Professional Documents

Culture Documents

Fast Braker

Fast Braker

Uploaded by

Alberto Alejandro SanchezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fast Braker

Fast Braker

Uploaded by

Alberto Alejandro SanchezCopyright:

Available Formats

FastBrake® Locomotive Brake Equipment

Integrated TransCal and FlowCal Test Procedure

For EMD SD-70ACE Locomotives

Information contained in this document is proprietary and confidential to, and the trade secret of, Wabtec Railway Electronics of

Germantown, Maryland. No part or whole of this document may be disclosed to third parties, copied, or reproduced in any manner

without prior written permission of Wabtec Railway Electronics.

1

WPN 31248/31248CD Rev. D

THIS PAGE LEFT INTENTIONALLY BLANK

Information contained in this document is proprietary and confidential to, and the trade secret of, Wabtec Railway Electronics of

Germantown, Maryland. No part or whole of this document may be disclosed to third parties, copied, or reproduced in any manner

without prior written permission of Wabtec Railway Electronics.

2

WPN 31248/31248CD Rev. D

Table Of Contents

Table Of Contents ............................................................................................................. 3

List of Figures ................................................................................................................. 3

Record Of Revisions ......................................................................................................... 4

I. INTRODUCTION...................................................................................................... 5

A. Purpose............................................................................................................. 5

B. Special Tools Required ................................................................................ 5

C. Equipment/Personnel Safety Precautions .............................................. 5

D. General System Overview ........................................................................... 6

II. TEST PROCEDURES ............................................................................................. 7

A. Prerequisites ....................................................................................................... 7

B. Pressure Transducer Verification Test ........................................................ 8

C. Brake Pipe Flow Verification Test ................................................................. 9

D. Transducer Calibration Test ......................................................................... 10

E. Brake Pipe Flow Calibration Test .................................................................... 11

Fastbrake Transducer Calibration/Verification Values Chart .............................. 12

III. DISPLAY SCREENS AND FUNCTIONS....................................................... 13

A. Accessing The Program............................................................................. 13

B. Air Brake Calibration Display Overview ................................................ 13

C. Air Brake Calibration – Verify/Calibrate Sensors Display Overview

15

D. Air Brake Calibration Results Display Overview ................................. 26

List of Figures

Figure 1 - Pressure Test Points.................................................................................. 7

Figure 2- Air Brake Calibration Display ................................................................. 13

Figure 3 - Air Brake Calibration About Display.................................................... 14

Figure 4 - Air Brake Calibration - Verify/Calibrate Sensors Display .............. 15

Figure 5 - Air Brake calibration - Options Display .............................................. 16

Figure 6 - Air Brake Calibration Options - Display BCP Coefficients Display ........ 17

Figure 7 - Air Brake Calibration Verification Display ......................................... 18

Figure 8 - Air Brake Calibration - Verify Flow Display ....................................... 19

Figure 9 - Air Brake Sensor Calibration Display.................................................. 20

Figure 10 - Air Brake Calibration - xxx Portion Display..................................... 21

Figure 11 - Air Brake Calibration - xxx Portion Verification Display.............. 22

Figure 12 - Air Flow Measuring Device Prompt Display.................................... 24

Figure 13 - Waiting to Establish Flow Display ..................................................... 25

Figure 14 - Air Brake Sensor Calibration - Flow test Completed .................... 26

Figure 15 - Air Brake Calibration Results Display............................................... 27

Figure 16 - Air Brake Sensor calibration Results - Display Details Display 28

Information contained in this document is proprietary and confidential to, and the trade secret of, Wabtec Railway Electronics of

Germantown, Maryland. No part or whole of this document may be disclosed to third parties, copied, or reproduced in any manner

without prior written permission of Wabtec Railway Electronics.

3

WPN 31248/31248CD Rev. D

Record Of Revisions

Revision Level Author Date of Revision Description of Revision

A JFD 01/05 Initial Release

B JFD 03/05 Added instruction to

perform verification after

calibration, corrected

typo’s, clarified verification

procedure, reformatted

entire document, added

Table Of Contents

C JFD 05/05 Clarified Main Reservoir

Pressure requirements in

Section II A Prerequisites.

D JFD 08/05 Corrected Figure 10

Information contained in this document is proprietary and confidential to, and the trade secret of, Wabtec Railway Electronics of

Germantown, Maryland. No part or whole of this document may be disclosed to third parties, copied, or reproduced in any manner

without prior written permission of Wabtec Railway Electronics.

