Professional Documents

Culture Documents

SK Bearings

Uploaded by

vkls0 ratings0% found this document useful (0 votes)

32 views4 pagesBearings

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentBearings

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

32 views4 pagesSK Bearings

Uploaded by

vklsBearings

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

SK Bearings

antidiivibration

STRUCTURAL BEARINGS

SKV & SKG TYPES

Introduction

City centre construction sites are

often complicated by having

surface rail or underground railway

tunnels clase to propased

foundations and piles, New office

complexes are frequently built

directly over existing raitway

stations where heavy diesel, as

well as underground trains, pass:

‘or teeminate, These essential

services generate ground bome

\ibration which enters buildings oF

conventional construction and can

make the life of eccupants

intolerable.

‘The solution for new constuction

is to design the building with SK

elastomeric anti-vibration bearings:

incorporated in the foundations.

This has been accepted practice

since 1963 and many buildings

have been isolated on elastomeric:

bearings of various types.

SK Bearings offers both laminated

natural rubber / steel plate bearings

‘designed to BS 5400 and fabric

reinforced bearings to BS 6177.

‘The praducts are a further

development of existing

technology and benefil fram over

30 years of experience in the

design and manufacture af

structural and bridge bearings,

The bearings are suitable for

isolating offices, hospitals, flats,

apartments, oil rig modules, TV,

radio and other studios, auditoria

elc,, where the structure is

required to be isolated from a

source of vibration

The curved roof of the Canary Wharf

Light Railway Station in Docktands sits

‘on SKG anti-vibration bearings which

protect il from wind-borne oscillation,

Guidance

General guidance on the selection

and use of elastomeric bearings

for isolating vibration from buildings

is published in BS 6177: 1982. ttis

recommended hawever, that the SK

‘engineering design office is

consulted for a bearing system

proposal since applying the wang

bearing design can compound a

vibration problem,

Life expectancy

Elastomeric bearings are made by

‘SK Bearings to strict specification

‘and quality control, thereby ensuring

‘4 maintenance free working life

‘generally comparable with the

expected design life of the structure,

Dynamic performance

Fis calculated using

the formula

m

2

‘The natural frequency | K } Vy

Fe

‘where K is the measured dynamic

siifness of the bearing at.a pre-

‘determined load and m is the

mass carried by the bearing.

Bearings are made from natural

rubber because of its superior

‘dynamic properties and exellent

‘abgue behaviour

The dynamic evaluation of the

bearing material has been carried out

by independent test laboratories.

(Rubber Consultants - MRRDB a

unit of the Malaysian Rubber Research

cand Development Board, Hertford)

SKV TYPE

Construction

‘The SKV material is manufactured to

BS 6177 from wulcanised natural rubber

‘canforming to bridge bearing standard

BS 5400. Non-metallic. reinforcement af high

tensile strength synthetic fabric is

‘valcanised inte the bearing ina similar

manner to steal piste reinforcement af

‘conventional bridge bearings The

basic material is moulded in 25mm thick

‘sheets, then cut into individual bearing

units and banded togethar to the required

finished thichness, Ths thickness depends

‘on the required natural frequency for the

(project and can vary fram 25mm to 15dmm_

in multiples of 25mm,

Static Load

Characteristics

Bearings are avellable in any plan size,

however, iis more economical ta make

use of the standard sizes cut from the sheets,

‘These range from a minimum of 100 x 100

x 25mm to 600 x 600 x 150mm generally

in mutiples of 50mm on pian dimensions.

8S 6177 gives engineers usaful information

when considering the instalation of besrings

‘for anti-vibration purposes. Items such as

‘fail sale devices, wind loading restraint,

‘fre protection, replacement, ete., are

also covered.

Bearings are shways used in groups rather

than one large ‘area’ of bearing material. This

‘ensures the optimum pertarmance is gained

‘ogether with other advantages such 2s ease

of installabon. For example, pile cap with a

‘vertical load of 6000 KN would require 16

bearings of 250mm square plan dimensions.

The pile head may therefore have tobe flared

‘to give sufficient area for bearings, fall safe

sdevioes and dowel bers for side restsint.

Dynamic performance

‘The basic material is manufactured in 25enrn

thick shaets and bonded together to provid

the required natural frequency al a design

vertical laa.

From tess, the Camping Ratio has been

‘measured 25 0.08 and Loss Factor has been

measured as (1,086 for SKV bearings

Recommended temperature operating range

30 to +70 dagroes 6.

NB: Alldata is for guidance only. Always

‘consult SK Bearings design service.

Load against Compression

300

Load (KN)

200

100

0

0 2 4 6 8

Compression (mm)

10

12 14 «16 «17 «18

Plan size 200 x 200mm

25mm = — 100mm

NB: Long term creep: creep is expressed as a percentage increase in

deflection (compression) to the initial deflection, generally taken as 25%.

Load against Natural Frequency

300

250

200

150

Load (kN)

100

50

o+

6 8 W 12 14 16

Natural Frequency (Hz)

18 20 22 24 26

25mm — 75mm — 125mm

Plan size 200 x 200mm = 56mm = — 400mm

Quality assurance & testing

‘The natural rubber compound is

‘manufactured and tested in aooardanoe with

the test procedure fald down in BS 903 and

‘compligs with BS 5400: Vuicanised natural

rubber.

