Professional Documents

Culture Documents

Hot Dip Galvanized Steel Strip Voestalpine en 20181002 Twoside

Uploaded by

Andy HuffCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hot Dip Galvanized Steel Strip Voestalpine en 20181002 Twoside

Uploaded by

Andy HuffCopyright:

Available Formats

HOT-DIP GALVANIZED

STEEL STRIP

Range of supply

April 2019

voestalpine Steel Division

www.voestalpine.com/steel

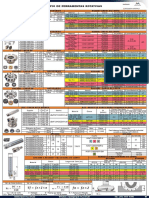

Yield Tensile Total Yield Tensile Total

Norms and strength strength elong. r value n value BH2 Norms and strength strength elong. r value n value BH2

specifica- Test Rp0.2 Rm A80 min. min. min. min. specifica- Test Rp0.2 Rm A80 min. min. min. min.

Steel grade tions dir. [MPa] [MPa] [%] [-] [-] [MPa] Exposed Steel grade tions dir. [MPa] [MPa] [%] [-] [-] [MPa] Exposed

Mild steels Bake-hardening steels

EN 10346 EN 10346 Rp0.2 Rm A80 r90 n10-20/Ag BH2 E

Rp0.2 Rm A80 r90 n10-20/Ag BH2 E

and voestalpine special grade

HX180BD EN 10346 Trans. 180 - 240 290 - 360 34 1.5 0.16 30

DX51D EN 10346 Trans. - 270 - 500 22 - - - -

HX220BD EN 10346 Trans. 220 - 280 320 - 400 32 1.2 0.15 30

DX52D EN 10346 Trans. 140 - 300 270 - 420 26 - - - -

HX260BD EN 10346 Trans. 260 - 320 360 - 440 28 - - 30

DX53D EN 10346 Trans. 140 - 260 270 - 380 30 - - -

HX300BD EN 10346 Trans. 300 - 360 400 - 480 26 - - 30

DX54D EN 10346 Trans. 120 - 220 260 - 350 36 1.6 0.18 -

VDA 239-100 Rp0.2 Rm A80 r0 n10-20/Ag BH2 E

DX56D EN 10346 Trans. 120 - 180 260 - 350 39 1.9 0.21 -

CR180BH VDA 239-100 Long. 180 - 240 290 - 370 34 1.1 0.17 30

DX57D EN 10346 Trans. 120 - 170 260 - 350 41 2.1 0.22 -

CR210BH VDA 239-100 Long. 210 - 270 320 - 400 32 1.1 0.16 30

DX58D voestalpine Trans. 110 - 170 250 - 330 43 2.3 0.23 -

CR240BH VDA 239-100 Long. 240 - 300 340 - 440 29 1.0 0.15 30

VDA 239-100 Rp0.2 Rm A80 r90 n10-20/Ag BH2 E CR270BH VDA 239-100 Long. 270 - 330 360 - 460 27 - 0.13 30

and voestalpine special grade

CR1 VDA 239-100 Trans. 140 - 300 270 - 410 28 - - - -

CR2 VDA 239-100 Trans. 140 - 240 270 - 370 34 1.3 0.16 - High-strength IF steels

CR3 VDA 239-100 Trans. 140 - 210 270 - 350 38 1.8 0.18 - EN 10346 Rp0.2 Rm A80 r90 n10-20/Ag BH2 E

CR4 VDA 239-100 Trans. 140 - 180 270 - 330 39 1.9 0.20 - HX180YD EN 10346 Trans. 180 - 240 330 - 390 34 1.7 0.18 -

CR5 VDA 239-100 Trans. 110 - 170 260 - 330 41 2.1 0.22 - HX220YD EN 10346 Trans. 220 - 280 340 - 420 32 1.5 0.17 -

CR6 voestalpine Trans. 110 - 170 250 - 330 43 2.3 0.23 - HX260YD EN 10346 Trans. 260 - 320 380 - 440 30 1.4 0.16 -

VDA 239-100 Rp0.2 Rm A80 r0 n10-20/Ag BH2 E

Structural steels CR180IF VDA 239-100 Long. 180 - 240 320 - 400 35 1.2 0.19 -

EN 10346 Rp0.2 Rm A80 r0 n10-20/Ag BH2 E CR210IF VDA 239-100 Long. 210 - 270 340 - 420 33 1.1 0.18 -

S220GD EN 10346 Long. ≥ 220 ≥ 300 20 - - - - CR240IF VDA 239-100 Long. 240 - 300 360 - 440 31 1.0 0.17 -

