Professional Documents

Culture Documents

ATEX Equipment Classification Labelling PDF

ATEX Equipment Classification Labelling PDF

Uploaded by

AlexisVillaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ATEX Equipment Classification Labelling PDF

ATEX Equipment Classification Labelling PDF

Uploaded by

AlexisVillaCopyright:

Available Formats

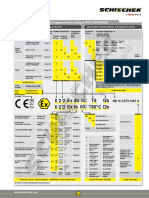

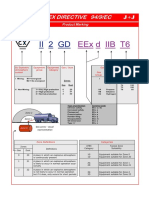

Labelling of explosion proof equipment

Labelling of explosion proof equipment according to ATEX 94/9/EC

Classification and labelling

Classification of explosion

and labelling proof

of explosion areas

proof areas Classification

Classification Explosion

Explosion groups & classes

groups + Temperature Temperature classes

(gases, mists, vapours)

Flammable Hazardous locations Classification Product classification Product Explosion Examples depending on

medium Probability of a of explosion level group - explosion group

potential explosive proof areas (EPL) - temperature class

atmosphere occuring Product Product

group category

Ammonia Ethanol Petrol Acetal-de-

Always, temporarily or Methane Cyclohe- Diesel fuel hyde

often present Zone 0 II IIA Ethane xene Fuel oil

Propane n-Butane n-Hexane

IIB

City gas Ethylene Ethyl glycol Ethyl ether

Gases, Acrylic Ethylene

mists, Occasionally present Zone 1 II 1G Ga IIC nitrile oxide

Carbon

hydrogen

vapours

2G Gb

Hydrogen Acetylene Carbon

Very seldom or only disulphide

present for a short period Zone 2 II 3G Gc

Attention: this list is only an extract of possible flammable

T1<450°C mediums and does not claim to be complete !

Always, temporarily or

often present Zone 20 II

T2<300°C

T3<200°C

Dusts Occasionally present Zone 21 II 1D Da

T4<135°C

2D Db

Does not occur or only T5<100°C

Zone 22 II 3D Dc

seldom for a short period

T6< 85°C

Official institutes Product use depending on temperature class (T1 - T6). The temperature

class indicates the max. temperature of the exposed surface of the

code Institute product. For dust explosion proof, the max. surface temperature is

number Notified Body (NB) directly shown (e.g. T80°C).

0102 PTB (Germany) Temperature class

0158 EXAM (Germany)

Example:

II 2G Ex d IIC T6 Gb NB 12 ATEX 1007 X

0158

II 2D Ex tb IIIC T80°C Db

Prevents transmission of flameproof IIIA flammable fibres

Ex d 1, 2 EN 60079-1 IIIB

the explosion outside enclosure

IIIC non conductive dust

Prevents high For common use –

temperatures and sparks increased safety Ex e 1, 2 EN 60079-7

conductive dust

Ex i ¹ 0, 1, 2 Code Dust classification

Low current / voltage supply intrinsic safety EN 60079-11

Ex iD ² 20, 21, 22

Positive pressure device

pressurised Ex p 1, 2

apparatus EN 60079-2 long periods of For use under

Ex pD 21, 22 8 –

immersion special X

the effects of tem- circumstances

Ex m ³ 0, 1, 2 7 – porary immersion

Encapsulated moulding EN 60079-18

Ex mD 20, 21, 22

totally protected strong jets of

6 against dust water

Parts immersed in oil to isolate dust - limited low pressure jets

from explosive atmosphere oil immersion Ex o 1, 2 EN 60079-6 5 ingress from all directions

solids objects sprays from all

4 > 1 mm directions

Prevents transmission of

explosion outside powder filling Ex q 1, 2 EN 60079-5 This product is an

solids objects direct sprays up to Ex-certified

3 > 2,5 mm 60° from vertical component for use U

As above, but for use in 2 solids objects direct sprays up to in a complete

protection “n” Ex n 2 EN 60079-15 > 12,5 mm 15° from vertical system

zone 2

solids objects vertical falling

1 > 50 mm drops of water

Dust explosion proof protection “tD” Ex t 20, 21, 22 EN 60079-31

IP66 0 no protection no protection

Protection principle Type of Code Symbol To use CENELEC IP Protection Protection Application Code

protection in zone against against

6

solids /dust water

Protection principle – Type of protection – EN 60079-0 General Requirements Ingress Protection EN 60529 Further information