'SKV Produation reinforced sheets 26mm

thick are manufactured and tested in

Becordance with BS 1577, including visual,

sifness and destructive testing

Additional testing on individsel laminated

bearings can be carried out to engineers!

fequirements and ate changed extra.

Certificates of conformity and or test

cetificates can be provided far ished

bearing tests.

‘SK Bearings have facilaies for testing to

Grade A standard, Our lest machine

which has a NaGonal Physical Laboratary

S KG TYP E Construction

a 7 SKG bearings are designed and

Load against compression manufactured to BS-5400 and comprise

natural rubber vulcanized with internal size!

plates in individual moulded units sinilar in

Load construction to normal bridge bearings:

kN As with SKY types, the dimensions of tne

600 bearing wil vary Gapanding on the aad

capacity required and the natural frequency.

500

400 / Static Load

Characteristics.

300

Bearings are available in a number of plan

200 sizes which can have a variation of internal

rubber thickness and metal plates, hence

400 load carrying capacity can vary forthe

same plan size

0 + —}— itis recommensied that SK Bearing's Design

oO 41 2 3 4 5 6 7 8 9 10 Cifioe i contacted fora bearing proposal.

Compression (mm! For example, a range of bearings may be

- (mm) 23 follows

NB: An allowance for creep of 25% should be added.

229 x 182 x 24mm typical load 150kN

Load against Natural Frequency 300 x 240 x 2mm typical load 450M

495 x 240 x 24mm typical load 750kN

400

Load Ash SKV type, SKG bearings are always

kN used in groups as illustrated on the

following page.

(300

Dynamic

performance

200

The bearings are manufactured in single

Moulied units and he dimensions are

caloulated to provide the required natural

100: frequancy at design vertical load.

The natural frequency is calculated using the

0 same formula es SKV. From tests the

Damping Ratio has been measured as

0.028 and Loss Factor has been measured

Natural Frequency (Hz) 95 0,056 for SKG bearings, The recommended

operating lemparature range for SKG bearings

Is -30 10-470 degrees C.

4 6 B 10 12 14 16 18 20 22 24

Key 29x 152x 24mm —= 300x240 24 mm

220 x152xd8mm — 300 x 240 48mm

220% 152x96mm —— 300 x 24096 mm

‘The Bolshol Theatre, has bean jackad-up

and lowered back onto SK anti-vibretion

bearings to protect it against the Moscaw

calibration certification, is capable of all stages thus ensuring that a high standard

imposing vertical loads up 1 10,000 kN is maintained throughout each stage of

‘cornbined with horizontal loads up to manufacture, Certificates and letters of

470 KN. Its possible therefore to carry canformily are available forthe produeis i

‘ult full scale foed tests on complete requited. SK Bearings is a Division of

bearings. the Dixon international Group Lid. -

Our qually control laboratory is fully Nillennium Product company - and is

‘equiped with the latest equipment to enable qualily assured'to ISO 9002.

our Lechnical staff to check our products at

Installation

Please note that in some cases, side

restraint will be required to ensure the

stabiity of the structure, This can usually

be provided by steel dowels which should

always have a rubber dowel sleave (SKD)

or some form of side restraint bearings

incorporating sliding (PTFE) faves to

account for veriical compression of the

main bearings.

Fail safe devices are usually fabricated

steel boxes or strip designs but concrete

upstands can also be used. For in situ

concrete structures a filler eg clayboard,

polystyrene or ather sultable filer material

can be used to infill between bearings prior

'o casting, Altematively a galvanised steel

base plate with starter bars.can be used

a a permanent shutter cn top of the

groups of bearings

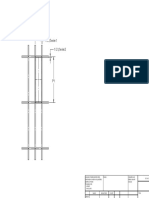

Bearings on concrete column head

foundation

General information

The finished bearing units are identified

by type, size or other markings preferred

by the engineers,

Rubber bearings are robust and not easily

damaged but it is prudent to treat them

with a certain amount of care ta avoid the

possibilty of accidental damage,

Before installation

Handle carefully. Use a orane itnecessary,

Store under eaver in clean conditions

and out af direct sunlight,

Do not remave transit clanps when

fitted,

During installation

Handle carefully. Use a crane ifnecessary,

Ensure correct location and orientation.

Bearings must be fully supported over

the entire area.

Bearings must not be subjected to

‘excessive loads - even for short periods.

‘When selting levels, do not apply uneven

loads or hammer blows to bearings.

After installation

Remove any temporary restraints and

check that the bearings upper faces ara

in contact with the supported structure.

Remove bedding mortar from the side

faces of elastomeric bearings,

Most important

NEVER install a damaged bearing

NEVER apply uneven loads or

hammer blows to alastemeric bearings.

‘Should @ bearing be damaged the

resident engineer mus! be informed

and a replacement ordered. The

installation positions are generally

detailed on the engineer's drawings

the surface anto which bearings are

installed should be flat and level

with no projections or air holes.