S250GD EN 10346 Long. ≥ 250 ≥ 330 19 - - - -

S280GD EN 10346 Long. ≥ 280 ≥ 360 18 - - - - Carbon-manganese steels

S320GD EN 10346 Long. ≥ 320 ≥ 390 17 - - - - Special voestalpine grade Rp0.2 Rm A80 r90 n10-20/Ag BH2 E

S350GD EN 10346 Long. ≥ 350 ≥ 420 16 - - - - HT440CMD voestalpine Trans. 280 - 380 ≥ 440 25 - - - -

S390GD EN 10346 Long. ≥ 390 ≥ 460 16 - - - - HT590CMD voestalpine Trans. 420 - 570 ≥ 590 14 - - - -

S420GD EN 10346 Long. ≥ 420 ≥ 480 15 - - - -

S450GD EN 10346 Long. ≥ 450 ≥ 510 14 - - - - Dual-phase steels

EN 10346 Rp0.2 Rm A80 r0 n10-UE BH2 E

Micro-alloyed steels

HCT450X EN 10346 Long. 260 - 340 ≥ 450 27 - 0.16 30

EN 10346 Rp0.2 Rm A80 r90 n10-20/Ag BH2 E HCT490X EN 10346 Long. 290 - 380 ≥ 490 24 - 0.15 30

HX260LAD EN 10346 Trans. 260 - 330 350 - 430 26 - - - - HCT590X EN 10346 Long. 330 - 430 ≥ 590 20 - 0.14 30

HX300LAD EN 10346 Trans. 300 - 380 380 - 480 23 - - - - HCT780X EN 10346 Long. 440 - 550 ≥ 780 14 - - 30 -

HX340LAD EN 10346 Trans. 340 - 420 410 - 510 21 - - - -

HCT980X EN 10346 Long. 590 - 740 ≥ 980 10 - - 30 -

HX380LAD EN 10346 Trans. 380 - 480 440 - 560 19 - - - -

VDA 239-100 Rp0.2 Rm A80 r0 n10-20/Ag BH2 E

HX420LAD EN 10346 Trans. 420 - 520 470 - 590 17 - - - - and voestalpine special grade

HX460LAD EN 10346 Trans. 460 - 560 500 - 640 15 - - - - CR260Y450T-DP voestalpine Long. 260 - 340 450 - 560 27 - 0.16 30

HX500LAD EN 10346 Trans. 500 - 620 530 - 690 13 - - - - CR290Y490T-DP VDA 239-100 Long. 290 - 380 490 - 600 24 - 0.15 30

VDA 239-100 Rp0.2 Rm A80 r0 n10-20/Ag BH2 E CR330Y590T-DP VDA 239-100 Long. 330 - 430 590 - 700 20 - 0.14 30

CR210LA VDA 239-100 Long. 210 - 300 310 - 410 29 1.0 0.15 - - CR360Y600T-DP voestalpine Long. 360 - 460 600 - 710 19 - 0.14 30

CR240LA VDA 239-100 Long. 240 - 320 320 - 430 27 - 0.15 - - CR440Y780T-DP VDA 239-100 Long. 440 - 550 780 - 900 14 - 0.11 30 -

CR270LA VDA 239-100 Long. 270 - 350 350 - 460 25 - 0.14 - - CR500Y780T-DP voestalpine Long. 500 - 620 780 - 900 13 - - 30 -

CR300LA VDA 239-100 Long. 300 - 380 380 - 490 23 - 0.14 - - CR550Y980T-DP voestalpine Long. 550 - 730 980 - 1130 10 - - 30 -

CR340LA VDA 239-100 Long. 340 - 430 410 - 530 21 - 0.12 - - CR590Y980T-DP VDA 239-100 Long. 590 - 740 980 - 1130 10 - - 30 -

CR380LA VDA 239-100 Long. 380 - 470 450 - 570 19 - 0.12 - - CR660Y980T-DP voestalpine Trans. 660 - 810 980 - 1130 10 - - 30 -

CR420LA VDA 239-100 Long. 420 - 520 480 - 600 17 - 0.11 - - CR700Y980T-DP VDA 239-100 Long. 700 - 850 980 - 1130 8 - - 30 -

CR460LA VDA 239-100 Long. 460 - 580 520 - 680 15 - 0.10 - -

2 H OT- D I P G A LVA N I Z ED S T EEL S T R I P • R A N G E O F S U PPLY • 0 4/2019 3

Yield Tensile Total Yield Tensile Total

Norms and strength strength elong. r value n value BH2 Norms and strength strength elong. r value n value BH2

specifica- Test Rp0.2 Rm A80 min. min. min. min. specifica- Test Rp0.2 Rm A80 min. min. min. min.