4

WPN 31248/31248CD Rev. D

FastBrake® Transducer Calibration and

Verification Using FIRE Computer

I. INTRODUCTION

A. Purpose

The purpose of this procedure is to provide step by step instruction on the

use of the FIRE Computer and the integrated TransCal software program

to perform the required calibration and verification of the FastBrake®

Locomotive Brake Equipment transducers used for pressure and flow

indication/feedback.

B. Special Tools Required

No special tools other than the correct brake pipe flow orifice/air flow

measuring device for the brake pipe/equalizing setup pressure for

locomotive operations; Part Number WPN 0650756-0xxx (xxx= setup

pressure) and a calibrated gauge with a range of at least 0 – 150 PSI,

connected to an air line with a quick disconnect on the end.

C. Equipment/Personnel Safety Precautions

All operating authority and Wabtec Railway Electronics personal protective

equipment (PPE) shall be complied with prior to performance of this

procedure. At a minimum, hard hat, safety shoes, safety glasses, and

hearing protection shall be worn.

All operating authority Blue Flag requirements shall be complied with prior

to performance of this procedure. Steps shall be taken to ensure

locomotive movement is prevented, wheels chocked and/or handbrake

set, during performance of this procedure.

Exercise caution when opening the air brake equipment locker door of the

locomotive and performing this procedure to prevent personnel injury.

Information contained in this document is proprietary and confidential to, and the trade secret of, Wabtec Railway Electronics of

Germantown, Maryland. No part or whole of this document may be disclosed to third parties, copied, or reproduced in any manner

without prior written permission of Wabtec Railway Electronics.

5

WPN 31248/31248CD Rev. D

D. General System Overview

The FastBrake® Locomotive Brake Equipment consists of three control

portions; the Brake Pipe Control Portion, Brake Cylinder Control Portion,

and the Independent Application and Release Portion (also called the

20/13 Pipe Control Portion); a Dead-In-Train Portion; and MC-31Control

Valve and Quick Service Valve which form the pneumatic back up brake.

A Cab Handle Unit (CHU) and Power Supply provide the means to power

the brake equipment and for operator control of the brake equipment.

Each control portion consists of a microcontroller, magnet valves, relay

valves, and transducers used to provide that control portion’s function(s).

The microcontroller logic is divided into two redundant channels, Channel

A and B. Each side of the logic is capable of driving the magnet valves,

and receives input from the transducers on that portion. When performing

either calibration or verification of calibration tests, BOTH sides must be

checked.

The integrated TransCal program provides the maintenance personnel

with a quick, user friendly, program with onscreen prompts provided for

guidance. It will allow the calibration/verification of transducer performance

in both pressurized and depressurized conditions, calculate and store the

transducer span and offset coefficients, and calculate/calibrate the brake

pipe charging flow transducer output. The program is accessed via the Air

Brake Maintenance Remote Session Display of the FIRE Computer.

IMPORTANT: When prompted by the software it is extremely important that the

reference gauge be placed on the correct pressure test fitting.

The software has no feedback as to which fitting the gauge is

connected to, or if a gauge is even connected and depends on

maintenance personnel/operating crew input. Incorrect connection

may result in an incorrect input of data by maintenance/operating

personnel, and resulting in improper system operation.

Information contained in this document is proprietary and confidential to, and the trade secret of, Wabtec Railway Electronics of

Germantown, Maryland. No part or whole of this document may be disclosed to third parties, copied, or reproduced in any manner

without prior written permission of Wabtec Railway Electronics.

6

WPN 31248/31248CD Rev. D

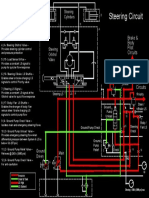

Figure 1 - Pressure Test Points

II. TEST PROCEDURES

A. Prerequisites

1. Locomotive handbrake set and/or wheels chocked.

2. Blue flag protection applied in accordance with local operating

authority requirements.

Information contained in this document is proprietary and confidential to, and the trade secret of, Wabtec Railway Electronics of

Germantown, Maryland. No part or whole of this document may be disclosed to third parties, copied, or reproduced in any manner

without prior written permission of Wabtec Railway Electronics.

7

WPN 31248/31248CD Rev. D

3. Both FastBrake® power supply circuit breakers closed.

4. No. 2 Main Reservoir Pressure at least 100 PSI when performing

transducer calibration, 120-140 PSI is required when performing

the brake pipe flow test.

5. All penalty and emergency brake applications reset.

6. Air Brake Calibration Screen selected for display on the FIRE

Computer.

7. FastBrake in LEAD/CUT IN with the Automatic Brake Handle in

HANDLE OFF/CONTINUOUS SERVICE and the Independent

Brake Handle in RELEASE.

8. Brake Pipe Pressure less than 15 PSI.

B. Pressure Transducer Verification Test

NOTE: Verify perquisites listed in Section II A have been satisfied prior to

starting the test.

