Professional Documents

Culture Documents

Wac 296-79-250

Uploaded by

Cast VazOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wac 296-79-250

Uploaded by

Cast VazCopyright:

Available Formats

WAC 296-79-250 Safety procedure for handling sulfur.

(1) Sulfur

burners. Sulfur-burner houses must:

(a) Be safely and adequately ventilated; and

(b) Have every precaution taken to guard against dust, explosion

hazards and fires, in accordance with American National Standards

Z9.2-1979 (R1991).

(2) Handling/storage of dry sulfur.

(a) Nonsparking tools and equipment must be used in handling dry

sulfur.

(b) Sulfur storage bins must be kept free of sulfur dust accumu-

lation, and buildings should be designed with explosion relief, in ac-

cordance with the latest revision of American National Standard

Z9.2-1979 (R1991).

(c) Sulfur-melting equipment must not be located in the burner

room.

(3) Handling/storage of liquid sulfur.

(a) Each facility utilizing liquid sulfur must:

(i) Carefully examine its own handling system; and

(ii) Formulate a written procedure for maintenance, receiving,

storing and using this product.

(b) A minimum of two trained employees must be assigned when a

tank car is first opened in preparation for venting and unloading.

(c) Approved respiratory protective equipment for H2S exposure,

chemical splash goggles and gloves must be worn when performing this

work.

(d) Spark producing or electric operated tools must not be used

to unplug railroad car vents.

(e) Where venting can cause harmful exposure to other unprotected

workers in the area:

(i) A venting system must be installed which adequately contains

any gas escapement from a tank car while venting;

(ii) The vented gas must be carried to a safe location for dis-

charge or circulated through a scrubbing system;

(iii) The venting system must be connected before valves which

would allow escapement are opened.

(f) Smoking, open burning or welding must be prohibited while un-

loading is in process or danger of gas escapement exists.

(4) Acid plant - Protection for employees.

(a) Where lime slaking takes place, employees must be provided

with rubber boots, rubber gloves, protective aprons, and eye protec-

tion. A deluge shower and eyewash must be provided to flush the skin

and eyes to counteract lime and acid burns.

(b) Hoops for acid storage tanks must be:

(i) Made of round rods rather than flat strips; and

(ii) Regularly inspected and safety maintained.

(c) Sulphur burner ignitors must have a means to automatically

shut off the fuel to the ignitor when the flame has been extinguished.

[Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, and

49.17.060. WSR 17-16-132, § 296-79-250, filed 8/1/17, effective

9/1/17. Statutory Authority: RCW 49.17.010, [49.17].040 and

[49.17].050. WSR 99-16-083, § 296-79-250, filed 8/3/99, effective

11/3/99. Statutory Authority: Chapter 49.17 RCW. WSR 91-24-017 (Order

91-07), § 296-79-250, filed 11/22/91, effective 12/24/91; Order 76-7,

§ 296-79-250, filed 3/1/76; Order 74-24, § 296-79-250, filed 5/6/74;

Order 70-6, § 296-79-250, filed 7/10/70, effective 8/10/70.]

Certified on 10/25/2019 WAC 296-79-250 Page 1

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Design of Bolted Beam Splice Connections According To EC3Document11 pagesDesign of Bolted Beam Splice Connections According To EC3Franklyn Genove100% (2)

- Bell Desk-2Document96 pagesBell Desk-2Arrow PrasadNo ratings yet

- 2009 PMI CatalogueDocument124 pages2009 PMI Cataloguedesbennett004No ratings yet

- Porting Relations 2 StrokesDocument10 pagesPorting Relations 2 Strokespistonbreaker100% (8)

- Suzuki B-King Indicator Mod CompleteDocument9 pagesSuzuki B-King Indicator Mod Completehookuspookus1No ratings yet

- Detailed Lesson Plan in Science 5Document5 pagesDetailed Lesson Plan in Science 5hs4fptm82gNo ratings yet

- Cooling Water BasicsDocument163 pagesCooling Water BasicsEduardo Castillo100% (1)

- Altenator PDFDocument26 pagesAltenator PDFluisNo ratings yet

- A Mesh-Free Solid-Mechanics ApproachDocument26 pagesA Mesh-Free Solid-Mechanics ApproachMustafa YildizNo ratings yet

- SuperOhm 3754 (3748-11) - Technical Data Sheet - ECC - Rev 2 - 2016-09Document2 pagesSuperOhm 3754 (3748-11) - Technical Data Sheet - ECC - Rev 2 - 2016-09igor brocaNo ratings yet

- Experiment SCDocument5 pagesExperiment SCnitinmgNo ratings yet

- ISO - 3601-2 O-Rings HousingDocument56 pagesISO - 3601-2 O-Rings HousingAlexey FlidliderNo ratings yet

- Error Number Mentor GraphicsDocument30 pagesError Number Mentor GraphicsMendesNo ratings yet

- Crisfield - Vol1 - NonLinear Finite Element Analysis of Solids and Structures EssentialsDocument360 pagesCrisfield - Vol1 - NonLinear Finite Element Analysis of Solids and Structures EssentialsAnonymous eCD5ZRNo ratings yet

- Ceilcote 383 Corocrete: Hybrid Polymer Broadcast FlooringDocument3 pagesCeilcote 383 Corocrete: Hybrid Polymer Broadcast FlooringNadia AgdikaNo ratings yet

- DC PandeyDocument3 pagesDC PandeyPulkit AgarwalNo ratings yet

- Cloud Computing - Feb-Mar 2017Document40 pagesCloud Computing - Feb-Mar 2017Abhishek SinghNo ratings yet

- Construction of Rajive Gandhi Urja Bhawan, Ongc Energy Center & Corporate OfficeDocument23 pagesConstruction of Rajive Gandhi Urja Bhawan, Ongc Energy Center & Corporate OfficeDevendra SharmaNo ratings yet

- Brochure FDP - EG 16.08.2021-1-2-2Document3 pagesBrochure FDP - EG 16.08.2021-1-2-2sri sivaNo ratings yet

- Transfer Action in Sap HRDocument3 pagesTransfer Action in Sap HRKarthi MrvkNo ratings yet

- Form WorkDocument12 pagesForm Workdharul khairNo ratings yet

- Stainless Steel: Presented By, Dr. Pragati Jain 1 YearDocument68 pagesStainless Steel: Presented By, Dr. Pragati Jain 1 YearSneha JoshiNo ratings yet

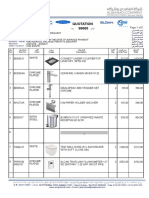

- Quotation 98665Document5 pagesQuotation 98665Reda IsmailNo ratings yet

- Circuito PCB Control Pedal V3 TerminadoDocument1 pageCircuito PCB Control Pedal V3 TerminadoMarcelo PereiraNo ratings yet

- Excel CatDocument132 pagesExcel Catjuanf_scribdNo ratings yet

- Nuendo 4 Remote Control Devices EsDocument24 pagesNuendo 4 Remote Control Devices EsRamon RuizNo ratings yet

- University of Tennessee - ChattanoogaDocument34 pagesUniversity of Tennessee - ChattanoogaMALIK ZARYABBABARNo ratings yet

- An Analysis of The Ejector-Ram-Rocket EngineDocument9 pagesAn Analysis of The Ejector-Ram-Rocket Enginefundamental_aeroNo ratings yet

- F4 Search Help To Select More Than One Column ValueDocument4 pagesF4 Search Help To Select More Than One Column ValueRicky DasNo ratings yet

- LRT JakproDocument21 pagesLRT JakproAzzah Auliya Ardindasari100% (1)