1

ia (zone 0, 1, 2), ib (zone 1, 2), ic (zone 2) 3

ma (zone 0, 1, 2), mb (zone 1, 2), mc (zone 2) 5

ta (zone 20, 21, 22), tb (zone 21, 22), tc (zone 22)

6

2

iaD (zone 20, 21, 22), ibD (zone 21, 22), icD (zone 22) 4

maD (zone 20, 21, 22), mbD (zone 21, 22), mcD (zone 22) Highest possible application areas

www.schischek.com

You might also like

- Pump Sizing Calculation: Tag No. P-101 Description Feed Pump Date 06-May-2017 by CheguideDocument6 pagesPump Sizing Calculation: Tag No. P-101 Description Feed Pump Date 06-May-2017 by CheguideAtty Atty100% (1)

- 938g II ElectricoDocument14 pages938g II ElectricoChrissz Noxd100% (3)

- Servise Manual f40 YAMAHADocument285 pagesServise Manual f40 YAMAHAZauf Satrapicus100% (1)

- TB6600 User Guide V1.2Document11 pagesTB6600 User Guide V1.2Anonymous gdJiDHNo ratings yet

- Compressor Anti-SurgeDocument4 pagesCompressor Anti-SurgestreamtNo ratings yet

- ATEX Marking Electrical Equipment Ex PDFDocument1 pageATEX Marking Electrical Equipment Ex PDFBinhvvNo ratings yet

- Atex ClassificationDocument1 pageAtex ClassificationDANE80No ratings yet

- ATEX Electric Equipment Classification Labelling PDFDocument1 pageATEX Electric Equipment Classification Labelling PDFRamius HamdaniNo ratings yet

- Ex Poster Bartec 2019 eDocument1 pageEx Poster Bartec 2019 eSubin ThomasNo ratings yet

- Flange LeakageDocument29 pagesFlange LeakageSandeep Bhatia100% (2)

- Classification Labelling o EquipmentDocument1 pageClassification Labelling o EquipmentAbdul RahmanNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- HVAC - Handbook Commercial Kitchen Ventilation - Best Practice PDFDocument39 pagesHVAC - Handbook Commercial Kitchen Ventilation - Best Practice PDFOliver HermosaNo ratings yet

- 3 Gasoline Pool CDDocument46 pages3 Gasoline Pool CDnareshpallaNo ratings yet

- Classification and Labelling of Electric Explosion Proof ATEX PDFDocument1 pageClassification and Labelling of Electric Explosion Proof ATEX PDFRamesh KumarNo ratings yet

- Marking Electrical Equipment ExDocument1 pageMarking Electrical Equipment ExFendy ShirahNo ratings yet

- Factsheet SGT-700 enDocument2 pagesFactsheet SGT-700 enAzril DahariNo ratings yet

- Hazardous Area Chart - BartecDocument1 pageHazardous Area Chart - BartecbandianwarNo ratings yet

- T 90 Tank DescriptionDocument23 pagesT 90 Tank Descriptionbrijeshgowda23No ratings yet

- Marking Non Electrical Equipment Ex PDFDocument1 pageMarking Non Electrical Equipment Ex PDFNicolae VisanNo ratings yet

- Factsheet TurritellaDocument2 pagesFactsheet TurritellaJeganeswaranNo ratings yet

- Bell Jaw Brochure - EnglishDocument12 pagesBell Jaw Brochure - EnglishChristopherNo ratings yet

- Statement of Purpose For A ScholarshipDocument2 pagesStatement of Purpose For A Scholarshipedsa mendpzaNo ratings yet

- Questions and Answers - Photovoltaic Training Session 2Document4 pagesQuestions and Answers - Photovoltaic Training Session 2Fernando NunoNo ratings yet