NOTE: Acceptance criteria is +/- 3 PSI of the reference gauge.

1. From the Air Brake Calibration Display select the “ENTER

CALIBRATION” pushbutton.

2. Select “VERIFY SENSORS” pushbutton.

3. Initially the BCP BCCT Port is selected, to select a different

transducer and/or control portion to be verified, use the “NEXT

PORT” pushbutton to advance the port selection.

4. Connect the gauge to the corresponding pressure test point for the

transducer to be verified on the Pneumatic Manifold.

5. Select the “CONTROL TO HIGH PRESS” pushbutton. Verify the

pressure increases. Once pressure settles out, verify the indication

on the FIRE display matches the gauge indication.

6. Record the value. Use the “FREEZE READING” pushbutton to stop

minor oscillations when recording.

Information contained in this document is proprietary and confidential to, and the trade secret of, Wabtec Railway Electronics of

Germantown, Maryland. No part or whole of this document may be disclosed to third parties, copied, or reproduced in any manner

without prior written permission of Wabtec Railway Electronics.

8

WPN 31248/31248CD Rev. D

7. Select the “CONTROL TO LOW PRESS” pushbutton. Verify

pressure decreases to 0 PSI. Once pressure settles out, verify the

indication on the FIRE display matches the gauge indication.

8. Record the value. Use the “FREEZE READING” pushbutton to stop

minor oscillations when recording.

9. Repeat steps 3 through 8 for each transducer on each control

portion to be verified.

NOTE: Perform the Transducer Calibration Test, Section II D if the verification

test is failed.

C. Brake Pipe Flow Verification Test

NOTE: Verify perquisites listed in Section II A have been satisfied prior to

starting the test.

1. From the Air Brake Calibration Display select the “ENTER

CALIBRATION” pushbutton.

2. Select “VERIFY FLOW” pushbutton.

3. After verifying the correct Air Flow Measuring Device is being used

for the setup pressure selected, select the “OK” pushbutton.

4. Follow the directions on the display, attach the Air Flow Measuring

Device to the Brake Pipe SHORT HOOD END. OPEN the Brake

Pipe Angle Cock and establish flow.

5. Select the “START FLOW” pushbutton. Once flow is established

and has settled out, verify flow indication on the FIRE display is 60

CFM +/- 2.

6. Record the value. Use the “FREEZE FLOW” pushbutton to stop

minor oscillations when recording.

7. Follow the directions on the display and CLOSE the Brake Pipe

Angle Cock.

8. Select the “STOP FLOW” pushbutton. Once flow has ceased and

has settled out, verify flow indication on the FIRE display is 0 CFM.

9. Record value.

Information contained in this document is proprietary and confidential to, and the trade secret of, Wabtec Railway Electronics of

Germantown, Maryland. No part or whole of this document may be disclosed to third parties, copied, or reproduced in any manner

without prior written permission of Wabtec Railway Electronics.

9

WPN 31248/31248CD Rev. D

NOTE: Perform the Brake Pipe Flow Calibration Test, Section II E if the

verification test is failed.

D. Transducer Calibration Test

NOTE: This test is ONLY to be performed if the Transducer Calibration

Verification Test, Section II B is failed.

NOTE: Verify perquisites listed in Section II A have been satisfied prior to

starting the test.

1. From the Air Brake Calibration Display select the “ENTER

CALIBRATION” pushbutton.

2. Select the “CALIBRATE SENSORS” pushbutton.

3. Select the “CAL XXX PRESSURES” pushbutton, where XXX = the

control portion whose transducers are to be calibrated, or select

“CAL ALL PRESSURES” when all transducers are to be calibrated.

4. Follow the directions on the FIRE display, and connect the

reference gauge to the pressure test point on the Pneumatic

Manifold that corresponds with the transducer to be calibrated.

5. Select the “GAUGE READY” pushbutton once the gauge is

connected.

6. Allow pressure to increase and stabilize. Compare the gauge

indication with the indicated transducer output pressure on the Air

Brake Sensor Calibration Display.

7. Use the “+.1, -.1, +1.0, -1.0” pushbuttons to correct the transducer

output pressure to match that indicated on the reference gauge.

8. Select the “CONFIRM VALUE” pushbutton once the transducer

output has been corrected to match the reference gauge indication.

9. Repeat steps 4 through 8 for each transducer to be calibrated.

When all transducers have been calibrated, the Air Brake Calibration Results

screen will be displayed. The transducer name, its pass/fail status, and if

applicable, reason for failure is shown.