Preferably a solfeveling epoxy

grout should be used to create a

‘smooth surface,

The bearings are designed to be

installed without adhesive, however

ifitis deemed necessary to lacate

the bearings, then a sultable epoxy

adhesive should be used.

Fire protection

Bearings should be protected from the

effects of fire with a method which does

rot impair their dynamic performance:

Al temperatures in excess of 100 degrees

C for long periods any elastomeric

bearing will be permanently damaged

‘and would require replacement. The

design engineer should oonsider the

‘alternatives avaikable such as-fireproof

screening with intumesoent-based

materials or board type materials to

protect the bearings fram direct contact

with flames along their exposed edges,

We recommend FireFoam developed by

‘our colleagues at Sealmaster, because it

Complies with BS 476 Part 20.

Gives up to 4 hours fire resistance.

Requires no fixings or adhesives.

Can be re-tted after inspacting bearings.

Has damp and water resistant properties.

‘Contact us for further details or consult

information on-line at

Contacting us

‘SK Bearings

Brewery Road

Pampisford

Cambridge

England

(CB2 4HG

Tel. 01223 835 623

Fax 01223 837 G68

‘The lifonmaticn gies hein and where supple

users isbsedon cur general esperiance and. whem

appleabie, en art Ye resus usr samples yest

man sctue, However, because afte mary factors

amacting te une of hes prot which ae ous our

range and cael ne canal accep ny

tnjry. osc damage resutng fom retance upon uch

jefration.AMough every efit ia ae la esr tak

the dita and iformtion Bis eset ae comet os

rot form pat ofa Canret and SK Baarngs does ret

accept rescanabdly for roncomplsnee. Sk Bearings.

reser he igh charge any predict or spectiemton

wth notin The neni hs i sheet the

pyigh oft On ileal Gu Ud. end mo

partolt may be repeducesby ary means witout pre

‘wten persis

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Experienced communicator seeks new role to help businesses growDocument2 pagesExperienced communicator seeks new role to help businesses growvklsNo ratings yet

- Hot Rolled Steel Vs Cold Rolled SteelDocument2 pagesHot Rolled Steel Vs Cold Rolled SteelvklsNo ratings yet

- ResponsibilitiesDocument2 pagesResponsibilitiesvklsNo ratings yet

- Technical DirectorDocument4 pagesTechnical DirectorvklsNo ratings yet

- MEng BristolDocument47 pagesMEng BristolvklsNo ratings yet

- Steel Sections Hollow Sections Dimensions and Cross Sectional PropertiesDocument13 pagesSteel Sections Hollow Sections Dimensions and Cross Sectional PropertiesCornelManescuNo ratings yet

- Managing Director 1565178076Document2 pagesManaging Director 1565178076vklsNo ratings yet

- Triton Wiremesh - Sheet1 PDFDocument1 pageTriton Wiremesh - Sheet1 PDFvklsNo ratings yet

- ABC Fencing CalcsDocument2 pagesABC Fencing CalcsvklsNo ratings yet

- MEng BristolDocument47 pagesMEng BristolvklsNo ratings yet

- Fence Engineering ManualDocument30 pagesFence Engineering ManualvklsNo ratings yet

- Guide To Impact TestingDocument28 pagesGuide To Impact TestingvklsNo ratings yet

- Export AffirmationDocument10 pagesExport AffirmationDoğan ArslanNo ratings yet

- ExpametDocument14 pagesExpametvklsNo ratings yet

- En PDFDocument3 pagesEn PDFGrosLepinNo ratings yet

- Metal Crash Barrier by DMondalDocument11 pagesMetal Crash Barrier by DMondalvklsNo ratings yet

- Concertina CoilDocument4 pagesConcertina CoilvklsNo ratings yet

- Easy PDFDocument76 pagesEasy PDFvklsNo ratings yet

- DesignTechnicalIssues2014 PDFDocument56 pagesDesignTechnicalIssues2014 PDFvklsNo ratings yet

- Joint AnalysisDocument10 pagesJoint AnalysisSaravanakumar IyyanarNo ratings yet

- SignStructuresGuide2010 PDFDocument54 pagesSignStructuresGuide2010 PDFindunil100% (1)

- Applied Mechanics by RK RajputDocument408 pagesApplied Mechanics by RK Rajputsarthak100% (2)

- Joint AnalysisDocument10 pagesJoint AnalysisSaravanakumar IyyanarNo ratings yet

- Getting Started Guide PDFDocument16 pagesGetting Started Guide PDFvklsNo ratings yet

- 1Document2 pages1vklsNo ratings yet

- Metallstaenderwaende w11 de 0815 0 Eng ScreenDocument12 pagesMetallstaenderwaende w11 de 0815 0 Eng ScreenmelvinkorahNo ratings yet

- As 5100.4Document22 pagesAs 5100.4vklsNo ratings yet

- PTC Mathcad 15.0 M045 Read This FirstDocument12 pagesPTC Mathcad 15.0 M045 Read This FirstMiguel Angel Carrasco QuintazeNo ratings yet

- BD 94 - 17 Minor StructuresDocument69 pagesBD 94 - 17 Minor StructuresAnil KumarNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)