- ATEX Classification Labelling of Electric EquipmentDocument1 pageATEX Classification Labelling of Electric EquipmentLudi D. LunarNo ratings yet

- Labelling of Explosion Proof Equipment: Ii2Gexdiict6 Ii 2D Ex TB Iiic T80°C GB DB GB DB GB T80°C T80°C DBDocument1 pageLabelling of Explosion Proof Equipment: Ii2Gexdiict6 Ii 2D Ex TB Iiic T80°C GB DB GB DB GB T80°C T80°C DBChirack Singh Tony AntonyNo ratings yet

- WWW - schischek.com:pdf:ATEX Classification Labelling of Electric EquipmentDocument1 pageWWW - schischek.com:pdf:ATEX Classification Labelling of Electric EquipmentfrancisNo ratings yet

- ATEXGuidelines LowDocument1 pageATEXGuidelines LowalphieNo ratings yet

- Marking Electrical Equipment Ex PDFDocument1 pageMarking Electrical Equipment Ex PDFrakacyuNo ratings yet

- Marking Non Electrical Equipment Ex PDFDocument1 pageMarking Non Electrical Equipment Ex PDFAgus RianNo ratings yet

- Marking Non Electrical Equipment Ex PDFDocument1 pageMarking Non Electrical Equipment Ex PDFMMNo ratings yet

- Marking Non Electrical Equipment ExDocument1 pageMarking Non Electrical Equipment ExTurkish Medical CareNo ratings yet

- Standards, Zone DefinitionsDocument3 pagesStandards, Zone DefinitionsKhalifa AljahawiNo ratings yet

- Marking IECEx Equipment ExDocument1 pageMarking IECEx Equipment Exadirocks89No ratings yet

- ATEX For Non-ElectricalDocument1 pageATEX For Non-ElectricalRajesh KumarNo ratings yet

- A Guide To The Use Of... : Electrical Equipment in Potentially Explosive AtmospheresDocument4 pagesA Guide To The Use Of... : Electrical Equipment in Potentially Explosive AtmospheresAsif Ullah KhanNo ratings yet

- Polyester Resins For Filled Fire Retardant Applications: Firepel K320-A Series Polyester ResinDocument3 pagesPolyester Resins For Filled Fire Retardant Applications: Firepel K320-A Series Polyester ResinA.Subin DasNo ratings yet

- Marking Iecex Equipment Ex..Document1 pageMarking Iecex Equipment Ex..jerrinjNo ratings yet

- Explaining ATEX & IECEx Certifications NotesDocument3 pagesExplaining ATEX & IECEx Certifications Notes何吉飞No ratings yet

- 50H Earlier Hygienic Flow MeterDocument24 pages50H Earlier Hygienic Flow MeterShishir JhaNo ratings yet

- Explosion Proof DefinitionsDocument2 pagesExplosion Proof Definitionsgallegos70No ratings yet

- Intrinsic Safety: A Technical Seminar OnDocument32 pagesIntrinsic Safety: A Technical Seminar OnGobinath BalasubramanianNo ratings yet

- Ex KodlariDocument1 pageEx KodlaridhnsekaranNo ratings yet

- Coal Processing Technologies For Added Value Mining Indonesia Conference by MH & ES FinalDocument32 pagesCoal Processing Technologies For Added Value Mining Indonesia Conference by MH & ES FinalMiftahul HudaNo ratings yet

- Eye C GasDocument3 pagesEye C GasLuis ReyesNo ratings yet

- Lecture 02 - FuelsDocument12 pagesLecture 02 - FuelsEkoms GamingNo ratings yet

- ΑΝΤΙΕΚΡΗΚΤΙΚΟΤΗΤΑDocument1 pageΑΝΤΙΕΚΡΗΚΤΙΚΟΤΗΤΑKonstantinos KantzavelosNo ratings yet

- AOC FR Resin K320-A - Technical DataDocument3 pagesAOC FR Resin K320-A - Technical Dataomarjaime01No ratings yet