Information contained in this document is proprietary and confidential to, and the trade secret of, Wabtec Railway Electronics of

Germantown, Maryland. No part or whole of this document may be disclosed to third parties, copied, or reproduced in any manner

without prior written permission of Wabtec Railway Electronics.

10

WPN 31248/31248CD Rev. D

10. From the Air Brake Calibration Results display, select the

“DISPLAY DETAILS” pushbutton.

11. Select the “STORE AND CONTINUE” pushbutton.

12. Perform Transducer Calibration Verification in accordance with

Section II B of this procedure.

E. Brake Pipe Flow Calibration Test

NOTE: This test is ONLY to be performed if the Brake Pipe Flow

Calibration Verification Test, Section II C is failed.

NOTE: Verify perquisites listed in Section II A have been satisfied prior to

starting the test.

NOTE: When prompted by the FIRE display to OPEN and CLOSE the

brake pipe angle cock, do it slowly to prevent an undesired

emergency brake application.

1. From the Air Brake Calibration Display select the “ENTER

CALIBRATION” pushbutton.

2. Select the “CALIBRATE SENSORS” pushbutton.

3. Select the “CAL FLOW ONLY” pushbutton.

4. After verifying the correct Air Flow Measuring Device is being used,

when prompted by the FIRE display, select the “OK” pushbutton.

5. Follow the directions on the Air Brake Sensor Calibration Brake

Pipe Portion Display, and when prompted connect the Air Flow

Measuring Device to the SHORT HOOD END of the Brake Pipe.

6. Slowly OPEN the Brake Pipe Angle Cock and establish flow. Select

the “CONTINUE” pushbutton.

7. Follow the directions on the Air Brake Sensor Calibration Brake

Pipe Portion Display, and when prompted CLOSE the Brake Pipe

Angle Cock. Remove the Air Flow Measuring Device from the

Brake Pipe. Select the “CONTINUE” pushbutton.

8. From the Air Brake Calibration Results display, select the “STORE

AND CONTINUE” pushbutton.

Information contained in this document is proprietary and confidential to, and the trade secret of, Wabtec Railway Electronics of

Germantown, Maryland. No part or whole of this document may be disclosed to third parties, copied, or reproduced in any manner

without prior written permission of Wabtec Railway Electronics.

11

WPN 31248/31248CD Rev. D

9. Perform Flow Calibration Verification in accordance with Section II

C of this procedure

Fastbrake Transducer Calibration/Verification Values Chart

Transducer Name Side A Side B Gauge

16

BCC

BC

ER

MRH

MRL

BPT

20C

20

13

Flow N/A

Table 1- FastBrake Transducer Calibration/Verification Values Chart

Information contained in this document is proprietary and confidential to, and the trade secret of, Wabtec Railway Electronics of

Germantown, Maryland. No part or whole of this document may be disclosed to third parties, copied, or reproduced in any manner

without prior written permission of Wabtec Railway Electronics.

12

WPN 31248/31248CD Rev. D

III. DISPLAY SCREENS AND FUNCTIONS

A. Accessing The Program

The FastBrake Integrated Transcal Program is accessed via the FIRE

Computer Primary Display Screen by selecting the “MAINTENANCE

MODE” pushbutton, entering the correct password, selecting the

”DIAGNOSTIC MENU” pushbutton, then the “AIR BRAKE DIAGNOSTICS”

pushbutton, and then the “TRANSDUCER CALIBRATION” pushbutton.

This results in the Air Brake Calibration Display screen being displayed.

B. Air Brake Calibration Display Overview

Figure 2- Air Brake Calibration Display

The Air Brake Calibration Display is the entry level display for the

integrated TransCal program. The display shows transducer output

pressures for all transducers with exception of 13 Pipe and 16 Pipe

Transducers. Pushbuttons provide the function selection:

Information contained in this document is proprietary and confidential to, and the trade secret of, Wabtec Railway Electronics of

Germantown, Maryland. No part or whole of this document may be disclosed to third parties, copied, or reproduced in any manner

without prior written permission of Wabtec Railway Electronics.

13

WPN 31248/31248CD Rev. D

EXIT → Returns display to the Main Operating Display.

ABOUT → Displays software version and part number (WPN),

pushbuttons provide the following functions:

Figure 3 - Air Brake Calibration About Display

OK → Returns display to the Air Brake Calibration Display.

EXIT → Returns display to the Main Operating Display.

OVERRIDE ERRORS → Allows entry into the calibration/verify calibration

function with a non or incorrectly calibrated Main Reservoir High or Brake

Pipe Transducer that would normally prevent meeting the prerequisites for

main reservoir and brake pipe pressure listed above. Makes the ENTER

CALIBRATION pushbutton available.