Steel grade tions dir. [MPa] [MPa] [%] [-] [-] [MPa] Exposed Steel grade tions dir. [MPa] [MPa] [%] [-] [-] [MPa] Exposed

Dual-phase high-ductility steels (cold rolled dual-phase steels with improved formability) Press-hardening steels

VDA 239-100 Special voestalpine grade Rp0.2 Rm A r90 n10-20/Ag BH2 E

Rp0.2 Rm A80 r0 n10-20/Ag BH2 E

and voestalpine special grade

phs-ultraform 490 unhardened Trans. 340 - 420 410 - 510 21 - - - -

CR330Y590T-DH voestalpine Long. 330 - 430 590 - 700 26 - 0.16 30 -

phs-ultraform 490 hardened* Trans. 340 - 470 460 - 700 12 - - - -

CR440Y780T-DH VDA 239-100 Long. 440 - 550 780 - 900 18 - 0.13 30 -

phs-ultraform 1500 unhardened Trans. 380 - 480 ≥ 480 18 - - - -

CR700Y980T-DH VDA 239-100 Long. 700 - 850 980 - 1180 13 - - 30 -

phs-ultraform 1500 hardened* Trans. 950 - 1250 1300 - 1600 5 - - - -

phs-ultraform 2000** unhardened Trans. 400 - 520 ≥ 580 16 - - - -

Complex-phase steels

phs-ultraform 2000** hardened* Trans. ≥ 1100 ≥ 1800 5 - - - -

EN 10346 Rp0.2 Rm A80 r0 n10-UE BH2 E phs-directform 1500 unhardened Trans. 300 - 600 600 - 900 12 - - - -

HCT780C EN 10346 Long. 570 - 720 ≥ 780 10 - - 30 - phs-directform 1500 hardened* Trans. 950 - 1250 1300 - 1650 5 - - - -

HCT980C EN 10346 Long. 780 - 950 ≥ 980 6 - - 30 -

VDA 239-100 Hot-rolled low-alloyed or micro-alloyed steels

Rp0.2 Rm A80 r0 n10-20/Ag BH2 E

and voestalpine special grade

VDA 239-100 Rp0.2 Rm A80 r0 n10-20/Ag BH2 E

CR570Y780T-CP VDA 239-100 Long. 570 - 720 780 - 920 10 - - 30 -

HR380LA VDA 239-100 Long. 380 - 480 450 - 570 20 - - - -

CR660Y780T-CP voestalpine Long. 660 - 820 780 - 960 10 - - 30 -

HR420LA VDA 239-100 Long. 420 - 520 480 - 600 19 - - - -

CR780Y980T-CP VDA 239-100 Long. 780 - 950 980 - 1140 6 - - 30 -

HR460LA VDA 239-100 Long. 460 - 560 520 - 640 17 - - - -

CR900Y1180T-CP VDA 239-100 Long. 900 - 1100 1180 - 1350 5 - - 30 -

HR500LA VDA 239-100 Long. 500 - 620 560 - 700 14 - - - -

HR700LA VDA 239-100 Long. 700 - 850 750 - 950 10 - - - -

TRIP steels

EN 10346 Hot-rolled ferritic-bainitic steels

Rp0.2 Rm A80 r0 n10-UE BH2 E

and voestalpine special grade

HCT600T voestalpine Long. 400 - 520 ≥ 600 25 - - 40 - EN 10346 Rp0.2 Rm A80 r0 n10-20/Ag BH2 E

HCT690T EN 10346 Long. 400 - 520 ≥ 690 23 - 0.19 40 - HDT580F EN10346 Long. 460 - 620 ≥ 580 15 - - - -

HCT780T EN 10346 Long. 450 - 570 ≥ 780 21 - 0.16 40 - VDA 239-100 Rp0.2 Rm A80 r0 n10-20/Ag BH2 E

and voestalpine special grade

VDA 239-100 Rp0.2 Rm A80 r0 n10-20/Ag BH2 E HR440Y560T-FB voestalpine Long. 440 - 600 560 - 680 15 - - - -

and voestalpine special grade

CR400Y600T-TR voestalpine Long. 400 - 520 ≥ 600 25 - - 40 - HR440Y580T-FB VDA 239-100 Long. 440 - 600 580 - 700 15 - - 30 -

CR400Y690T-TR VDA 239-100 Long. 400 - 520 690 - 800 24 - 0.19 40 -

Hot-rolled complex-phase steels

CR450Y780T-TR VDA 239-100 Long. 450 - 570 780 - 910 21 - 0.16 40 -

EN 10346 Rp0.2 Rm A80 r0 n10-20/Ag BH2 E

HDT750C EN 10346 Long. 620 - 760 ≥ 750 10 - - - -

HDT760C EN 10346 Long. 660 - 830 ≥ 760 10 - - - -

VDA 239-100 Rp0.2 Rm A80 r0 n10-20/Ag BH2 E

HR660Y760T-CP VDA 239-100 Long. 660 - 820 760 - 960 10 - - 30 -

* Mechanical parameters and coating properties in hardened condition are standard values achieved in professional processing of flat sheets.

