 0.15 mm

Max- 0.25mm must be replaced

Danger- 0.3 mm severe damage will occur

The bearings should also be replaced if less than 75 % shows on

the surface.

Flow characteristics of controlled feed pumps

Constant speed ( electric )- Below 10% turbulence becomes so

great that the pump operates very inefficiently and must not be worked in this

range. Hence, a recirc valve must be used. At full flow pressure is only just

sufficient to feed the boiler

Pressure governed- Pressure droop designed in to give stable

control.

Flow + Speed and/or Pressure- The extra element must be

added with the flow otherwise the system becomes unstable. Characteristic can

be level or slightly rising giving low pressure at low flow rates conserving

energy and preventing water being forced at high pressures through partly

open feed control valve.

Gland

Can be operated at very low flow rates due to reduced speed

You might also like

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Electronic Ticket Receipt, October 11 For ARTATES MERLAMINA MSDocument2 pagesElectronic Ticket Receipt, October 11 For ARTATES MERLAMINA MSRamilArtatesNo ratings yet

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- Condenser Siphon Seal-WellsDocument3 pagesCondenser Siphon Seal-Wellstwins19564839100% (1)

- Valva MechanismDocument38 pagesValva MechanismAnkitSingh100% (1)

- Turbine Blades: Impulse Blading System DesignDocument10 pagesTurbine Blades: Impulse Blading System DesignPappuRamaSubramaniamNo ratings yet

- Turbines 1Document40 pagesTurbines 1sjois_hsNo ratings yet

- Mud Pump GTS FinalDocument77 pagesMud Pump GTS FinalSanjiv Pathak0% (1)

- Consructional - Features - Kaplan TurbineDocument13 pagesConsructional - Features - Kaplan TurbineASHITA K BNo ratings yet

- Jabsco Flexible Impeller PumpsDocument46 pagesJabsco Flexible Impeller PumpsstratoschaNo ratings yet

- Types of PumpsDocument8 pagesTypes of Pumpskarthick_sailor100% (2)

- Types of PumpsDocument7 pagesTypes of PumpspakNo ratings yet

- Technical Case Study: PumpsDocument43 pagesTechnical Case Study: Pumpsfahad670100% (1)

- Conventional Pumping System GuidelinesDocument20 pagesConventional Pumping System GuidelinesT.N. Ramnauth Co LtdNo ratings yet

- Fluid Mechanics: Presentation By:-Mohammad Hammad JoufarDocument14 pagesFluid Mechanics: Presentation By:-Mohammad Hammad JoufarHammad JoufarNo ratings yet

- Kaplan TurbineDocument7 pagesKaplan TurbineAaditya Aadi100% (1)

- Study and Troubleshooting of Alum Dosing PumpDocument22 pagesStudy and Troubleshooting of Alum Dosing PumpShyam HambardeNo ratings yet

- CepDocument7 pagesCeppramod_tryNo ratings yet

- Aurora Regenerative Turbine 150 Series BrochureDocument8 pagesAurora Regenerative Turbine 150 Series Brochurethehammer2No ratings yet

- HPM CatalogDocument8 pagesHPM CatalogNaser JahangiriNo ratings yet

- Plunger LiftDocument5 pagesPlunger LiftrocacantuNo ratings yet

- Experiment No. 01: ObjectDocument12 pagesExperiment No. 01: Objectpurushottam prajapatiNo ratings yet

- Project Report On Andritz HydroDocument36 pagesProject Report On Andritz HydroTashmeet SinghNo ratings yet

- Know Your Equipment - Centrifugal PumpDocument93 pagesKnow Your Equipment - Centrifugal Pumpsgupta_615796100% (2)

- Amcot Cooling Tower Corporation: Operating Instructions and Service Manual For Model ST 3 1500Document13 pagesAmcot Cooling Tower Corporation: Operating Instructions and Service Manual For Model ST 3 1500HECTOR IBARRANo ratings yet

- PeltonDocument7 pagesPeltonKunal Kumar DasNo ratings yet

- Steam Turbine ReportDocument32 pagesSteam Turbine ReportAbdulBasit67% (3)

- BeamDocument6 pagesBeamsaeedNo ratings yet

- Axial Flow PumpsDocument3 pagesAxial Flow PumpsahadNo ratings yet

- Advantages and Disadvantages of Screw Pumps PaperDocument6 pagesAdvantages and Disadvantages of Screw Pumps PaperRenato Orosa100% (1)