NOTE: Entry into the calibration/verify calibration function with actual main

reservoir pressure less than 100 PSI WILL result in test failure as there

Information contained in this document is proprietary and confidential to, and the trade secret of, Wabtec Railway Electronics of

Germantown, Maryland. No part or whole of this document may be disclosed to third parties, copied, or reproduced in any manner

without prior written permission of Wabtec Railway Electronics.

14

WPN 31248/31248CD Rev. D

will not be enough pressure in the air brake system to verify correct

response of the transducers when pressurized.

ENTER CALIBRATION → Allows the maintenance personnel/operating

crew to select transducer calibration, verification of transducer calibration,

or to view previously established and stored transducer coefficients via

pushbuttons on the Verify/Calibrate Sensors Display. Makes the

Verify/Calibrate Sensors Display available.

C. Air Brake Calibration – Verify/Calibrate Sensors Display

Overview

Figure 4 - Air Brake Calibration - Verify/Calibrate Sensors Display

The Air Brake Calibration – Verify/Calibrate Sensors Display provides

indication of all transducer output pressures divided up by control portion

and pushbuttons that provide the following functions:

EXIT → Returns the display to the Main Operating Display.

Information contained in this document is proprietary and confidential to, and the trade secret of, Wabtec Railway Electronics of

Germantown, Maryland. No part or whole of this document may be disclosed to third parties, copied, or reproduced in any manner

without prior written permission of Wabtec Railway Electronics.

15

WPN 31248/31248CD Rev. D

OPTIONS → Displays the Air Brake Calibration – Options Display, used to

select and display the control portion and flow transducer previously

stored coefficients. Pushbuttons provide the following functions:

Figure 5 - Air Brake calibration - Options Display

EXIT → Returns the display to the Main Operating Display.

MAIN MENU → Returns the display to the Air Brake Calibration

Options Display.

DISPLAY XXX COEFs → Selects the control portion(s) transducers

or flow transducer to have its stored coefficients displayed.

Selection causes the selected control portion/flow transducer

coefficients to be displayed. Pushbuttons provide for the following

functions:

Information contained in this document is proprietary and confidential to, and the trade secret of, Wabtec Railway Electronics of

Germantown, Maryland. No part or whole of this document may be disclosed to third parties, copied, or reproduced in any manner

without prior written permission of Wabtec Railway Electronics.

16

WPN 31248/31248CD Rev. D

Figure 6 - Air Brake Calibration Options - Display BCP Coefficients Display

BACK → Returns the display to the Air Brake Calibration –

Options Display.

EXIT → Returns the display to the Main Operating Display.

SET XXX TO DEFAULT → Selects and sets the selected

control portion transducer coefficients to factory default

values.

VERIFY SENSORS → Displays the Air Brake Calibration – Verify Sensors

Display, used to verify transducer calibration ONLY. Provides step by step

onscreen instructions for verification of transducer performance, both

pressurized and depressurized. Comparison to the reference gauge

indication for each transducer is made. Pushbuttons provide the following

functions:

Information contained in this document is proprietary and confidential to, and the trade secret of, Wabtec Railway Electronics of

Germantown, Maryland. No part or whole of this document may be disclosed to third parties, copied, or reproduced in any manner

without prior written permission of Wabtec Railway Electronics.

17

WPN 31248/31248CD Rev. D

Figure 7 - Air Brake Calibration Verification Display

CONTROL TO HIGH PRESS → Commands system pressures to

be adjusted to the high end of the test range.

CONTROL TO LOW PRESS → Commands system pressures to

be adjusted to zero.

NEXT PORT → Selection advances the test to the next transducer

to be verified.

FREEZE READING → Holds the indicated pressure at a steady

value to allow recording the value.

MAIN MENU → Returns the display to the Air Brake Calibration

Options Display.

EXIT → Returns the display to the Main Operating Display.

Information contained in this document is proprietary and confidential to, and the trade secret of, Wabtec Railway Electronics of

Germantown, Maryland. No part or whole of this document may be disclosed to third parties, copied, or reproduced in any manner

without prior written permission of Wabtec Railway Electronics.

18

WPN 31248/31248CD Rev. D

VERIFY FLOW → Displays the flow calibration verification screens

with the step by step instructions to condition the brake pipe for the

flow test. Pushbuttons provide the following functions:

Figure 8 - Air Brake Calibration - Verify Flow Display

OK → Selection allows verification input by maintenance

personnel that the correct Air Flow Measuring Device is

being used for the test.

START FLOW → Commands system to start recording input

from flow transducer and calculate/display flow when flow

conditions established.

STOP FLOW → Commands system to start recording input

from flow transducer and calculate/display flow value for no

flow condition.

FREEZE FLOW → Holds the indicated flow at a steady

value to allow recording the value.