The indicated values are not guaranteed by voestalpine Stahl GmbH

** Steel grade being developed, indication of preliminary values

4 H OT- D I P G A LVA N I Z ED S T EEL S T R I P • R A N G E O F S U PPLY • 0 4/2019 5

SURFACES DIMENSIONS

AND SERVICES

Surfaces according to EN 10346 and VDA 239-100 Available dimensions: wide strip (coil)

Norms and Normal Improved Best Thickness Width Outside diameter Inside diameter

Product variant Coatings

specifications surface surface surface Product variant [mm] max. [mm] max. [mm] [mm]

EN 10346 Z70 - Z450 NA, MA MB MC* Zinc coating 0.45 - 4.00 1730 2000 500 / 600

Zinc coating

VDA 239-100 GI40 - GI115 - U E*

Zinc-iron coating 0.45 - 2.30 1730 2000 500 / 600

EN 10346 ZF80 - ZF120 RA RB RC

Zinc-iron coating corrender

VDA 239-100 GA40 - GA50 - U E 0.45 - 2.30 1730 2000 500 / 600

Zinc-magnesium coating

corrender EN 10346 ZM70 - ZM350 NA, MA MB MC*

Zinc-magnesium coating VDA 239-100 ZM30 - ZM50 - U E*

Available dimensions: slit (slit strip)

* The zinc and zinc-magnesium coating variants are available in MC/E surface quality with reduced waviness, texplus®.

Thickness Strip width Outside diameter Inside diameter

Product variant [mm] [mm] [mm] [mm]

Subsequent surface treatment Zinc coating 0.45 - 4.00 10 - 1730 700 - 2200 500 / 600

Chemically Zinc-iron coating 0.45 - 2.30 10 - 1730 700 - 2200 500 / 600

Forming aid dryform multiface ®

Product variant Oiled passivated and oiled Dry forming aid Anti-fingerprint corrender

(and oiled) 0.45 - 2.30 10 - 1730 700 - 2200 500 / 600

Zinc-magnesium coating

Zinc coating ( )

Zinc-iron coating ( ) - - Available dimensions: cut-to-length (sheet)

corrender

( ) - Thickness Width Length Package weight

Zinc-magnesium coating

Product variant [mm] [mm] [mm] max. [t]

Zinc coating 0.45 - 4.00 210 - 1730 200 - 6700 6

Selected services

Zinc-iron coating 0.45 - 2.30 210 - 1730 200 - 6700 6

Special coil Roughness deviation Reduced dimensional Material testing according

labeling from standard tolerance to EN 10204 corrender

0.45 - 2.30 210 - 1730 200 - 6700 6

Zinc-magnesium coating

Indicated references are standard values. The available combinations of widths and thicknesses and supply forms vary

depending on the steel grade and coating system. Limitations are possible depending on thickness.

This document provides an overview of the hot-dip galvanized steel strip products supplied by the voestalpine Steel Division.

Other grades are available upon request. Please find further information and downloads under the following link:

www.voestalpine.com/steel

The information and product properties contained in this printed material are non-binding and serve the sole purpose of technical orientation.

They do not replace individual advisory services provided by our sales and customer service teams. The product information and characteristics

set forth herein shall not be considered as guaranteed properties unless explicitly stipulated in a separate contractual agreement. For this rea-

son, voestalpine shall not grant any warranty nor be held liable for properties and/or specifications other than those subject to explicit agree-

ment. This also applies to the suitability and applicability of products for certain applications as well as to the further processing of materials

into final products. All application risks and suitability risks shall be borne by the customer. The General Terms of Sale for Goods and Services of

the voestalpine Steel Division shall apply to all materials supplied by the voestalpine Steel Division and can be accessed using the following link:

www.voestalpine.com/stahl/en/The-Steel-Division/General-Terms-of-Sale

Technical changes are reserved. Errors and misprints are excepted. No part of this publication may be reprinted without explicit written

permission by voestalpine Stahl GmbH.