- Yarway Valve DesignDocument12 pagesYarway Valve DesignwaqashabibNo ratings yet

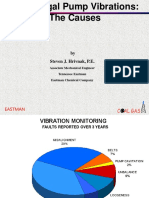

- By Steven J. Hrivnak, P.E.: EastmanDocument54 pagesBy Steven J. Hrivnak, P.E.: EastmanMohsin Qadeer100% (1)

- Prof Ir Dr. Ab Saman B. Abd Kader, Peng, Miem, Mcit Faculty of Mechanical Engineering, UtmDocument21 pagesProf Ir Dr. Ab Saman B. Abd Kader, Peng, Miem, Mcit Faculty of Mechanical Engineering, UtmakusuperNo ratings yet

- Fire Pump Theory: Sugar Land Fire Department Driver/Operator-Pumper Academy Spring 2003Document70 pagesFire Pump Theory: Sugar Land Fire Department Driver/Operator-Pumper Academy Spring 2003Jose AndradeNo ratings yet

- Building Services and Workshop TechnologyDocument21 pagesBuilding Services and Workshop Technologytiffa BosiboriNo ratings yet

- Natural Circulation in BoilerDocument9 pagesNatural Circulation in BoilerSajjad AhmedNo ratings yet

- Basic Part of TurbDocument10 pagesBasic Part of TurbAashish AggarwalNo ratings yet

- Bill of Quantities Schedule 1 Ite M No. (As Per Price Bid)Document15 pagesBill of Quantities Schedule 1 Ite M No. (As Per Price Bid)Prasenjit DeyNo ratings yet

- Sintech Make Pumps For Power Generation IndustryDocument16 pagesSintech Make Pumps For Power Generation Industrysahildhingra0% (1)

- Crude Oil Transfer PumpDocument5 pagesCrude Oil Transfer PumpEduardo RodriguesNo ratings yet

- Dynamic PumpsDocument62 pagesDynamic PumpsRaunaq AroraNo ratings yet

- Building Service Course WorkDocument20 pagesBuilding Service Course WorkKemigisa MarthaNo ratings yet

- Rotating EquipmentDocument202 pagesRotating EquipmentJithin Rajan Joseph100% (1)

- Dealing With GasDocument10 pagesDealing With GasYasser HashimNo ratings yet

- Pump Training 2Document5 pagesPump Training 2kevinGojiNo ratings yet

- Fausto - TALLER Y PDLDocument12 pagesFausto - TALLER Y PDLromina_montes_1No ratings yet

- Automatic Recirculation Valve BrochureDocument12 pagesAutomatic Recirculation Valve BrochureYuvaraj NithyanandamNo ratings yet

- Cooling Water PumpsDocument5 pagesCooling Water PumpsEshan BhatNo ratings yet

- Articulo Bom 3 TornilloDocument4 pagesArticulo Bom 3 TornilloJosé Olivier RománNo ratings yet

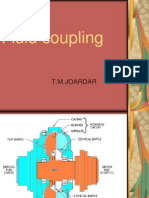

- Fluid Coupling: T.M.JoardarDocument43 pagesFluid Coupling: T.M.JoardarKuntal Satpathi50% (2)

- 902 Ds Boiler Start Up Valve Type Be PDFDocument4 pages902 Ds Boiler Start Up Valve Type Be PDFGautam Sunil KumarNo ratings yet

- Pelton Wheel Turbine (Brief Notes)Document27 pagesPelton Wheel Turbine (Brief Notes)Harshanagasai ManyamNo ratings yet

- HM Laboratory ManualDocument41 pagesHM Laboratory ManualSreesh P Somarajan100% (1)

- Pelton WheelDocument14 pagesPelton WheelAqsajabeenNo ratings yet

- Turbine ConstructionDocument7 pagesTurbine ConstructionPrasannaNo ratings yet

- Hydraulic Pumps IIDocument61 pagesHydraulic Pumps IIregis_456No ratings yet

- Animal RightsDocument12 pagesAnimal RightsAmeer HamzaNo ratings yet

- WHO Generic Palliative Care (Dr. Rudi)Document26 pagesWHO Generic Palliative Care (Dr. Rudi)Inna RosdyasariNo ratings yet