Information contained in this document is proprietary and confidential to, and the trade secret of, Wabtec Railway Electronics of

Germantown, Maryland. No part or whole of this document may be disclosed to third parties, copied, or reproduced in any manner

without prior written permission of Wabtec Railway Electronics.

19

WPN 31248/31248CD Rev. D

BACK → Returns the display to the Air Brake Calibration –

Verify Sensors Display.

RESUME FLOW → Commands system to re-establish flow.

CALIBRATE SENSORS → Displays the Air Brake Sensor Calibration

Display, used to calibrate transducers ONLY. Provides step by step on

screen instructions for calibration of transducer performance. Comparison

to the reference gauge indication for each transducer is made and then

pushbuttons allow transducer output to be modified to match the gauge

reading. Pushbuttons provide the following functions:

Figure 9 - Air Brake Sensor Calibration Display

EXIT → Returns display to the Main Operating Display.

MAIN MENU → Returns display to the Air Brake Calibration

Display.

Information contained in this document is proprietary and confidential to, and the trade secret of, Wabtec Railway Electronics of

Germantown, Maryland. No part or whole of this document may be disclosed to third parties, copied, or reproduced in any manner

without prior written permission of Wabtec Railway Electronics.

20

WPN 31248/31248CD Rev. D

CAL XXX PRESSURES → Selects the control portion or portions

whose transducers are to be calibrated. XXX indicates the control

portion to be tested. Displays Air Brake Sensor Calibration Display

with step by step directions on how to perform a transducer

calibration and both A and B Side pressure inputs.

CAL ALL PRESSURES → Selects all control portions and flow

transducers to be calibrated. Displays Air Brake Sensor Calibration

Display with step by step directions on how to perform a transducer

calibration and both A and B Side pressure inputs.

When a control portion (XXX) is selected, the Air Brake Calibration

– XXX Portion screen is displayed. Prompts will direct the

maintenance person performing the test to attach the reference

gauge to each pressure test point for the control portion(s) whose

transducers are to be calibrated. Pushbuttons provide the following

functions:

Figure 10 - Air Brake Calibration - xxx Portion Display

Information contained in this document is proprietary and confidential to, and the trade secret of, Wabtec Railway Electronics of

Germantown, Maryland. No part or whole of this document may be disclosed to third parties, copied, or reproduced in any manner

without prior written permission of Wabtec Railway Electronics.

21

WPN 31248/31248CD Rev. D

GAUGE READY → Provides input to system that commands

pressure to be changed.

ABORT CALIBRATION → Cancels the test in progress,

returns the display to the Air Brake Sensor Calibration

Display. No values are changed from the currently stored

values from the previous test.

EXIT → Returns the display to the Main Operating Display

Once the pressure has been adjusted the Air Brake Sensor

Calibration Display will change the pushbutton selection to

allow modification of the transducer output pressure and

confirmation of the change.

Figure 11- Air Brake Calibration - xxx Portion Verification Display

+.1/-.1/+1.0/-1.0 → Allows maintenance personnel to change

the value indicated on the display by the amount indicated

Information contained in this document is proprietary and confidential to, and the trade secret of, Wabtec Railway Electronics of

Germantown, Maryland. No part or whole of this document may be disclosed to third parties, copied, or reproduced in any manner

without prior written permission of Wabtec Railway Electronics.

22

WPN 31248/31248CD Rev. D

by the pushbutton to match that indicated on the reference

gauge.

ABORT CALIBRATION → Cancels the test in progress,

returns the display to the Air Brake Sensor Calibration

Display. No values are changed from the currently stored

values from the previous test.

EXIT → Returns the display to the Main Operating Display

CONFIRM VALUE → Allows maintenance personnel to

confirm the change requested in the transducer output by

use of the +/- pushbuttons. Commands the system to

calculate/display transducer coefficients.

NOTE: It is not possible to select an individual transducer on a

control portion for testing. The lowest possible level of

selection is the portion and when selected, all transducers

on the selected portion are tested in a fixed order, each first

at the depressurized condition and then pressurized.

CAL FLOW ONLY → Allows maintenance personnel to perform the

brake pipe flow calibration without having to

calibrate all Brake Pipe Control Portion

Transducers. Selection displays prompt for

verification of proper Air Flow Measuring

Device followed by step by step onscreen

instructions to condition the Brake Pipe for

testing.

NOTE: This only needs to be performed if the brake pipe flow

verification test is failed.

Pushbuttons on the AFM Device Verification provide the

following functions:

Information contained in this document is proprietary and confidential to, and the trade secret of, Wabtec Railway Electronics of

Germantown, Maryland. No part or whole of this document may be disclosed to third parties, copied, or reproduced in any manner

without prior written permission of Wabtec Railway Electronics.