6 H OT- D I P G A LVA N I Z ED S T EEL S T R I P • R A N G E O F S U PPLY • 0 4/2019 7

04/2019

voestalpine Steel Division

voestalpine-Straße 3

4020 Linz, Austria

T. +43/50304/15-8018

produktmanagement@voestalpine.com

www.voestalpine.com/steel

You might also like

- Uniformat TemplateDocument5 pagesUniformat TemplatekrisNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- BS 3059-2Document11 pagesBS 3059-2abhiNo ratings yet

- EFI ResistanceDocument3 pagesEFI ResistanceMuni Muniyappan33% (3)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Database Management Systems: Understanding and Applying Database TechnologyFrom EverandDatabase Management Systems: Understanding and Applying Database TechnologyRating: 4 out of 5 stars4/5 (8)

- Self-Aligning Bearing Units NTN-SNRDocument125 pagesSelf-Aligning Bearing Units NTN-SNRDenis DavydovNo ratings yet

- Raft Slab DesignDocument5 pagesRaft Slab DesignLekins Sefiu Yekini100% (2)

- 5SDocument30 pages5SPrema Nanda HottaNo ratings yet

- Ocean Cable Engineering Handbook Vol4 Compiled by Ian S. CooteDocument154 pagesOcean Cable Engineering Handbook Vol4 Compiled by Ian S. Cootemannydesousa52100% (1)

- Hot-Dip Galvanized Steel Strip: Range of Supply April 2019Document8 pagesHot-Dip Galvanized Steel Strip: Range of Supply April 2019Meme VillacortaNo ratings yet

- Hot-Dip Galvanized Steel Strip Range of SupplyDocument12 pagesHot-Dip Galvanized Steel Strip Range of SupplyvictorNo ratings yet

- Cold Rolled Steel Strip Voestalpine en 111021Document7 pagesCold Rolled Steel Strip Voestalpine en 111021Shailendra SharmaNo ratings yet

- Dual Phase Steels Voestalpine EN 28092018Document4 pagesDual Phase Steels Voestalpine EN 28092018Silverio AcuñaNo ratings yet

- Dual-phase steels data sheet highlights strength propertiesDocument4 pagesDual-phase steels data sheet highlights strength propertiespranayNo ratings yet

- En 10139Document2 pagesEn 10139releone11No ratings yet

- Din En1563-2018Document2 pagesDin En1563-2018FAPEMA SGQNo ratings yet

- Applications: Type TestedDocument4 pagesApplications: Type TestedFV AllanNo ratings yet

- En 1563 - Spheroidal Graphite Cast IronsDocument4 pagesEn 1563 - Spheroidal Graphite Cast Ironsvamsi patnalaNo ratings yet

- Chemical Composition: Si Fe Cu MN MG Ni ZN SN Ti PB CRDocument2 pagesChemical Composition: Si Fe Cu MN MG Ni ZN SN Ti PB CRQuality teamNo ratings yet

- Cardápio de Ferramentas Rotativas: WCS503507HDocument2 pagesCardápio de Ferramentas Rotativas: WCS503507HRafael A. CarvalhoNo ratings yet

- Venvu 116Document1 pageVenvu 116ronaldb322No ratings yet

- CatalogDocument3 pagesCatalogPham Ba ManhNo ratings yet

- Reliable wastewater pumps for buildingsDocument4 pagesReliable wastewater pumps for buildingsArmando BarrancoNo ratings yet

- Metal Coated HSLA Steels, EN10346:2015Document3 pagesMetal Coated HSLA Steels, EN10346:2015ronakguptaNo ratings yet

- Equivalent TableDocument1 pageEquivalent Tableliamcs88% (8)

- DC01 Steel Data Sheet: Mechanical Properties, Chemical Composition, ApplicationsDocument9 pagesDC01 Steel Data Sheet: Mechanical Properties, Chemical Composition, ApplicationsHung NguyenNo ratings yet

- Datasheet-Sandvik-3r60-En-V2020-12-10 07 - 47 Version 1Document7 pagesDatasheet-Sandvik-3r60-En-V2020-12-10 07 - 47 Version 1Bruno AlfanoNo ratings yet

- Dual Phase High Ductility Steels Voestalpine EN 12062019Document2 pagesDual Phase High Ductility Steels Voestalpine EN 12062019RhushikeshNo ratings yet

- pm3600 SeriesDocument3 pagespm3600 SeriesAli AbbasNo ratings yet

- MS-M-07-MATERIAL SUBMITTAL - (Galvanized Duct)Document10 pagesMS-M-07-MATERIAL SUBMITTAL - (Galvanized Duct)khalilNo ratings yet

- Dual Phase High Ductility Steels Voestalpine EN 12062019Document2 pagesDual Phase High Ductility Steels Voestalpine EN 12062019Willian FreireNo ratings yet