- Storage and Processing of Edible Mushrooms Emilia Bernaś, Grażyna Jaworska, Waldemar KmiecikDocument19 pagesStorage and Processing of Edible Mushrooms Emilia Bernaś, Grażyna Jaworska, Waldemar KmiecikarthozNo ratings yet

- IP Ref List-MOST RECENT-8-2-13Document30 pagesIP Ref List-MOST RECENT-8-2-13BlaireNo ratings yet

- Hawasa CL 3 Pre-Optimization Drive Test ReportDocument29 pagesHawasa CL 3 Pre-Optimization Drive Test ReportfashiondsnnNo ratings yet

- PROFITABILITY ANALYSIS at ASIAN PAINTSDocument62 pagesPROFITABILITY ANALYSIS at ASIAN PAINTSRajesh BathulaNo ratings yet

- DPL Ensayo de Penetracion Ligera Mecanica de SuelosDocument60 pagesDPL Ensayo de Penetracion Ligera Mecanica de SuelosErnesto Guillermo Dobbertin SaldañaNo ratings yet

- Colgate Full Marketing AnalysisDocument30 pagesColgate Full Marketing AnalysisHuy Hoàng NguyễnNo ratings yet

- Comprehensive of Combined BA and BS-MD Medical ProgramsDocument15 pagesComprehensive of Combined BA and BS-MD Medical Programssonnynguyen208682100% (1)

- TG 9780190700140 5Document124 pagesTG 9780190700140 5ayesha shafiqueNo ratings yet

- B353-OL3-009 - Text - Rev - CDocument103 pagesB353-OL3-009 - Text - Rev - CvrajakisoriDasiNo ratings yet

- Dsm-Iv DSM-5: Table 3.36 DSM-IV To DSM-5 Insomnia Disorder ComparisonDocument2 pagesDsm-Iv DSM-5: Table 3.36 DSM-IV To DSM-5 Insomnia Disorder ComparisonRashella Jessica JoeNo ratings yet

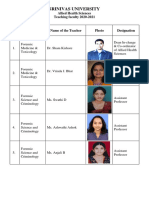

- Teaching Faculty For Allied Health Sciences - 2021Document9 pagesTeaching Faculty For Allied Health Sciences - 2021jamoonNo ratings yet

- Demography: Population DistributionDocument6 pagesDemography: Population DistributionnathNo ratings yet

- AdimeDocument4 pagesAdimeapi-340838547No ratings yet

- Aggression PDFDocument2 pagesAggression PDFAhmed BaigNo ratings yet

- Power Engineering PM Check ListDocument11 pagesPower Engineering PM Check ListSelvn SubramanianNo ratings yet

- BIR Form 2551 - PDFDocument1 pageBIR Form 2551 - PDFMichael LaquianNo ratings yet

- Guide To Site - Box CulvertDocument4 pagesGuide To Site - Box Culvertjs kalyana ramaNo ratings yet

- Memorandum of Association NokiaDocument45 pagesMemorandum of Association NokiaRoohi Salvi100% (1)

- Manual de Serviço Injeção EletrônicaDocument87 pagesManual de Serviço Injeção EletrônicaMarcos MedradoNo ratings yet

- The Effects of Unbalanced Circuit in Power Losses and EfficienyDocument9 pagesThe Effects of Unbalanced Circuit in Power Losses and EfficienyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Latihan Passive VoiceDocument9 pagesLatihan Passive VoiceAlby MaulanaNo ratings yet

- REPORT ON PNB MetLife India Insurance and Its Various PlansDocument5 pagesREPORT ON PNB MetLife India Insurance and Its Various PlansSUSUWALANo ratings yet

- Vegan+Egg+Replacement+BAKERpaper FinalDocument7 pagesVegan+Egg+Replacement+BAKERpaper FinalSQF PractitionerNo ratings yet

- List of E-Books Department WiseDocument45 pagesList of E-Books Department WiseAnurag ChaturvediNo ratings yet

- Nightingales Environmental Theory 2Document21 pagesNightingales Environmental Theory 2samanthanicolemercadoNo ratings yet

- "The Social Contract Is Broken": Why Millennials Who Lack Rich Parents Feel Increasingly HopelessDocument5 pages"The Social Contract Is Broken": Why Millennials Who Lack Rich Parents Feel Increasingly HopelessviniciuscastanheiraNo ratings yet

- DR Laser ProtocolDocument26 pagesDR Laser ProtocolKatherinne Meza RamosNo ratings yet