23

WPN 31248/31248CD Rev. D

Figure 12 - Air Flow Measuring Device Prompt Display

OK → Acknowledges correct AFM Device used for the Air Brake

Sensor Calibration Flow Test

EXIT → Returns the display to the Main Operating Display

When “OK” is selected the Air Brake Sensor Calibration BP Portion

Display is shown. This indicates flow in units of CFM and pushbuttons

provide the following functions:

Information contained in this document is proprietary and confidential to, and the trade secret of, Wabtec Railway Electronics of

Germantown, Maryland. No part or whole of this document may be disclosed to third parties, copied, or reproduced in any manner

without prior written permission of Wabtec Railway Electronics.

24

WPN 31248/31248CD Rev. D

Figure 13- Waiting to Establish Flow Display

EXIT → Returns display to the Main Operating Display.

ABORT CALIBRATION → Cancels the test in progress, returns the

display to the Air Brake Sensor Calibration Display. No values are

changed from the currently stored values from the previous test.

Once flow has been established a series of displays prompt the test

personnel to OPEN and CLOSE the Brake Pipe Angle Cock as necessary

for test performance. Pushbuttons provide the following functions:

Information contained in this document is proprietary and confidential to, and the trade secret of, Wabtec Railway Electronics of

Germantown, Maryland. No part or whole of this document may be disclosed to third parties, copied, or reproduced in any manner

without prior written permission of Wabtec Railway Electronics.

25

WPN 31248/31248CD Rev. D

Figure 14- Air Brake Sensor Calibration - Flow test Completed

CONTINUE → Advances the test to the step.

EXIT → Returns display to the Main Operating Display.

ABORT CALIBRATION → Cancels the test in progress, returns the

display to the Air Brake Sensor Calibration Display. No values are

changed from the currently stored values from the previous test.

When all transducers on the control portion(s) selected for calibration have

completed, the Air Brake Calibration Results screen is displayed.

D. Air Brake Calibration Results Display Overview

The Air Brake Calibration Results Display indicates the transducer name,

its status, and if applicable the reason for failure. Pushbuttons provide the

following functions:

Information contained in this document is proprietary and confidential to, and the trade secret of, Wabtec Railway Electronics of

Germantown, Maryland. No part or whole of this document may be disclosed to third parties, copied, or reproduced in any manner

without prior written permission of Wabtec Railway Electronics.

26

WPN 31248/31248CD Rev. D

Figure 15- Air Brake Calibration Results Display

EXIT → Returns display to the Main Operating Display.

ABORT CALIBRATION → Cancels the test in progress, returns the

display to the Air Brake Sensor Calibration Display. No values are

changed from the currently stored values from the previous test.

STORE AND CONTINUE → Stores the values obtained for the

transducer coefficients in memory and returns the display to the Air

Brake Sensor Calibration Display.

DISPLAY DETAILS → Displays the coefficients calculated for the

depressurized and pressurized condition for both Side A and Side

B logic inputs. Pushbuttons provide the following functions:

Information contained in this document is proprietary and confidential to, and the trade secret of, Wabtec Railway Electronics of

Germantown, Maryland. No part or whole of this document may be disclosed to third parties, copied, or reproduced in any manner

without prior written permission of Wabtec Railway Electronics.

27

WPN 31248/31248CD Rev. D

Figure 16 - Air Brake Sensor calibration Results - Display Details Display

BACK → Returns display to the Air Brake Calibration

Results Display.

EXIT → Returns the display to the Main Operating Display.

Information contained in this document is proprietary and confidential to, and the trade secret of, Wabtec Railway Electronics of

Germantown, Maryland. No part or whole of this document may be disclosed to third parties, copied, or reproduced in any manner

without prior written permission of Wabtec Railway Electronics.

28

WPN 31248/31248CD Rev. D

Filename: 31248_MainRevD.doc

Directory: C:\Documents and Settings\jdotter\FastBrake\Integrated

Transcal Procedures

Template: C:\Documents and Settings\jdotter\Application

Data\Microsoft\Templates\Normal.dot

Title: FastBrake Tansducer Calibration and Verification Using

The Onboard Computer

Subject:

Author: jdotter

Keywords:

Comments:

Creation Date: 8/3/2005 11:05:00 AM

Change Number: 2

Last Saved On: 8/3/2005 11:05:00 AM

Last Saved By: jdotter

Total Editing Time: 1 Minute

Last Printed On: 8/3/2005 11:05:00 AM

As of Last Complete Printing

Number of Pages: 28

Number of Words: 4,089 (approx.)