- Rifeng PAP 2Document37 pagesRifeng PAP 2Sota KarunaNo ratings yet

- Zeron 100Document2 pagesZeron 100NAVANEETHNo ratings yet

- Hot-dip galvanized sheet steel grades mechanical propertiesDocument2 pagesHot-dip galvanized sheet steel grades mechanical propertiesgorakdiasNo ratings yet

- S690Document2 pagesS690corsini999No ratings yet

- Lenze 6 Terminal Rectifiers Types 14.630.32.016, 14.630.33.006Document1 pageLenze 6 Terminal Rectifiers Types 14.630.32.016, 14.630.33.006Aly AbdelhamedNo ratings yet

- Catalogo Ses 2023Document51 pagesCatalogo Ses 2023Edzon Mambo GarciaNo ratings yet

- Global Marketing For Tube & PipeDocument4 pagesGlobal Marketing For Tube & PipedsyashankaNo ratings yet

- Features: Finishing-Purpose of Negative Chip Breaker For Steel TurningDocument4 pagesFeatures: Finishing-Purpose of Negative Chip Breaker For Steel TurningArdeleana TisaNo ratings yet

- CM-9CB TG-S9Cb US-9CbDocument3 pagesCM-9CB TG-S9Cb US-9Cbamit singhNo ratings yet

- Autrod 1264Document2 pagesAutrod 1264Anonymous yL7oldKNo ratings yet

- Iso 559-77 Welded or Seamless Steel Tubes For Water Sewage and GasDocument2 pagesIso 559-77 Welded or Seamless Steel Tubes For Water Sewage and GasDejan KostadinovicNo ratings yet

- Rotel RB 1080 Service ManualDocument6 pagesRotel RB 1080 Service Manualsandy nNo ratings yet

- Metal Forming: Grade Specifications and Application ChartDocument2 pagesMetal Forming: Grade Specifications and Application ChartimtiyazNo ratings yet

- Power transistors specificationsDocument2 pagesPower transistors specificationsRodrigo Ariel PatriarcaNo ratings yet

- Molded RF Inductor: FeaturesDocument2 pagesMolded RF Inductor: FeaturesStuxnetNo ratings yet

- 05 - 14 Steel RepairsDocument1 page05 - 14 Steel Repairsmaxuya2001No ratings yet

- 05 - 14 Steel RepairsDocument1 page05 - 14 Steel Repairsmaxuya2001No ratings yet

- AWS A5.20 E71T-1C BS EN ISO 17632-T42 2 P C 1 H10 Jis Z3313 Yfw-C50Dr CSA W48-01 E491T-1-H8 GB/T 10045 E501T-1Document2 pagesAWS A5.20 E71T-1C BS EN ISO 17632-T42 2 P C 1 H10 Jis Z3313 Yfw-C50Dr CSA W48-01 E491T-1-H8 GB/T 10045 E501T-1Andre Brama AlvariNo ratings yet

- Fine Wire Product Specifications and Chemical CompositionsDocument2 pagesFine Wire Product Specifications and Chemical CompositionsAlejandra Paz San MartínNo ratings yet

- Mild Steels Voestalpine EN 09082019Document5 pagesMild Steels Voestalpine EN 09082019Alma Aliza VillaberNo ratings yet

- MGD623SDocument2 pagesMGD623SMindSet MarcosNo ratings yet

- TablesDocument3 pagesTablesJojolasNo ratings yet

- Page 1 Of 4 Bg Transistors: Вид Тип U (U), V I Ma (A) F, F Mhz H P Mw (W) ЦокълDocument4 pagesPage 1 Of 4 Bg Transistors: Вид Тип U (U), V I Ma (A) F, F Mhz H P Mw (W) Цокълsluz2000000No ratings yet

- Engineering DetailDocument30 pagesEngineering DetailSatyaprakash PrakashNo ratings yet

- Zetty Catalogue 121Document1 pageZetty Catalogue 121ramukolakiNo ratings yet

- X20Cr13 %C %si %MN %P %S %CR %cu %mo %NB %niDocument2 pagesX20Cr13 %C %si %MN %P %S %CR %cu %mo %NB %nibhanu.kiranNo ratings yet

- M 001 22Document1 pageM 001 22LUISNo ratings yet

- Material Data Sheet for S355J2 and Related Steel GradesDocument3 pagesMaterial Data Sheet for S355J2 and Related Steel GradesRushangNo ratings yet

- Emin - 212Document3 pagesEmin - 212linggaputera26No ratings yet

- RuukiDocument20 pagesRuukiproje01No ratings yet

- Alloy 2319 welding data sheetDocument2 pagesAlloy 2319 welding data sheetSyam NathNo ratings yet