- Safe Oxygen Production Large Safe Hydrogen FacilitiyDocument5 pagesSafe Oxygen Production Large Safe Hydrogen FacilitiyTS WongNo ratings yet

- Alvega: Salt - New Breakthrough Solid Acid Alkylation TechnologyDocument11 pagesAlvega: Salt - New Breakthrough Solid Acid Alkylation TechnologyhamedNo ratings yet

- II 1/2G Ex DB IIC T4 Ga/Gb: Internally/externally EPL Internally/externallyDocument2 pagesII 1/2G Ex DB IIC T4 Ga/Gb: Internally/externally EPL Internally/externallyDhananjay BhaldandNo ratings yet

- Topic 2 WEEK 5 8 Fire Fighting Onboard ShipsDocument27 pagesTopic 2 WEEK 5 8 Fire Fighting Onboard Shipslawrence christian dragidoNo ratings yet

- Voluntary GHG Reporting Summary Tables Emissions Factors 2015 PDFDocument2 pagesVoluntary GHG Reporting Summary Tables Emissions Factors 2015 PDFJorge Tení CaalNo ratings yet

- Egemaster-Non Sparking Tools Safety PDFDocument5 pagesEgemaster-Non Sparking Tools Safety PDFZulfiqar AliNo ratings yet

- Session 2 - Explosion Protection FundamentalsDocument24 pagesSession 2 - Explosion Protection Fundamentalsdijoz85No ratings yet

- NEC Poster e PDFDocument1 pageNEC Poster e PDFRahul PatilNo ratings yet

- Acs Iecr 7b01462Document12 pagesAcs Iecr 7b01462ดั๊มพ์ วาสนาทิพย์No ratings yet

- Solaronics Catalogue 2015 Guide Technique en v5Document8 pagesSolaronics Catalogue 2015 Guide Technique en v5ดั๊มพ์ วาสนาทิพย์No ratings yet

- Hot - Tapping - 1683962219 2023-05-13 07 - 17 - 06Document84 pagesHot - Tapping - 1683962219 2023-05-13 07 - 17 - 06ดั๊มพ์ วาสนาทิพย์No ratings yet

- Oman - IEA - Report - 1686634467 2023-06-13 05 - 34 - 33Document54 pagesOman - IEA - Report - 1686634467 2023-06-13 05 - 34 - 33ดั๊มพ์ วาสนาทิพย์No ratings yet

- En 50216-10Document16 pagesEn 50216-10ดั๊มพ์ วาสนาทิพย์No ratings yet

- Experimental Study of Micro-Particle Fouling Under PDFDocument12 pagesExperimental Study of Micro-Particle Fouling Under PDFดั๊มพ์ วาสนาทิพย์No ratings yet

- Pressure Equipment Directive (PED) Classification Guide For Regulator ProductsDocument8 pagesPressure Equipment Directive (PED) Classification Guide For Regulator Productsดั๊มพ์ วาสนาทิพย์No ratings yet

- Types ACE95 and ACE95Sr Tank Blanketing ValvesDocument12 pagesTypes ACE95 and ACE95Sr Tank Blanketing Valvesดั๊มพ์ วาสนาทิพย์No ratings yet

- Type Y692 Gas Blanketing Regulator SystemDocument12 pagesType Y692 Gas Blanketing Regulator Systemดั๊มพ์ วาสนาทิพย์No ratings yet

- Type T205B Balanced Tank Blanketing RegulatorDocument24 pagesType T205B Balanced Tank Blanketing Regulatorดั๊มพ์ วาสนาทิพย์No ratings yet

- Tank Blanketing and Vapor Recovery Solutions: Application MapDocument1 pageTank Blanketing and Vapor Recovery Solutions: Application Mapดั๊มพ์ วาสนาทิพย์No ratings yet

- Type 1190: Installation Guide D101644X014 English - November 2015Document4 pagesType 1190: Installation Guide D101644X014 English - November 2015ดั๊มพ์ วาสนาทิพย์No ratings yet

- Brochure Alfa Laval Packinox PPI00196ENDocument20 pagesBrochure Alfa Laval Packinox PPI00196ENดั๊มพ์ วาสนาทิพย์No ratings yet