Number of Characters: 22,451 (approx.)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Astm D380-94R12Document10 pagesAstm D380-94R12Igor BastosNo ratings yet

- Api 576 .Document4 pagesApi 576 .sheikmoinNo ratings yet

- Copeland Compressor PDFDocument24 pagesCopeland Compressor PDFveerapen clydeNo ratings yet

- STARLET 2221: The Multi-Purpose Handle For Professional DemandsDocument2 pagesSTARLET 2221: The Multi-Purpose Handle For Professional DemandsanellNo ratings yet

- S110-10, S1110-10 SchematicDocument1 pageS110-10, S1110-10 SchematicWattsNo ratings yet

- Cross HeadDocument4 pagesCross Headshamim imthiyasNo ratings yet

- TA35-40 G7 Steering AnimationDocument1 pageTA35-40 G7 Steering AnimationWalid AouiniNo ratings yet

- Product - Info C 1 HTO C Controlled Atmosphere Oven HTMA EN PDFDocument9 pagesProduct - Info C 1 HTO C Controlled Atmosphere Oven HTMA EN PDFBeto RiveroNo ratings yet

- Hydrostatic Lubricator For Steam LocomotivesDocument6 pagesHydrostatic Lubricator For Steam LocomotivesVikk SuriyaNo ratings yet

- PDF Filter Separator Vessel Manual DLDocument40 pagesPDF Filter Separator Vessel Manual DLRosa SparksNo ratings yet

- 09 - Buchholz Relay - AspeDocument13 pages09 - Buchholz Relay - AspeJosé ZambranoNo ratings yet

- A4vg eDocument43 pagesA4vg eHarun VijayakumaranNo ratings yet

- EC250D BRIC - Hyd - eng-GB20025770B - HDocument30 pagesEC250D BRIC - Hyd - eng-GB20025770B - Hفتحي الجمل فتحي الجملNo ratings yet

- Documentatie GRUNDFOS 3 7 Pompa Dozatoare Membrana Hidromecanica DMHQ 1500 LH H 200 Bar Sialco Distribuitor GRUNDFOS RomaniaDocument80 pagesDocumentatie GRUNDFOS 3 7 Pompa Dozatoare Membrana Hidromecanica DMHQ 1500 LH H 200 Bar Sialco Distribuitor GRUNDFOS Romaniajoko setiawanNo ratings yet

- Válvula Antisísmica PDFDocument1 pageVálvula Antisísmica PDFJhonattan AlvarezNo ratings yet

- V-500 Series DSR After Oct 2011 TK55255-0.0-E-18-PM 11-11Document83 pagesV-500 Series DSR After Oct 2011 TK55255-0.0-E-18-PM 11-11Arturo Michel Moreno JimenezNo ratings yet

- Manual F30-55 EN DE RU v2 2 0Document92 pagesManual F30-55 EN DE RU v2 2 0ТОВ Компресормаш-СервісNo ratings yet

- Opel Corsa C Coolant Pump ReplacementDocument10 pagesOpel Corsa C Coolant Pump ReplacementAndrásBakosNo ratings yet

- Material Schematic Hydraulic System Motor Grader 16h CaterpillarDocument34 pagesMaterial Schematic Hydraulic System Motor Grader 16h CaterpillarJeri Rizal FirdausNo ratings yet

- Steering System Repair ManualDocument13 pagesSteering System Repair Manualsample nameNo ratings yet

- CSA Direct Acting Valves 8.2017Document42 pagesCSA Direct Acting Valves 8.2017dalla nabilNo ratings yet

- Lecture 17 (Compatibility Mode)Document23 pagesLecture 17 (Compatibility Mode)Cybex EngineeringNo ratings yet

- 3 - IADC Ocean KingDocument17 pages3 - IADC Ocean KingArturo PerezNo ratings yet

- Product Support Department: Technical Inspection ReportDocument3 pagesProduct Support Department: Technical Inspection ReportMarcial Jr. MilitanteNo ratings yet

- Om 2003 Rev A 01016385DDocument53 pagesOm 2003 Rev A 01016385DWynn Wood HOA Web MasterNo ratings yet

- CometCat05 NopricesDocument52 pagesCometCat05 NopricesMariano ErdbecherNo ratings yet

- Transport SG 540Document6 pagesTransport SG 540Truck FumpNo ratings yet

- P B 109 Bi Fold BulletinDocument2 pagesP B 109 Bi Fold Bulletincmorley5057No ratings yet

- Jaquar FaucetsDocument20 pagesJaquar Faucetssonalsonal303No ratings yet

- 10 Single Drum WinchesDocument54 pages10 Single Drum Wincheskelvinyeoh100% (3)