- Accesorios compresores herméticosDocument2 pagesAccesorios compresores herméticosVictor Rodriguez RIverosNo ratings yet

- Technical Manual: Five-Channel Power AmplifierDocument8 pagesTechnical Manual: Five-Channel Power Amplifierudal64No ratings yet

- General Updates: More Frequent and More SevereDocument14 pagesGeneral Updates: More Frequent and More SevereAndy HuffNo ratings yet

- Northern Dynasty (NAK US) : MiningDocument23 pagesNorthern Dynasty (NAK US) : MiningAndy HuffNo ratings yet

- We Believe Lexinfintech Holdings Ltd. (Nasdaq: LX) Is A Leverage Time Bomb About To ExplodeDocument32 pagesWe Believe Lexinfintech Holdings Ltd. (Nasdaq: LX) Is A Leverage Time Bomb About To ExplodeAndy HuffNo ratings yet

- Letter To Our Co Investors 2Q20Document26 pagesLetter To Our Co Investors 2Q20Andy HuffNo ratings yet

- Something of ValueDocument18 pagesSomething of ValueForkLogNo ratings yet

- The Broyhill Letter 2020.08 FINALDocument12 pagesThe Broyhill Letter 2020.08 FINALAndy HuffNo ratings yet

- Greenhaven Road Partners Fund (2020 Q2) Quarterly LetterDocument3 pagesGreenhaven Road Partners Fund (2020 Q2) Quarterly LetterAndy HuffNo ratings yet

- Rhizome Partners Q2 2020 Investor Letter FinalDocument12 pagesRhizome Partners Q2 2020 Investor Letter FinalAndy HuffNo ratings yet

- Epoch's Quarterly Capital Markets Outlook: William W. Priest, Cfa Lilian Quah, Cfa Kevin Hebner, PHDDocument23 pagesEpoch's Quarterly Capital Markets Outlook: William W. Priest, Cfa Lilian Quah, Cfa Kevin Hebner, PHDAndy HuffNo ratings yet

- Letter To Shareholders Excerpted From The 2020 Semiannual Financial Statement PDFDocument21 pagesLetter To Shareholders Excerpted From The 2020 Semiannual Financial Statement PDFAndy Huff100% (1)

- Survivor & Thriver: Capital IQ, JDP EstimatesDocument4 pagesSurvivor & Thriver: Capital IQ, JDP EstimatesAndy HuffNo ratings yet

- Letter To Shareholders Excerpted From The 2020 Semiannual Financial Statement PDFDocument21 pagesLetter To Shareholders Excerpted From The 2020 Semiannual Financial Statement PDFAndy Huff100% (1)

- Letter To Shareholders Excerpted From The 2020 Semiannual Financial Statement PDFDocument21 pagesLetter To Shareholders Excerpted From The 2020 Semiannual Financial Statement PDFAndy Huff100% (1)

- Spruce Point Activism Succeeds in Canada with Average 77% Share Price DeclinesDocument107 pagesSpruce Point Activism Succeeds in Canada with Average 77% Share Price DeclinesAndy HuffNo ratings yet

- Third Point Q2 2020 Investor Letter TPOIDocument13 pagesThird Point Q2 2020 Investor Letter TPOIZerohedge100% (1)

- 2Q20 Investor LetterDocument6 pages2Q20 Investor LetterAndy HuffNo ratings yet

- Fluidigm (FLDM) - The Stock That Will Spit To $35: BackgroundDocument10 pagesFluidigm (FLDM) - The Stock That Will Spit To $35: BackgroundAndy HuffNo ratings yet

- Time Period Hayden (Net) S&P 500 MSCI World (ACWI)Document13 pagesTime Period Hayden (Net) S&P 500 MSCI World (ACWI)Andy HuffNo ratings yet

- Q2 2020 Investor LetterDocument14 pagesQ2 2020 Investor LetterAndy HuffNo ratings yet

- Lakewood Capital - 2020 Q2 Letter PDFDocument10 pagesLakewood Capital - 2020 Q2 Letter PDFcaleb wattsNo ratings yet

- 2020 08 10 Askeladden Capital Q2 2020 Letter UnkindDocument9 pages2020 08 10 Askeladden Capital Q2 2020 Letter UnkindAndy HuffNo ratings yet

- Industry 4.0: Volume Lii July 2020Document8 pagesIndustry 4.0: Volume Lii July 2020Andy HuffNo ratings yet

- Small-Cap Value Fund: AS OF JUNE 30, 2020Document5 pagesSmall-Cap Value Fund: AS OF JUNE 30, 2020Andy HuffNo ratings yet