- Manuals Position Monitor Bracket PMB Mounting Kit Installation Sheet Fisher en en 6104004Document4 pagesManuals Position Monitor Bracket PMB Mounting Kit Installation Sheet Fisher en en 6104004ดั๊มพ์ วาสนาทิพย์No ratings yet

- 3Hq H (Ƞv0Rvw:Lgho/8Vhg+Rvh: Series 700 Stainless Steel HoseDocument1 page3Hq H (Ƞv0Rvw:Lgho/8Vhg+Rvh: Series 700 Stainless Steel Hoseดั๊มพ์ วาสนาทิพย์No ratings yet

- Bulk Modulus - My DataBookDocument4 pagesBulk Modulus - My DataBookดั๊มพ์ วาสนาทิพย์No ratings yet

- Predict Storage-Tank Heat Transfer Precisely-LibreDocument6 pagesPredict Storage-Tank Heat Transfer Precisely-Libreดั๊มพ์ วาสนาทิพย์No ratings yet

- Coke Formation Onsilica-Alumina Cracking CatalystsDocument6 pagesCoke Formation Onsilica-Alumina Cracking Catalystsดั๊มพ์ วาสนาทิพย์No ratings yet

- Flaresim 3 Nov 2010Document27 pagesFlaresim 3 Nov 2010ดั๊มพ์ วาสนาทิพย์No ratings yet

- 2306c-E14tag1a 2 3Document9 pages2306c-E14tag1a 2 3German O.No ratings yet

- Lecture 12 Secondary Tillage PDFDocument7 pagesLecture 12 Secondary Tillage PDFsujan paudelNo ratings yet

- Barricades and ScaffoldsDocument17 pagesBarricades and Scaffoldseroll palomarNo ratings yet

- Hilti-Hy 200-RDocument74 pagesHilti-Hy 200-RHumberto EstevezNo ratings yet

- Design, Prototyping and Construction: CSSE371 Steve Chenoweth and Chandan Rupakheti (Chapter 11-Interaction Design Text)Document20 pagesDesign, Prototyping and Construction: CSSE371 Steve Chenoweth and Chandan Rupakheti (Chapter 11-Interaction Design Text)CarlosNo ratings yet

- Autoihumobile ProjectDocument17 pagesAutoihumobile ProjectOm KalkeriNo ratings yet

- Commercial Use Heat Pump Water Heater: Ecological Energy Recovering Heat Energy From The AirDocument20 pagesCommercial Use Heat Pump Water Heater: Ecological Energy Recovering Heat Energy From The AirPetre DragomirNo ratings yet

- Thermo Cr422 Troubleshooting ManualDocument35 pagesThermo Cr422 Troubleshooting ManualRuben DuranNo ratings yet

- LiquiTOCi Manual OperationDocument83 pagesLiquiTOCi Manual OperationJose Antonio Sanchez MarinNo ratings yet

- 16H Plano Eléctrico NA Version 6ZJDocument2 pages16H Plano Eléctrico NA Version 6ZJmanryNo ratings yet

- Auto Rickshaw Redesigned - Design ProjectDocument31 pagesAuto Rickshaw Redesigned - Design ProjectShantanu Maheshwari100% (1)

- Installation and Operating Instructions of Balmoral Rainwater Harvesting TanksDocument16 pagesInstallation and Operating Instructions of Balmoral Rainwater Harvesting TanksGreen Action Sustainable Technology GroupNo ratings yet

- Nepal Road Standard 2027 Revision 2045Document22 pagesNepal Road Standard 2027 Revision 2045erjuniorsanjip0% (1)

- Isolator PDFDocument14 pagesIsolator PDFbharathNo ratings yet

- Methanol Project PDFDocument50 pagesMethanol Project PDFPaola Nair M ChNo ratings yet

- Critical Environment Radial FlowDocument6 pagesCritical Environment Radial FlowAnonymous S9qBDVkyNo ratings yet

- Dynapac Vibro CA250Document2 pagesDynapac Vibro CA250Rachmat ArifNo ratings yet