- Baron Asset Fund: June 30, 2020Document4 pagesBaron Asset Fund: June 30, 2020Andy HuffNo ratings yet

- 5f0b44cdc10751fbb7009cf3 - McLain Capital Q2 2020 Investor LetterDocument19 pages5f0b44cdc10751fbb7009cf3 - McLain Capital Q2 2020 Investor LetterAndy HuffNo ratings yet

- Massif Capital 2nd Quarter Letter To InvestorsDocument6 pagesMassif Capital 2nd Quarter Letter To InvestorsAndy HuffNo ratings yet

- TABLE I: Alluvial Fund LP Returns (%) As of June 30, 2020: YTD 2019 2018 2017 Cumulative AnnualizedDocument6 pagesTABLE I: Alluvial Fund LP Returns (%) As of June 30, 2020: YTD 2019 2018 2017 Cumulative AnnualizedAndy HuffNo ratings yet

- RBC Global Insight - May-13Document13 pagesRBC Global Insight - May-13Andy HuffNo ratings yet

- 11018e PDFDocument1 page11018e PDFAndy HuffNo ratings yet

- Catalogo de Ensamble de ManguerasDocument424 pagesCatalogo de Ensamble de ManguerasCesar Fernando Via SaldarriagaNo ratings yet

- Australian Standards 2550Document6 pagesAustralian Standards 2550yousuf79No ratings yet

- Chapter 05Document13 pagesChapter 05irsyadiskandarNo ratings yet

- CE Akrapovic 2Document2 pagesCE Akrapovic 2ivanmesa.90No ratings yet

- Consumer Buying BehaviorDocument36 pagesConsumer Buying BehaviorJyoti Kabra100% (1)

- General Website Design AgreementDocument6 pagesGeneral Website Design AgreementMarian SantosNo ratings yet

- En 42Document2 pagesEn 42Meghan GhoneNo ratings yet

- HBS Annual Inspection Report Sample NewDocument6 pagesHBS Annual Inspection Report Sample NewhgmNo ratings yet

- ABAQUS TutorialsDocument59 pagesABAQUS TutorialsMikael Bezerra Cotias Dos Santos80% (5)

- October 2014 Line Blind ReportDocument70 pagesOctober 2014 Line Blind Reportr_chulinNo ratings yet

- ISOLAB Catalog-2015 PDFDocument252 pagesISOLAB Catalog-2015 PDFThanhSơnHồNo ratings yet

- INventory Management at Health CareDocument33 pagesINventory Management at Health CareishabihNo ratings yet

- Rent Payment Process With Sap Mm1Document14 pagesRent Payment Process With Sap Mm1Alfonso Herrera RojasNo ratings yet

- Wire Rope 6x19 IWRC: 6x19 IWRC Strength and Weights Chart (Inches Crush ResistantDocument2 pagesWire Rope 6x19 IWRC: 6x19 IWRC Strength and Weights Chart (Inches Crush ResistantAmirNo ratings yet

- Process Failure Modes and Effects Analysis Process Failure Modes and Effects AnalysisDocument2 pagesProcess Failure Modes and Effects Analysis Process Failure Modes and Effects AnalysisEnzo AscañoNo ratings yet

- Compiler Design CSE / IT Final Year Notes, Books, Ebook PDF DownloadDocument89 pagesCompiler Design CSE / IT Final Year Notes, Books, Ebook PDF DownloadVinnie SinghNo ratings yet

- Aluminium - Section G AcessoriesDocument43 pagesAluminium - Section G AcessoriestechgovindNo ratings yet

- Pend AnDocument13 pagesPend AnRa'aed SadoonNo ratings yet

- Quality Management PlanDocument87 pagesQuality Management PlanLasanthaNo ratings yet

- Classical Approaches Ed ManagementDocument20 pagesClassical Approaches Ed ManagementRoginee Del SolNo ratings yet

- ZTT SOFC SubmaineCableDocument35 pagesZTT SOFC SubmaineCabletanto_deep_15No ratings yet

- MM - Brazil - Fiscal - Book - Mastersaf 2 1Document30 pagesMM - Brazil - Fiscal - Book - Mastersaf 2 1guroyalNo ratings yet

- English - Hindi DictionaryDocument1,821 pagesEnglish - Hindi DictionaryAnil Bishnoi0% (1)

- Appendix A - Turbine Manufacturer Technical Specification - 2.75MWDocument82 pagesAppendix A - Turbine Manufacturer Technical Specification - 2.75MWKaio Dos Santos SilvaNo ratings yet

- Automation Testing Expert Seeks New ChallengeDocument5 pagesAutomation Testing Expert Seeks New ChallengeEkanshNo ratings yet